Topics Last 30 Days

Showing topics, images, events and files posted in for the last 28 days.

- Today

-

55 year old Z master cylinder / slave cylinder

Here's the early slave with spring tab. Motorsport Auto - The Z Store - Clutch Slave Cylinder, 70-72 240Z

-

EGR relay, can i remove it?

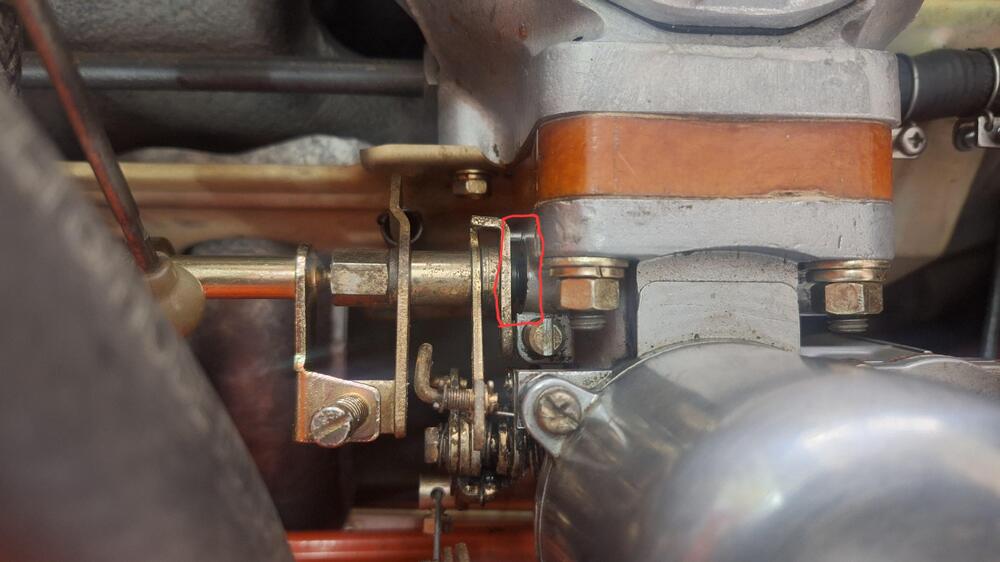

I am still thinking what to do about that indeed. Also the gas return spring on the flat tops is located on the carbs ofcourse. But atm i am planning to use the balancetube from the round top. Because it is been made almost to factory state. But then i have to find a new throtle linkage. I am also blocking off the coolant through the carbs. And then i but a sensor in the waterhousing. So that i can but electrical fans. Hoping it cools alot better. My old radiator was broken so bought that one also new.

-

Wire identification

Hi, quite a stir i made hihi... A 1979 eccs is without any microprocessor, i can tell you as a electronics engineer. Those rond tin boxes (with cooling crown) are early integrated circuits, nice to see! Later on the plastic black boxes came. (Some are already on the printed circuit) The 6801 is a microprocessor and works with 0 and 1 signals of 0 and 5Volt. As far i know the switch was made between 1982 and 1983. Then analog "computing" became Digital computing where real microprocessors took over the work. I don't know for the USA But overhere in europe the 1983 280zx turbo was the first z with real processor in the managementsystem. (Europe never had a 280zx turbo before 1983!) All those boxes in 280z and 280zx were called ECCS until the 1983 turbo came out. (I belief..) (Don't hold me to it, i'm not a wizard, just remembering this stuff..) ;-)

-

1977 280z clock issue #xx of yy

@Captain Obvious Very impressive analysis of the circuit. Thank the Lord I went to school for that!,

-

How vibration free is your 70-71 240Z?

