All Activity

- Past hour

-

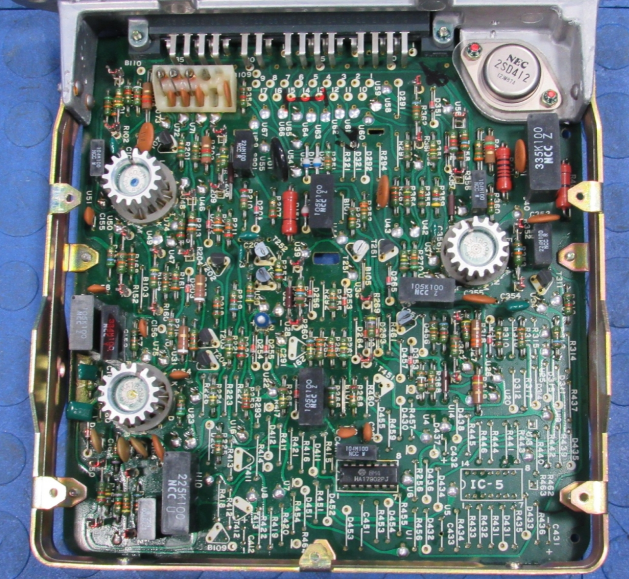

Wire identification

Hi, quite a stir i made hihi... A 1979 eccs is without any microprocessor, i can tell you as a electronics engineer. Those rond tin boxes (with cooling crown) are early integrated circuits, nice to see! Later on the plastic black boxes came. (Some are already on the printed circuit) The 6801 is a microprocessor and works with 0 and 1 signals of 0 and 5Volt. As far i know the switch was made between 1982 and 1983. Then analog "computing" became Digital computing where real microprocessors took over the work. I don't know for the USA But overhere in europe the 1983 280zx turbo was the first z with real processor in the managementsystem. (Europe never had a 280zx turbo before 1983!) All those boxes in 280z and 280zx were called ECCS until the 1983 turbo came out. (I belief..) (Don't hold me to it, i'm not a wizard, just remembering this stuff..) ;-)

- Today

-

Yarb started following 1977 280z clock issue #xx of yy

-

1977 280z clock issue #xx of yy

@Captain Obvious Very impressive analysis of the circuit. Thank the Lord I went to school for that!,

