Leaderboard

-

SteveJ

Free Member7Points9,567Posts -

nix240z

Free Member4Points468Posts -

Zup

Free Member4Points1,163Posts -

dmorales-bello

Free Member3Points627Posts

Popular Content

Showing content with the highest reputation on 03/11/2019 in all areas

-

Patton Machine Fuel Injection

6 pointsI just received notice that the shipping label has been prepared. The fun will commence soon. ?6 points

-

Complete roof R&R

3 pointsa few pics... after replaced roof skin... multi layers of metal.... sunroof skin out... drill spot welds from top lead front pillar.. donor roof ... drill spot welds from bottom/inside on this one. after.....3 points

-

Let's show vintage racing pictures. I'll start.

The above photo is of Andy Flagg's record setter and those B & W photos are of the #33 GTU BSR shell. They were on a roll of undeveloped 35mm film that was part of the trailer full of BSR parts we purchased several years ago.3 points

-

Engine lift for front cross member removal

2 points

-

[2019] What Did You Do To/with Your Z Today?

Hey Jim, the red/blue illumination lead you can connect in parallel with the blue +12v power, to see if the bulbs for lighting are functioning. Look forward to your feedback on the chrome pen.2 points

-

Let's show vintage racing pictures. I'll start.

The car in the B&W photos I’ve owned since 1980. There is a picture of the car on a Page 50 -Orange #39.Well funded National car. The pictures were from 1977 when it was built. You’re confusing it with Sharp’s car because the same fabricator built them2 points

-

Replacement tar mat

1 pointAfter 8 years of fits and starts restoring "Buttercup", a 7/70 build date 240Z (#7032) it has come down to the interior, which was completely stripped and the old tar mat removed. While "Murdermat", "Fatmat", and the like are what are commonly used as upgrade/replacement--- I wanted the original deal--- as close to the factory fitment as possible. After lots of net searching I finally found what I thought would be as near the original asphaltic mat as I was apt to find. I bought the mat from AutoAtlanta FOR PORSCHE: WU890100, WU8 901 00 - READY TO SHIP - (WURTH FLOOR PAN TAR SOUND DEADENING INSULATING KIT) , a purveyor of restoration parts for Porsche autos: I used a roll of rosin paper to trace the original floor mat outlines---- from the interior of another '70 240Z I had purchased as a parts car---- and cut out the patterns , traced it again and cut the new mat out with scissors. Here's how that looks: Next I proceeded to install the mat using a heat gun and a couple of hand tools to shape the mat to the sheet metal contours of the floor pans, transmission tunnel and rear hatch floor: The mat has an adhesive and a release paper and when heated can be formed easily to the contours of the metal. It took several hours to create the patterns and do the install. I deviated from installing the mat on bare metal by painting all of the interior first, but the mat will be painted the body color as was done originally with a complete re-spray of the interior . All in all I am satisfied with the product and offer this to assist to anyone wanting to do the same in the restoration of their Z. Paint should follow in the next few days and I will post up a few photos when that has been completed. Jim D. "Zup"1 point