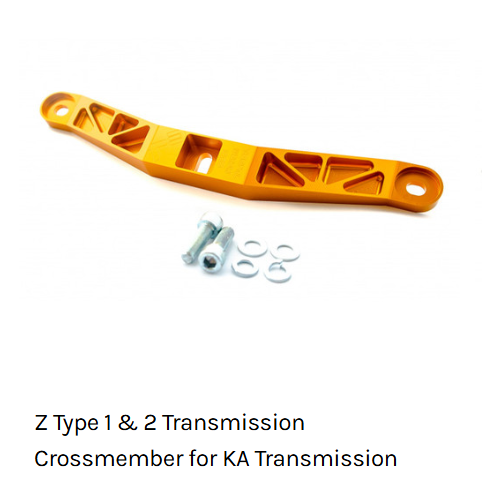

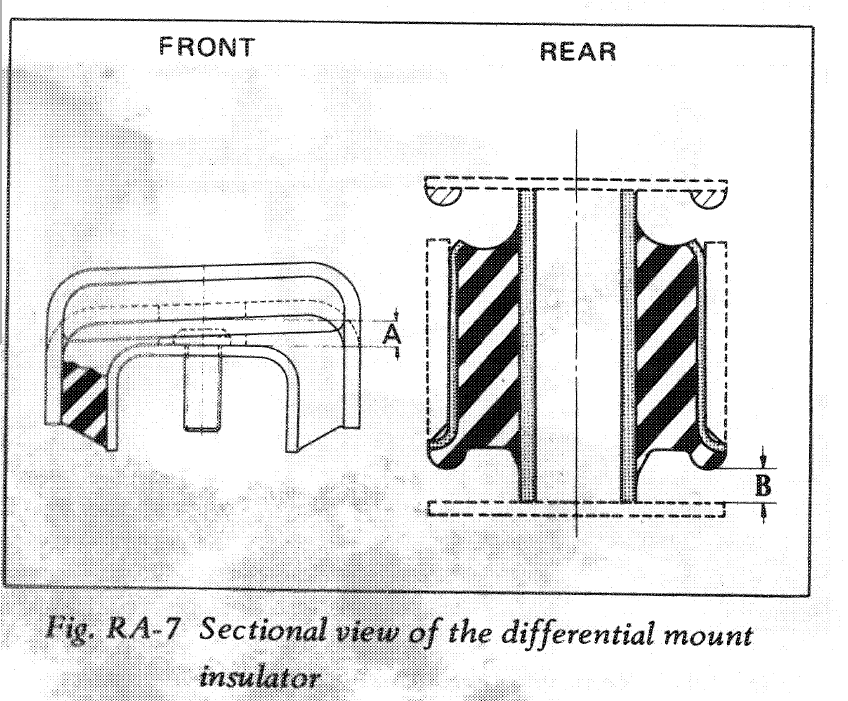

I played around with lowering the rear of the transmission today after work. I backed off the bolts securing the transmission mount (Techno Toys Tuning) to the body to see what kind of change in angle would result. Picture of the mount I have (for use with the 240SX transmission) in the early Z: Backing the bolts off to drop the rear of the transmission more than 5/16 of an inch only changed the angle from 89 to 88.5. I expected more change in angle. Anyway, now I am thinking through various things. I find myself asking why the front differential insulator mount has such a "large" angle to it. First of all, I confirmed that my insulator mount is part number 55415-E4102 (the early one). When looking at the factory workshop manual, the image clearly shows an inclination. As my car is sitting on the lift, I measured the inclination of the pinion flange, and it was 87.1 degrees. Why is it so far away from 90? I mean, the driveshaft is supposed to operate with less than 3 degrees of angularity on the u-joints. If I was able to match the 87.1 at the transmission, that would be 2.9 degrees on each u-joint. And, we all know that when power is applied to the input flange, the nose of the differential lifts upwards (i.e. the need for the "arrestor" belt which limits to differentials upward movement at the front). It seems to me, that instead of dropping the rear of the transmission down, it would be far better for me to change the angle of the front pinion flange, by either lowering the front of the differential, or raising the rear of the differential. Since I have used lowering springs to lower the car a bit, it seems to me that it would be more desirable to raise the rear of the differential. However, that would require modification of my stock parts here, perhaps removing the upper washers that have rubber bonded to them and replacing them with flat washers? I went through a fair amount trouble to source these washers as I am fairly certain they are what came originally on my 6/71 car. Further, I believe that the front differential mount, front differential insulator, rear differential mount, and rear differential mount washers are all as original for my car. So, I am baffled why the pinion flange angle is what it is. Am I missing something? How do I confirm that my front differential mount is the correct part number for my car - 55411-E4100 (used up through 6/71)? What is the difference between that one and the later 55411-N3001 used from 7/71 to 7/73

-

Complete list of seals/gaskets/replacement parts for R180 and F4W71A transmission?

