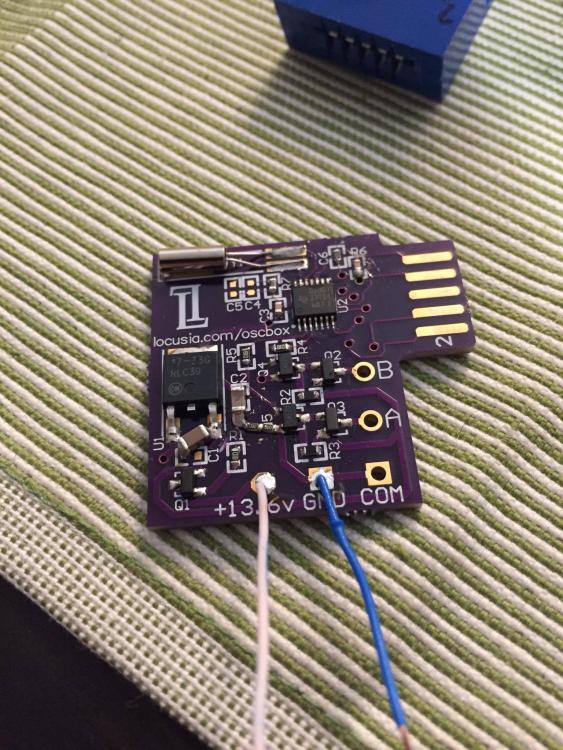

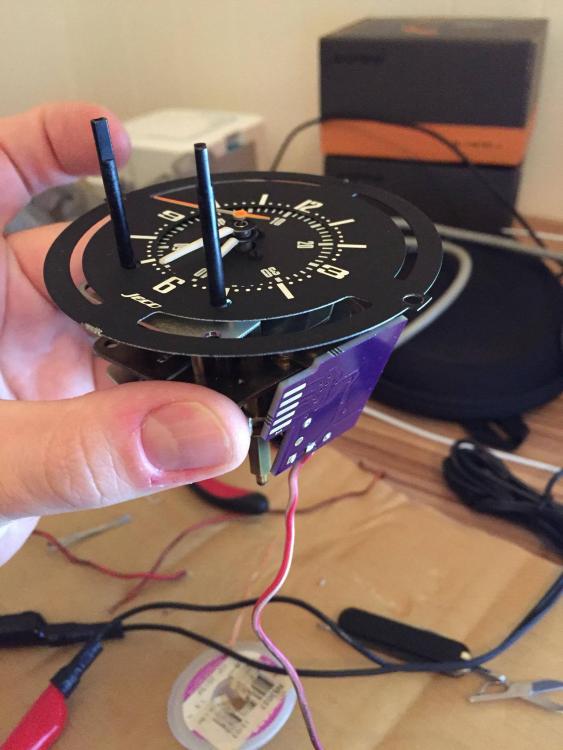

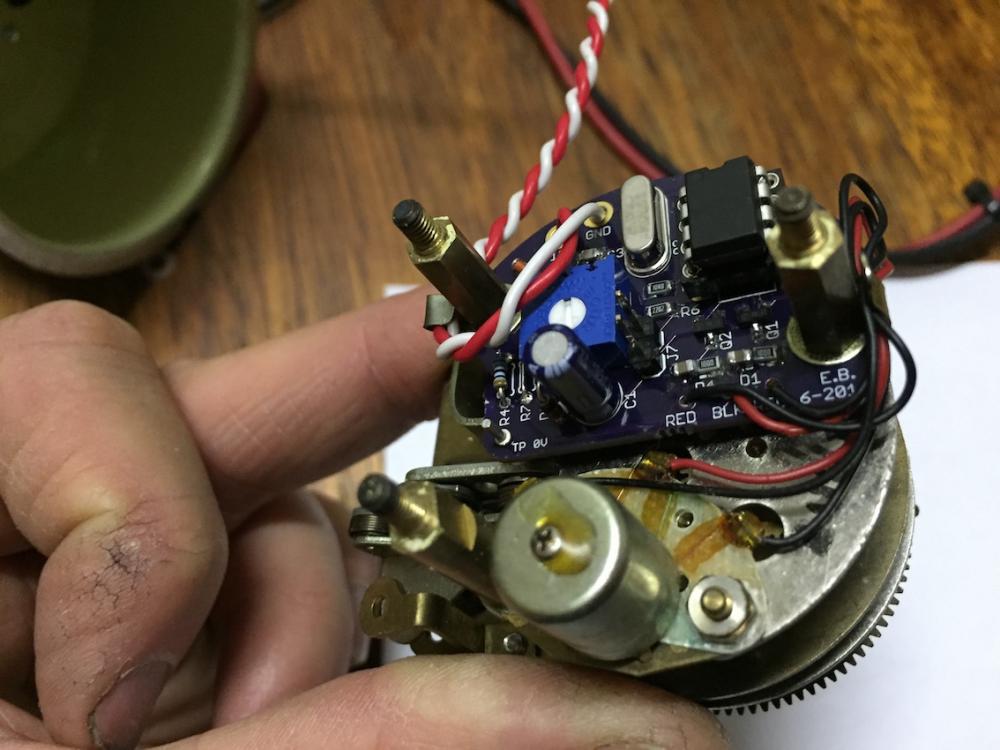

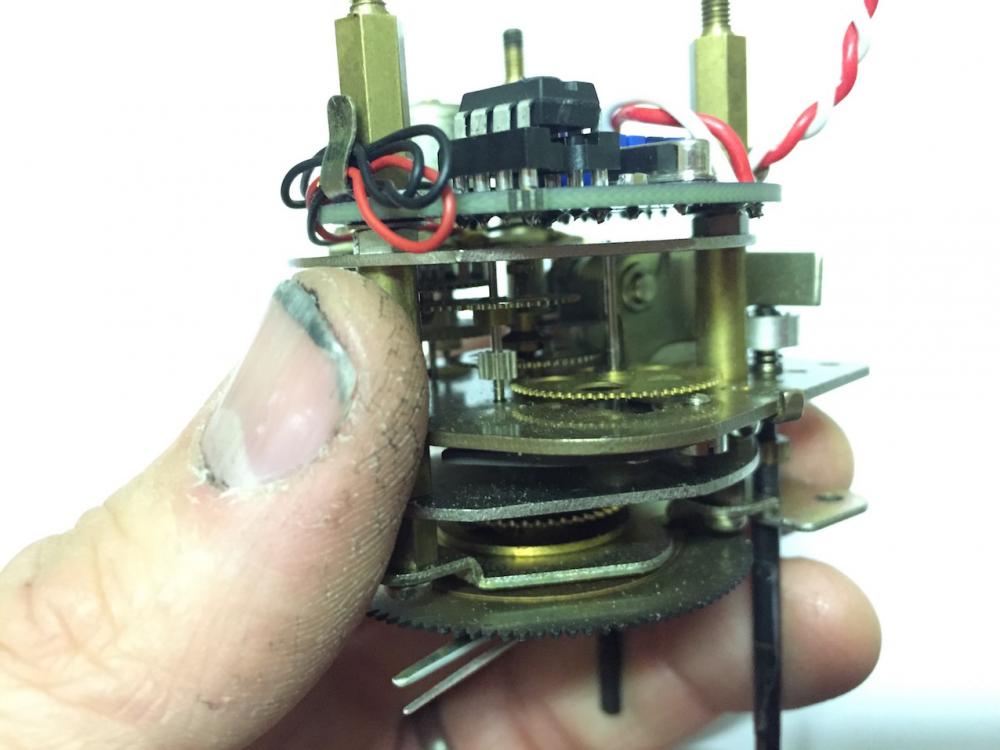

Update time. I've received the purple pcb oscillator and installed it. It's way smaller that it looks in the pictures. It took about 20 minutes to solder in the new board and bolt it in.

I will be testing it with my other clocks to see how accurate it is. Right now i've had it running a couple hours and its keeping accurate time.

It has built into it, reverse polarity protection for those of us that are electronically challenged, myself included.

I've ordered a small amount of boards as I don't anticipate many people will need them.