-

55 year old Z master cylinder / slave cylinder

-

1977 280z clock issue #xx of yy

Sorry for geeking out. I was on a roll. 😄

-

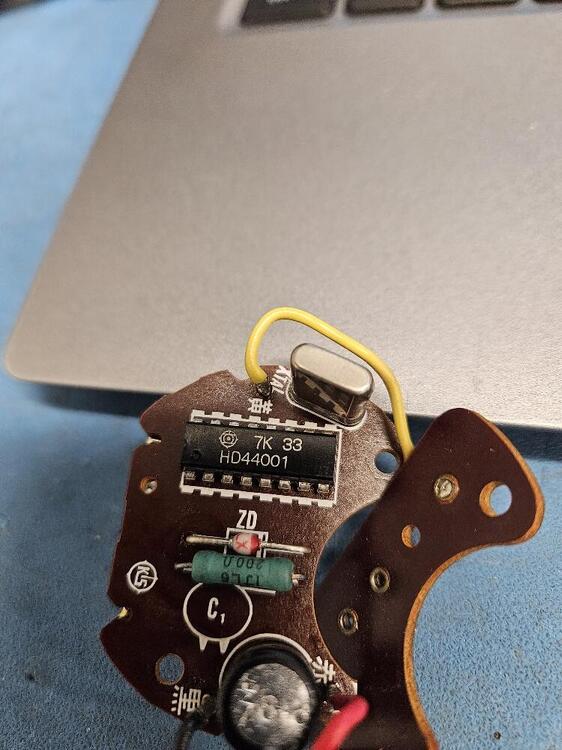

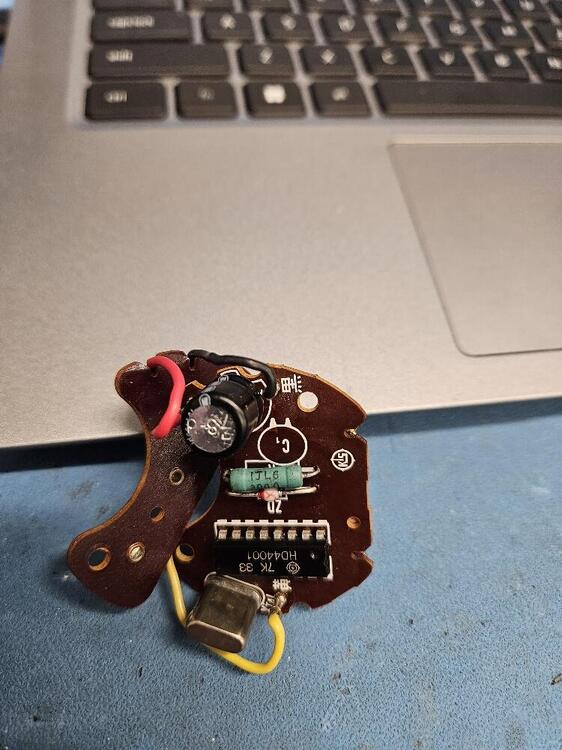

1977 280z clock issue #xx of yy

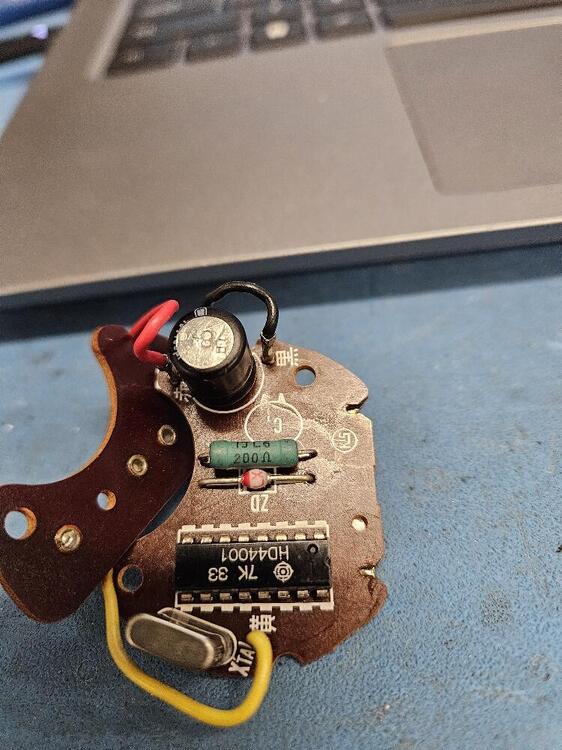

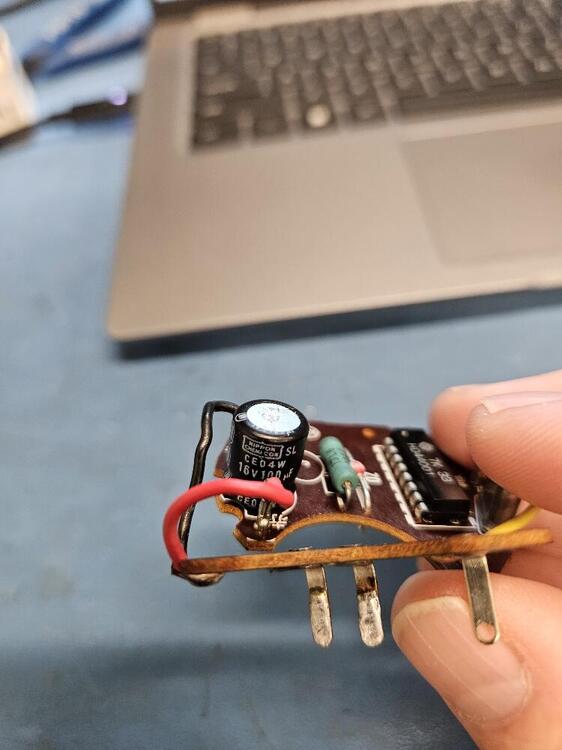

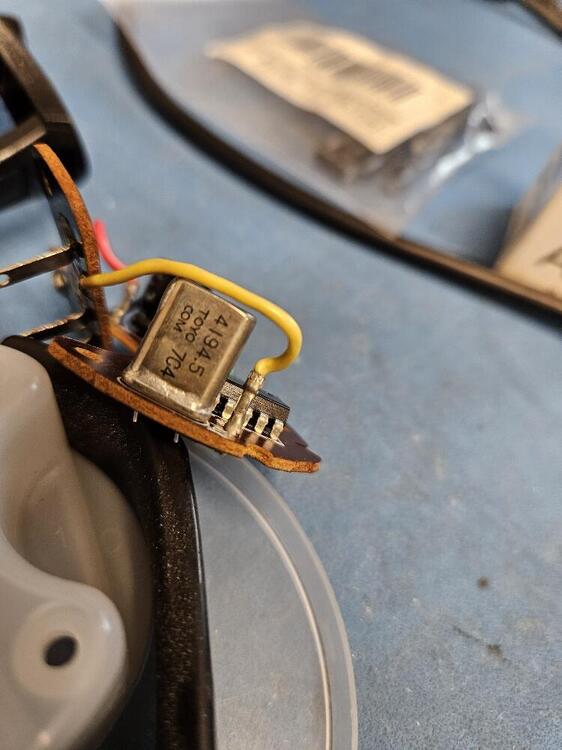

Your analysis of the parts is correct... Resistor, zener, capacitor - Those three parts are used for power supply and regulation*. They are relatively easy to source, and other than the zener voltage, the specs are relatively unimportant. By that, I mean... You could use a 180 Ohm resistor or a 150uF cap. Within reason, the values don't matter. The resistor will dissipate less than half a watt, so a one watt resistor would be fine. Composition (wirewound, metal film, carbon... Doesn't matter.) Crystal, and control chip - Those two are not easy to source. Hope that your problem is not one of those two. The HD44001 control chip does not appear to be available. Probably designed for the application and sold only to the clock manufacturer. And I would try hard to not mess with the crystal. The frequency is a little unusual, and even if you can find another crystal with "close enough" frequency, it's not guaranteed that it would work paired with the electronics inside the control chip. They are used as a shunt regulator system with the cap as a filter. System has about 30 mA quiescent current and therefor a little less than that in compliance.

-

How vibration free is your 70-71 240Z?

