Leaderboard

-

Captain Obvious

Free Member6Points9,848Posts -

inline6

Subscriber

Subscriber 5Points1,236Posts

5Points1,236Posts -

Av8ferg

Free Member4Points1,538Posts -

madkaw

Free Member2Points4,338Posts

Popular Content

Showing content with the highest reputation on 11/16/2019 in all areas

-

Restoration of BringaTrailer 240z - HLS30-35883

The car with most of the exterior stripping and metal work complete. The hood got some more work after this pic which can be seen in pics I already shared. The tail light panel and rear apron received a lot of hours because of the light tap that the car took at some point in its life. Also, the front passenger side fender was damaged as you can see in the bring a trailer pic at the bottom of these: Some rust through on the lower corner of passenger fender. Also more metal work to be done on fender (middle pic) Shrinking and stretching was necessary to get this area in good enough shape to require only a skim coat of bondo. BAT pic:4 points

-

Restoration of BringaTrailer 240z - HLS30-35883

I liked the Black Diamond for stripping paint, plus the texture on some things. You can strain it and reuse it a couple of times. 50lbs for $10. https://www.tractorsupply.com/tsc/product/black-diamond-fine-blasting-abrasives2 points

-

Failed CO emissions - all controls removed - where to start?

2 points

-

L28 full rebuild assembly

2 pointsHaha!! Just trying to pay it forward. What's the prospect of all three of us having our new shiny motors powering our cars at ZCON 2020?2 points

-

Different ignition

2 pointsWhere I've only been interested in simple carbureted engines, I've never felt the need to learn anything else, points ignition, one wire alternator and a starter was all I needed or wanted. It took me forever to even use a hei distributor. It's only ever been 50s 60s and early 70s cars and trucks, but I absolutely love this rotted out datsun. I've owned some awesome prostreet cars, hot rods, rat rods, but I've seriously connected with this car. I feel like a new student in an advanced calculus class that had a D- in basic math.2 points

-

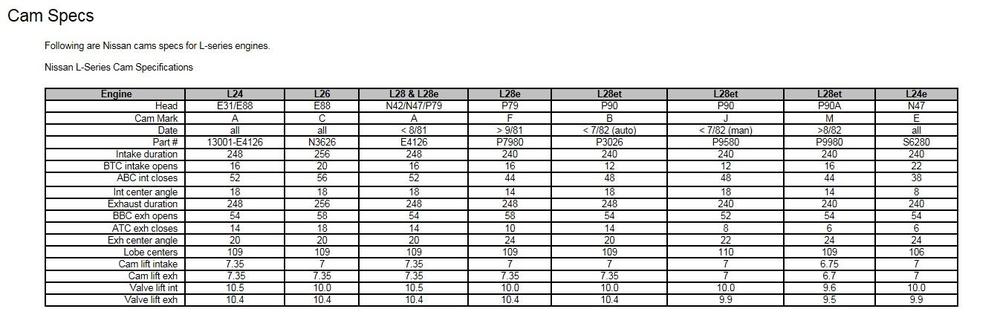

Turbo vs Non-Turbo Camshafts - B vs F

So @GGRIII and I are putting motor parts together and he's got two cams... One of them is an "F" grind from an 82 non-turbo car and the other one is a "B" grind from an 82 turbo car. We're trying to figure out which one would be better to use. According to the interwebs, the lift numbers for both of them are the same and the valve timing specs for the two are as follows: Format in FSM - a / b / c / d / e / f - ex duration / intake duration / intake open btc / intake close abc / ex close atc / ex open bbc "F" (na) - 248 / 240 / 16 / 44 / 10 / 58 "B" (turbo) - 248 / 240 / 12 / 48 / 14 / 54 It appears to me that the only difference between the two is the non-turbo (F) has all the valve timings four degrees advanced when compared to the turbo version? Seems to me that the turbo cam on sprocket position #2 would be identical to the non-turbo cam? Do the cam experts here concur?1 point

-

L28 full rebuild assembly

1 pointPerfect, I was hoping he wasn’t like this guy! Sent from my iPhone using Tapatalk1 point

