All Activity

- Today

-

1977 280z clock issue #xx of yy

I had mentioned in an earlier post to seek out @zclocks. He has been a consistent contributor to the forum and welcome to questions and advice.

-

Yarb started following Darn Tire Jockeys

-

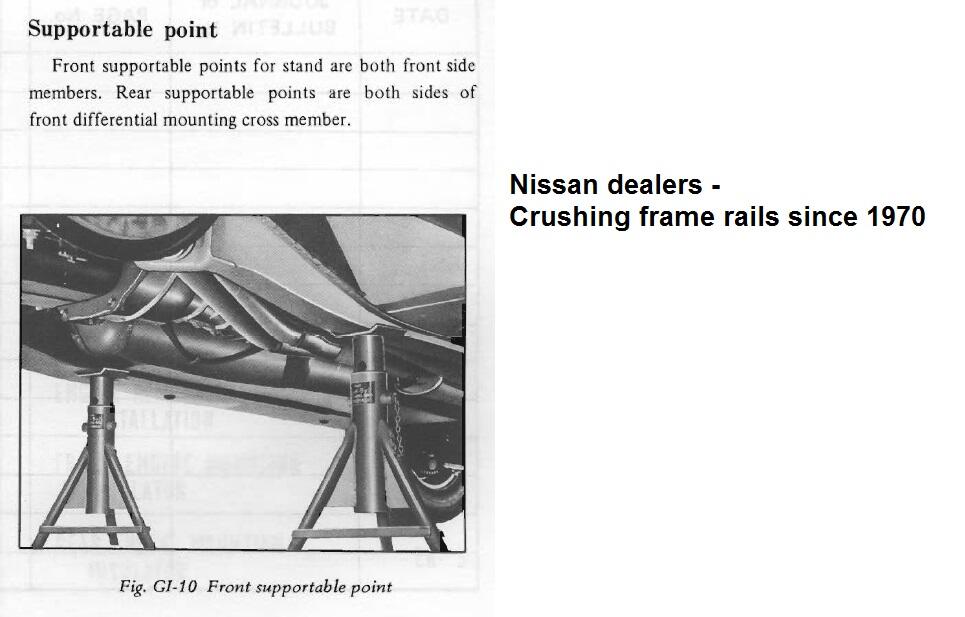

Darn Tire Jockeys

Personally on my 78 280, If I rested those stands there it would not be pretty. I rest my stands on the very front of the rail at the weld joint.

-

Hose Clamp Finishes

Oh yeah, this is from a May 1971 car

-

Broman started following Hose Clamp Finishes

-

Hose Clamp Finishes

I've heard some conflicting info on the subject, so I figured I'd consult the hive mind. Regarding the wire-type hose clamps used all over... 1) Were they all clear zinc/cad, all yellow zinc (zinc with yellow chromate), or are their two variants? 2) If two variants, what is the rule of thumb as to which ones go where? 3) If two variants, did they have different part numbers? I ask because it was my understanding (perhaps incorrect) that they were all clear zinc, then I discovered this when disassembling my clutch master cylinder tonight: Extra credit: Have any other data guru's out there put together a spreadsheet that lists all clamps and their sizes? Thanks!

-

1977 280z clock issue #xx of yy

Socorob, Your looking way to deep for the problem. 99% of the time it's a mechanical .Email me , ron@zclocks.com

-

Darn Tire Jockeys

- Charging fun with Zedyone !

