All Activity

- Today

-

EGR relay, can i remove it?

Yeah my brother is very good with making a new one, so i think with heatshield i do that. Thanks alot for helping, i will send you a picture when its in. (It will take a while) Thanks alot for helping!

-

1977 280z clock issue #xx of yy

I found on another forum where someone posted this in 2014 where they called ToyoCom, which I think is now Epson about the crystal: Thanks a lot, I gave them a call and they only sell in bulk, $300 minimum order. Wouldn't answer any questions. https://www.4starelectronics.com/mfgs/Toyo-Distributors.html This was the website he said he called. I was hoping there would be a source for some old stock somewhere to rebuild these, because I like having an accurate clock and like the look of the stock clock. This clock I took apart doesn't appear to ever had lube anywhere, unless it totally evaporated and disappeared, so I'm not sure if these clocks used any lube from the factory. I tried running it with all the gears off except for the 1 drive gear, and that doesn't turn. I don't believe the coil could fail without it being noticeable.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

Gotcha. Was just making sure the readings you were seeing were "first order" and you you weren't reading something that was fooling your AFM gauge. Something like a lean misfire that can read rich. That sort of thing.

-

1977 280z clock issue #xx of yy

I see sites like that all the time claiming that they have stock of old obsolete electronics. I've never actually tried to order from any of them, but I'm skeptical as to the legitimacy of them. Might be completely legit, might be a complete scam. And that's an interesting thought about the programability of the 44001. I guess there is a possibility it's a programmable part. And if so, there's the follow-up question of "when you buy it, is it already programmed?". The 4V drop across the resistor is good. It should be "battery voltage - zener voltage" across the resistor. So if battery is 12 and zener is 7.5, you should see 4.5V across the resistor. if you've got that correct drop across the resistor and the clock doesn't run, then it's either mechanical or one of the remaining components (Xtal or control chip). Your other clock that sometimes holds time and sometimes doesn't sounds more mechanical than electrical. Maybe old lube has turned to tar and is gumming up the works?

-

55 year old Z master cylinder / slave cylinder

When I rebuilt that old slave cylinder, I included an internal spring. So now I have both internal and external. It gives me guilty pleasure thinking that the two of them are battling it out on my car right now! Hahaha!! 😄

-

EGR relay, can i remove it?

You need to fit one of the older heat shields from the round tops so you can use the return springs. And depending on what the climate is where you are located, the water through the carbs isn't a big deal. Good luck with the project!

-

How vibration free is your 70-71 240Z?

Good thought. I do. I will have a look at it to compare.

-

How vibration free is your 70-71 240Z?

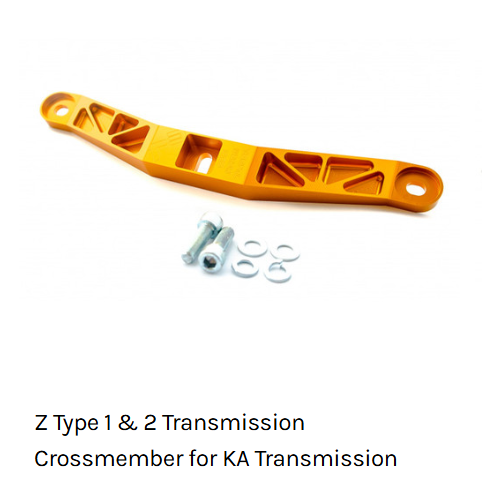

Do you have a Nissan factory transmission mount to try? Maybe you're fcoused on the wrong member. The T3 mount is the only "non-factory" part.

-

Choosing an SU Needle - If I have needle station info and real world AFR, can I use that to find the right needle?

Oops, missed that question. Yes, when I pull the choke lever a bit, the AFRs change - the numbers come down.

-

How vibration free is your 70-71 240Z?

I bought one of these Magnetic Bore Laser Sight to help with alignment of the transmission to the differential. Still pondering on the options for how best to solve my issue.

