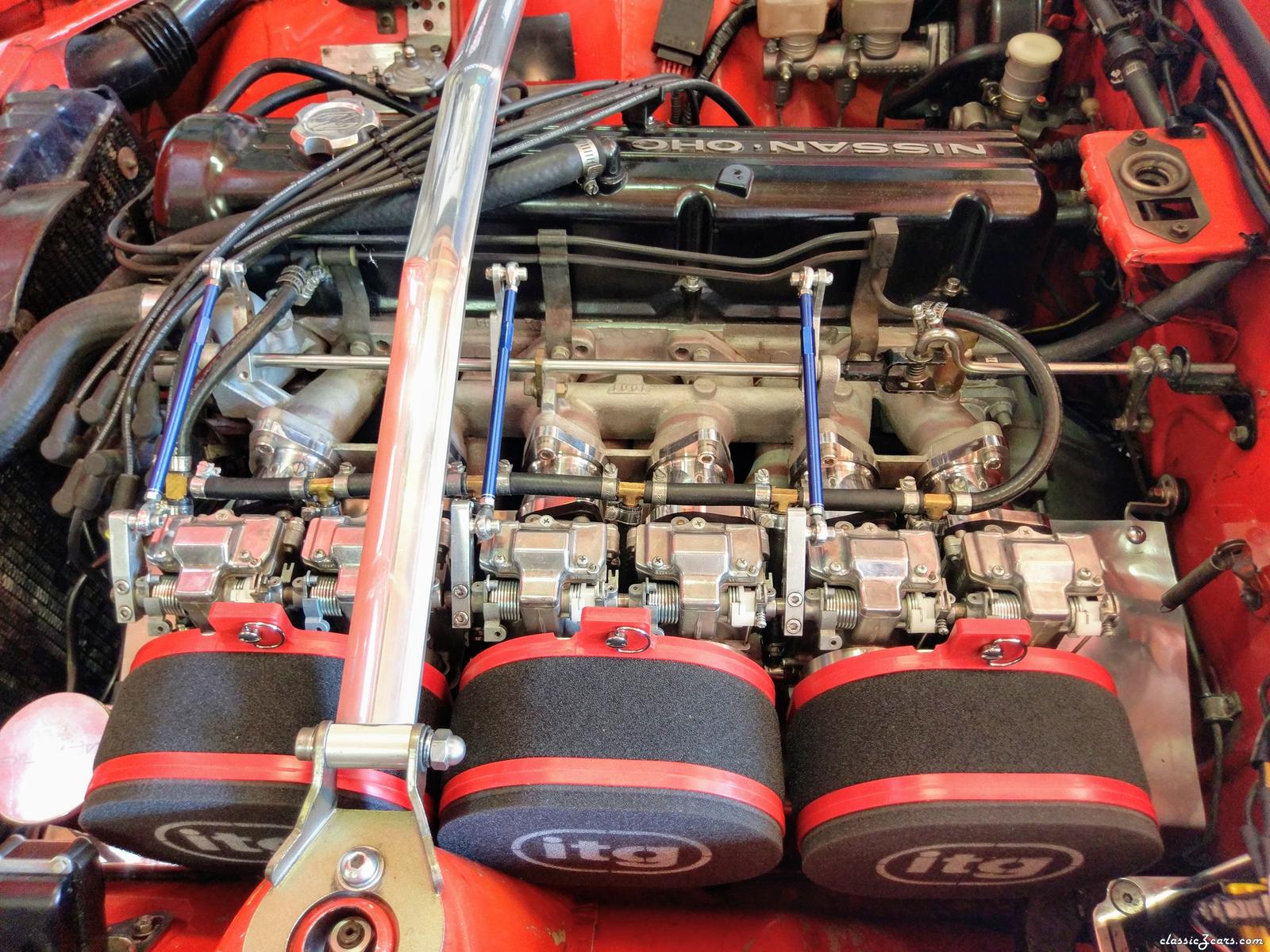

2400 OHC Cam Cover Before & After a Refresh

This is a - before and after - a refreshing image of a NISSAN 2400 OHC cam cover I recently did.

I enjoy doing these covers over quite a bit and just had to expand my cam cover storage rack to handle the growing crowd of them.

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now