All Activity

- Today

- Duffy's 1/71 Series 1 240z build

-

Wire identification

Don't forget the "black box" or the "voodoo" part. "Dr. Bosch's Black Box of Analog Voodoo and Wizardry". That's what makes the engine go vroom. * "DBBBOVAW"

-

Distributor rotor identification

That's awesome. You totally nailed it!!

- Yesterday

-

Wire identification

-

Wire identification

I didn't even get my explanation right. I used the chapter label, EFEC, instead of ECCS. I'm not really sure what ECCS stands for.

-

Wire identification

I'm just going off what here. They call it an ECU. My FSM calls it a "control unit". Either way, the analog wizardry box that makes the engine go vroom.

-

Wire identification

-

Wire identification

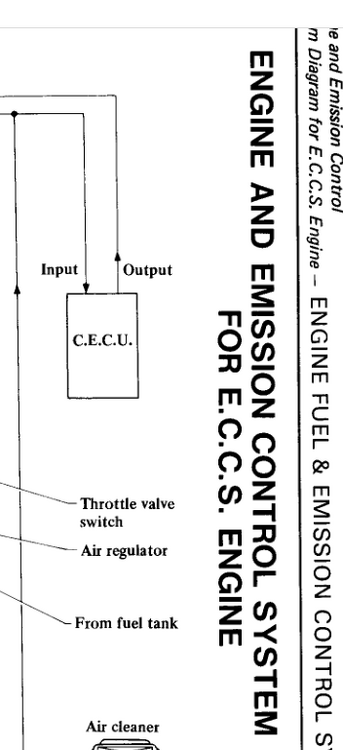

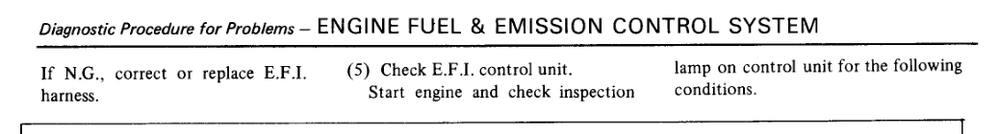

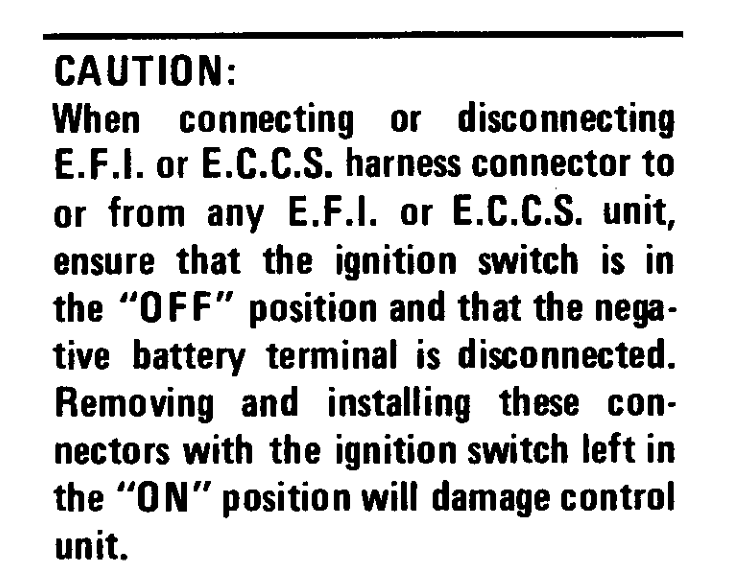

Actually, the the ECCS was introduced with the 280ZX's. The ECU is used in both but started with the 280Z's. Generally, ECU stands for Electronic Control Unit or EFI contol unit. Edit - not sure what ECCS stands for. Of course, it's all translated from Japanese, so the words might not make the most sense in English. But that's how ECU and ECCS are used in the FSM. From the 1982 FSM, below. Might be the the ECCS "computer" should actually be called the ECCSU. There have been some discussions about what should be called a computer. I don't think that either of these actually do any number crunching.

-

Distributor rotor identification

Nice! Thanks

-

Distributor rotor identification

Hey,@Parman I was wrong about the symbol being for YEC brand. I had a look at my pats stash and found that is actually for Daiichi Mfg Co Ltd.. Here are a few pics of some more ignition parts with the same symbol. Also shown are an OE Hitachi contact point set and condenser, you can see the Hitachi logo on those.

-

EGR relay, can i remove it?

Is your 260Z a manual, or an automatic transmission? On the manual cars, the EGR relay only controls the EGR system. But on the automatic trans cars, the EGR relay also controls the ignition timing by switching the ignition module to use either the retarded and advanced pickups from the distributor. So, if your car is a manual, then yes... The only implication of removing the relay (and it's associated wiring) is to the EGR system. But if your car is an automatic (or came from the factory originally as an automatic), then there will be implications to the ignition system as well.

-

MarceloFA joined the community

-

Wire identification

There are times to be pedantic. This isn't one.