- Yesterday

-

1977 280z clock issue #xx of yy

https://www.worldwayelec.com/pro/cs-elec/hd44001/4250271 https://www.1sourcecomponents.com/availability/HITACHI--HD44001.htm https://fr.excesschip.com/product/details/hd44001 https://de.excesschip.com/product/details/hd44001 These are the only things I was able to find online for the 44001. Not affiliated with any of these, so click on them at your own risk. The top place shows they have some with a minimum order of 100, but not sure how accurate that is. I couldnt find a datasheet on these, so not sure if they would need to be programmed or not.

-

1983 280zx na cranks wont start help

ZCarDepot has been good at sourcing parts. He shows a pickup coil for a ZX. The other parts are hard to find though. I've seen the bushings for sale in the past but not recently. Might be simpler to put in a 240Z distributor with a Pertronix conversion. Or a 280Z with an HEI module. Z Car Depot IncSearch: 38 results found for "distributor"New, used, and OEM repair and replacement parts for Datsun 240Z, 260Z, 280Z, 280ZX, and 510.

-

Wire identification

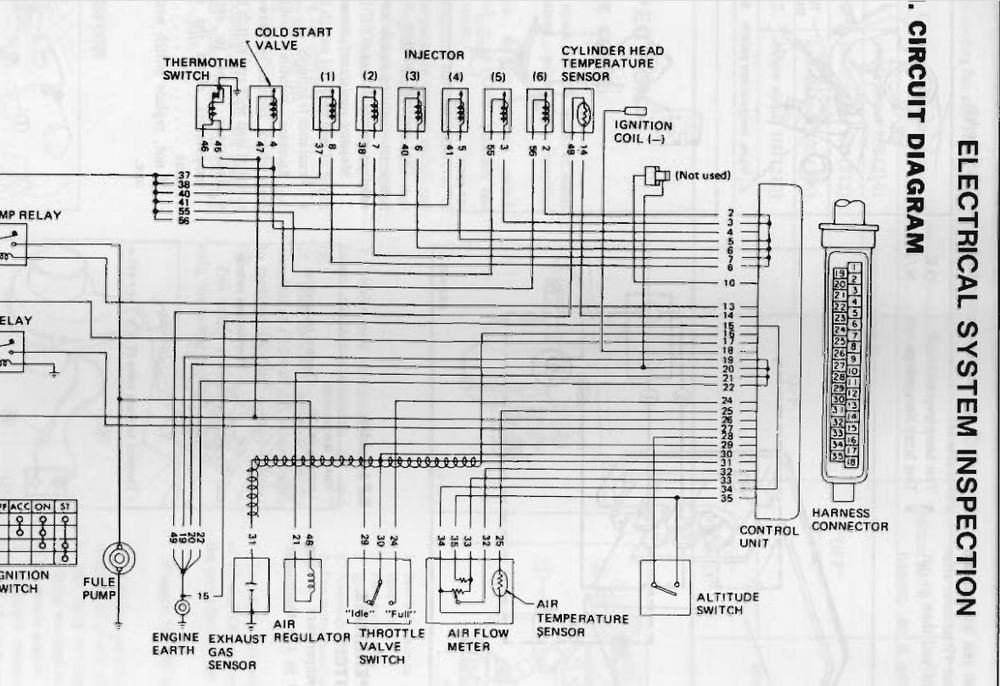

I found an old thread with several of us iin it. I feel kind of dickish reading my old comments. Hopefully I've mellowed. The 6801 has come up before, I'd forgotten about it. I also pulled up the 79 and 83 EFI ECU wiring diagrams and they seem essentially the same. Odd though that the 79 diagram doesn't show the O2 sensor circuit to the ECU. Just interesting that they apparently added the microprocessor to what had been a processor-free system. 1979 Uploading Attachment... 1983 Uploading Attachment...

