My pleasure. Glad to help. So did you see the pic of the aftermath of the party? https://www.classiczcars.com/forums/topic/60026-friends-over-for-a-party-in-the-shop-yesterday/

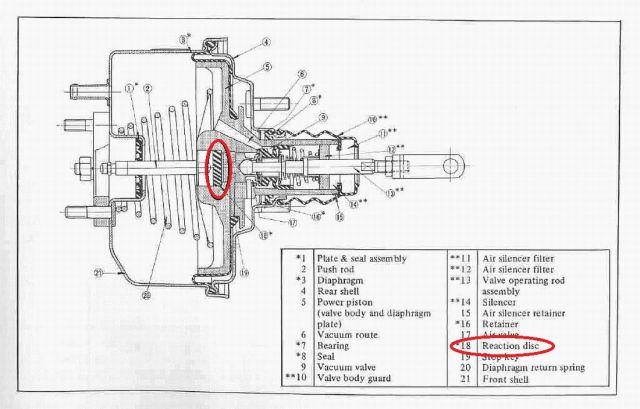

So to provide a little more info about Matthew's bearings... The shop that had previously worked on the car really screwed things up.

They had forced the spindle pin tapered retainer pins into place without having the spindle pin located properly. This not only ruined the taper pin, but raised a huge burr on the (brand new) spindle pin and we had to use the hydraulic press just to get the spindle pin out.

And the problem that Matthew originally noticed when he got the parts back from the shop was that the stub axle didn't spin freely, and had significant tight and loose spots when it spun. We traced this issue to a huge burr kicked up inside the strut housing on the bearing surface from them pressing the bearing in cockked at an angle. In other words... It wasn't straight, wouldn't go in, and they just kept applying more force instead of stopping to figure out what the problem was.

We dressed the upset material (high spots) off the inside of the strut housing and cleaned and inspected everything to make sure there weren't any other surprises. Once the burrs were removed, the new bearings went in fine and everything spun perfect. We dressed the burrs off the spindle pins, and after that, they went back into the housings OK as well.

And if that's not enough... They had ground down one of his distance pieces on a belt sander. Not only was it not square on one end, but it was also now almost .100 too short. When you tightened the stub axle nut, it would pull the inner races together so tight that you couldn't turn the axle.

And they're professionals!!

I chucked up the distance piece in the lathe today and squared up the end. Won't ever be able to be reused for a distance piece, but it sure makes a handy drift for doing future wheel bearings. Into the box of misc stuff that lives next to the hydraulic press!

It was a good day in the shop.