-

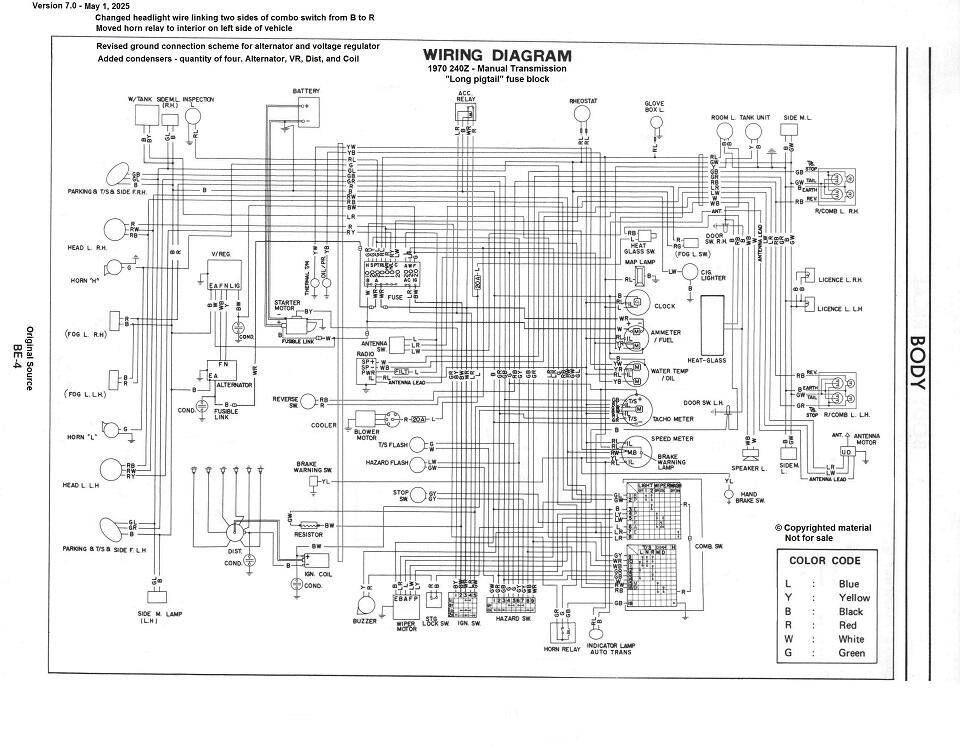

1970 Wiring Diagram

So @Mike , I tried to delete the old obsolete incorrect previous version of the wiring diagram (version 6.0 on page five of this thread), and the edit privileges will not allow me to do so. I'm assuming there is a time limit on how far back in time one can go to edit something? And that post on Feb 11 has exceeded that time limit? Can we change that? Or at least, can YOU delete it if you won't allow me to do so?

-

1970 Wiring Diagram

Glad to help. Hope you get some good use out of it! Well actually, that's probably not a good sentiment, since it implies you may develop electrical issues that would warrant needing a wiring diagram. So I hope you do NOT get good use out of it! Hahaha!! 😄 In any event, I'm glad to help!

-

Namerow started following Darn Tire Jockeys

-

Darn Tire Jockeys

I suspect that Nissan, based on its limited world knowledge in the early 1970's, fell victim to expectations that repairs would only be carried out by authorized/factory-trained specialists who lived up to Japanese-market standards. I'll bet there were zero lift-point-related damage issues experienced by Japanese Z owners during the first 2 or 3 generations of ownership. Or maybe never. Until computer-controlled powertrains intervened, the American automotive service industry was the Wild West. Maybe it still is.

- Yesterday

-

Still struggling with car at idle after 8 years

Faulty PCV valve? Not surprised. The quality control for these 'consumable' automotive parts is atrocious (spark plugs may be the only exception). They can cripple a car's performance, but spotting a defective item is difficult. You really need to install your 'tune-up' parts one at a time. If the car's performance collapses, you know you've just installed a new-but-defective part. Moral: Buy only the best -- even though they're just 'routine maintenance' parts. Even then, be alert and be suspicious. The auto business is a low-margin enterprise. Even name-brand 'replacement parts' manufacturers have to skate close to the edge in order to keep their shareholders happy. p.s. They do a much better job when it comes to supplying parts for new cars b/c now there are new-vehicle warranty costs involved and their customers (the auto manufacturer) will pay more to keep those costs under control. In the auto biz, it's all about $$$. I will defer to others when it comes to your fuel pump circuitry. My thesis is all about making the system (your engine, along with its fuel and electrical systems) as simple as can be, so that problems much easier to diagnose. Once that's done, you can add back the complexity (emissions control equipment) as you see fit. If it were me, living in Panama and driving a carbureted 50-year-old classic, I'd limit that to the PCV system. All the rest of the 240Z's emissions control gear, viewed from a 2025 perspective, is -- not to put too fine point on it -- finicky crap.

