1952 Datsun produced their first sports car, the DC-3 "Datsun 20" RHD. They made 70, sold only 30, then converted the remaining 40 back to trucks.Japan was not ready for a Nissan sports car in 1952.

1959-60 Datsun produced their second sports car, the SP211 "Datsun 1000" RHD. They made only 20. Again Japan was not ready for a Nissan sports car in 1959.

1960-61 Datsun produced their third sports car, the SPL212 "Datsun 1200" LHD They made 228. Nissan skipped the domestic market and made all (100%) for the USA market.

1961 Datsun produced their fourth sports car, the SPL213 "Datsun Fairlady" LHD They made 217. Nissan again skipped the domestic market and made all (100%) for the USA market.

1962 Datsun produced their fifth sports car, the SPL310/SP310 "Datsun 1500/Fairlady" LHD/RHD. They made 6460. ~4160 (64%) for USA market.

1965 Datsun produced their sixth sports car, the SPL311/SP311 "Datsun 1600/Fairlady" LHD/RHD. An iteration of the SLP-310. They made 27,400. ~26,430 (96%) for USA market . The first successful sports car sales!!!

1965 Detroit officials were called to testify on automobile safety before the Senate Government Operations Subcommittee on Executive Reorganization chaired by Sen. Abraham A. Ribicoff.

1966 Changes in USA safety regulations make continued production of convertibles more challenging. National Traffic and Motor Vehicle Safety Act of 1966 gave regulators until January 31, 1967 to develop federal motor vehicle safety standards that were practical, stated in objective terms, and met the need for motor vehicle safety.

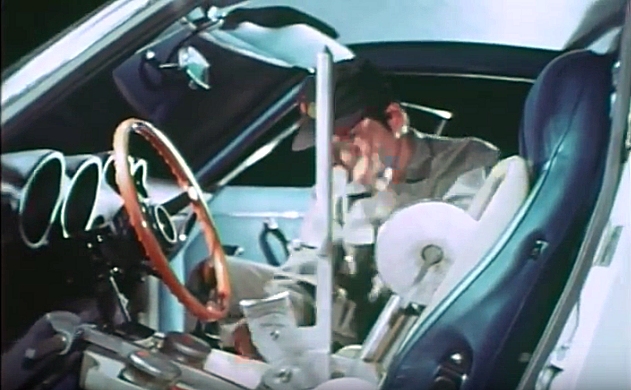

1966 August. All Datsun 240Z sketches and clay models from designers up to August 1966 were convertibles. Model "A11" had an optional hard top affixed similar to the one used by designers to retrofit to the SPL310 (Figure 2 below). It is clear the direction of design changed at this point.

In Q3/Q4 of 1966, Datsun designers made their first 240z model with a full hard top. It was design model "C3.

Oct. 11, 1967 Federal Highway Administration (FHA), the National Traffic Safety Bureau (NTSB) issues an Advanced Notice of Proposed Rule Making (ANPRM) on 47 issues, including roof intrusion, seeking public comment.

1967 Datsun produced their seventh sports car, the SRL311/SPR311 "Datsun 2000/Fairlady" LHD/RHD It was again an iteration of the SPL-310. They made 14,990. ~12,880 (86%) for USA market.

