Leaderboard

-

zKars

Subscriber

Subscriber 4Points3,747Posts

4Points3,747Posts -

Captain Obvious

Free Member4Points9,849Posts -

240260280

Free Member3Points4,441Posts -

Mike

Administrator2Points23,018Posts

Popular Content

Showing content with the highest reputation on 12/07/2019 in all areas

-

Hello

2 pointsGents, in the future please refrain from responding to spammers in the forum and use the "report post" feature. I have tools and methods in the back-end that can usually help me determine if this is a spam bot or a real user. Just assuming this kind of user is a spammer on the front-end doesn't work. He could have been a valid user who was just trying to be friendly. However, in this case, I was 50/50 split on my decision. His profile looked legit but the red-flag was his posts were very general and the email address was questionable. It had nothing to do with our Facebook SSO or other integrations. Remember, I have tools that can help me solve the kinds of issues, so please report posts so I can look into it. Thank you! Mike2 points

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Probably? it's seems to be the better Nylon.. Here's an interesting read for anyone who wants to learn a bit about engineered thermoplastics. It doesn't specifically mention Delrin because Delrin is the trade name for a Dupont product that falls into the category of 'Acetal POM' (acetal polyoxymethalene). Celcon is a similar product from a different manufacturer (Celanese). POM's, along with PA's (polyamides -- includes nylon) fall into the category of 'semi-crystalline' thermoplastics. From my quick read of the selection guide, Delrin and other POM's might be suspect for the task at hand, which would seem to require: resistance to chemicals (gearbox lube and possible additives) resistance to high temperatures (heat generated by sliding friction) good abrasion resistance Look at the case study in Slide #50, where Nylon 66 with glass-fibre and mineral/bead additives is selected for automotive oil pan applications. This looks like it might be a better solution for the fork friction pads. Just source a typical 'composite' oil pan from the wreckers and then cut out a section that can be used to machine the pads. Thermoplastics - An Engineers Guide to Specifying - RTP Co (USA) - 2014.pdf2 points

-

"The Orange"

2 pointsLooks pretty! I would clean the paint off the oil washed surfaces though. Especially the pressure relief valve. I worry that the paint will come off that ball once bathed in hot oil. Probably not enough paint to really matter, but just for the insurance, a little carb cleaner on a rag should wipe it off. That's just me. :)2 points

-

My two swiss S30Z Fairlady Restoration build thread

One of my fav threads! Thanks always for the update and have a good weekend!2 points

-

L28 full rebuild assembly

2 pointsThanks, now I feel compelled to weigh my assemblies and see where they are. Ordering a scale from Amazon now that is accurate within .5 grams. Home Built By Jeff posted a video of him balancing his pistons assemblies. He did it with pistons connected to rods. Down the rabbit hole I go. Sent from my iPhone using Tapatalk2 points

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

You've got a lathe, right? That bushing should be easy-peasy!1 point

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

http://zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm Sure enough, its the 1-2 rod that's larger. 16mm vs 14mm But a little 1mm thick bushing could be used to make the C fork "fit" the B rod. Never say die!1 point

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

And then you find things like this: and you begin to wonder just how similar the C type transmissions are inside. Especially since, as previously mentioned, you CAN get parts for THEM Oh look, there's a couple of "C" cores out on the grass.... (actually a snow bank at the moment). Guess I know what I'm doing this afternoon. Other than shoveling snow....1 point

-

140psi oil gauge $100 on ebay

1 pointThat's the Auction broker selling someones hoard I posted about in "Internet Finds" They are trickling parts out one at a time. Some are reasonable and others are overpriced like the hand throttle. Some have sold right away like the oil pressure gauge and metal fan. others are still there from the start, like the air filter housing. https://www.ebay.com/sch/eBay-Motors/6000/m.html?item=293365062656&hash=item444deb9c00%3Ag%3AVQsAAOSwE19d6AUr&_ssn=auctionworks11 point

-

78 280z trans/clutch/flywheel advice, car sitting 12 years!