-

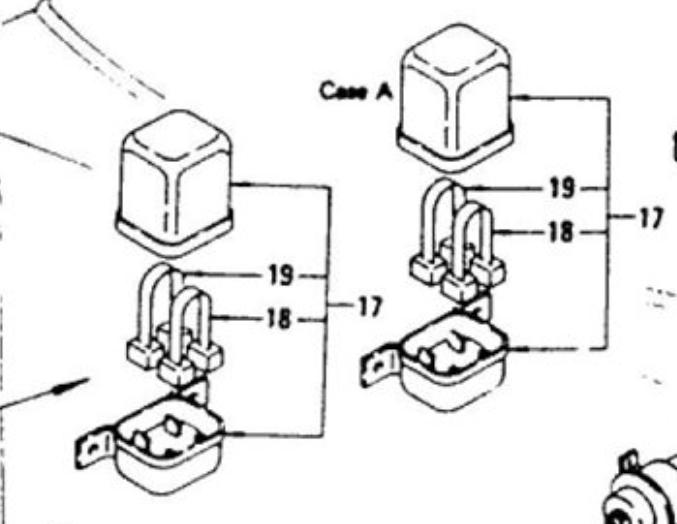

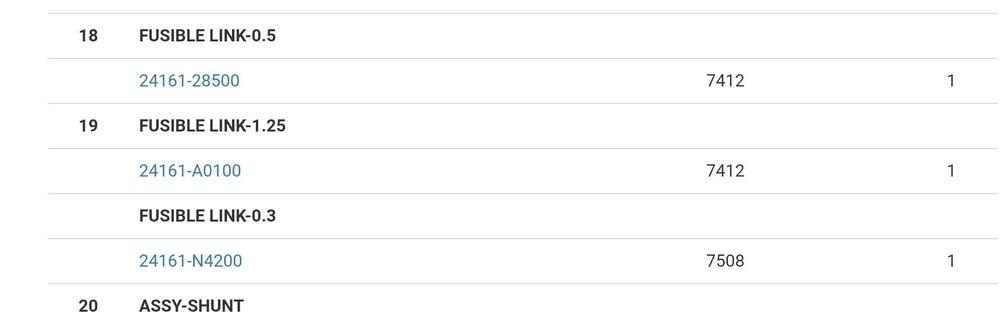

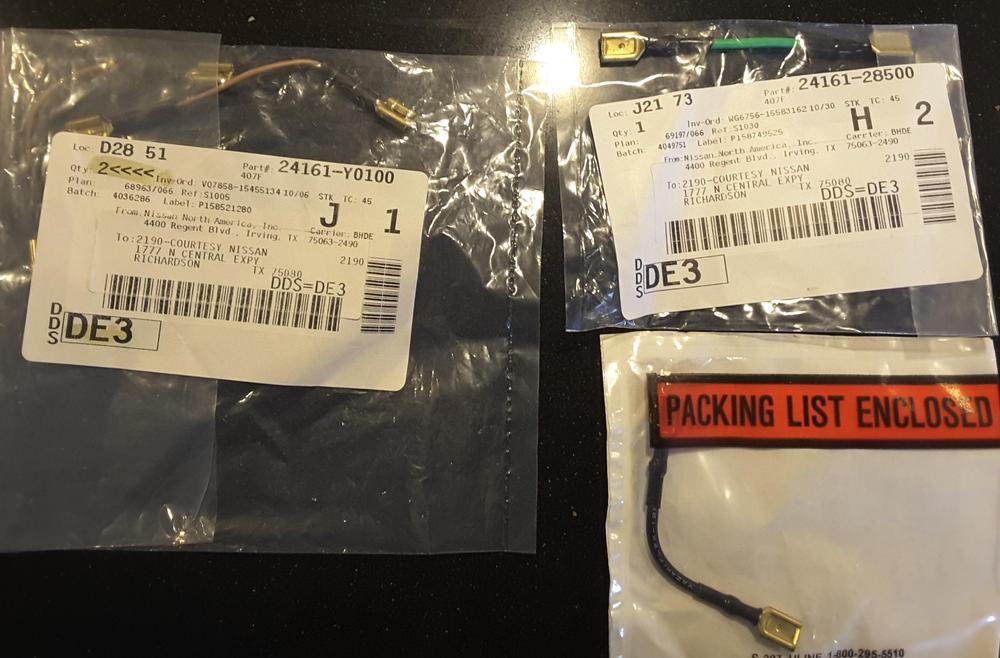

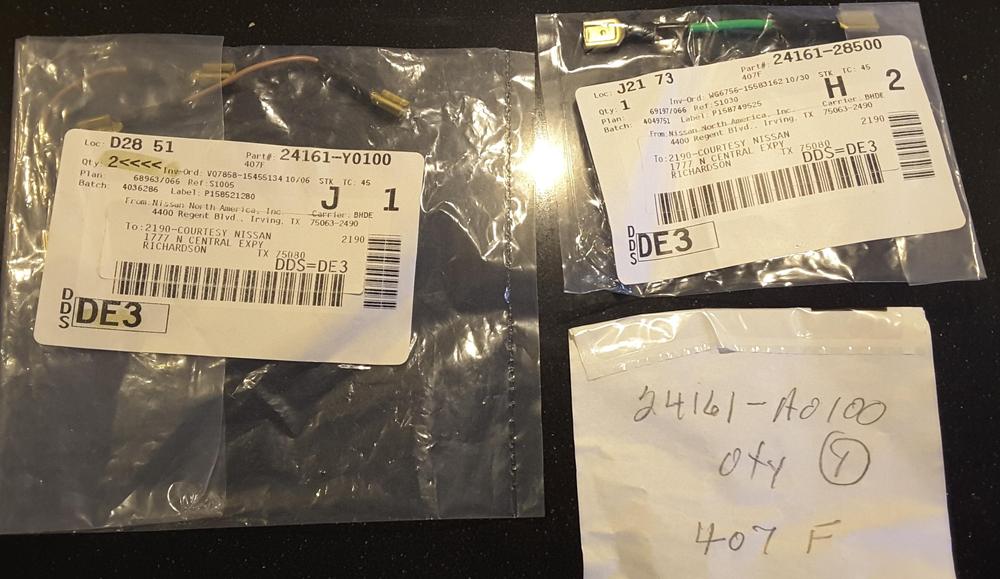

280Z fusible links

1 pointBack in 2014 I purchased a set of fusible links from my local Nissan dealer. They sourced the parts from Coutesy Nissan. Wayne is buzy with an update of his electrical diagram and this was a point of discussion. Im not sure if they changed the colors, but the set I received is: 1x Black p/n: 24161-A0100 (YAZAKIFLWX-1.25) 1x Green p/n: 24161-28500 (YAZAKIFLWX-0.5) 2x Brown p/n: 24161-Y0100 (FTX-0.3) In (brackets) are codes on the link insulation. The brown have a different number compared to the manual,. They are brown instead of the original red. That could explain the different part number. Refering to the parts manual en Waynes color electrical diagram. According to the parts manual Pos 19 is the two (outside) links A and C with a value of 1.25 Pos 18, link B and D have two values, which doesn't make sense, 0.3 and 0.5. That corresponds with one brown 0.3 and the green 0.5. Did nissan get this mixed up? Looks like I should have two blacks for A and C, one green for B and one brown for D. That doesn't match the three reds and a black on the diagram. Could be just color changes over the years. Any thoughts on this? Thanks Eurodat1 point

-

Patton Machine Fuel Injection

