All Activity

- Today

-

Transmission Swap and other things

I did not. Was going to wait and see if there was going to be a problem with the heat.

-

1976 280Z Fuel Issues Troubleshooting

Sounds like your fuel pump relay is bad. Send me a pm.

-

1976 280Z Fuel Issues Troubleshooting

Update: My 280Z will not start. I am getting 0 PSIG on the fuel pressure gauge on the fuel oil supply line. I was able to source a replacement fuel damper and plumbed up everything. Troubleshooting per the Fuel Injection and Factory Service Manual led me to find the following: All wiring connections are as intended - I did not find any plugs or harnesses disconnected. The fuel pump is not getting power when I start the car. No voltage is present at the fuel pump across the power and ground terminals when the key is in the "On" position. No voltage is present at the wiring harness under the passenger seat at the green wire and black ground when the key is in the "On" position. The fuel pump relay clicks when I try to start the car. The fuel pump operates when I run a direct line from the positive battery terminal to the pump. All of troubleshooting checks from the "Engine won't Start" section of the Fuel Injection Bible pass and my efforts lead to quote "try a different ECU." I was able to source a second ECU on eBay, but it yields the same result. My taillights and license plate lights do not work (not getting power). Running a separate ground wire from the fuel pump negative terminal to a chassis ground does not resolve the no starting condition. Based on my findings above, I am not sure what my issue is or to diagnose why I am not getting any power to the pump. Anyone have a similar problem and can diagnose? I thought maybe it was a bad ground, but wouldn't the separate ground wire have resolved the problem? From what I understand, the main ground that the fuel pump, taillights, etc. are connected to requires removal of the gas tank to access. I was hoping to avoid this, but if it is my next step, so be it. Also, when the previous damper failed, it did drip gasoline on to the pump and terminals. This is because on 1976 280Zs, the damper is above the pump and the whole kit (damper, pump, hoses, wiring) is mounted to an L shaped bracket that is mounted with three screws to the chassis. This was changed in 1977 and 1978 models to a flat plate that mounts to the chassis but places the damper and pump side-by-side. I'm guessing this was an improvement that would have reduced the possibility of a failed damper leaking fuel onto the pump. Could that wetting of the pump terminals have ruined my ground wire or power wire to the pump? How likely is it that my remanufactured aftermarket ECU and the eBay replacement (which was started to be from a 1976 2+2 4 speed, just like mine) are both bad and presenting the same exact issue?

-

Transmission Swap and other things

Did you have the headers Ceramic coated? I understand that’s not the issue at hand but will eliminate carb problems.

-

Transmission Swap and other things

Sorry for the delay. The transmission is in, without to much drama. Installed my new Z Story exhaust (Street Sport Header) That went well. Thanks for the tips from @Patcon But now to the what was I thinking catagory☹️ Went to install my heat shield and it is not going to clear the new header. Should of new that from the start. So what are my options? No heat shield? If so what do you attach the return spprings to? Does anyone make a shield that will work? (running SU's) Any ideas would be welcomed. Patcon are you going to run SU's? If so do you have a plan? Thanks for the help. Stee

-

Check out this ATK crate L28 engine on BaT

Somebody called datsunparts bid $2200. There's a business called datsunparts, looks Roadster focused. Might be worth more parted out. Those exhaust ports are weird. Maybe it's a "detuned" L28 for a different model. Maybe the Z's got the good stuff. https://datsunparts.com/

-

1970 Wiring Diagram

Found a picture on BaT. #138 shows a condenser on the back of an alternator. Bring a TrailerNo Reserve: 1972 Datsun 240Z 4-SpeedBid for the chance to own a No Reserve: 1972 Datsun 240Z 4-Speed at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #181,834. Uploading Attachment...

-

Still struggling with car at idle after 8 years

I’m personally done. If his mechanic is that good there’s really no reason to post on a topic thats well over 6 years old and pretty much has not accepted any one persons advivce nor reported back on the findings from suggestions that were given.

-

1970 Wiring Diagram

Awesome. Thanks for the help. So it sounds like there are supposed to be four condensers: One on the distributor. One over by the coil, attached to coil (+) One on the back of the alternator, and One by the voltage regulator. Anyone else want to weigh in? Input from people who document pretty much everything? ( @CanTechZ )

-

55 year old Z master cylinder / slave cylinder

Hahahaha!! I've been called worse than stickler as well. And that was just today!! 😄 I'm confident with your attention to detail, that stuff I noticed has already been addressed, or will be in the near future.

-

Still struggling with car at idle after 8 years

We are testing the car again tomorrow morning. I do notice some backfire when releasing the gas pedal maybe its due to the closing of the damaged pcv valve which permitted the oil flood of plugs 3 and 4. Car is not even reaching over 6000 rpms. A lot of misfire after getting out of traffic.

