Leaderboard

-

Dave WM

Free Member6Points3,591Posts -

dmorales-bello

Free Member5Points627Posts -

wheee!

Free Member3Points4,607Posts -

madkaw

Free Member3Points4,338Posts

Popular Content

Showing content with the highest reputation on 09/20/2019 in Posts

-

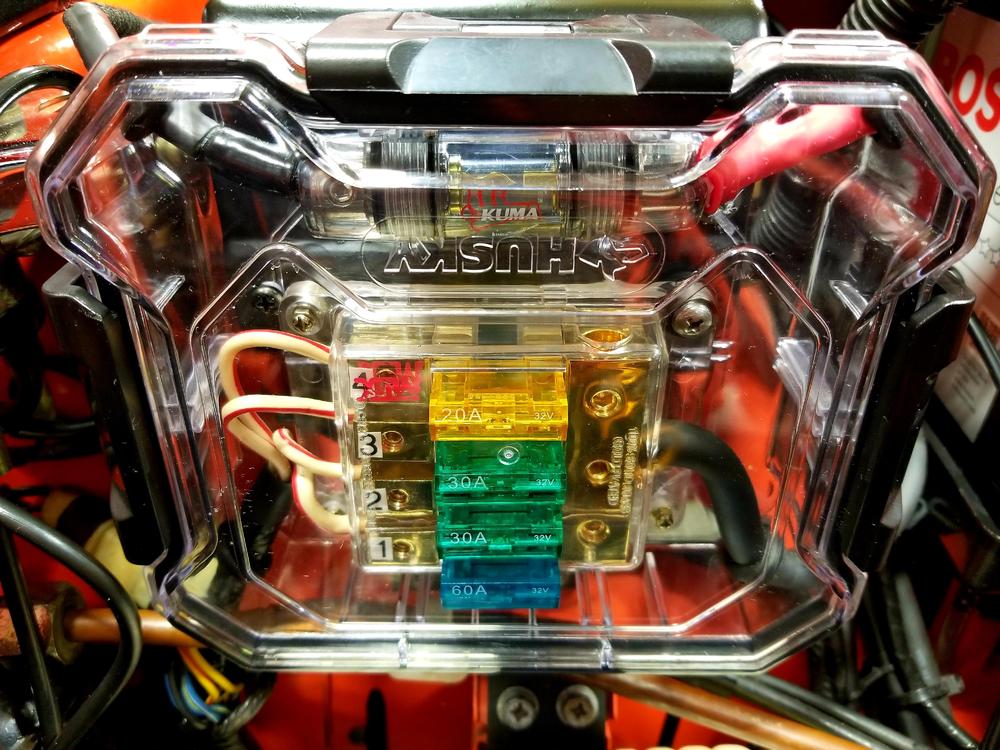

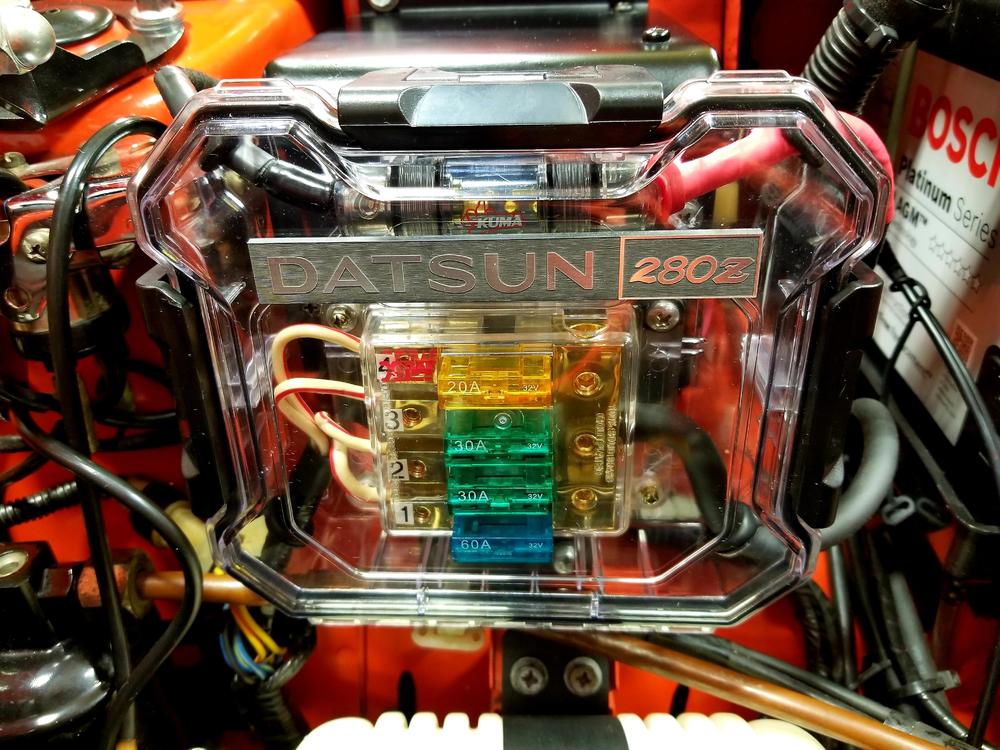

Waterproofing a Fuse Block

4 pointsI've been running my Maxifuse 4 circuit fuse block for a few months (replacement for the old fusible link set up) and all the electricals are working well. My worry has been the fact that the set up is definitely not water resistant (much less water proof) which could be a huge problem if I get caught in rain or simply carelessly wash my car. I like the fact that it's a simple 4 circuit system with readily available fuses so I found a way to put it inside a Husky brand (Home Depot) WATERPROOF 6" small parts box ( measures exactly 6"x6"x2") made of hard clear plastic. It looks like acrylic but I'm not sure. I pulled out all the partitions, opened 4 holes (one in each angled corner) and fit them with rubber grommets for all the input and output cables. Fixed the fuse block inside with well nuts placed on the bottom of the case (as well as the sound system fuse holder) and attached the set up back again in place of the old fusible link holders. Oh yeah, and I covered up the inverted "husky" logo with a spare 3D printed 280Z logo I had laying around. All the electricals tested well. I will run this for a while to test the durability of the clear plastic but I think it'll fare very well considering the fuse block itself was exposed to the heat of the engine bay for months without issue and this plastic seems very similar to that. I'll report long term findings if any. Pics below.4 points

-

Pikes Peak trip!

4 pointsvideo near the top. the engine cut out takes place about 1/2 thru if you want to cut to the action.4 points

-

L28+(maxima)47 build

3 pointsJust love breaking this engine in! The torque is very strong. I’ve limited myself to 5500 at this point, but still pulling very strong. Have to be careful not to hit it too hard in lower gears or I just break the tires loose. Able to run 35 degrees timing so far, but probably close to the limit. Need to break this bad boy in and and get to the dyno to dial it in. Running very similar tune I did with my 2.4, just more fuel. Seems to be doing rather well on the MPG- beauty of EFI. On the dyno I will probably advance the cam a bit too if I can get away with it. I’ll see where the power curve comes in. Took a peek at the cam and everything looks peachy. Just finishing up the install of my old motor in to the customers car. After it’s gone I can devote more time to tuning. Right now just driving around and letting Megasquirt do it’s thing.3 points