-

Darn Tire Jockeys

-

Darn Tire Jockeys

"Anyone else"... Can't tell you how many of these we saw at our shop... Z owners REALLY need to know the lifting points AND make sure the shop or garage KNOWS where they can lift AND WHERE THEY CANNOT! Also HOW they can lift. That fender deformation is not that easy to repair and do it correctly. Unfortunately it's in a spot that's not that easy to notice and most owners don't see it before they leave the offending shop. Shops are famous for crushing frame rails and the flange under the rocker panels besides ruining front fenders...

-

Duffy's 1/71 Series 1 240z build

I got my Datsun Z Car Series Oil Sending Unit Relocation / Remote Block done! I have only one for sale now, but more are on order. I am pretty proud of this design. Three outlet remote oil sending unit block. Metal 3D printed out of aluminum to look stock and mimics the 240z, 260z and 280z brake proportioning block design. Block has 3 outlets, all are 1/8 NPT. Comes with a custom length -3AN hose and one 1/8 NPT -3AN fitting and either a 1/8 BSPT or 1/8 NPT for the engine block side of the hose. Stock sending unit on a 240z is BSPT, this will require a NPT sending unit like this. [https://zcardepot.com/products/oil-pressure-gauge-sender-240z-260z-280z-70-77?variant=32184292737137](https://zcardepot.com/products/oil-pressure-gauge-sender-240z-260z-280z-70-77?variant=32184292737137) No sending units come with this order. Pictures of sending units are just for reference. Link: https://www.m2racing.com/shop/p/datsun-z-car-series-oil-sending-unit-relocation-remote-block

- Charging fun with Zedyone !

-

1970 Wiring Diagram

Bruce, Many thanks for all your hard work on this project. Jim

-

Mike started following Darn Tire Jockeys

-

Darn Tire Jockeys

I'd make them pay for the repair

- Charging fun with Zedyone !

-

Charging fun with Zedyone !

Yes, that would indicate a failed to me as well. It failed open circuit. And by the way, for educational purposes... With the new digital meters, it's pretty much impossible to check diodes integrity using the resistance scale. It needs to be on the diode check setting. If you happen to have an old ANALOG meter with a needle sweep, you can often check diodes with the resistance scale. But analog meters, like the dinosaur, are either extinct, or headed that way. So what SHOULD you have seen? Using the diode check setting, you should have seen "OL" in one direction, and some small voltage in the other direction. Something like 0.50 to 0.80 Volts.

-

1970 Wiring Diagram

Here's the latest wiring diagram. I moved the horn relay to the interior side of the firewall. It was previously shown out in the engine compartment, but in reality it's actually located on the left side of the interior near the driver's left knee and the hood release pull. Changed the way the alternator and voltage regulators make connection to ground. And made a couple of minor wire color changes. And lastly... Thanks to the help from the folks here, it now has condensers. <V7.0> _obvious 240Z Wiring Diagram 7.0.pdf

- Darn Tire Jockeys

-

Putting out the feelers

I agree, I wouldn't touch it

-

Zpenman started following Darn Tire Jockeys

- Darn Tire Jockeys

-

Impossible Oil Leak?

Well he is a mechanic and used to also race a camaro single carburetor car. He is 69 years old. Ill guess ill just wait for the new parts to arrive.

-

Impossible Oil Leak?

You know that 3 and 4 have their own individual runners so I'm wondering if there's anything resulting from that? Maybe try snugging up the intake bolts? look for soot around the runners. Try accepting what the mechanic tells you instead of what you're reading on the www.com. He knows more than you, live with it and do what he suggest.

.thumb.jpg.770791ce807b4d175218af094632a9e5.jpg)

.thumb.jpg.9d0c5d1b04adf0f02030a28e2f6af068.jpg)

.thumb.jpg.6931a04d511993083b2d34c500e05ad0.jpg)

.thumb.jpg.7026fbda1317600494c4561d602563ea.jpg)