Leaderboard

-

wheee!

Free Member7Points4,607Posts -

zKars

Subscriber

Subscriber 6Points3,747Posts

6Points3,747Posts -

Captain Obvious

Free Member3Points9,849Posts -

gnosez

Free Member3Points1,633Posts

Popular Content

Showing content with the highest reputation on 12/17/2019 in all areas

-

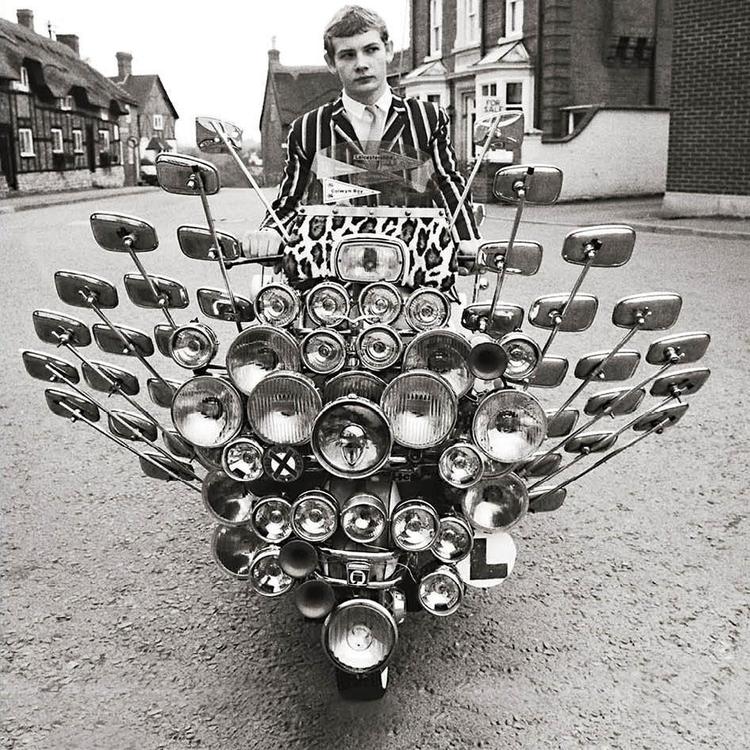

Let's show vintage racing pictures. I'll start.

Following an incident when a 240Z tried to use a B8 as a launch pad, Chevron have MODified one for Brian Johnson's next race:2 points

-

Alternative Brake Vacuum Hose Source?

On the east coast, Bel-Metric in Massachusetts has a wide assortment of name-brand braided hose (mostly Continental), sold by the meter. Prices are competitive. This is a large, well-established vendor with excellent shipping. Huge catalog metric fasteners and hardware, as well. www.belmetric.com The fittings for the S30 vacuum hoses measure 10mm OD. That suggests that a 9mm hose will be the correct size.2 points

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

I know you know this already, but you always need more tooling. Always.2 points

-

1976 280Z Restoration Project

2 pointsSo far I have seen very little to no trash in the finish work. The door panel middles that are covered with door cards have a bit but that is because I didn’t prep them the same, just cleaned them. I expect I will need to cut the finish clear coat on the car when I’m done, but the base coat is coming out flawless. I’m pretty stoked to see this coming along! The valance is the first piece of the cars outer work I have painted. Tomorrow is the shells edges and doorways etc. Then the inside of the hood and hatch.2 points

-

Steering wheel parts

2 points

-

Alternative Brake Vacuum Hose Source?

If you want some braided hoses, jbugs in Southern California has a bunch all in nice metric sizes too, i think they give you a discount on the first order through them if you sign up for news letter.2 points