-

55 year old Z master cylinder / slave cylinder

Thanks much guys. That certainly explains why there isn’t an internal spring. I kept seeing the later version, and was pretty sure I didn’t loose it.

-

1977 280z clock issue #xx of yy

I'm fairly certain the problem is either the crystal or the HD44001. I have voltage everywhere, get about a 4 volt drop across the resistor, and the little gear still doesn't spin. This was my spare clock I had pulled out of a junkyard years ago. The one in my car sometimes holds time, sometimes loses lots of time, depending on how it feels. I was hoping to try to see if these were possible to rebuild, and then just swap the clocks and do the same to the other after. I think its a metal resistor, but not 100% certain on that.

-

1983 280zx na cranks wont start help

Sorry meant to quote the air gap, link is the refurb it seems so I reckon I'll read threw it and try a repair

-

1983 280zx na cranks wont start help

Good call was finally able to get back to the car, the rotor bushing in the distributor seems shot now, it's just like the picture in the link. Anything I can do to fix that without buying new?

-

w3wilkes started following 55 year old Z master cylinder / slave cylinder

-

55 year old Z master cylinder / slave cylinder

Here's the early slave with spring tab. Motorsport Auto - The Z Store - Clutch Slave Cylinder, 70-72 240Z

-

EGR relay, can i remove it?

I am still thinking what to do about that indeed. Also the gas return spring on the flat tops is located on the carbs ofcourse. But atm i am planning to use the balancetube from the round top. Because it is been made almost to factory state. But then i have to find a new throtle linkage. I am also blocking off the coolant through the carbs. And then i but a sensor in the waterhousing. So that i can but electrical fans. Hoping it cools alot better. My old radiator was broken so bought that one also new.

-

Wire identification

Hi, quite a stir i made hihi... A 1979 eccs is without any microprocessor, i can tell you as a electronics engineer. Those round tin boxes (with cooling crown) are early integrated circuits, nice to see! Later on the plastic black boxes came. (Some are already on the printed circuit) The 6801 is a microprocessor and works with 0 and 1 signals of 0 and 5Volt. As far i know the switch was made between 1982 and 1983. Then analog "computing" became Digital computing where real microprocessors took over the work. I don't know for the USA But overhere in europe the 1983 280zx turbo was the first z with real processor in the managementsystem. (Europe never had a 280zx turbo before 1983!) All those boxes in 280z and 280zx were called ECCS until the 1983 turbo came out. (I belief..) (Don't hold me to it, i'm not a wizard, just remembering this stuff..) ;-)

-

Yarb started following 1977 280z clock issue #xx of yy

-

1977 280z clock issue #xx of yy

@Captain Obvious Very impressive analysis of the circuit. Thank the Lord I went to school for that!,

-

55 year old Z master cylinder / slave cylinder

-

1977 280z clock issue #xx of yy

Sorry for geeking out. I was on a roll. 😄

-

1977 280z clock issue #xx of yy

Your analysis of the parts is correct... Resistor, zener, capacitor - Those three parts are used for power supply and regulation*. They are relatively easy to source, and other than the zener voltage, the specs are relatively unimportant. By that, I mean... You could use a 180 Ohm resistor or a 150uF cap. Within reason, the values don't matter. The resistor will dissipate less than half a watt, so a one watt resistor would be fine. Composition (wirewound, metal film, carbon... Doesn't matter.) Crystal, and control chip - Those two are not easy to source. Hope that your problem is not one of those two. The HD44001 control chip does not appear to be available. Probably designed for the application and sold only to the clock manufacturer. And I would try hard to not mess with the crystal. The frequency is a little unusual, and even if you can find another crystal with "close enough" frequency, it's not guaranteed that it would work paired with the electronics inside the control chip. They are used as a shunt regulator system with the cap as a filter. System has about 30 mA quiescent current and therefor a little less than that in compliance.

-

How vibration free is your 70-71 240Z?