1 pointHaving done what I hope is enough research, I have started down the road on my next off-beat modification. I decided to pull the trigger to go with the Patton Machine fuel injection kit on my 260Z. I still think I'm going a little lean at times at the top end with my current SU setup, and I hope this will remedy that situation. The cost appears to be less than sourcing a non-egr FI intake, AFM, MS setup, etc., and it seems to be nicely sorted out. I'll try to remember to take a lot of photos for posting. I hope to get the setup in March.1 point

-

Complete roof R&R

1 pointI think I would remove the roof skin and then patch the underlying structure where necessary. Then reattach the roof skin. As long as the rust doesn't get too far into the corners, this would give the best repair I think. I don't think I would trust my welding on an A pillar not to mention the potential warpage1 point

-

Parts for Sale: S30 Console Ashtray Cup

View Advert S30 Console Ashtray Cup Stripped and professionally replated in clear zinc, no pitting, chrome fittings are in near perfect condition. $60, includes standard domestic shipping. Payment via PayPal, PM if interested. Thanks. Advertiser jfa.series1 Date 03/11/2019 Price $60.00 Category Parts for Sale1 point

-

Engine lift for front cross member removal

1 point

-

Complete roof R&R

1 pointI am going to need to replace a massive sunroof, but I am not planning on cutting the a-pillars. At @zKars suggestion I am going to cut a patch from a donor roof and epoxy it in. A guy in Sweden did it years back. Posted a bunch of pics and vids but I don’t know if they are still around. Aside: inspired me to build a jig. Google “Project Hugo 240z” or “Projekt Hugo” What happenned to yours? Here is mine. (Please ignore the mess made by the PO ...fortunately I have spares)1 point