-

Pikes Peak trip!

2 pointsI made is, Orlando FL to Pikes Peak Co in my 75 280z. Left Thursday noon, drove to Phenix City Alabama (about 400 miles). Have family there so stayed the night. Left early about 2am Friday, thru Bham, on hiway 22 to NW AL, then thru a little bit of MS, and then AR. Took a north turn up thru the Ozark mountains toward MO. from Joplin the garmin took me to Wichita KS via rt 400 (2 lane, 180 miles dead of night, yikes). North from Wichita to I-70, then across to CO. Arrived at Pikes Peak about 1PM Saturday. in AR I lost my brakes (replaced a drum slave cylinder a few weeks ago, did not tighten a line fitting, so I did a McD parking lot fix with help from a passer by to bleed the brakes. The only other casualty was I lost my radio somewhere in KS (not a fuse checked the both). Not a big deal as I prefer to listen to the engine :) Other than that Dat Boi handled the trip great, but I did find the operational ceiling of the Bosch L jet tronic system. On the way up past the 13 mile shuttle stop (about 11,400 ft) I suddenly lost power and the engine stopped and could not be restarted and run for more than a few seconds. I was on a fairly steep incline, on a section with no guard rails, a steep drop off on one side and a steep wall with a bit of a ditch on the other for shoulders. After a bit of panic (am I going to have to back down this thing) I managed to get the engine to run long enough to make a multipoint turn around on the narrow road. Got the nose down and got back to the shuttle launch area. I took the shuttle to the top. With hind sight I prob should have removed the air filter before the final accent, maybe that would have helped. My guess is with the thin air, the AFM flap just presents too much of a restriction for the engine to overcome, but that is just a guess. I seem to recall some discussion about a altitude compensation device for the L jet tronic. Getting down was uneventful since engine braking meant I did not hardly have to use the brakes at all. I have a lot of video (including the fail, should be interesting to watch. Will post up later and link.2 points