Looking at reinstalling the 4-speed monkey motion (including the R180) into my 240z, but obviously need to service everything. I saw an amazing list of 240z fasteners from @inline6 (linked here), and wondering if similar thing exists for the seals, gaskets, pinions, bearings, bolts, washers, o-rings and such that can be replaced when servicing transmission/differential? I have a very pricey Motorsport Auto cart ready to go, but I'm confident I've missed a lot. I also reached out to ZCarDepot, but they understandably didn't have anything collated, and as far as I know, a "restoration bundle" doesn't exist anywhere. I had noticed ZCarDepot had a few bolts that ZStore didn't have, but going a bit crazy cross referencing. I know the microfiche and FSM could be of use here, but as a first-timer I get a little lost and looking to help myself out! Bonus points for any other Google Sheet resources beyond this need that might be useful for reference! A bit of a sucker for a database. Any help or steer would be appreciated, thank you!

-

Best OEM-style muffler/exhaust system in 2025?

Hi all! Looking to replace the ancient aftermarket exhaust system on my Series 1 240z, and curious what the best options available to me are. I saw a car recently on BaT that had the original style black tips, but not sure where that came from. I've never seen it on my internet travels. Check it out here: https://bringatrailer.com/listing/1970-datsun-240z-129/ I'd like to be as stock/OEM as possible. Pretty sure my headers are original, but would need muffler, exhaust, mounts etc.

- Yesterday

- Duffy's 1/71 Series 1 240z build

- Last week

-

Z's on BAT and other places collection

Not bad. There are still good Z project opportunities popping up out there. https://bringatrailer.com/listing/1972-datsun-240z-357/

-

Restoration of BringaTrailer 240z - HLS30-35883

The odometer clicked over 500 miles on Friday night, so I took the valve cover off yesterday and did both the leak down test and adjusted valves. Here were my leak down percentages: #1 = nearly 4% #2 = 2-3% closer to 2 #3 = 4% #4 = 4% #5 = 3% #6 = a little over 1% For my Iskenderian cam, the valve lash is .006" on the intakes and .008" on the exhaust. I set each so that the feeler gauge was a snug fit while the engine was cold. All of the cam lobe surfaces looked great! The next time I fire it up and get the oil warm, I'll change the oil. Today, I removed a portion of the exhaust and the driveshaft and measured the angles of the front engine dampener and the pinion flange on the differential. I believe I will be able to lower the transmission rear crossmember to bring the engine/transmission assembly to the same 87.1 degrees that the pinion flange is at. I will just need to add shims between the transmission crossmember and the car body. Oh! And I just remembered that I should check the angles in the horizontal plane (not just vertical) as well.

-

Distributor rotor identification

That's awesome. You totally nailed it!!

-

can door locks work without the knob rod/key cylinders?

Why not contact “junkyard Jenny” She probably has what you need to replace your existing mechanism. Sounds like you might need both sides. Good people.