-

dutchzcarguy started following Wire identification

-

Wire identification

Hi Jan, You mention a ECU.. but a 280z has a ECCS.. looks like a ECU. but it's a analog computer. Only the latest 280zx has a ECU, which deals with digital signals. AND most important has a microcomputerchip on board. A analog computer has a lot of analog input signals and "computes" this to a final signal for the different inputs like the cold engine start injector as an example.

-

LHdtuch260z started following EGR relay, can i remove it?

-

EGR relay, can i remove it?

Hello guys, i hope i am not opening up a topic what already has been talked about, if so please send that. I tried to find it but couldnt. So i have a 260, '74. But i am converting from a flat top carbs to round top carbs. Because i dont want the egr system. can i just remove the EGR relay? since the egr system is gone. i tried to track down the wiring and i found out yellow goes to the temp switch, Black and white to the ignition and lasty the green red to throttle opener solonoid. So my thougt is i track down those wires and delete them. Is this a good plan or no? thank you for your help already. i also put a photo of my car here. This was how i got it. the paint is awful on it. on the photo it looks good but it has been dan with a paint brush. so you can imagine how it looks. i will bring it to the paintshop and make it the factory green again. because on the fire wall in th engine bay you can also see that is was green before. I just love that color. kind regards,

-

LHdtuch260z joined the community

- Last week

- Duffy's 1/71 Series 1 240z build

-

can door locks work without the knob rod/key cylinders?

Why not contact “junkyard Jenny” She probably has what you need to replace your existing mechanism. Sounds like you might need both sides. Good people.

-

CanTechZ started following Distributor rotor identification

-

Distributor rotor identification

I think that might be a YEC brand rotor. OE ones are Hitachi, they have a different logo.

- Duffy's 1/71 Series 1 240z build

-

Parman started following Distributor rotor identification

-

Distributor rotor identification

Can anyone identify the logo or symbol on this rotor? It's of high quality and I would like to find another one. Could it be Mitsubishi?

-

Klocko98 joined the community

-

Duffy's 1/71 Series 1 240z build

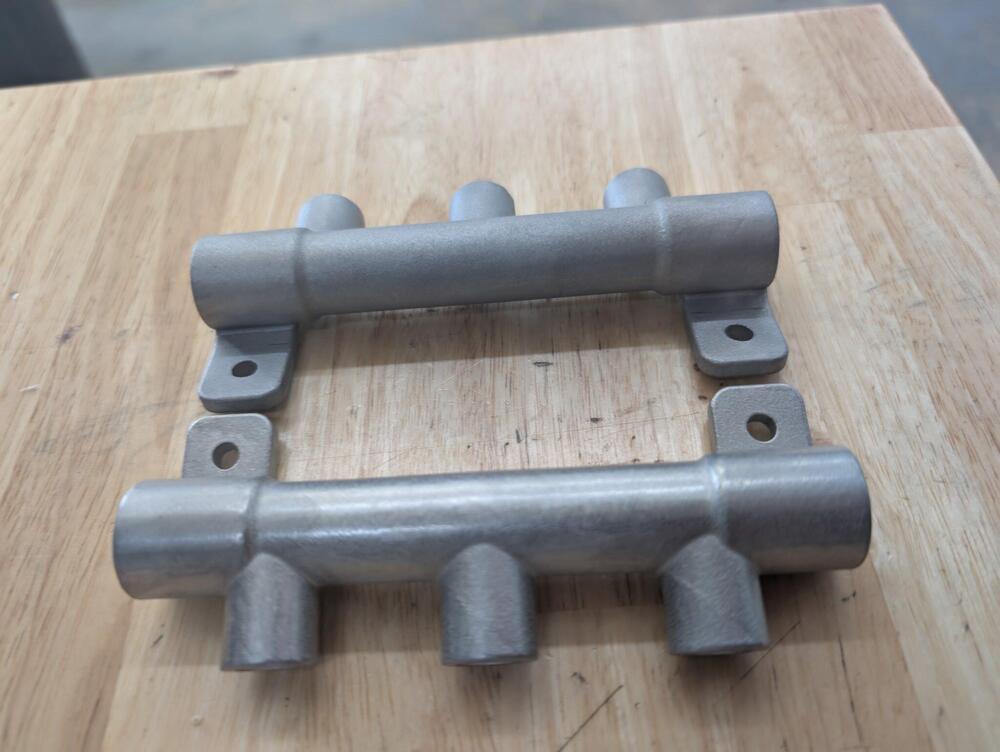

Here is something fun/ silly I have been thinking of and finally made. It’s a remote oil pressure distribution block made to look like the stock 240z brake prop valve. I previously had a steel T In the block, that broke off and then when I was using an easy out I cracked my stock block bung. I said never again! 3D metal printing is neat stuff. I had it tumbled to look even more cast. I run stock gauges and my ecu needs its own signal. This location allows stock wiring to also work.

-

can door locks work without the knob rod/key cylinders?

This makes sense. This is likely the reason the previous owner had riveted it in place so that it wouldn’t accidentally lock as there isn’t a key hole nor rod knob.