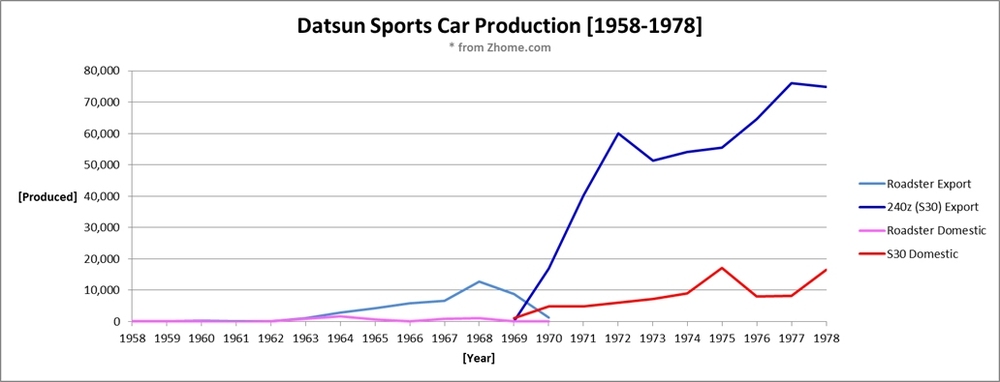

Figure 1. Datsun Production Sports Cars Preceding the 240z

After a testing of the waters for selling sports cars in Japan in 1952 and again in 1959, it was clear that the domestic market was not ready for sports cars. Datsun immediately re-focused on the USA market for selling sports cars. For the next two model years from 1960 to 1962 they produced only LHD models and only for the US market. Although the market and production numbers were small. Nissan management had chosen to go after the USA sports car market early on. Unfavourable post-war trade barriers with many other countries may have also shaped Nissan's export focus on the USA at this very early point. Countries in Europe traditionally manufactured small cars where as in the USA cars were typically large. Having small Japanese cars enter the market in the USA presented nearly zero competition with the large car manufacturers however, in Europe small Japanese imports would have competed directly with all manufactures so protectionist tariffs were maintained against Japan.

In 1962, Datsun re-designed/styled the convertible. This new design (SPL-310 Datsun 1500) remained relatively unchanged until all convertible production ended in 1970.

In 1965 and 1966, production numbers were up, and sales in the USA were growing exponentially however, changes in the safety requirements for automobile design in the USA were well underway. In 1965, preliminary documents from the USA Govt. the creation of new Govt. automotive safety agencies, and discussions throughout the industry & media pointed to significant safety challenges to come for manufacturers of convertibles. At this time, manufacturers had no details regarding the extent of the new rules to come so it was anyone's guess as to how difficult it would eventually become to produce a convertible that would meet the impending new requirements. The fact that new roll-over tests were required made convertibles seem vulnerable to failing this test.

Immediately after the US Govt. began the process to increase safety requirements, Nissan management began to re-risk and focus on developing a new enclosed coupe. Up to that point, all Datsun sports cars were convertibles*. To continue expanding into the USA market without risk, it was clear that a convertible was not the way. A coupe would guarantee a path through the impending stricter safety requirements. In fact, Datsun did not significantly change the design of their 1500 sports car beyond that point in time apart from some engine changes and safety compliance changes. It was clear they were done with it apart from churning out more as it was most profitable to continue an existing product. Almost immediately after the new regulations warning, contingency stop-gap tests occurred (in case the safety requirements changes came earlier). One such test in August of 1966 was the fitting of a large hard-top roof to their popular SPL-310 convertible.

Figure 2. Datsun SP-310 Testing Optional Hard Top August 1966

Figure 3. Datsun 240z Convertible Prototype Model "A11" with Optional Hard Top ~July, 1966

It should be noted that during the design and development of the 240z, the designers and engineers at Nissan had to keep abreast of the evolving USA safety standards. As mentioned by Mr. Takeshi Kume Tamura, the Chief designer of the 240z during its final stages prior to going to a prototype: "During this time, design changes occurred such as significant changes to size of the complete body, modifications to the fenders, due to the change of the wheel, and changes to the design to match American safety standards".

By the end of the 60's Datsun had produced ~ 50,000 convertible sports cars . The expected stringent safety restrictions did not materialize however Datsun had moved away from the convertible and completely stopped convertible production in 1970.

Of all Datsun Sports Cars produced prior to the 240Z, approximately 44,000 (88%) were LHD sold in the USA market.

Whereas sales in the USA market grew substantially for Nissan throughout the 60's, domestic sales did not significantly change. Nissan management would have observed this pattern as it evolved through out all of the 60's.

From the graph below, it is clear to see that domestic sales of Datsun sports cars (convertible and S30) did not show significant growth for the convertibles or even later with the S30. On the other hand, the convertible grew in the USA market and the 240z design exploded in the USA market.

Prior to the 240z, the convertible sport cars growth was only in the USA.

1969-1970 production crossover from the convertible to 240z is easy to see. One product ramped up and one ramped down, This was partly due to sharing of some production facilities.

Production for both convertibles and the 240z confirm Nissan's management made a wise decision to go after the USA sports car market.

Low sales in the domestic market did not warrant the need for so many iterations of the S30 platform however the iterations were done and they seem to be more for the requirements of automobile racing that Nissan was involved in since Mr. K's stimulus in the 1950's. Rally racing, the avid road racing scene in Japan, and the success of road racing roadsters in the USA during the 1960's were the prime drivers for small quantities of variants to the standard model sold in Japan. The basic models sold in Japan and the USA came with L engines (2.0 litre for the domestic market and 2.4 litre for the USA).

