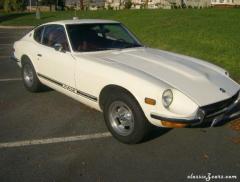

Hi everyone, I am in the final stages of a complete rebuild of my 72 Z. 133 thousand miles on the odo. Transmission is complete, head done with a midly agressive cam, block refinished and bored to .030, crank polished, ground and balanced. I had ordered a "complete" engine kit including fuel, oil water pump, all gaskets pistons, rings. This kit was ordered from a well known z car parts supplier.

I received the kit and a thourough inspection by me and my trusted mechanic exposed the following issues:

1. Head gasket was too thick and did not fit correctly.

2. Pistons were ITM make and skirts ( bottom) was 0.5-1mm wider than the piston head. They were also 26-30 grams heavier than the stock ones I removed. ( I know, the were 83.75 vs 83.00). Two of pistons weighed 1.5 grams more than the others, and one weighed 2.1 gram more. 487 grams was the base weight.

3. oil pump did not rotate completly

4. Timing chain guides had 1 small air bubble underneath the rubber coating

5. Timing chain was thin and not as robust as the stock one removed.

After an exhaustive internet search, the following corrective action(s) were taken:

1. Felpro oem gasket ordered ( $56.00) vs $22.00 kit Fits perfectly.

2. New " Silv-O-Lite pistons ordered from United Engine & Machine Company, Carson, Nevada. They have been in business since 1922. I also ordered new " perfect circle" rings from Mahle sizes 2mm 2mm 4mm. The web site for the pistons is: uempistons.com

2-5. New oil pump and timing chain kit from Beck Arnley

The pistons and rings should arrive Friday so I will update at that time. Attached are a few picks I will also downloads more soon, and document rebuild as much as possible.

Also am replacing the stock exhaust with a new 35 year old original "new old stock" ABARTH. See attached ad from the August 1973 Road & Track magazine.

Lon