clock running with new purple oscillator

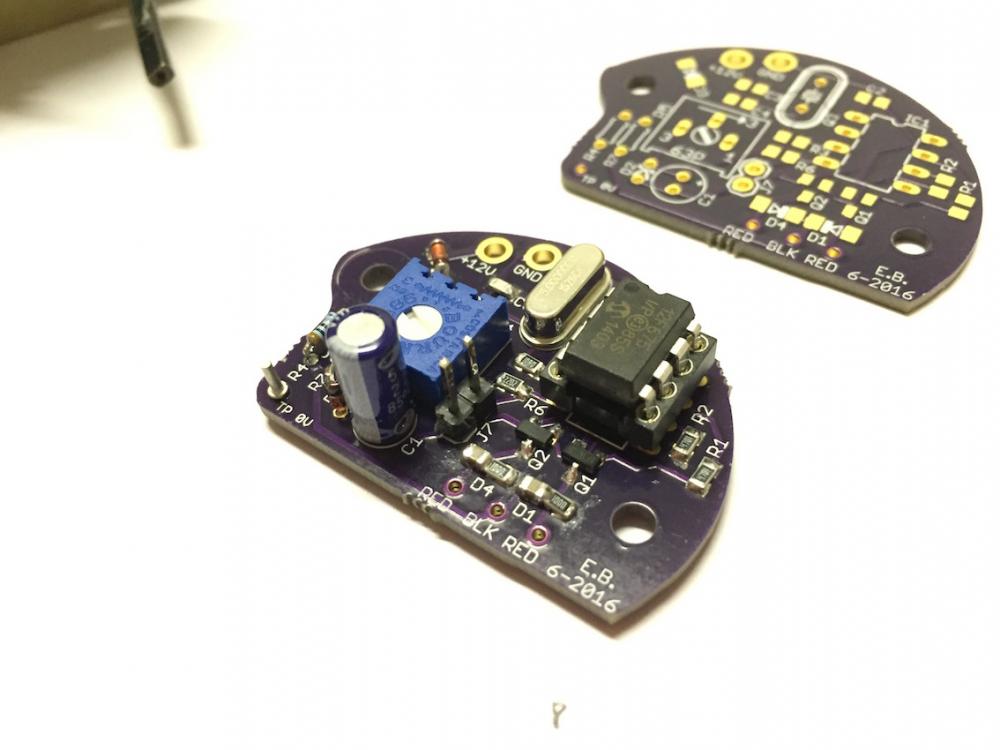

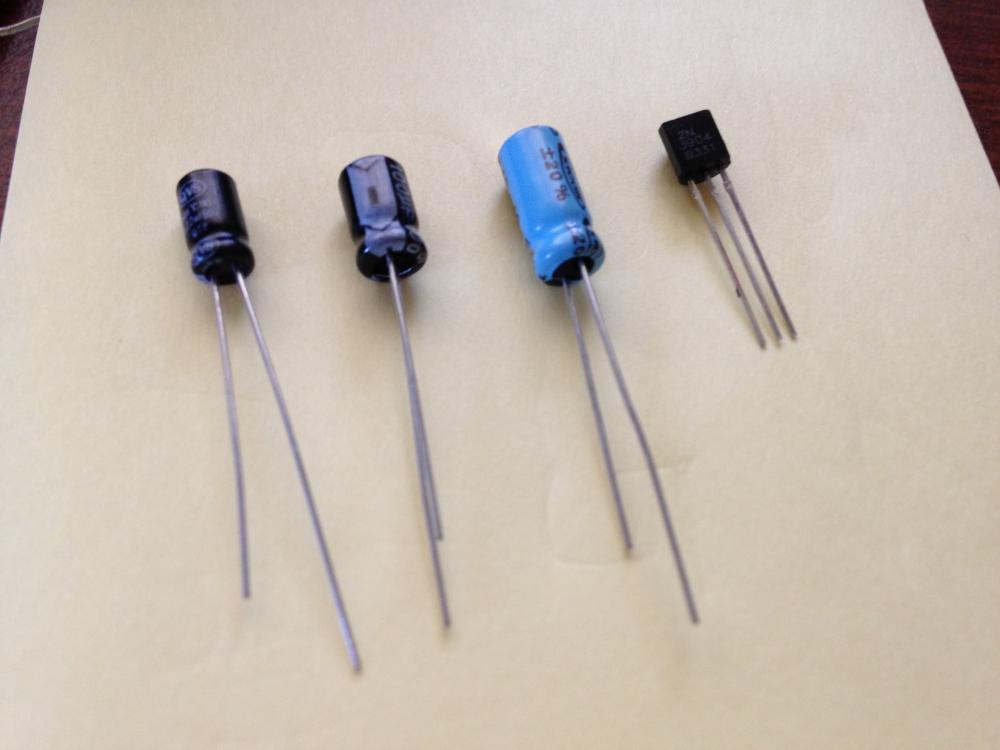

Reverse engineering this clock and running it on 21'st century electronics was no small feat. Here is some of the C code that Eric wrote for the prototype and resides in the

little IC chip. AWESOME work he does.

__________________________________________________________________________________________________________________________________________________

#include <htc.h>

#include <xc.h>

//#include <float.h> // do I need this?

#define _XTAL_FREQ 4000000 // Internal Oscillator... for now. Required

// for __delay_ms function

/* The configuration bits can be set in the IDE 'Configuration Bits' window,

* or they can be set here. */

// PIC12F675 Configuration Bit Settings:

/* CONFIG */

#pragma config FOSC = INTRCIO // Internal oscillator.