-

Still struggling with car at idle after 8 years

I vowed years ag that I would never again respond to JAlex's pleas for help. The commentary over the years has devolved into a back-and-forth recourse of the classic 'fuel vs ignition' debate. I will offer the following comments and withdraw forever from the discussion: I suspect that JAlex's problems are the result of poor local fuel quality combined with local high-temp conditions. Most of us -- whether from the USA, Europe, or Canada -- are not qualified to provide proper guidance on this combination. Maybe not even Nissan. JAlex is prey to local tech help whose credentials are highly (self) promoted but probably sub-standard... but more than willing to take his money. It's too bad that we don't have some overarching expert who could just cut to the chase. All that aside, CZCC members (including JAlex) are the greatest and I hope this will end with JAlex piloting the Panama's best Z on his local streets.

- Yesterday

-

Still struggling with car at idle after 8 years

Bottom line that’s not the way the engine was designed unless he thinks you had a defective thermostat.

-

Still struggling with car at idle after 8 years

This new mechanic says the pcv valve is shut. We are making a test drive on monday again and see what happens. The car is also now driven with no thermostat.

-

Check out this ATK crate L28 engine on BaT

Already $1800. I'm surprised it's that high considering it's been sitting and you really don't know what you've got until you take it apart. Is the compression ratio a turbo level compression ration?

-

How vibration free is your 70-71 240Z?

You could look at the RT mount and customize the diff angle

-

Still struggling with car at idle after 8 years

IMHO Pull the head.

-

Still struggling with car at idle after 8 years

Plugs pulled and with the pcv valve shut there is a difference in plugs 4 and 3 no more. However the initial problem is still there. If i accelerate the car in neutral and idle when warm it only reaches 6000 rpm. It struggles to go over those rpms. First picture top to bottom 6 5 4 3 2 1 Second picture plug 4

-

Still struggling with car at idle after 8 years

We are still in Panama. Trump is making life in Europe very expensive. Im pulling out the 6 plugs and revert shortly.

-

How vibration free is your 70-71 240Z?