-

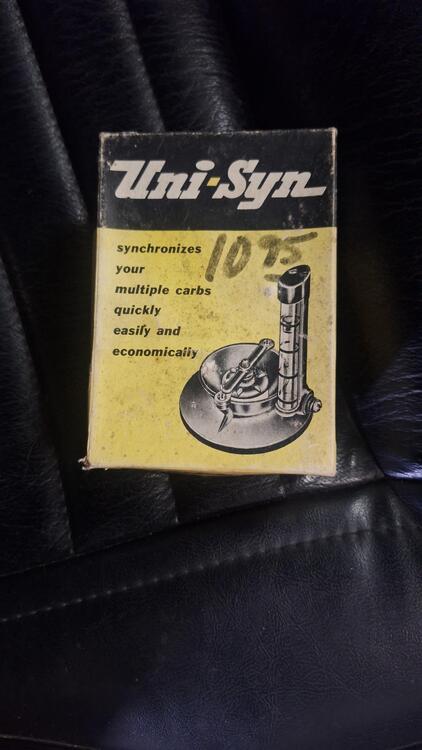

Saving car #34464

After adjusting the valve lash a couple times, I timed the distributor which was really close. I tried my hand at tuning the carbs. This video VHS and flowmeter came with the car. I backed everything off, but still was getting a 1,000 rpm idle. Seemed a bit high. I would put the flow gauge on the front carb and adjust it so the ball was in the middle. Then go to the rear carb, the ball was way high, no way to back down the idle screws anymore. I figured there must be a vacuum leak somewhere. I squirted brake clean around but didn't make any noticeable difference. I couldn't get them the same. The next day, while fiddling around with it, I grabbed my broken stethoscope, and started poking 1 of the hoses around when whaaam! There it is. The rear carb is leaking around the throttle shaft. These carbs were just done by ZTherapy 2 or 3 years before the car was parked some 22 years ago. I had a chat with them, boxed them up, and they are now in their hands. I hope it's an easy fix.....

-

Clutch fork throw

-

1983 280zx na cranks wont start help

-

fuel tank sending unit question

I used piggy back connectors on the nail head studs on the top of the sending unit. Coverd it all with liquid electrical tape. Worked good for me, the rubber boots fell all to pieces on my '72.

- Earlier

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

Disconcerting that your AFM numbers went a little leaner when you tightened everything up. The tightening might be related, or it might be a red herring. But disconcerting either way. So did you ever try giving it a little bit of choke enrichment with the lever while you're driving? Does it react as expected and the numbers come down?

-

Jenvey ITB Cable Throttle Wheel?

Trying to setup my Jenvey ITB's without a linkage rod. I have seen some people use a throttle wheel for a cable setup that bolts up to the side of one of the ITB's. Does anyone know where I can find something like that? Jenvey does not seem to sell anything like that. I would prefer that setup as it keeps everything really clean without a linkage rod. Thank you!

-

[2025] What Did You Do To/with Your Z Today?

Man that is a sexy z car

-

WTB Driver's Side (left) Headlight Scoop

It's more indecision than anything. I'm not usually prone to indecision, but I'd really like to stick with a fiberglass scoop, and couldn't convince myself to go metal. I also think you're better off selling the four pieces together, than having two fenders and one scoop, so it probably works out OK. I do appreciate you checking on them for me. Good luck! As a friend of mine likes to say, "My wife loves that sh*t!". @CanTechZ I'll send you a PM and hopefully we can move this forward!

-

SOLD - Refurbished S30 Antenna - Bullet Tip

@jfa.series1 That certainly didn’t take long!!

-

The Development Story & Specification Of The European Spec Datsun 240Z

Yes, a great read and many thanks to @JDMjunkies.ch for putting that together. Great job, as always, to Kats and Alan.

-

1971 HLS30-14938 "Lily" build

Perfect, thanks Ernest

-

Fuel tank sending unit leak

You might have to use some sealant on the inside. I believe "Seal-all" would be my first choice https://www.amazon.com/Seal-All-380113-Adhesive-2-Ounce/dp/B0015AE0AU/ref=asc_df_B0015AE0AU?mcid=73fbe515071334428dde54fff0cb8519&hvocijid=2708339363523471354-B0015AE0AU-&hvexpln=73&tag=hyprod-20&linkCode=df0&hvadid=721245378154&hvpos=&hvnetw=g&hvrand=2708339363523471354&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9010452&hvtargid=pla-2281435177578&psc=1

-

New Fujitsubo Exhaust System to be Released

Are you buying these from a supplier? If so it should state the fitment parameters. Gotta know more details. Is this exhaust new or used?