-

L28 from 82 ZX teardown

2 pointsNot a chance. I wouldn't do well at all. The only position I would be even remotely fit to fill would be grabbing them by the covfefe.2 points

-

Zs 50th Anniversary meet : Le Mans Classic 2020

Hello. This might seem a long way away from you guys but maybe, for once, you want to be there at Le Mans, especially after the recent Fordvs. Ferrari film ? Club Datsun-France is preparing for this prestigeous and enormous biennial event, the dates for which have been set as Thursday 2nd July – Sunday 5th inclusive. We aim to continue the 50years theme and to improve upon the 2018 attendance of 50x cars, so we’re counting upon you all to come together to celebrate and share a great moment against the fabulous old-school atmosphere of Le Mans ! In order to benefit from the preferential club stand, discounted tickets and no booking stress for you, I as usual on behalf of our club, will be organising the Datsun/Nissan ticket bookings direct with Peter Auto including camping accommodation via the ACO ! It’s not too early to book for track sessions, accomodation and a place on the stand ! I invite you to contact me at : seanz@wanadoo.fr for a more complete information package including estimated* prices. *we’re awaiting the official figures. Kind regards, Sean Président, Club Datsun-France http://datsun-france.com1 point

-

Waterproofing a Fuse Block

1 pointWhee, with that digital display, yours will look even more like a flux capacitor than mine! I hope it fits. I love it!1 point

-

Picking up a 1977 280z 6 Hours Away. Tips?

280Z Front Air Dams https://r.tapatalk.com/shareLink/topic?share_fid=83168&share_tid=62746&share_pid=582834&url=https%3A%2F%2Fwww%2Eclassiczcars%2Ecom%2Findex%2Ephp%3F%2Ftopic%2F62746-280Z-Front-Air-Dams-%2Fpage__view__findpost__p__582834&share_type=t&link_source=app1 point

-

Picking up a 1977 280z 6 Hours Away. Tips?

Hi everyone, i finally completed the suspension upgrade for my Z! Thank you to everyone who gave me advice and tips on the install. Here’s a photo of the Z with 205/60/15. Is there a trick to installing the Konig hubcaps on the front? Id like to add the BRE spoiler and Air Dam. Does the Official BRE spoiler for better than the MSA spoiler with two bolts? Do you guys have a recommendation on where to get the Air Dam with Brake Ducts?1 point

-

Waterproofing a Fuse Block

1 point

-

Waterproofing a Fuse Block

1 point

-

F54/P79 Swap Project

1 pointI can send you FW bolts and a new bushing to add to the cause. Just let me know. I have your address ?1 point

-

1976 280Z Restoration Project

1 pointThanks. I would rather do it right the first time than try and take it apart later to correct something I should have done properly at the time. The car is getting closer for sure. The body work should be done this fall/winter and that hopefully leaves me enough time to get the interior done by summer. The drivetrain is complete other than wiring so that shouldn’t be too much of an issue now. My list of parts to buy is getting smaller all the time. I just have to stop looking...1 point

-

L28 from 82 ZX teardown

1 pointThanks for the tips. Pistons are coming out nicely after cleaning the cylinders ridges with brake cleaner. Got my Machine Shop quotes today. $50 Hot Tank and inspection $65 Re-honing $65 clean and inspect the head. 7 day turnaround Sent from my iPhone using Tapatalk1 point

-

Mr.Uemura wrote a book "making story of a Fairlady-Z"

Thanks Alan , if we don’t understand fully line up of Nissan at that time , we can’t see what was happening with the S30 . Kats1 point

-

Duffy's 1/71 Series 1 240z build

1 pointOil pressure sensor is in and linkage is all adjusted. I think it’s just time to wire. Which I’m dreading.1 point

-

Mr.Uemura wrote a book "making story of a Fairlady-Z"