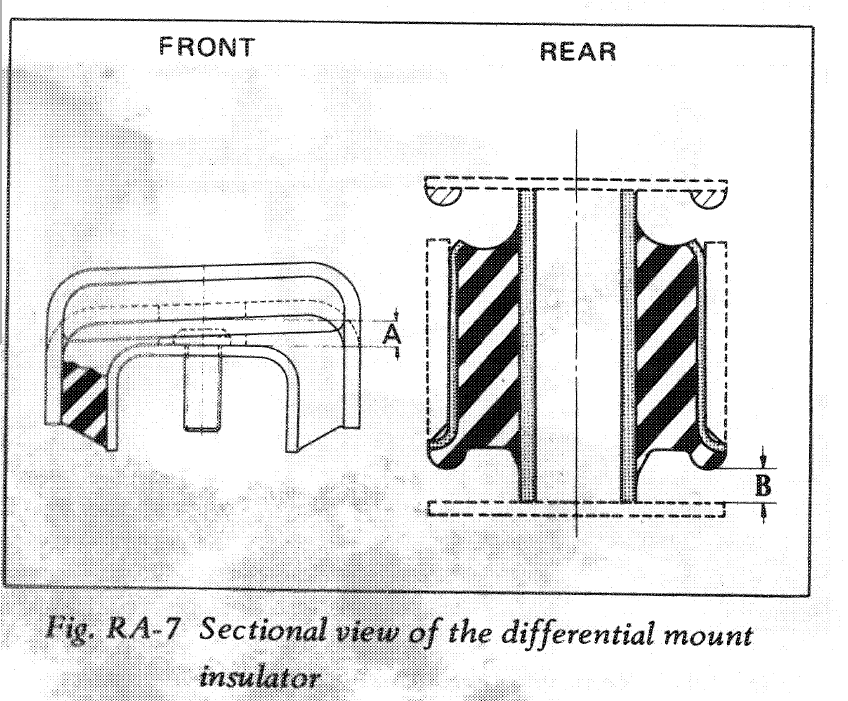

I played around with lowering the rear of the transmission today after work. I backed off the bolts securing the transmission mount (Techno Toys Tuning) to the body to see what kind of change in angle would result. Picture of the mount I have (for use with the 240SX transmission) in the early Z: Backing the bolts off to drop the rear of the transmission more than 5/16 of an inch only changed the angle from 89 to 88.5. I expected more change in angle. Anyway, now I am thinking through various things. I find myself asking why the front differential insulator mount has such a "large" angle to it. First of all, I confirmed that my insulator mount is part number 55415-E4102 (the early one). When looking at the factory workshop manual, the image clearly shows an inclination. As my car is sitting on the lift, I measured the inclination of the pinion flange, and it was 87.1 degrees. Why is it so far away from 90? I mean, the driveshaft is supposed to operate with less than 3 degrees of angularity on the u-joints. If I was able to match the 87.1 at the transmission, that would be 2.9 degrees on each u-joint. And, we all know that when power is applied to the input flange, the nose of the differential lifts upwards (i.e. the need for the "arrestor" belt which limits to differentials upward movement at the front). It seems to me, that instead of dropping the rear of the transmission down, it would be far better for me to change the angle of the front pinion flange, by either lowering the front of the differential, or raising the rear of the differential. Since I have used lowering springs to lower the car a bit, it seems to me that it would be more desirable to raise the rear of the differential. However, that would require modification of my stock parts here, perhaps removing the upper washers that have rubber bonded to them and replacing them with flat washers? I went through a fair amount trouble to source these washers as I am fairly certain they are what came originally on my 6/71 car. Further, I believe that the front differential mount, front differential insulator, rear differential mount, and rear differential mount washers are all as original for my car. So, I am baffled why the pinion flange angle is what it is. Am I missing something? How do I confirm that my front differential mount is the correct part number for my car - 55411-E4100 (used up through 6/71)? What is the difference between that one and the later 55411-N3001 used from 7/71 to 7/73