-

Steering wheel shake, my story

1 pointI am sure this has been covered but wanted to share anyway. Since I have owned the car it has had the same tires on it, they were fairly new looking when I go the car a few years ago. The car has always had a slight shake or shimmy I guess you would call it that would cause the steering wheel to shake MOST TIMES around 40-45 mph. That is it would almost always have this shake but not always. After going thru all the front end parts looking for an issue, including take the wheels off and having them re balanced, I finally decided to try some new tires/rims. This dates back to when we had a 1974 260z that did the same exact thing, it came from the dealer with turbine rims (yes we paid for the "upgrade"). After several attempts to resolve a same shimmy in the steering wheel we return to steel rims and the problem when away. Due to the generosity of a member here (JSM) he let me try out some wheels he had been storing. They were steel rim with 205/60 IIRC tires. The tires I had were TOYO brand 195/70. the 60 profile means the diameter of the wheel in quite a bit smaller. After a extensive test drive at all speeds the shimmy is completely gone in my 280z :) I don't know if my alum mag is the problem or the TOYO had flat spots or still improperly balanced, but its nice to know for sure its a wheel issue. The 60 profile tire effected the reading of the speedo quite a bit, 80 indicated was more like 73 actual. I assume the analog speedo is not the accurate to start with but just something I noted (used the gps for actual speeds). The 60s also seemed to allow for a more "pep" as the engine wound up higher, I presume due to the smaller wheels making like a higher number diff ratio. I will still go back to the 70 series though since the look of the 60's just is not right with a 14" rim (just too small over all). I can see how the 70's really need a 3.7 vs the 3.54 diff for a bit more spirited a drive with the ZX 5 speed and its .75 OD. I have correct hub caps coming that should make the car look totally original. again a HUGE thankyou to JSM for letting me try out those wheels, with out that I would not have known for sure the issue without the expense of trying new stuff, now I know for sure.1 point

-

1977 280z Light Restoration Project

I had to use a 1/2" drive 24 inches long pull handle in the plug then pushed it up with a floor jack. My cheap impact wouldn't budge it.1 point

-

Alternative Brake Vacuum Hose Source?

Hi , here is another choice of those hoses , I made them from the fuel hose 17239-E4600 . This hose is still available from local Nissan 1500 yen (13 USD ) , my friend bought it last week in Japan . I did this work in 2008 , pretty much satisfied with the results. And functioning perfectly still now , my blue 240Z and Z432 had got these hoses installed and no problems. Kats ,1 point

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Looking for trans parts? These guys have a decent selection. Even claim to have my shift fork. https://www.transmissionpartsdistributors.com/fs5w71-fs5w71a-fs5w71c-fs5w71e-fs5w71g-fs5w71h/ Thanks to Aaron Heath on FB for pointing this out. I put out a plea for parts last night.1 point

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

I knew I could count on you guys. Of course! The boring head. And a coax? Looks complicated, but you need what you need, right? off to the tooling store! Yahoo! all this requires that my mill head fits down into the transmission case. Haven’t tried that yet....1 point

-

Let's show vintage racing pictures. I'll start.

The Chevron is RHD. Chevron is an English race car manufacturer with all sorts of credentials. The B8 was a 2-liter sports car championship car from the mid-late 60s. They came with BMW or Ford Cosworth 2-liters. Tube frame and aluminum panel chassis.1 point

-

Another running rich, or not so running thread

Chock another FI problem to corroded wires. 1975 280z new to me. Got it running after new injectors and rehabbed fuel tank. It ran well until it warmed up then would sputter and eventually fail to start. Would start when cooled off but eventually it wouldn't do that either. Plugs were drenched in fuel. If I pulled the PCV hose off air intake hose it would run but not well. I blocked fuel line to cold start valve but no change. Next pulled connector to coolant temp sensor and snapped it back on, no change. Then traced wires back to the 2 bullet connectors, pulled apart, shorted them to each other and voila, it started, albeit it popped and stumbled until warmed up. I figured poor running on start was due to the lack of the extra shot of fuel to injectors during cold start. So, I pulled the entire wire set, CTS connector to bullet connectors, soldered a new CTS connector on pigtail, cleaned all terminals with Deoxit and a pick or wire wheel (depending on male v. female ends). Now it seems to run proper. When I get my clutch sorted out, I'll be able to drive it. It seems to be stuck on flywheel. The car sat for decades. BTW, that Deoxit seems to clean electric parts very well. It's pricey but you don't need to use much.1 point