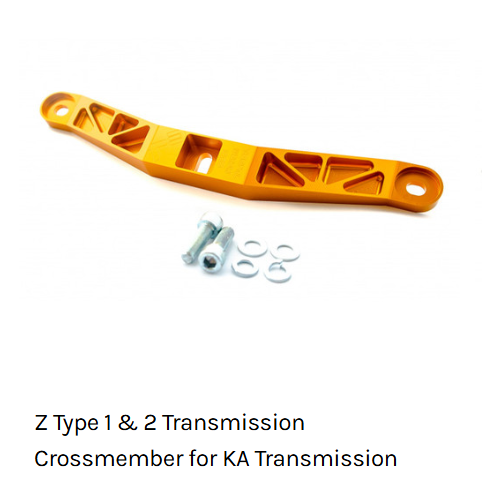

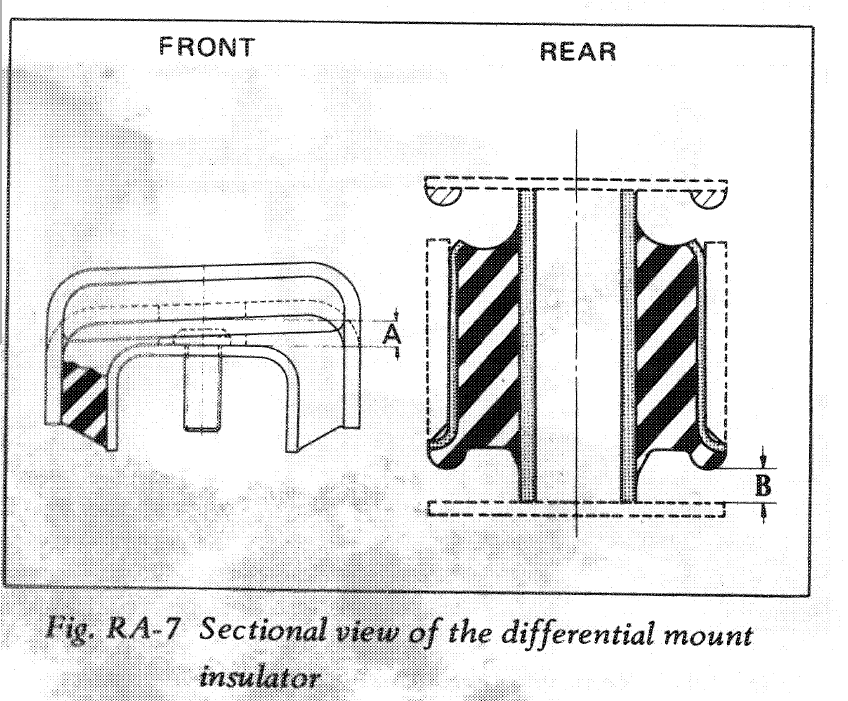

I played around with lowering the rear of the transmission today after work. I backed off the bolts securing the transmission mount (Techno Toys Tuning) to the body to see what kind of change in angle would result. Picture of the mount I have (for use with the 240SX transmission) in the early Z: Backing the bolts off to drop the rear of the transmission more than 5/16 of an inch only changed the angle from 89 to 88.5. I expected more change in angle. Anyway, now I am thinking through various things. I find myself asking why the front differential insulator mount has such a "large" angle to it. First of all, I confirmed that my insulator mount is part number 55415-E4102 (the early one). When looking at the factory workshop manual, the image clearly shows an inclination. As my car is sitting on the lift, I measured the inclination of the pinion flange, and it was 87.1 degrees. Why is it so far away from 90? I mean, the driveshaft is supposed to operate with less than 3 degrees of angularity on the u-joints. If I was able to match the 87.1 at the transmission, that would be 2.9 degrees on each u-joint. And, we all know that when power is applied to the input flange, the nose of the differential lifts upwards (i.e. the need for the "arrestor" belt which limits to differentials upward movement at the front). It seems to me, that instead of dropping the rear of the transmission down, it would be far better for me to change the angle of the front pinion flange, by either lowering the front of the differential, or raising the rear of the differential. Since I have used lowering springs to lower the car a bit, it seems to me that it would be more desirable to raise the rear of the differential. However, that would require modification of my stock parts here, perhaps removing the upper washers that have rubber bonded to them and replacing them with flat washers? I went through a fair amount trouble to source these washers as I am fairly certain they are what came originally on my 6/71 car. Further, I believe that the front differential mount, front differential insulator, rear differential mount, and rear differential mount washers are all as original for my car. So, I am baffled why the pinion flange angle is what it is. Am I missing something? How do I confirm that my front differential mount is the correct part number for my car - 55411-E4100 (used up through 6/71)? What is the difference between that one and the later 55411-N3001 used from 7/71 to 7/73

-

55 year old Z master cylinder / slave cylinder

Early cars have an external spring

-

GoldAir changed their profile photo

-

EGR relay, can i remove it?

Glad to help. So, are you planning to change over to the round-top style balance tube and throttle linkage shepherds hook? Or are you thinking you'll keep your flat-top balance tube and just cap off the EGR valve? Either way, don't forget that you'll need the round-top throttle linkage that goes between the two carbs. The flat-top and round-top designs are different and not interchangable.

-

-

Complete list of seals/gaskets/replacement parts for R180 and F4W71A transmission?

Looking at reinstalling the 4-speed monkey motion (including the R180) into my 240z, but obviously need to service everything. I saw an amazing list of 240z fasteners from @inline6 (linked here), and wondering if similar thing exists for the seals, gaskets, pinions, bearings, bolts, washers, o-rings and such that can be replaced when servicing transmission/differential? I have a very pricey Motorsport Auto cart ready to go, but I'm confident I've missed a lot. I also reached out to ZCarDepot, but they understandably didn't have anything collated, and as far as I know, a "restoration bundle" doesn't exist anywhere. I had noticed ZCarDepot had a few bolts that ZStore didn't have, but going a bit crazy cross referencing. I know the microfiche and FSM could be of use here, but as a first-timer I get a little lost and looking to help myself out! Bonus points for any other Google Sheet resources beyond this need that might be useful for reference! A bit of a sucker for a database. Any help or steer would be appreciated, thank you!