#pragma config WDTE = OFF // Watchdog Timer disabled.

#pragma config PWRTE = OFF // Power Up timer off.

#pragma config MCLRE = OFF // MCLR pin disabled, I/O function of GP3.

#pragma config BOREN = OFF // Brown-out detect off.

#pragma config CP = OFF // Program memory code protection off.

#pragma config CPD = OFF // Data memory code protection off.

unsigned int pulse_width_count = 0; // Used to adjust pulse width.

volatile unsigned int T_pot_setting; // Most sig 8-bits from pot ADC conversions.

volatile unsigned int F_pot_setting; // Use all ten bits, so need 16-bit word.

volatile char outputs; // bit0 for output 0 (GP0), bit1 for output 1 (GP1).

volatile unsigned int analog_reading; // The 10-bit ADC result.

/********************************* SETTING UP ************************************/

/*********************************************************************************/

void init_ports(void){

// Set input & output pins: GP2 (AN2) and GP4 (AN3) set as inputs for analog signal,

// GP3 can only be input.

TRISIO = 0b00011100;

// Comparators off.

CMCONbits.CM = 0b111;

// Analog input register ANSEL set in setup_ADC() below.

}

////////////////////

void setup_osc(void){

;

// Nothing to do here. The oscillator is set above by setting the FOSC bits.

// OSCCAL = 0x00; // Shouldn't be needed.

}

////////////////////////

void setup_timer1(void){

// Timer1 is 16-bit. It will count to 65535 before overflowing.

// With a 4MHz internal clock (Fosc), the instruction clock operates at 1MHz:

// (Fosc/4, so Tcyc = 1usec).

// With a desired interrupt time of 11.43msec, we have 11430 instruction cycles,

// which is under the 65535 cycles possible with Timer1. So using Timer1 should be

// fine!

T1CONbits.TMR1ON = 1; // bit 0 = 1: TMR1ON -> turn timer on.

// bit 1 = 0: TMR1CS -> Clock source = Fosc/4.

// bit 5,6 = 00: T1CKPS -> prescaler = 1:1 - no scaling.

}

/////////////////////

void setup_ADC(void){

// Pulse_Width is analog input on AN2.

// Pulse_Frequency is analog input on AN3.

// Set ADCON0 configuration bits:

// ADFM = 1 : ADC result right justified as we will use all ten bits. Two most

// sig bits in ADRESH, the eight least sig bits in ADRESL.

// VCFG = 0 : ADC reference is Vdd pin.. for now.

// <CHS1:CHS0> = 0b10 (2dec) to select AN2 input, (<CHS1:CHS0> = 0b11 3dec) for

// AN3 input.

// ADON = 1 : Turn on the ADC.

ADCON0bits.ADFM = 1; // ADC result right-justified.

ADCON0bits.CHS = 3; // Select AN3 for ADC for first conversion (freq).

ADCON0bits.ADON = 1; // Turn on the ADC.

// Set ANSEL configuration bits:

// <ADCS2:ADCS0> = 101 for 4us TAD conversion time (datasheet recommended for 4MHz

// clock). Analog input on AN2 (GP2) set for pulse time adjustment pot, and AN3

// (GP4) for frequency adjustment pot.

ANSELbits.ADCS = 0b101;

}

/**************************** INTERRUPT SERVICE ROUTINE ***************************/

void setup_timer1_interrupt(void){

// Timer1 is a peripheral, so peripheral interrupts must be enabled

// (and also global interrupts).

TMR1IF = 0; // Clear Timer1 Interrupt Flag.

PIE1 = 1; // Enable Timer1 Interrupt.

PEIE = 1; // Enable Peripheral Interrupts.

GIE = 1; // Enable Global Interrupts.

}

void interrupt ISR(void){

// Interrupt Service Routine

// This interrupt it called at twice the motor (electrical) frequency.

// Timer1 has timed out so we must aternate the GP0 and GP1 outputs.

// The interrupt activates on overflow, so the starting value of the timer

// must be determined to get the correct timer period. Calculations at end

// of code.

// Here we read and manipulate the last ADC result and initiate the next ADC

// conversion. We will perform ADC on the two analog inputs alternately

// (one for pulse frequency, and one to control the pulse width)

// In reversing the pin polarity, the pins themselves are not reversed as they

// might both be 0 (as the expiration of pulse_width_count will set both outputs

// to zero). So 'outputs' records the last setting of output pins, and it is

// 'outputs' that is reversed. This is then copied to the GPIO pin register.

TMR1 = (0xDC00 - F_pot_setting); // Reset TMR1.

outputs = outputs^0b00000011 ; // XOR - reverse outputs for GP0 and GP1.