Couple questions and suggestions. It's been many moons since I've pulled the tranny out while leaving the block in the car... Once the tranny cross member has been removed, isn't it necessary to support the rear of the engine to keep it from rocking on the two side engine moutns? Block of wood on a jack under the oil pan or something? Or is a support under the front pulley? I don't remember which direction the engine wants to tip. Other things? You don't need an alignment tool to remove the clutch plate. It'll drop a little bit once you remove the pressure plate, but no big deal. No need to mess with the alignment tool there though. You got two hands. And when putting the new clutch plate into place, I'm not sure the clutch alignment tool fits through the spring fingers of the pressure plate. The reason that 's important is that I think you might have to put the pressure plate on first. Loosely into place before you reach in and lift up the clutch disk to slip the tool into place. But again, been many moons. This step "Turn clutch tool to match trans input shaft as best as possible." I think is an exercise in futility and optimism. I don't think you can align the splines rotationally by eye before trying to fit the tranny into place. And even if you can, wouldn't it be a lot easier to turn the transmission input shaft to match? Haha! Lastly, You used the word "hammer" a bunch of times. I would prefer the word "tap". It's semantics, but if other people are thinking of using this procedure, I think it conveys a better mental image.1 point

-

Sourcing Coolant Leaks

1 pointCoolant pressure test should really pinpoint the issue . Watch your pressure as the engine runs . If it starts to rise , start pulling spark plug wires one at a time until you find the one that stops the pressure from rising .1 point