-

Throttle cable upgrade

1 point1 point

- Throttle cable upgrade

1 point1 point- Throttle cable upgrade

1 point1 point- Throttle cable upgrade

1 point1 point- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Simple... I wouldn't have to create anything. I'd use a boring head who's purpose in life is to do exactly what you described. And if your mill is R8 native spindle, you can skip the collet as well. Use a small one (like 2 inch) and dial it in. Easy-peasy. And as for the centering, I wouldn't mess around with that either. I'd whip out the Blake co-ax and indicate it in-situ. Blake is expensive, but there are far-east options that won't blake the bank. If you don't have a boring head, or a co-ax, you could resort to a fly-cutter and an edge finder.1 point- 78 280z died and won't start back up

problem solved! I guess my spark just wasn't strong enough. I did test for spark and it was there but it mustve been weak. I pulled the distributer cap to find a small amount of moisture and the points had been corroded. Cleaned em off with a file and she started right up.1 point- carter crt-p60430

1 pointwell I ordered the pump and will post how it runs should be by end of the week if anybody is interested. also I found today that carter bought airtex a few months ago from the carter people that's is very interesting.1 point- tail shaft leaking

1 pointwell I think I found why there is a problem with my leak . I ordered this seal nos oem Nissan part and it does not have the internal spring around the rubber lip. I check on line with Timken and national brand seals and they have the inner spring which will kept it tight around the yoke . my Nissan brand must have been missing the part or there was a problem and the aftermarket company improved with the spring. so I will pull out the seal again and change with the Timken brand and really look over the yoke again and if I see any concerns I will order a new yoke and u joint . thanks for the help, and I will post how the up date fix went.1 point- Stock Brakes for Track?

1 pointYour problem is that you selected the wrong pads. Pads and fluid are the two most important components in a brake setup. I have raced my Z for years with no fade using stock front and rear hardware other than the pads, fluid and SS flex hoses. I use Ate Super Gold fluid and Porterfield R4-E pads (I endurance race and the R4-E is an endurance pads). I do run brake ducts, but only added them recently. I also have a 2.8L high compression engine, light flywheel and 195/60R14 Falken RT615K tires. That said, I am now in the middle of a major upgrade. I am switching to the vented front setup using Z31 rotors, S12-W calipers and T3 spacers. In the back, I am going to Mustang GT calipers and vented rotors using the Silvermine caliper brackets. The hydraulics will be handled by a Wilwood 1" bore MC and an adjustable prop valve. Pads will be Porterfield R4-E up front and stock GT500 rear pads which are track capable. I might or might not need to upgrade the rear pads to Porterfield. The new brakes will be paired with 15" Konig Rewind wheels and 225/45R15 Hankook RS4 tires. There are tons of great brake pads out there for track use. I like Porterfield, but Carbotech, Hawk, and others make good stuff as well. Spend 10 minutes on either Porterfield's website or Carbotech's website looking at their compound descriptions. Both go into great detail expailing the temperature ranges of each compound and their intended usage. If you are upgrading the fronts, you can either stick with the stock drums, or go with a disc swap. Keep in mind that most disc swaps, while easy to service, provide LESS stopping power than the drums. Most people stuggle to get enough rear stopping power. The adjustable prop valve will only reduce rear pressure and is no use with an undersized rear swap.1 point- 1976 280Z Restoration Project

1 point1 point- FS5W71B Rebuild Thread - Tips tricks and discoveries!