Nissan's determination for the 240z to succeed in the USA market is exemplified by the additional pre-release road testing they did in North America above and beyond the their standard product development and certification testing done in Japan.

Nissan's sports car sales success to this day is traceable to the fact they had chosen to go after the USA sports car market at an early stage rather than most other manufacturers in Europe who focused on local markets first. This ultimately shaped Nissan's continued success where as many others failed to make a sports car for the USA market like the 240z.

Nissan successfully designed for, and successfully sold in the largest sports car market place in the world... the USA.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

General Service Administration (GSA) Published the following 17 new standards on June 30,1965. More were to come.

Anchorage for seat belt assemblies.

Padded dash and visors.

Recessed dash instruments and control devices.

Impact-absorbing steering wheel and column displacement.

Safety door latches and hinges.

Anchorage of seats.

Four-way flasher.

Safety glass.

Dual operation of braking system.

Standard bumper heights.

Standard gear quadrant, P-R-N-D-L, automatic transmission.

Sweep design of windshield wipers-washers.

Glare reduction surfaces.

Exhaust emission control system.

Tire and safety rim.

Backup lights.

Outside rear view mirror.

FEDERAL REGISTER NOTICES:

31 (March 8, 1966): 4091, GSA proposes safety standards for Federally purchased vehicles.

31 (July 15, 1966): 9631, GSA final rule, safety standards for Federally purchased vehicles.

31 (December 3, 1966): 15212, NPRM for the initial FMVSS.

32 (February 3, 1967): 2414, final rule for the initial FMVSS, including FMVSS Nos. 103, 105, 108, 201, 203, 204, 205, 206, 207, 208, 209, 210 and 301. [Notable technologies are seat belts; energy absorbing steering assemblies; door locks, latches, and hinges; occupant protection in interior impact; dual cylinders /

Front disc brakes; and trailer conspicuity tape.] 32 (October 13, 1967): 14278, ANPRM to consider regulations to limit roof crush and intrusion.

32 (December 16, 1967): 18033, final rule extending FMVSS No. 108 to cars and LTVs.

32 (December 28, 1967): 20865, NPRM to establish FMVSS No. 202 for passenger cars.

33 (February 14, 1968): 2945, final rule establishing FMVSS No. 202 for passenger cars.

33 (August 16, 1968): 11652, final rule establishing FMVSS No. 212 for passenger cars. [Adhesive windshield bonding]

33 (October 5, 1968): 14971, ANPRM announcing the intention to regulate side door strength.

33 (December 11, 1968): 18386, first NPRM proposing FMVSS No. 214.

34 (January 24, 1969): 1150, final rule extending FMVSS No. 206 to trucks, buses and multipurpose passenger vehicles. 34 (July 2, 1969): 11148, initial ANPRM to consider air bags or other automatic protection.

__________________________________________________________________________________________________________________________________________________________________________________________________________________________

Below the next few photos are Roof Crush Testing and Policy Development in the USA that Nissan would have been aware of with their Eastern USA Vice President's Mr. Soichi Kowazoe's Liasons with DC (It is interesting how this timeline fits with 240z prototyping and affected roof height changes during the 240z development process):

Measuring Roof Height as per FMVSS 208 & 216 (Passenger Restraining in Crash/Roll Over and Roof Crush)

FMVSS 208 Roll Over Testing 240z with DOHC Engine. (Note Split Exhaust)

FYI: Prototype "CA-4" 240z with Split Exhaust

In 1962 the Impact and Roll-Over Test Procedures Subcommittee of the Society of Automotive Engineers (SAE) was formed in order to develop test procedures for evaluating vehicle structural integrity under various types of impacts. (Deadly By Design reference 14) The subcommittee's members included representatives from General Motors (and Fisher Body - a division of General Motors), Ford Motor Company, Chrysler Corporation, Kaiser Jeep Corporation, International Harvester Company, Volkswagen of America, Inc. and American Motors Corporation. (DBD - 15)

In June 1963 the subcommittee developed and approved the SAE Recommended Practice, "Roll-Over Tests Without Collision - SAE J857." (DBD - 16)

On October 6, 1966 the Secretary of Commerce announced the development of initial Federal motor vehicle safety standards pursuant to the National Traffic and Motor Vehicle Safety Act of 1966. (DBD - 34) The Static Crusher was then being developed at Fisher Body by James Augustitis, an associate senior research engineer. (DBD - 35) Fisher Body was responsible for building the vehicle bodies for General Motors.