-

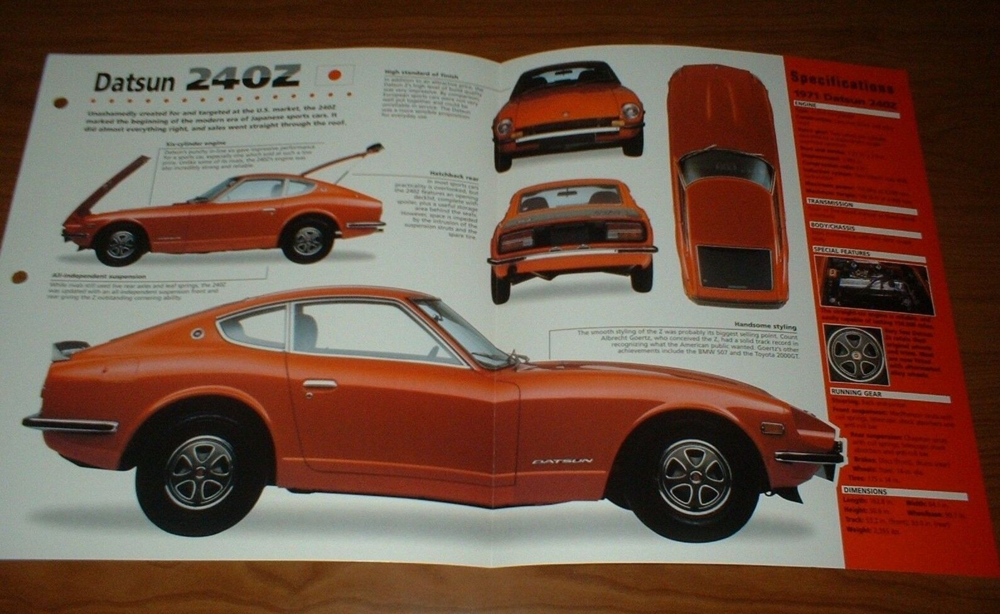

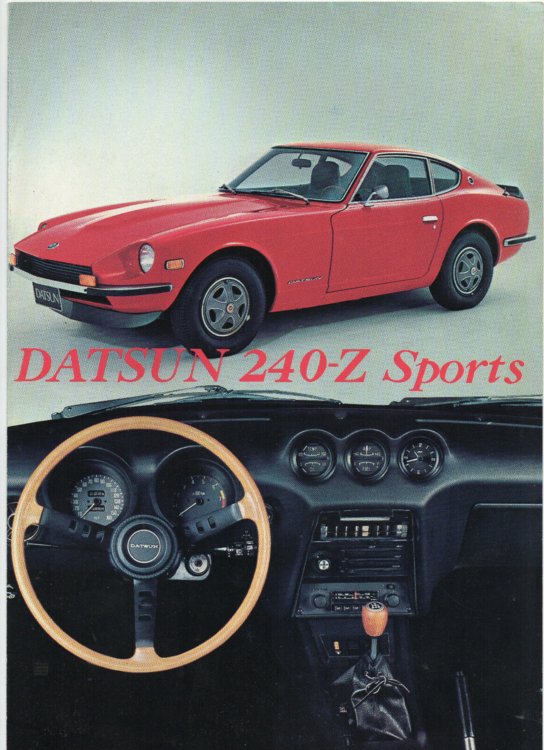

Fairlady 432 at Auction

1 pointHi Gavin , safari gold is rare I think too . They are not Auction but currently three Z432 are available here , https://www.carsensor.net/usedcar/search.php?CARC=NI_S026&AL=1&SORT=4&STID=SMPH0001 Two white ( one of them 1969 made ) , one orange. And this green car was for sale 16,500,000 Yen at カーセンサー recently. Some weeks ago it was dropped so someone bought I think . The car is a survivor, very original car . I even may want it to be as it is to enjoy its patina look . This car can be drivable easily. Kats1 point

-

My two swiss S30Z Fairlady Restoration build thread

Thanks a lot sir. Only problem with this thread is the slow progress, lol ? but since the house is finnished now, i hope i slowly find more time to get back into the project ?1 point

-

140psi oil gauge $100 on ebay

1 pointI've got to start cleaning up all the gauges I have accumulated over the years.1 point

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Now something VERY interesting. I have two 5 speeds and a 4 speed apart. I've been working on and showing pictures from the rusty one with the bad 1/2 fork. The OTHER one, now that I look at it's shift forks (the one with the totally gone counter shaft intermediate bearing) has, just as ZedHead had mentioned as a possibility, shift forks that are exactly like the ones in the 4 speed! Haven't put it on to prove it yet, tomorrow! Roll pin's in the same place by the looks of it, shape and orientation is the same, they are just steel in the 4 speed, aluminum in the 5. Well that doesn't solve my need to source a fork for the other 5 speed, its shifter rod has the dowel pin holes in different places, but you 'COULD' slide the 4 speed fork on and tack weld that sucker in place on the rod. Or drill and tap for a couple of set screws, etc etc. There is always a way! Now I'm cursing myself for all the 4 speeds I've recycled.... and those little balls for the rod detents that go astray, etc etc. Oh well. I also have to take apart a C type and see it THOSE shift forks adapt into the FS5WB.1 point

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Ok, stupid insulation is in place. Man I itch all over, but some antibiotics will cure that ? First pictures of the worn fork. Here is the "good" side of the fork so you can so the little plastic wear block with the two pins that hold it. Then the bad side. both tips have the wear block worn right off. The pins push through to the other side, so they stay in place, but look at the groove worn in the entire circumference of the fork from pushing against the selector. Here is the full shot of the bad side. Here is a repost of the shot that showed the groove and selector together so you get the full picture. You can even see the plastic pad pushed away from the fork with the pins keeping it in place. To think about a repair on this part, sure, you could weld up the new groove at the ends where the pads were (that's all that touches), and machine it back down to the right thickness, but very hard to come up with a new wear pad. How long would a newly welded bare aluminum pad last? As long as the shifting is easy and you keep your sticking mitts off the shifter when driving, maybe a long time!1 point

-

L28 full rebuild assembly

1 pointI ground the weight off the skinny side of the rods with a die grinder. Up and down both sides until they weighed.1 point

-

need guidance on 78 z gas tank and sending unit

Thanks for reference. Yes, CLR works magic and restore s the unit quite well. Mine was pretty decrepit and is now 100%1 point

-

Hello

1 point

-

Fairlady 432 at Auction

1 point1 point

-

Z's only a mother could love thread

1 point

-

Fairlady 432 at Auction

1 pointMaybe you can start a little side business to tell art galleries that they don't need to buy those Rothkos, and that you'll knock them up something similar at a fraction of the price...?1 point

-

1977 280z Light Restoration Project

I would pick up any 5 speed for $75, but I am some what of a "collector"1 point