-

-

Best OEM-style muffler/exhaust system in 2025?

Hi all! Looking to replace the ancient aftermarket exhaust system on my Series 1 240z, and curious what the best options available to me are. I saw a car recently on BaT that had the original style black tips, but not sure where that came from. I've never seen it on my internet travels. Check it out here: https://bringatrailer.com/listing/1970-datsun-240z-129/ I'd like to be as stock/OEM as possible. Pretty sure my headers are original, but would need muffler, exhaust, mounts etc.

- Yesterday

-

bluez started following 55 year old Z master cylinder / slave cylinder

-

55 year old Z master cylinder / slave cylinder

So I took my Z out of hibernation yesterday after 4+ months. Started up checked everything, car drove fine (so I thought), stopped at store, went about 200 yards, and lost clutch pedal, almost all the way to the floor. Pulled over and checked master cylinder bowl, it was full, but black (was clean last fall). Turned engine off, went right into gear, started up car took off, headed home (2 miles). Good until dam stop lights, shut engine off 2 more times, till I made it home. Pulled master cylinder, found it stuck, (original to the car). Ordered a new one (OEM Nabco). Pulled the slave cylinder out to check and clean, seemed ok. While looking at a parts diagram, it shows a spring behind the piston. I had no such spring in mine. Did early Z’s not have a spring?

-

75dottydatsun280z joined the community

-

-

La_Bob joined the community

-

1977 280z clock issue #xx of yy

Thanks for the post, I'm trying to get a spare clock working now. My 1978 quartz clock started losing time last summer. I had a spare, so took it apart to see what could be changed. There are only 5 components on the circuit board as follows: 1. 16v 100uF capacitor (Nippon chemi con CEO4W) 2. 200 ohm resistor. (Cant figure out the exact specs. It has 200 ohms and either I or 1 JL6 printed on it and its green. Its about 11 or 12 mm long, which from read I have read may mean its a 1 watt??? and 3 or 4 mm wide. Under it on the board is printed R for resistor presumably.) Not sure what kind of resisitor it is. 3. Next to that is what I'm guessing is a Zener Diode as it has ZD printed on the board next to it, and has a band on one end. Its white with a red band and has either LX or X7 written on it. 4. I think a crystal oscillator labelled 4194.5 TOYO COM 7C4. It has XTA printed on the board next to it. 5. A 16 pin chip that I think the symbol on it may be hitachi? HD44001 7K 33. The capacitors are all over Amazon, so not a problem to find. Does anyone know if any of these other parts can be sourced anywhere? I would like to replace with new as much as possible while I have it apart. Thanks.

- Duffy's 1/71 Series 1 240z build

-

EGR relay, can i remove it?

Thanks alot! It is a manual. I have been searching alot and this is very helpful.

-

Wire identification

More piling. Sorry, but now that the original question has been answered I'm just following this new thing. Edit - there is a lot in this Hybridz thread. Answers some questions. Way beyond my skill level, couldn't even try to fake it. Just curious. HybridZre-mapping and live tuning L28ET 1982/83 S130 ECCSEdit for latest information; See posts further down for full details on modifying 1982/83 ECCS for re-mapping and live tuning. All information related to reproducing this project can be found on Gi...

-

Wire identification

Usual pile on... I found what is supposedly a 1979 280ZX ECU on the internet with some good pictures. I don't see a 6801. Maybe there's an earlier controller in there somewhere? I'm not an electronics guy. The guy has a nice web site. If you click on the picture you can scroll through all of them and blow them up to a good size with another click. https://www.importapart.com/product/79-datsun-280zx-2-8l-l28-ecu-ecm-pcm-engine-computer-a11-616-420-oem-1869/

-

Wire identification

I found an old thread that might have some pictures. Haven't gone all the way through it. Funny though, Nissan uses the word "compute" in describing how the ECU (1978 I think) sets the injector pulse length. It's on page 3, post numbers are gone. Edit there's only a few pictures of early 280Z "ECU"s.