In August of 1967 the Impact and Roll-Over Test Procedures Subcommittee developed and approved SAE Recommended Practice, "Inverted Vehicle Drop Test Procedures - SAE J996." (DBD - 36)

By mid August the subcommittee's work on test procedures was nearing completion. Members used the top drop test procedures as a means for obtaining values for drop height and encroachment distance. The procedure was designed to be a repeatable and reliable test methodology. It was concluded that initially vehicles should be dropped from 2 feet. (DBD - 37)

Only a week or so after the subcommittee's Inverted Drop Test - SAEJ996 was approved, and the recommended drop height of 2 feet was initially established, Fisher Body dropped two 1967 Chevrolet "B" 4 door hardtops from 6 inches which resulted in 8 inches of dynamic intrusion.(DBD - 38) Fisher Body tested the same 1967 Chevrolet "B" 4 door hardtop with the static crusher and the vehicle's roof withstood 6000 pounds withjust 3 inches of crush. (DBD - 39)

Immediately after General Motors' vehicles failed the two drop tests on September 6 and 7, Ed Klove of Fisher Body prepared a proposal of a Roof Crush Test Procedure. (DBD - 40) P.O. Johnson of Fisher Body (and also a subcommittee member) presented Klove's proposal to the SAE Impact and Roll-Over Test Procedures Subcommittee on September 29, 1967. Klove's proposal stated its advantages: "more impressive numbers are obtained - three inches crush for 6000 lb. load. (A six inch vehicle drop height allowing eight inches crush is not impressive)." (DBD - 41) Fisher Body now realized that all their vehicles would not even meet a drop height of 6 inches. (DBD - 42) Klove's proposal dared to pose the question, "Who can say that it does not provide as good a measure of vehicle safety as does an inverted drop test?" (DBD - 43) It was Klove's idea to suggest this test procedure as an alternative method of showing compliance.(DBD - 44) Fisher Body's nickname for the Static Crusher was "GOLDFINGER." (DBD - 45)

On December 8, 1971, NHTSA adopted General Motors' proposal (one that GM's vehicles could already pass) (DBD - 47) and announced that FMVSS 216 was being created as a temporary alternative to FMVSS 208 rollover testing. (DBD - 60)

The December 11, 1971 NHTSA News Release read: "The new standard is intended as an alternative to Standard No. 208 rollover test, and will become effective on August 15, 1973.

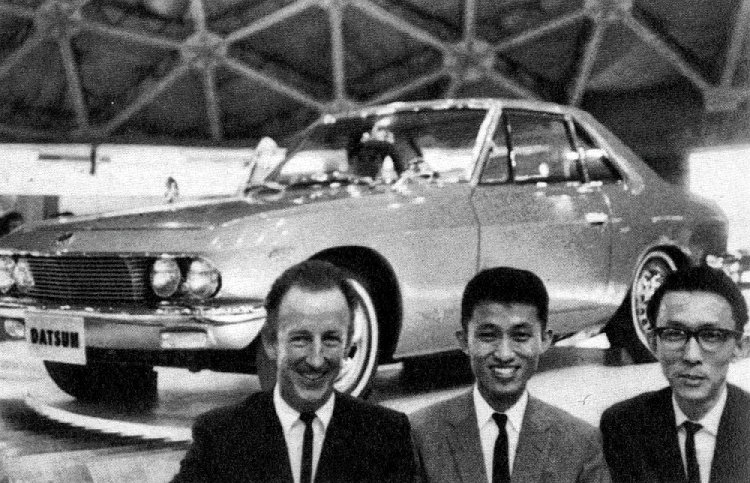

End of the line for Goertz at Nissan: Oct 1964 Tokyo Motor Show (CSP-311 Silva Coupe) Note earliest 240z sketches were ~ 1 year later.

* apart from the CSP-311 Silva coupe that was more of an experiment. It was difficult to produce (only 554) and sold poorly like the DC-3. It was a good learning experience for Nissan as to how not to design a coupe.