Leaderboard

-

Mike

Administrator10Points23,018Posts -

EuroDat

Free Member4Points3,308Posts -

grannyknot

Free Member4Points5,158Posts -

Dave WM

Free Member3Points3,591Posts

Popular Content

Showing content with the highest reputation on 08/06/2019 in all areas

-

Intake manifold interchangeability.

2 pointsI would stick with the 76 throttle body. The ZX butterfly is smaller and will restrict flow a little. Years ago there was a modification with a 60mm throttle body and the AFM from a toyota cressida. You had to solder the 280Z electronics into the toyota unit. A resistor in the temp sensor wire allowed you to, all be it little, adjust the ECU to compensate for the extra air flow. Tip: If you do these changes to a running engine. Check the performance before making the changes. The way I do it is this. - Pick a quiet road where you can safely drive up to 70 mph. - Drive in 4th or 5th gear at 25mph and accelerate to 60 or 70 mph. Don't change gear. - Have someone video the speedo and tacho while you do it and plot the values against time (seconds) in excel. That will give you a performance curve you can refer to after you do the mods.2 points

-

Cylinder head flatness - is milling really necessary

You use peanut oil, or motor oil? Pics or it didn't happen.2 points

-

Intake manifold interchangeability.

2 pointsCareful folks. Consider carefully before changing major EFI components without having any control over the stock ECU to adjust fuel and AFM response curves to match. Larger throttle bodies without other corresponding changes will do little but reduce air velocity into the AFM. That flap that gets pushed around responds to air velocity....2 points

-

carb balance with Twinmax

2 pointsAs much as I love ZTherapy's work, they also reccomend that you throw your flat top carbs in the garbage, and a few of the members here have proven that to be completely wrong.2 points

-

carb balance with Twinmax

2 pointsI like the Uni-Syn for high RPM balancing check when the air flow is high.... but the STE Synchrometer is very accurate and repeatable. It works nicely for SU's at ~ 7 to 11 kg/h (depending on calibration) for idle. You can pull the rubber lip out a bit to expose the holes in the throat then dial up the rpms so that the front carb is at 35 kg/h then move to the back carb to adjust the balancing screw to get the same 35 kg/h Note: The BK Black version is 1-35 kg/h but the SK Silver version is 1-30 kg/h. The black one is better for SU tuning.2 points

-

carb balance with Twinmax

2 pointsConnected the vacuum spigots to the insulators today. Measured and marked the center of a side, pilot drill 0.1090" then tap drill 0.1695" Tapped with M5 x 0.8, threaded the brass spigots in with a thin layer of Permatex #2. Keen to try this out. FWIW I can't diss the UniSyn; that's what Z Therapy recommends! This is just an experiment based on my years of balancing twin carb motorcycle engines like BSA, Triumph, Norton, Ducati.2 points

-

Cylinder head flatness - is milling really necessary

(Edit: it was mark maras, madkaw, and eurodat that got me thinking it was possible and helped inspire the methods i used. I wanted to refer to their previous comments but had to go back to find their names, thanks each of ya. It's the only reason I made an account here, just to thank you.) I just did a bit different approach to the similar problem, not with an opel but I have a Ford truck with a head gasket failure, and found it warped about .033 up in the center. I didn't have a thick plate of steel to bolt onto, but found a girder and hoped to make it work. The approach I took was much different, rather than air heating and cooling, I figured that oil heating would more effective to thoroughly heat everything through to temp, taking notes from the kitchen chefs, and also slowly cool it. Borrowing from old blacksmith forgings. So far it appears that the head is not nearly as crooked, wheras before you could stand back ten feet and eyeball it and see where it warped at. I used washers about .090 thick, heated the head, and bolted it to the cool c-beam, bastardizing a feeler gauge set to do some math and combine multiple shims to brace between the beam and head, stacked between each L-R row of head bolts: Began with .033 warp, with .090 washers at the corners, and from what someone said here I went half the distance past center? It was a long weekend, but I basically stacked the feeler shims in a combination equal to what distance was needed, increasing in the stack sizes towards either end, with the old head bolts, nuts and lock washers on the beam side And with an old metal oil drum cut in half, two old gasoline Coleman camp grills, a propane weedtorch, digital thermometeras well as industrial use temp needle gauge that is fitted in processing equipment, I basically deepfried the cylinder head. It had already been fried once! But this time, heated the head upside-down so the c-beam would be out of the oil, in an attempt to keep it from distorting as well, if I could manage to keep it somewhat cooler than the head and thus remain more rigid while subjecting the head to the heat, and also left the mounting bracket on the head so I could dip it in or pull it without reaching in. I also had several fire extinguishers on hand, and a forklift to lift or lower it. Currently, I'm looking at it, it looks like it may be straighter, but I'll admit I'm nervous to unbolt the thing. Even with the criss-cross outermost and working in, what if somehow I made it worse?2 points