-

HLS30-09579 selling for pretty cheap on eBay

1 point

-

Transmission Swap

1 pointThank you all for your advice. Since my transmission tunnel is only bent up and my original console is already trimmed, I'm going to alter the shifter handle with sharper angles. I won't be doing any more damage and I can use the original style rubber boot. Thanks Again.1 point

-

Looking for ATI harmonic balancer users

That is one sexy bit of kit!!!!! Nice work. This is what I had to do - it's rather large but it will never vibrate onto the damper especially as it's 2mm thick steel ;)1 point

-

Let's show vintage racing pictures. I'll start.

gnoseZ, now that you have your good glasses on take a look at the Bonneville car again. It's not Andy Flagg's car. It's the 1970 240Z built by Nissan USA employees and which set the F/GT speed record at Bonneville in 1976. It's part of the Nissan USA collection and was on display at the Lane Museum in Nashville in the photo posted above. Here is a thread I started about it several years ago after I bought the items I included in the post.1 point

-

HLS30-09579 selling for pretty cheap on eBay

1 point

-

Rust Proofing 240z Dealer Guide

1 pointHi Jim , yes the can which he has in the video is the clear coat . We used to have black coat which was common for the dealer service men when they work for periodically maintenance required by the regulation. I have heard it was an additional service, they sprayed black all over the chassis without asking customers!! They don’t do it without customers request nowadays . I was asked by the service man , he said it is good for the car , no more black , it is clear coat. I said OK let’s do it . Kats1 point

-

[2019] What Did You Do To/with Your Z Today?

To augment Jim's post on his wonderful find I'm throwin' this in just in case anyone with an interest missed it the first time---1 point

-

Problem With Differential Installation

And adjusting the hub position to help correct the early design's leading-diff/trailing-hub situation would have made the tire sit even further forward inside the wheel opening. I've heard it explained (source?) that the S30's differential was pushed forward late in the design cycle when Nissan's engineers became concerned over meeting the new US FMVSS requirement for rear impact. The explanation was that they wanted to move the differential further way from the front of the fuel tank to reduce the liklihood that it would puncture the tank when the rear of the car folded up. I don't think this was guess work. They must have observed a potential problem or else they wouldn't have taken such an unnatural design path. There was a lot of confusion and uncertainty within the industry over what form the actual FMVSS rear impact standard would take when made into law (impact speed and fixed vs. moving barrier were still being debated). I wonder if Nissan decided to take an extra-conservative route to begin with and then relaxed the design back to 'normal' when they felt more comfortable? It's all very curious. A lot of parts had to be changed, at enormous expense, and giving back the crash safety margin in the process. This would not have been done unless Nissan felt there was a major problem with offset design. And yet modern-day owners of Z's with the offset design never seem to complain about the expected issues (which are: 1) drivetrain resonance at cruising speed, and; 2) premature halfshaft U-joint wear).1 point

-

Local Police Trying to Find this Man

Shouldn't be too difficult to identify. Having a crime wave in the Scotia??1 point

-

Rust Proofing 240z Dealer Guide

1 pointWhat was the clear coat undercoating your Nissan service tech applied kats? Was it from the can he holds in the video? Is it a commonly used type or is it something special you found?1 point

-

R180 half shaft dislodged from differential.

The grease inside the half shafts can contain lead, so be mindful. Especially if you have little ones around!1 point

-

Patton Machine Fuel Injection

1 pointThe middle line is the "typical" (perfect) measurement. and the outside lines are range "limits". So if you are designing a system, you should probably aim for typical (halfway between max and min), but since any sensor you might purchase could be anywhere between those two points, you have to either characterize the sensor and trim the system for that sensor, or your system needs to be able to work acceptably with any sensor within that range. Those sensors are RTD's and they are available with different curves. And looking at the data for that GM sensor, it looks like it's a different curve. Doesn't the EFI system you are putting in place already expect a specific certain sensor curve? Is there any info in the documentation about what it's expecting? And lastly, here's a chart I put together for the 280 coolant temp sensor. I didn't look into it, but I would assume the ZX is the same?1 point

-

240zrubberparts project car

1 point1 point