GPIO = outputs; // Assign 'outputs' to actual output pins.

// Alternately update the Frequency setting (F_pot_setting) and pulse width

// (T_pot_setting).

if ((outputs & 0x01) != 0){ // Set pulse width.

analog_reading = ADRESL + (ADRESH * 256); // Change 10-bit value to 8-bit

T_pot_setting = (analog_reading >> 2); // value (max 255).

ADCON0bits.CHS = 3; // Change A/D channel to measure Frequency pot

// next time around.

__delay_us(50); // Delay after channel swap, avoids cross-talk.

}

else{ // Set pulse frequency.

analog_reading = ADRESL + (ADRESH *256);

F_pot_setting = (analog_reading << 1); // Mult by 2 to scale to 0x7FE.

ADCON0bits.CHS = 2; // Change A/D channel to measure pulse width pot

// next time around.

__delay_us(50); // Delay after channel swap, avoids cross-talk.

}

ADCON0bits.GO_DONE = 1; // Start next A/D conversion.

pulse_width_count = 0; // Reset counter for pulse width.

// GPIO5 = 1; // Turn on LED at GP5 - program running.

TMR1IF = 0; // Reset Timer1 overflow interrupt flag.

return;

}

/********************************** MAIN PROGRAM **********************************/

/**********************************************************************************/

void main() {

setup_osc();

init_ports();

setup_timer1();

setup_timer1_interrupt();

setup_ADC();

outputs = 0b00000001; // Initialise output pulses variable with pulse

// at GP0.

GPIO = outputs; // Write to GPIO register.

// Turn on LED at output GP5 - program running.

while(1){

pulse_width_count++; // Delay chosen so that that 255 (0xFF)

__delay_us(28); // increments take up the full 11.4 millsec.

if (pulse_width_count > T_pot_setting){

GPIO = GPIO & 0b11111100; // Turn off outputs.

GPIO5 = 1; // debug - turn on LED

pulse_width_count = 0; // Reset so we don't keep coming back.

} // if

} // while

} // main

/* Determining the Timer1 starting value for interrupt for clock frequency:

*

* The clock I tested needs the outputs to be alternated every 11.43 millisec

* for the clock to operate at about the right speed.

* The microcontrller clock speed (Fosc) is set to 4MHz in the config parameters

* at the start of the program. Timer1 increments with each instruction cycle which

* is equal to Fosc/4 = 1MHz, so it increments at 1 microsec intervals. For 11.43

* millisec, the clock increments 11430 times. As the timer interrupts at overflow,

* then the timer must start at 65535 (0xFFFF) minus the 11430.

* 65535 - 11430 = 54105 (0xD359) approx.

* The result from the A/D converter is 10-bit, i.e. 0-1023 (0x00 - 0x3FF).

* This permits an adjustment time of about 1 millisec. If I want an adjustment

* time of +/- 1 millisec (2 millisec) then I will double the A/D conversion result.

* So the timer starting point will have to be about 0xD539 + 0x3FF, so that up

* to 2 * 0x3FF can be subtracted from it. So starting point will be about 0xD938.

* This is approximate as there will be some latencies in processing the code, etc

* The final value will be higher and determined experimentally. So we should

* have a range of about 9.4 millisec to 11.4 millisec with the 'correct'

* 10.4 millisec setting when the control pot is set to the middle position.

*

* Determining pulse width:

*

* The output of the pulse width pot is saved as an 8-bit value: 0xFF (255 decimal).

* At lowest frequency, the pulse width above will be up to 11.4 millisec, so we

* need the pulse width counter to increment at 45 microsec at a time (45us * 255

* = 11.5 ms. An added delay of 28 microsec resulted in desired increment delays .

*

*/

.jpg.865598d091dc5456fca1c6c77ed10636.jpg)

.jpg.3c8160f20d0cc41cafe2e63640f4dab4.jpg)

.jpg.d4466d7903d86d9dd83762cf8b06db11.jpg)

.jpg.81daa98527b2b50087a9019501a7556a.jpg)

.jpg.45b57c7995c158d0b938900a1e413d96.jpg)

.jpg.f1e1bad67a69814bc5d8c36c207cad81.jpg)

.jpg.d18e9b9eb5ceb4904d8b9e056ab0d1fd.jpg)

.jpg.dfd008eff0ca9b7a0e547a189d38edaa.jpg)

.thumb.jpg.d624ef33f6b2a5f1541cbe56e927cb37.jpg)

.png.ae0f62fbefb2e0eff4899bfd9341b9ba.png)