-

Wire identification

But what do you mean by "computer"? Does the controller contain a program? Does it perform computations? Or does it just convert one electrical input in to another? I don't know. I found some interesting things about it. It looks like it does contain programming, I wonder how complex it is. It would be interesting to see some of the code with comments. I assume that the code/program would be considered digital but the inputs and outputs not. https://www.cpushack.com/2017/12/07/cpu-of-the-day-hitachi-hd6801s0pj-automotive-6801/ http://www.bitsavers.org/components/hitachi/_dataBooks/U24_Hitachi_6301_6801_Assembler_Text_Editor_Users_Manual.pdf So, going backward from 1983, do you know when the Hitachi controller was introduced in to the ECU's? I know that the FSM's say that the 1979 and later ECU's cannot be plugged in to 1978 and earlier systems, even though they use the same connector. The pinouts are different, maybe because 1979 and up contain the controller. Does 1979 contain the controller and 1978 does not? Referring to what HS30-H said above, maybe the controller was introduced in to the ECU's also in 1979, along with being used in the ECCS. Only commenting to learn some new stuff. I started watching repair videos for modern vehicles and learned that they have all kinds of modern tech with high speed and low speed communication networks, and numerous "modules" each usually with its own controller, communicating on the networks. I think that even the intrument cluster in my truck has its own controller. Crazy. Always something new to learn...

-

Wire identification

I've been inside a non-turbo 83 ECU, and it was, in fact, computer controlled. They were running a Hitachi 6801 embedded controller. And even though I've never personally been inside the turbo ECU, I am nearly 100 % confident that it would also contain a microcontroller as the turbo required much more control than the NA version. So yes, the later years were digital, and computer controlled. Don't know when they made the switch though.