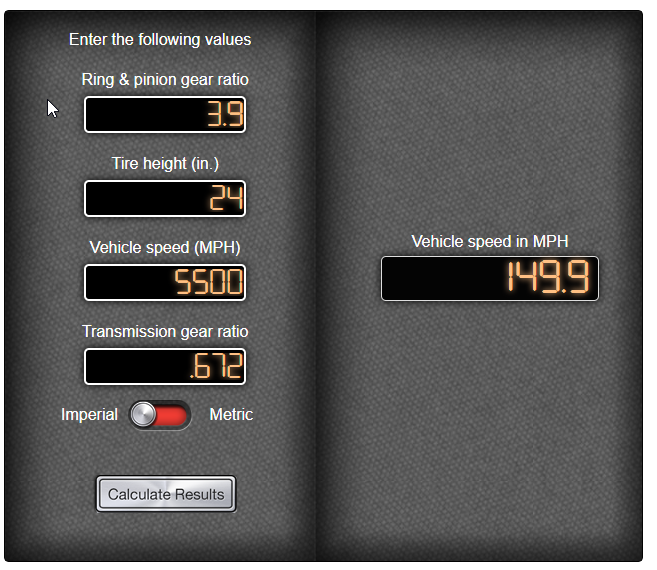

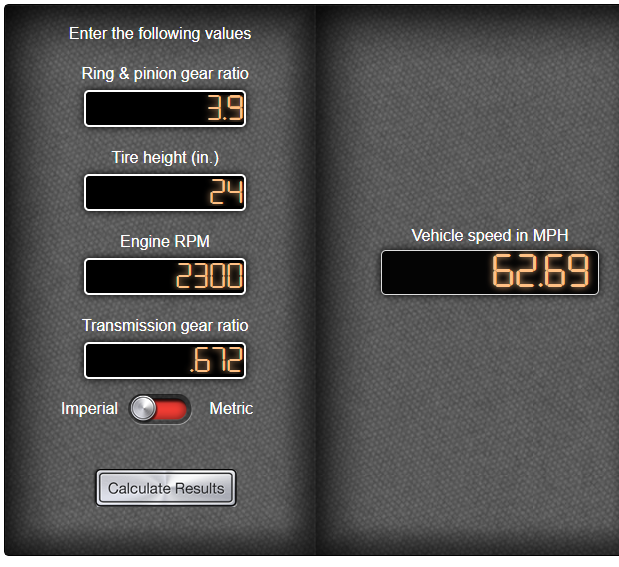

I have closer to 24 in tires Would be fun to get my little yellow brick to go 150! My WAG about 2300 at 62 mph/100 kph is pretty close!1 point- Alternative Brake Vacuum Hose Source?

1 point- Let's show vintage racing pictures. I'll start.

I never raced in historic events, just SCCA. They were both past the spinning car on the left when the Chevron took the line into the kink. The Chevron was ahead - it was his line. Morton plowed into the back of him. That's the way I see it.1 point- Let's show vintage racing pictures. I'll start.

Please note that there is a difference between "understand" and "agree". I understand why John and Randy see things but I'm not sure if they are right. It's a race but not a race in that no one wins any money so some modicum of caution is in order especially at the start. That being said, you're out there racing and it's hard not to press an advantage when you see one. That whole incident took place literally in at best two blinks of an eye. I run with VRG that has three race groups (small, medium and big bore) and while I could race in either the medium or the big bore group I elect to run with the V8s, V6s and 930 turbos along with other Zs. I get jumped hard at the start of most races by cars that have slower lap times but are much quicker off the mark at the start of the race. I consider a race start as a Darwinian experiment, one I don't wish to participate in and one in which some of my fellow racers exit before completing a single lap. It takes me a few laps but I manage to get by some of them by hanging all over them in the turns and late braking them on the straights.1 point- Let's show vintage racing pictures. I'll start.

The HSR passing rule doesn't go into any detail on when a pass in a corner can be taken (front tires or door to front tire of the passing car as an example) or anywhere else on the track so I'm not sure how they will judge everyone's actions (reactions) and this incident took place at the most dangerous of all points in a race; at the start, when folks are fighting for position. In the end it will be the decision by the Driver's Committee, Race Stewards or a similar group of people who will review videos and talk with those involved that matters. I am unaware of the outcome of any review and can understand John's and Randy's opinion that John was not in the wrong in that the Chevron left him no "racing room". I can also see where the driver of the Chevron may not of had a clear view of John's approach before moving right. Nothing good happened.1 point- Let's show vintage racing pictures. I'll start.

Each race organization has their own set of rules regarding car to car contact. Here is HSR's policy: "PASSING: The responsibility for a clean pass rests with both drivers. It is the responsibility of the passer to make a clean pass and responsibility of the passee to maintain a predictable line. " And this "UNSAFE OR DANGEROUS DRIVING WILL NOT BE TOLERATED. Sanctions will be imposed on drivers who are found at fault at the discretion of the Competition Director. Drive safely without incident."1 point- Alternative Brake Vacuum Hose Source?

You can also use that same size copper tubing with both ends open, insert it into the full length of the hose, bend it to shape then install just as it is with no baking. The copper tube has to be about 3" shorter than the hose so there is room enough on either end for the hose to slip over the nipples. There is more than enough space inside the copper tubing to accomodate the vacuum needed by the booster.1 pointRemove Ads - Throttle cable upgrade

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.