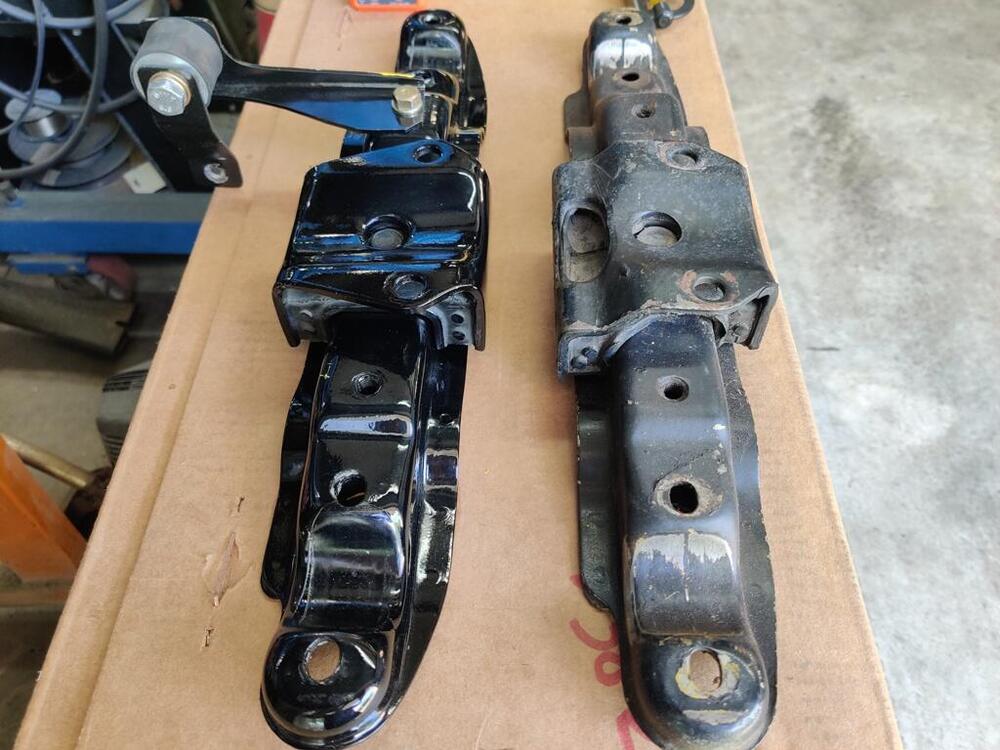

I hear ya. I guess since I now know I have something that isn't right, I feel I need to fix it. Working on it today, I found some interesting things. One, I was thinking would be a problem, and it is. The front yoke of my driveshaft had some corrosion on it. I tried to clean it up as best I could and was hoping that when I sent the driveshaft off to be shortened and balanced, that the part where the seal rides would be ok. This black goo in the first pic is the rear transmission seal wearing at an accelerated rate. In the second picture, I have removed the yoke shield, and you can see where the seal was contacting at the two points (front and rear edges of the seal) on the shaft. In the third picture, you see where the yoke has been touching the transmission tail shaft inner bushing. That should not be, and could be indicative of another problem. Or, it could be evidence that the driveshaft is not happen and vibrating around because of the improper u joint angularity. This is after 500 miles. I received a new yoke this week from ZCarDepot. I am going to transfer the yoke shield over to the new one (two spot welds) and then take the parts to a local driveshaft shop. Given where the "wear" marks are from the tail shaft bushing on the old yoke input shaft (kind of centered front to back), and that I didn't have any problems with rubbing, I think the propeller shaft assembly length is ok. But, it barely fits between the transmission and the differential. When installing it, I have to bottom it out inside the transmission and rotate it to a particular position before the rear will go onto the front pinion flange. Once there it pulls back just a bit and the two mating surfaces contact. As far as how I am going to deal with the excessive angle at the pinion flange, I am open to ideas. The front of the differential points upwards noticeably when mounted in the car. I think I will need to focus my efforts on modifying the front differential/suspension crossmember, and/or front isolator. I have a spare front differential/suspension crossmember, and a spare isolator (55415-N4301). I could flip it around 180 degrees and cut and weld on it to remove the incline... And, I could cut the top surface of the differential/suspension crossmember where the isolator sits to lower it a bit. Going to do other stuff for now and wait for opinions and think on it some more.

-

Still struggling with car at idle after 8 years

I know you had a heat problem when in Panama. Did you also have that problem after moving to Europe? Maybe just a lower temp thermostat rather than no thermostat should at least get your engine to warm up a little quicker. On the PCV and thermostat, both should be readily available at any auto parts store. Both thermostat and PCV are very easy to replace.

-

How vibration free is your 70-71 240Z?

I'm not saying you're wrong about the vibration source, but many years ago, a friend had a '56 Ford pickup that someone had slopped a 302 ci engine into. The engine was visibly out of alignment both vertically and horizontally, and it ate u-joints every six months, but it never vibrated at speed.

-

Still struggling with car at idle after 8 years

Well short story, according to new experienced mechanic the PCV ia shut and needs to be replaced. This was causing oil built up on cylinder 3 and 4. He also removed the thermostat for the car to run better. Im still testing the car as i really dont like waiting so long for the engine to warm up and scared of the fact the pcv is shut and needs to be replaced. I guess nobody really wants to test this car under heavy traffic conditions to determine the cause and solution of this problem.

-

How vibration free is your 70-71 240Z?