-

L19 joined the community

- Last week

-

Wire identification

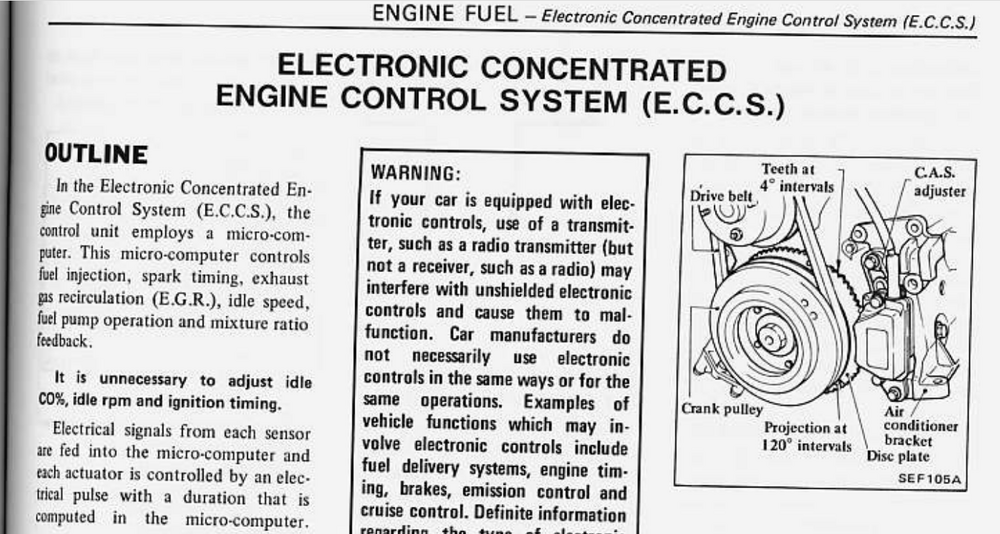

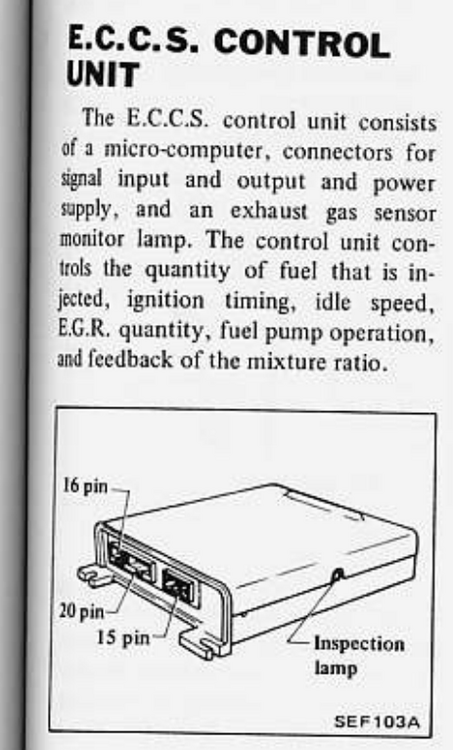

Thanks for the clue. I had looked in the 1982 FSM and found the combined EFI and ECCS descriptions, letters only, but should have started at the beginning. In the first 280ZX use of the ECCS, the 1981 Turbocharged 280ZX, they created an ECCS-only Supplement chapter, where they actually used the words, as defined above. Image below. They do call it a "micro-computer" in their description. I'm still not sure though that it does computing, in today's sense of computing. Besides the fact that it's not digital. (Sorry SteveJ, now that's really pedantic, Just having fun.). But it was still early days for computers, and I think the definition still varies today. From the 1981 Turbo Supplement Engine Fuel chapter -

-

Z's on BAT and other places collection

Not bad. There are still good Z project opportunities popping up out there. https://bringatrailer.com/listing/1972-datsun-240z-357/

-

Restoration of BringaTrailer 240z - HLS30-35883

The odometer clicked over 500 miles on Friday night, so I took the valve cover off yesterday and did both the leak down test and adjusted valves. Here were my leak down percentages: #1 = nearly 4% #2 = 2-3% closer to 2 #3 = 4% #4 = 4% #5 = 3% #6 = a little over 1% For my Iskenderian cam, the valve lash is .006" on the intakes and .008" on the exhaust. I set each so that the feeler gauge was a snug fit while the engine was cold. All of the cam lobe surfaces looked great! The next time I fire it up and get the oil warm, I'll change the oil. Today, I removed a portion of the exhaust and the driveshaft and measured the angles of the front engine dampener and the pinion flange on the differential. I believe I will be able to lower the transmission rear crossmember to bring the engine/transmission assembly to the same 87.1 degrees that the pinion flange is at. I will just need to add shims between the transmission crossmember and the car body. Oh! And I just remembered that I should check the angles in the horizontal plane (not just vertical) as well.

-

How vibration free is your 70-71 240Z?

I found the angles today of the front dampener and the pinion flange: I measured these with the car on the lift. The rear moustache bar is locked in solid - there is no vertical movement at the mounting location. Same for the front diff mount. So, I don't have to consider suspension movement (doing this with the suspension loaded). The angle at the differential pinion flange is 87.1. And the angle at the engine dampener is 89. I should be able to drop the rear of the transmission, hopefully a small amount, to get the angle at the dampener to match. I am glad I didn't use the original motor mounts, which were shorter, and would make this problem worse.