-

Grinding Weld Beads - Recommendations, please

I didn't have any beeswax on hand so used an old candle, works great!2 points

-

vintage dashes 280z

1 pointI am glad I have the donor dash, will be taking a lot of video to aid in the location of removal screws.1 point

-

vintage dashes 280z

1 point

-

Intake manifold interchangeability.

My mistake on the TB fitting. It must have been the hoses between the AFM and the TB that I was thinking of. The ZX hose and TB inlet is smaller. I thought that there was a bolt pattern issue but apparently not. p.s. edit - although I do also vaguely remember a throttle linkage problem. Worth double-checking, but kind of pointless if you have the other parts. Just like when swapping any of the EFI parts there's always a way to make it work. It's a crude system. The engines all have about the same power from 75-83.1 point

-

vintage dashes 280z

1 point

-

Intake manifold interchangeability.

I've been musing about the same thing. I will hopefully have a F54/P79 combo in my car sometime in the not too distant future and I've been thinking about how I will dress the motor when it's in there. I could redress it as a 77 using just the block and head. That would use my original throttle body, intake manifold, and ECU. Or I could bring over the entire system from 83 including the ECU. The biggest thing there is that I would need to incorporate an O2 sensor. Or I could do something hybrid like use some of the 83 parts (like the intake manifold) but keep the original 77 ECU and wiring. As far as interchangeability goes for the intake manifold... I compared 77 and 83 intake manifolds and throttle bodies, and I believe they are interchangeable. Mounting holes are in the same spots and the diameters of the airflow ports are the same. The throttle butterfly plate is the same diameter and all that, so I don't think there would be any problem mixing and matching them. I don't think the ECUs would know the difference between any of them. The BCDD for 83 does not reside on the throttle body, but is separate and located on the underside of the manifold. So if you're mixing and matching, you would need to pick one. The only other complication I could find was that the inlet side of the throttle body where the ducting connects is a little smaller. It's the same ID so there's no functional change, but the OD is a little smaller. Not the end of the world, but something you would need to address. I don't know about other years, but that's what I found when comparing 83 to 77.1 point

-

Picked up a couple of hard to find parts recently

Carl, I ended up with my stash of Holy Grail parts through pure serendipity. For the past 30 or so years I've kept in touch with Nissan/Datsun parts availability through careful tea reading combined with help from the guys at my local dealer with whom I've had a relationship for almost 40 years.1 point

-

Intake manifold interchangeability.

The 76 throttle body is still pretty puny. If you’re looking to gain air flow and performance you will not be able to run the stock ecu... Negative effects of the ZX intake? Not tracking.1 point

-

We're bringin' back the Flat Tops!

Thanks for the information Rich. I'm going to look into having some exact 1973 decals made. As long as they have an adhesive backing, installing them would be very similar to installing window film. Use a mild soapy solution, once positioned where you want it, use a firm rubber squeegee and there should be no bubbles (as long as you cleaned the lint and dust off).?1 point

-

Intake manifold interchangeability.