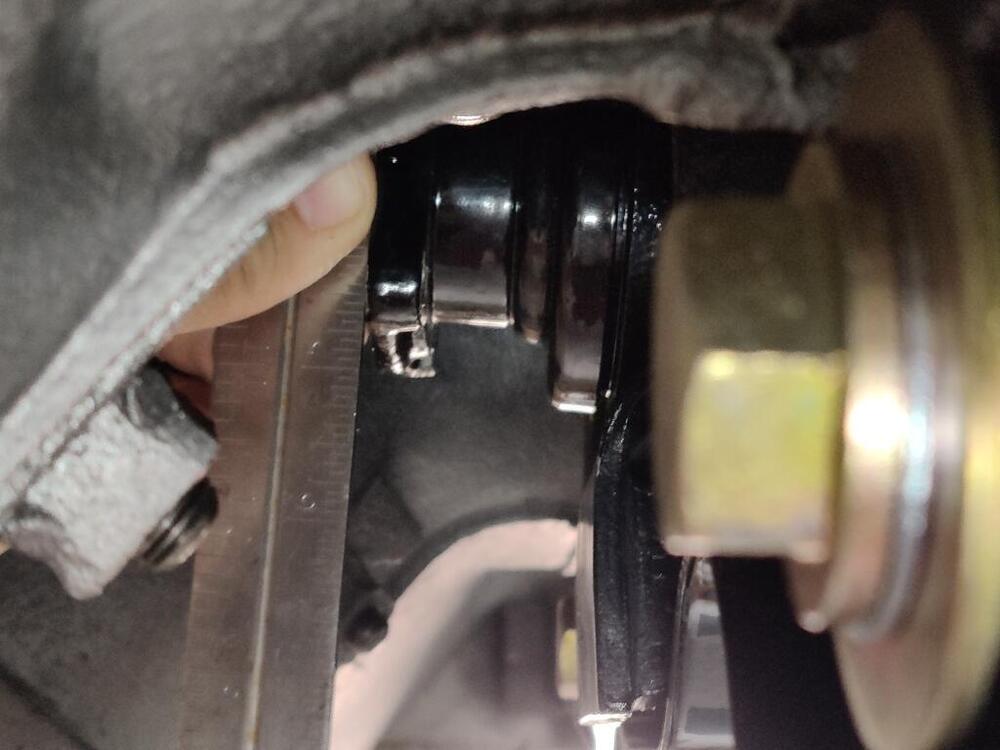

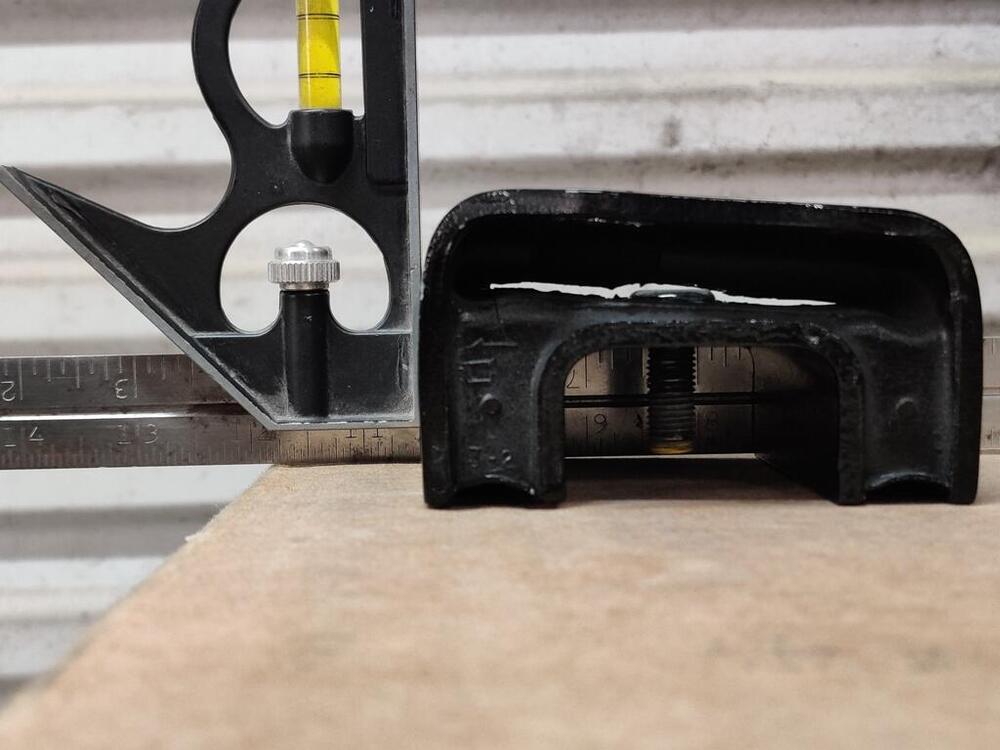

Ok, I took a measurement on the factory transmission crossmember. The crossmember has a "drop" of 5/8". So, when the crossmember is bolted into place, the top surface that the transmission isolator is 5/8" lower than the ends. The Techno Toys Tuning has the same amount of drop. The difference is that the hole for the isolator is shifted back also - it is not exactly in line with the transmission crossmember mounting holes like the stock one. It seems that all is well up front. It is possible that the 240SX transmission locates in a slightly different position vertically than the stock 4 speed. However, as I discovered when loosening the transmission crossmember bolts enough to drop the transmission about a 1/4" or so, the angle of the output shaft of the transmission didn't change much. It went from about 89 degrees to about 88.5. Turning my attention to the rear differential isolator, it is easy to see that there is an angle "built into it". While somewhat difficult to see in this picture while installed in the car, if you look closely at the vertical plate of the isolator and compare to the straight edge, you might be able to tell that the top of the vertical plate is closer to the straight edge than the bottom. Removing the isolator from the car, I confirmed that part number of 55415-E4102. This one was replaced new by the prior owner of the car and remained unused other than supporting the diff in the car for about 28 years. Outside the car, it is easier to see the amount of incline built into the part. I measured the angle on the cardboard surface and got .3. So, 3.6 minus .3 is 3.3 degrees. Ok... Why? One would have to assume that there is something different about my car. Too much angle on the rear section of the driveshaft which is causing a driveline vibration - it would not be a possibility that the engineers got this wrong, would it? And, now that I have been through all of this, I am fairly certain that I have been here and done this with my track car before. I believe I ended up modifying the differential isolator to reduce this angle for that car as well. I am very interested to see if this issue (too much upward incline at the front of the differential relative to the output of the transmission) is present in unmodified pre-72 model year cars.

-

55 year old Z master cylinder / slave cylinder

Too funny. That's what I get for buying someone else's project. BTW, I've been called worse than stickler. Lol.