-

L28 full rebuild assembly

1 pointYep! I’m in debt at ZCON for an undisclosed amount of beer though. I’m hoping he’s a lightweight Sent from my iPhone using Tapatalk1 point

-

L28+(maxima)47 build

1 pointOkay - turns out I have an oil issue . Oil is getting into to cylinders 4-6 , progressively worse from 4 on . The oil is diluting the charge and causing a misfire - especially in 6. 4&5 seems to be able to burn it off . I removed the intake to check for vacuum leaks to find an oily film in the runners 4-6 . Runners of intake and head both had oil film. First suspect was/is the valve stem seals. I tried a different kind on this build vs my L24. Visually they looked fine . They took a lot of persuasion to install and thought maybe I used too much . Last seals were a Ford seals , which were difficult because they are finicky as hell to install. Actually replaced #6 seal while head was in motor - ran motor and still have same results . Not being able to pin this down I decided to pull the head and look at the guides and anything else . Getting good at this now I guess - 1 hour later the head was on the beach . But no smoking gun found . I ordered more seals anyway. Decision time now . Do I go deeper and pull pistons or throw all new valve seals on and reinstall head and keep fingers crossed ? I was getting ready to leave town and really wanted an answer so I dropped the pan and pulled 6. Still no smoking gun - as far as my experience(novice) eyes can tell. Got on the phone to my machinist - but didn’t hear back yet. My inspection was very quick , so when I’m back in town I will scrutinize closer . Just trying to determine source of oil . I was expecting to see a collapsed expansion ring or another failed ring . There was marks on the bores on the thrust side that were fairly significant visually , but nothing you could feel. I have an extra assembled f54 flat top short block sitting there untouched by amateur hands with 110k miles with perfect wear in the bores . Also pulled a couple of bearings and everything looked spot on. Depending on what I find or not find it might be the next plan. With the head off it makes assembly decision equal. Though this is frustrating , the hobby of engine building will have these outcomes I guess . Not being a stock engine makes this more of a challenge . Missing the L24 right about now because I enjoy driving my car - a lot ! I was hoping for more engine swap and tune - not engine swap and troubleshoot . Hopefully I learn from my mistakes1 point

-

Restoration of BringaTrailer 240z - HLS30-35883

Did some searching and reading today. Interestingly, I don't see anyone selling copper slag in the US. I see shopping suggestions of other abrasives in Google Shopping when I search for copper slag. Coal slag is available. Both have descriptions that typically refer to applications which are thick metal (truck frames, trailers, etc.) I see Black Diamond is available in fine and medium. It's pretty cheap. I think I will get some and try it. I have a bunch of suspension parts and other similar items that need to be done, so if this is too aggressive for body panels, I still should get use out of it for these other items.1 point

-

L28 full rebuild assembly

1 pointMaybe I’ll sneak in there too with a fresh motor - if I ever get the beast to stay together - lol1 point

-

Different ignition

1 pointStick, Yes... We have clearly veered into a purely academic avenue on your thread, but we're good clean fun. We'll help with the math.1 point

-

L28 full rebuild assembly

1 point

-

L28 full rebuild assembly

1 pointNot yet, but I will before I move forward. I’ve been gone a lot for work lately. Dial Indicator on it way thanks to one of our favorite members CO who offered me one of his extras.1 point

-

L28 full rebuild assembly

1 pointP-series are Tri-metal bearings. They have a steel backing, copper middle and aluminum surface. They are capable of handling a higher RPM than the A-series and are better on performance engines I’ve read. The A series are all aluminum. Sent from my iPhone using Tapatalk1 point

-

1973 Rebuild

1 pointBought another Moog OTRE and finally got the right part, so I’m back in business on the rack. Should be done by Monday. Hoping to have a progress report on the body by Thanksgiving. I passed on your comments regarding the door, so we will see if he’s receptive to those ideas.1 point

-

Spark plug reading

1 pointLooks right. The part number seems to be used on a number of motors. I cross referenced nissanpartsdeal.com and it shows a range of engines that use that seal. So I think I'm good to order it. I appreciate you looking into it for me. Sent from my Coolpad 3310A using Tapatalk1 point

-

Duffy's 1/71 Series 1 240z build

1 point