Thanks Carl , yes I think so too , it is not that simple . Reading many books from my book collection , I see these. 1961 Mr.K started a KAKU “ U “ project to let not only engineers but also executives know what is needed for selling cars in the US . Mr. K and Mr . Hara they met already at this point . 1965 L20 six cylinder went on production 1965 Mr. K became a president of Nissan USA 1965 Mr. Matsuo / Mr. Yoshida / Mr. Chiba these styling designers began to study for a new sports car 1966 Chassis Engineers had began to study for a new sports car ( Mr. Kambara is the key person for this ) 1966 late Mr. K met Mr. Matsuo, at this point the cray model which would become S30 was not settled yet . 1967 is the most important year for the birth of the S30 I think . 1967 Feb Mr. Tamura joined the studio and started refreshing the body . Mr.K saw a cray model and said “ I buy this car “ . 1967 Mar Mr .Hara who was a manager of Design engineering and styling section had been watching activity of styling designers and chassis engineers had had decided to start a project of a new sports car . He also believed Nissan can make a new sports car and well sold in the US . 1967 April A meeting was held by production management to set the target of a new sports car. This is the moment of S30 officially became to have six- cylinder engine. A base model is four -cylinder engine, a high performance model is six-cylinder engine. And set the target main market - USA . However this was not seem to tell the styling designer until June , Mr.Tamura . Because he said “ one day Mr. Matsuo came to see my work and suddenly told me “ this car became to have six-cylinder engine “ . That was the summer of 1967 “ . 1967 June 1st new sports car meeting was held and this project was named “ Maru Z Kei kaku “ . The engine has two types , L16 and L20 . 1967 November Mr.Hara had an idea to achieve an approval of a new sports car from executives. I think Mr. Hara did a great job at the presentation. So the answer of the question “What made S30 prototype upgrade to a six- cylinder engine from a four- cylinder engine? will be , “ the meeting of production management held April 1967 “ . As a side note , Maru Z Kei Kaku decided to install a L24 for USA model is July 1968 . Kats1 point

-

L28 from 82 ZX teardown

1 pointYour engine is looking more and more like just a high miles engine. That glued on badge is an odd thing now. Aftermarket sprockets only have to match the tooth pattern and shape. They're not rebuilt like alternators, they are brand-new parts, but made from the aftermarket manufacturers' tooling. Look for a good brand name. Cloyes seems to be well known in timing sprockets and chains. Often you'll find the same exact part for different prices from different suppliers. Sometimes there's only one company making a part so you might as well just buy the cheapest, unless there's a warranty.1 point

-

F54/P79 Swap Project

1 point

-

Early 74 260Z Adventure

1 pointThe plan is pretty good. I would have a professional handle the media blasting. They need to be careful as the cars are easily damaged or ruined. As for the oil canning, do some searching on metal shrinking on here and you tube. Need to paint right away after blasting!1 point

-

My Datsun 240Z

1 point

-

Early 74 260Z Adventure

1 pointSounds about how my luck goes, welp, looks like I'm about to get real good at A pillar sheetmetal repair, lol1 point

-

1971 240z Refurbish in Denver

1 pointThanks man, Those reproduction dashes look pretty nice. I hope I don't ever decide to try and do that job, it looks pretty involved. I hit all the nuts w PB blaster today. Then I ordered all kinds of parts, struts, springs, brake stuff, bushings, mounts, seals, ect.. I adjusted the clutch slave cylinder yesterday. It was too tight. It didn't help with the third gear synchro but it really made the car drive a lot nicer. I can't wait to drive this thing with it all dialed in.1 point

-

saturday night music thread

1 point1 point

- 240z hood hinges

1 pointI have a couple of decent tight hinge sets left over. I went through my stash last year and threw away 2/3's of them because of excessive pivot point slop. There is just about no way to keep you hood aligned with sloppy hinges. PM me and we'll get some on the way.1 point- L28 from 82 ZX teardown

1 point- SURVEY: 240z Hitachi AM/ FM Radio Question

It doesn't make a difference to me, although others may feel differently. I would prefer it to be updated and if it kept the OEM exterior appearance, all the better. My '71 Z is currently a collection of OEM, installed at the factory in Japan, and replacement parts installed in five or six states. So, no worries. I can't imagine a "purist" pulling a radio and opening it to see if it had original circuitry. That kind of fanatic would probably also "sniff-check" the air in the original spare to see if it had been replaced. After dealing with Porsche cars and car shows for 40 years, I know there are Porsche owners and show judges who are probably that fanatical. But, I haven't run across the equivalent in the "Z" community. Dennis1 point- Mr.Uemura wrote a book "making story of a Fairlady-Z"