-

CatalinZee joined the community

-

Wire identification

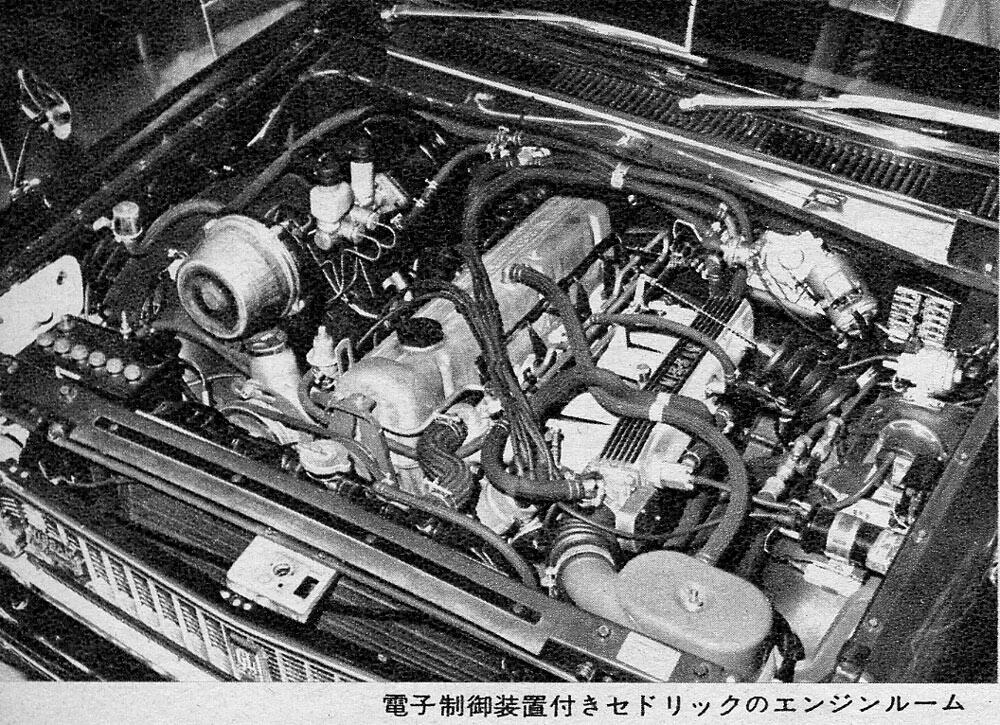

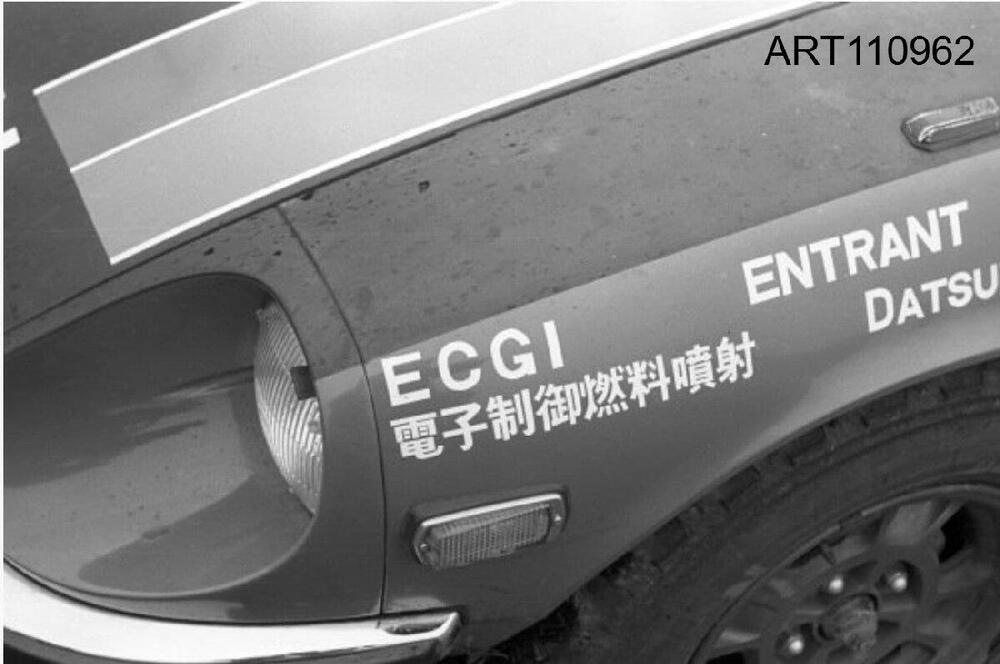

ECCS was first used on the 430-series Nissan Cedric in Japan (June 1979). ECCS stands for Electronic Concentrated (Engine) Control System. Electronically-controlled (via an ECU) injection was introduced on a 230-Series Nissan Cedric 'EL' model at the 1970 Tokyo Motor Show: Nissan was actively using a system ECGI (Electronic Controlled Gas Injection) back in 1971. Nissan group affiliate Diesel Kiki licensed the Bosch D-Jetronic system patents and re-engineered it to use with double and triple sidedraught throttle bodies on competition cars:

- Duffy's 1/71 Series 1 240z build