If you do anything to improve air flow and volume, you will need a new ecu... But that is a great way to improve performance. Especially if you add a Borla TWM throttle body and port match the head and intake.1 point

-

vintage dashes 280z

1 pointTake pictures & label any wiring that isn't obvious where it goes. Seats out is a very good idea. (easy with 280 seats) Dash looks great buy the way....1 point

-

Rust Advice 78 280z

1 point

-

Need a replacement gas cap - Know a good option?

I have a set available. See: 1972-1975 Fuel cap and ring (new plating) Keith1 point

-

Cylinder head flatness - is milling really necessary

not weighing in on whether this is the right thing to do - out of my league here... but if your home oven won't work, most foundries have heat treating ovens that are large, very accurate and set up for large parts and long, constant bake cycles. not an expensive proposition if you have your head set up, mounted/shimmed/etc. and they just take it and bake it.1 point

-

Cylinder head flatness - is milling really necessary

Just watched a guy on UTube straighten a warped six cyl. head. .007 brass shims under the ends, baked it 5-6 hours at 500` and let it cool in the oven. He baked it twice until the cam towers were aligned then sent it out to be surface milled.1 point

-

Cylinder head flatness - is milling really necessary

No, I never did try this. It seems all that I have read says 400-500 for 4 or 5 hours. I was also considering a powder coating shop for the job. Need to make a hefty fixture to bolt down the head to. My head is probably. 030 out, so it would take good size shims. I came across 2 more good heads so there was no need to rush into this fix. I'm going to use my warped mn47 for the flow bench so it doesn't matter much1 point

-

Cylinder head flatness - is milling really necessary

OK. Now that we're finally coming around to your solution, did you ever try it? I remember the talk about it but I think everyone was concentrated on milling & the unintended consequences at the time. Rolling the idea around in my head, oven size came to mind. I know my oven isn't large enough to slow bake a six cyl. head & if it was I would have to send my wife out of town. But any powder coating business has an oven that could. Temp 400 - 450. Sound OK?1 point

-

Cylinder head flatness - is milling really necessary

Last time I mentioned here ,the fact I was going to straighten a head ,it was considered crazy talk. The fact is there is few shops that will do this. Usually just told to find another head. Bolt it down with some shims and throw it in the oven with the chicken dinner and see how it comes out. Cook it low and slow though!1 point

-

Cylinder head flatness - is milling really necessary

I was generalizing on why not to shave a ohc head. A warped head is not good, but shaving it to get a flat surface is only going to solve one problem and create another. If Bob would use the head as it is now it shouldn't be a problem for the cam. The headgasket between 3 and 4 might be a possible issue, but you could compensate by overtorqueing the center group of head bolts. Bob's head in not that bad. I have heard 0.15 is ok to use on a six cylinder. The opel head I mentioned was a lot worse, somewhere around 0.3mm might have been more, but it 4 years ago. The point I was trying to make is: Shaving an ohc cylinder head should not be done to correct warpage. It needs to be straightened first. Some machine shop don't realise the difference between an ohv en ohc heads.1 point

-

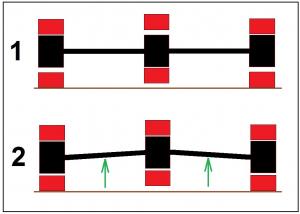

Cylinder head flatness - is milling really necessary

Checking if the cam spins freely may not be enough. The can journals have a maximum clearance of 0.1mm which would give you a fear amount of tolerance. The problem is that the cam doesn't run in this condition, but runs with the valve springs forcing the cam upwards. This will press the cam up towards the top of all the journals and causing the cam to bend ever so slightly per revolution. Its not much and won't have any immediate effect, but fatigue will eventually take its toll and break the cam somewhere in the middle. Then the back end will punch a couple of valves through the pistons...... I made a quick exaggerated sketch to explain it better. 1. is free spinning and 2. is under normal conditions. I agree with Mark. Its Bob's spare engine, so I would use something like A4 printer paper folded double under both ends of the head and tighten it down on the centre bolts. That would give you a very slight reverse bow and leave it like that until you want to use it.1 point