Heater blower motor squeal stop

It is possible to lubricate both blower motor bearings without taking the motor out of the car to stop squeals or other noises related to motor bearings. I realized this after I had taken the motor out to lubricate the bearings. Many have opted to replace the existing blower motor and fan with a Honda civic heater fan. I like to fix things so I oiled the old motor because it was turning slowly and was squealing.

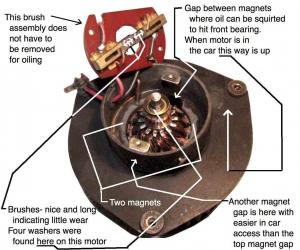

Oiling both bearings with the fan in place in the car can be done by taking the end cover plate off of the motor keeping an eye out for the 4 washers that may be on the motor shaft.

There were four on my 1/1970 car with one of the middle ones being a red fiber washer I imagine to reduce mechanical noise transmitted to the motor housing. The washers can stick to the end plate when it is removed and then drop off if they aren't noticed. The rear bearing is easy to lubricate with a light lithium grease or other suitable lubricant as it is a part of the end plate. The front bearing is easily accessed for lubrication with an old fashioned oiler that squirts oil or possibly by using WD-40 with its spray straw. WD-40 is explosive so if it is used a good airing out of the motor before reassembly might be a good idea. There are two magnets in the motor with a gap near the top of the motor between them of maybe 1/2 inch. An oil can with a long nozzle that squirts can be inserted in this gap to squirt oil up to the front bearing. WD 40 could also be used by inserting the straw that comes taped to the can in the same gap between the magnets that an oiler would use. The top gap would be preferred for the oiling as the oil can flow down to the bearing though the bottom gap can be used. When replacing the motor end cap be sure the tang gets aligned with the rubber grommet for the wires. If this isn't done the motor end cap can be installed 180 degrees out from the proper position resulting in it being slightly cocked over at an angle due to the tang sticking out which would not be good for bearing alignment with the motor shaft.

Rear bearing can be seen here:

Since I had already taken the motor out of the car to oil the front bearing I sat it on a workbench with the fan side down and poured motor oil into the gap between the magnets knowing it would flow down to the front bearing. I could not get the fan off and remember reading a thread where someone else ran into the same thing though your situation might be different.

Recommended Comments