-

Restoration of BringaTrailer 240z - HLS30-35883

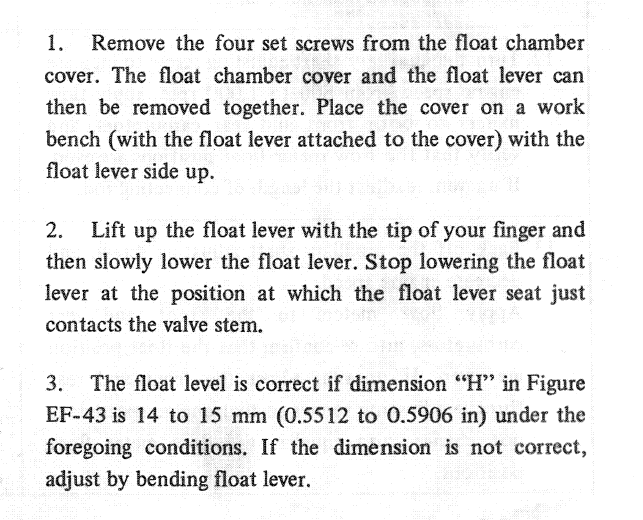

It's been a while since I posted an update on the restoration! I have been driving the car - I have 488 miles on it. I reset both front and rear floats using the method in the factory workshop manual. To do so, I cut some "3d" finishing nails to the approximate lengths of 14 mm and 15 mm and then finished them to size with a benchtop grinder. The procedure from the factory workshop manual: Holding the assembly in its installed orientation (not upside down), I first place the 15 mm nail section in between the flat metal part of the float and the underside of the float chamber cover. I put it in place using needle nose pliers so that it is straight vertically. I pinch it to hold it in place by lightly squeezing the float and the chamber cover together. Note that when held in the installed orientation, the needle in the needle is in "free fall" and is in a fully open position. Then, using a magnifying glass, I inspect the area of the float tab and the tip of the needle. I verify that the tip of the needle is not touching the curved arm (tab) of the float. It does have to be within 1 mm of it however. If not, when you swap to the 14 mm nail section, the tab will still not touch the tip of the needle. I adjust the tabs so that both carburetor floats contact the tip of the needles with the 14 mm section of the nail in place. Interestingly, after I had set the floats this way, I noticed that with the 15 mm section of the nail in place, I could blow through the fuel inlet tube, and with the 14 mm section of the nail in place, I could not. So, what I found was that from fully open, to seated, the needles have less vertical movement than 1 mm. While I have been driving the car to break the engine in, I have been looking at air fuel ratios (AFR) using a wideband 02 sensor. I swapped from what I believe to be stock N27 needles to some SM needles. But, I have observed AFRs moving around a bit which is unusual and not expected, and which I think may be due to the engine still breaking in. I started a separate thread that details more about what I was doing and seeing here: https://www.classiczcars.com/forums/topic/69292-choosing-an-su-needle-if-i-have-needle-station-info-and-real-world-afr-can-i-use-that-to-find-the-right-needle/ This weekend I plan to do a leak down test on the engine to confirm break in is complete, change to standard oil (instead of break in oil), and adjust the valves. If the engine is fully broken in, I will do some more AFR testing and determine how to proceed. I may need to modify the SM needles in the cruising and pick up stages by some very light "sanding" - removing material by chucking them up in drill and using 2500 grit sandpaper only in a certain area of each needle. With the driving I have done, I also noticed a vibration at higher speeds. I started a separate thread for that issue: https://www.classiczcars.com/forums/topic/69334-how-vibration-free-is-your-70-71-240z/#comment-675670 Today, I am going to buy a digital angle gauge so I can check some angles in the driveline. I am hopeful doing this will help me determine the cause and fix that issue.

-

can door locks work without the knob rod/key cylinders?

So in the last pic, the part with rivet, lets call it the "hook". It is touching a bar just to the right. We'll call it the "drum catch". When the drum in the center w the spring rotates the "drum catch" locks into the ratchets on the drum. When it does that the "drum catch" moves down slightly. Then the "hook", which is the lock mechanism, can move over to prevent the "drum catch" from unlatching. I would make you some pictures but all my locks are at the platers. I just recently studied this mechanism as I went through mine and was working on refurbishment

-

can door locks work without the knob rod/key cylinders?

sigh, i think i know what’s going on. the previous owner put a rivet on the lever here so it wouldn’t move. when it should look like this instead:

-

can door locks work without the knob rod/key cylinders?

So before I go and dismantle the window/door etc, I have a question about how this is supposed to work. As it sits now, the door latches and opens fine. You can see the red arrow pointing at the mounting screw. This looks like it prevents the knob rod (green) and the keyhole tab (yellow) from moving downward. Is this expected? If the knob rod (green) was working as intended, would the blue part move as well? With the green/yellow parts in that position, are they in a door locked or door unlocked position? May be an obvious answer, but I thought I would ask to be 100% sure. I’m wondering if the previous owner did something crazy like weld it to keep it “unlocked” forever. Thanks in advance!