So are you stating categorically that nobody said it, or are you stating that the L20 six was not the six cylinder engine first slated for the 'Maru Z'/'270KK' project? As I asked before (rhetorically...), how could anyone - let alone Katayama - have specifically requested the L20A or L24 when they didn't even exist at that point? And why are you apparently so scared to consider that the 'old' L20 six was part of the design and engineering process? What's the problem with that? Which "existing 4 cylinder block" was that? Twin carb versions of the C130-series Cedric were never dropped and the 'old' L20 six - with progressive updates and improvements in materials - was produced and sold well into 1970. This is one of the casualties of a poor non-technical translation of the Hiroshi Iida interview in Nos Hero and a lack of understanding of the Japanese market models. Of course, what you're doing is setting out your stall to paint the L20 six as 'bad' and the L16/L24 as 'good'. Because... Ah, here it is. L16 being portrayed as genesis with no mention of the L13. Because... Katayama Lore ahoy! When did Katayama know the L24 was "coming", Carl? Got a date for that? And we have the old "L16 for America" nonsense in there too. The L16 - designed along with the L13 - was part of the L-gata modular series that was used in the Japanese market, later to include the L14, L15 and L18. The L16 was not "for America", it was for Nissan, and the Japanese market got it too. Katayama was not "responsible for getting the L16 designed", he was simply lobbying for more power, more flexibility and better driveability, which was what the Japanese market also wanted. He was not creating particular bore and stroke combinations. You're painting the L20 six as some kind of failure. What does "short lived" mean? It was in production for a good five years and used for export markets as well as domestic. Being the very first Nissan 'L-gata' OHC design it was due for updating by 1969, which was a natural process and made sense for ongoing commonalisation of componentry, installations and servicing. You're drawing an arbitrary line in the middle of a normal progression. Like they did with - for example - the C10-series Skyline? It debuted in short-nose form (G15 4cyl engine) in July 1967, with the L20 six - yes, the 'bad' one, following in September 1968 with the debut of the GC10 models. At one point Nissan was selling C10-series Skylines with both the 'old' L20 six and the updated L20A in the C10-series Skyline lineup, with the 'A' suffix added to avoid confusion between the two types. So, far from Nissan not "planning on using an engine that was going out of production", they did just that very thing on the C10-series Skyline. C10-series Skyline production during its 1967 through 1972 life was knocking on the door of half a million units. The first six cylinder engine slated for the 'Maru Z'/'270KK' project - which would become the S30-series Z - can only have been the 'old' L20 six, because that's all that existed at the time. It was soon joined by the S20 and, by the time the project matured, the L20 had progressed - naturally - to its updated L20A type form. Unless we look at what else Nissan was designing and producing during the same period we will never fully understand the S30-series Z.1 point- Mr.Uemura wrote a book "making story of a Fairlady-Z"

OK so that explains the apparent M180 Engine Lineage. It was a tribute/replica-like borrowing. Now we know the complete story! Interesting the development went L6 >> L4 >> L6.1 point- Mr.Uemura wrote a book "making story of a Fairlady-Z"

However - nothing ever seems to work out so simply. I believe that there are good reasons no one initially said - “Hey lets put that big engine in that car”. Mr.Idia revealed in an interview with Nostalic Hero Magazine that he started development of an in-line six cylinder engine in July of 1964. The purpose of this was to compete with Toyota, which already had a six cylinder engine in the Toyota Crown. In order to catch-up with Toyota Mr. Idia’s team, in the Large Engine Development section was given only one year to develop the L20. The L20 was introduced in Oct. of 1965 in the Cedric. Mr. Idia tell us that the fastest way to develop an in-line six cylinder engine, was to use an existing 4 cylinder block and add two cylinders. Which he did. He said he liked the Mercedes Benz OHC and chain driven valve train - so he used that. Because of the rushed development, and shortened evaluation cycles, the L20 suffered from several problems. Some problems were found during endurance bench testing, others showed up later on road testing and as customers put more miles on them and made complaints. The L20 obtained high power of 115ps by using SU twin pots, in order to compete with the Prince six cylinder engines that already existed. However here were problems with engine component parts suffering premature failures. The output adjustment of two carburetors was difficult and the idle speed was so high it resulted in increased fuel costs. Customers complained about this. Larger oil consumption was another problem due to bad valve guides, valve stem oil seals and oil rings. The engine was improved one year later to solve some of these problems - maintenance was improved and they used a single down-draft carburetor, but max power was reduced to 105ps. The improved L20A was the result of engine development having been turned over to the Small Engine Development team, after they developed the L16 for the Datsun 510. The L16 benefited from a complete development cycle, so the L20A used the improvements from the L16 and added two cylinders to that. All these problems resulted in the L20 being a short lived engine, and they were known to the people within Nissan. I can’t see them planing on using an engine that was going out of production. I can see them planing on using the new L20A as it was based on the successful L16 and in development within the Small Engine Group at the time. Executive management wanted to use the new Price S20 and Mr. K knew the L24 was coming. Mr. K was responsible for getting the L16 designed and put into production for the 510 for America. Nostalgic Hero, Vol. 102, April 2004 http://zhome.com/DatsunLSeries/L20NH2004April.htm English translation: http://zhome.com/DatsunLSeries/L20NH2004AprilTrans.htm1 point - 240z hood hinges

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.