Leaderboard

Popular Content

Showing content with the highest reputation on 01/12/2020 in all areas

-

Mint '71 240Z - More Fun Coming to BaT

Dennis you're absolutely right. In the past year I've had 3 very long term customers give up their Zs due to their ages. Two of them are original owners. I find this situation very sad indeed. Perhaps my sadness is reflected in my own situation. Although I get around just fine at almost 70 and still put a few hundred miles on my 280 every year I recognize that the end is closer than the beginning.5 points

-

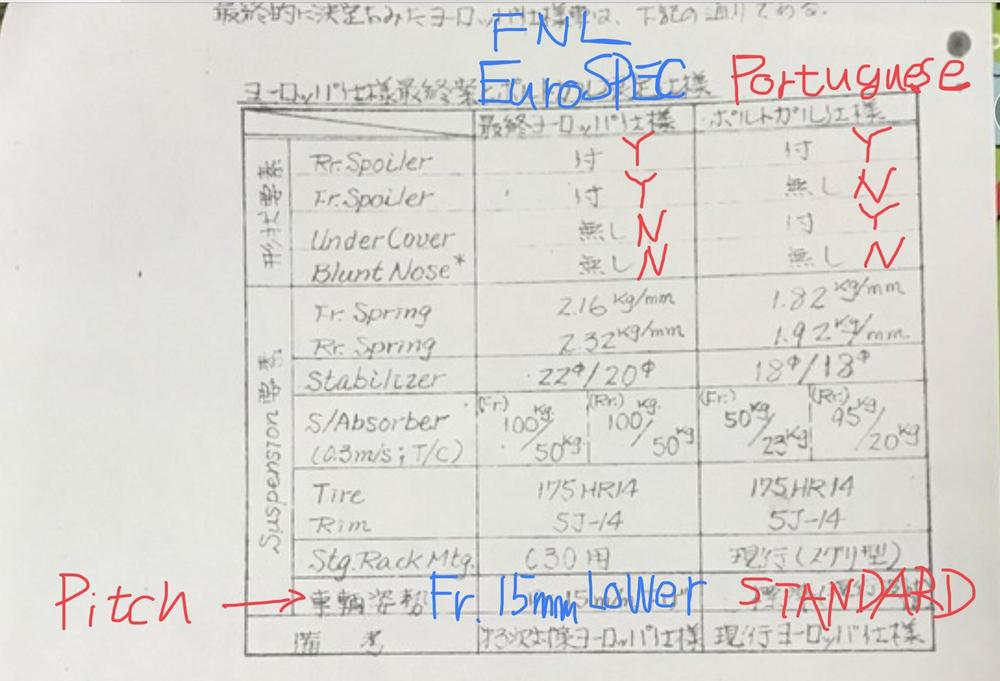

Test report of "HLS30Q (Z Europe model) countermeasures High speed stability "

3 points

-

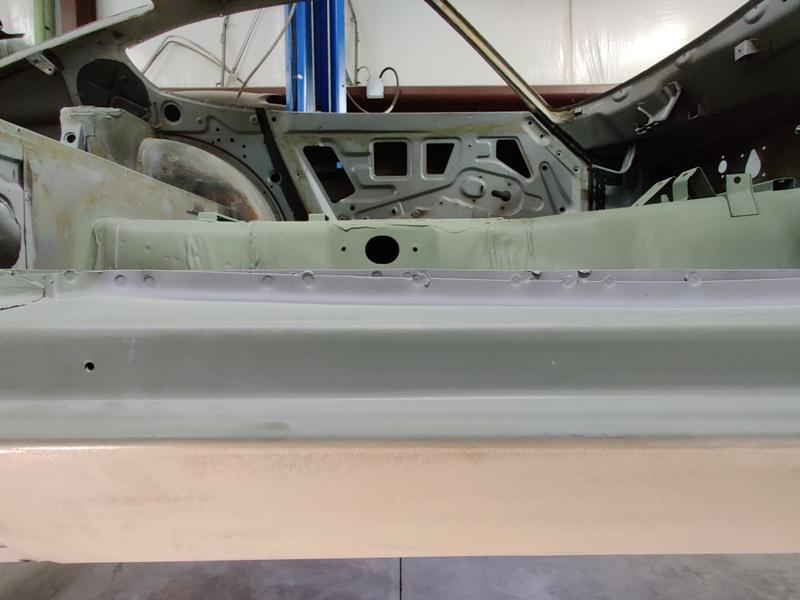

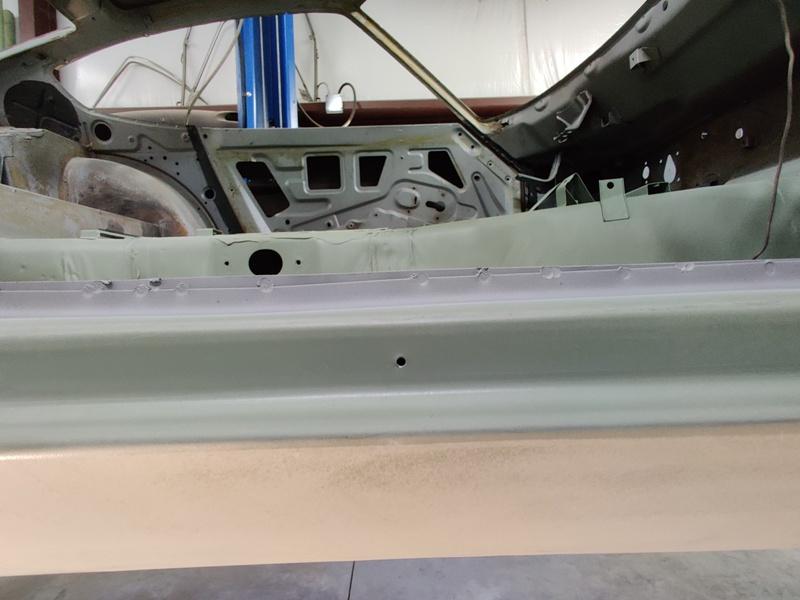

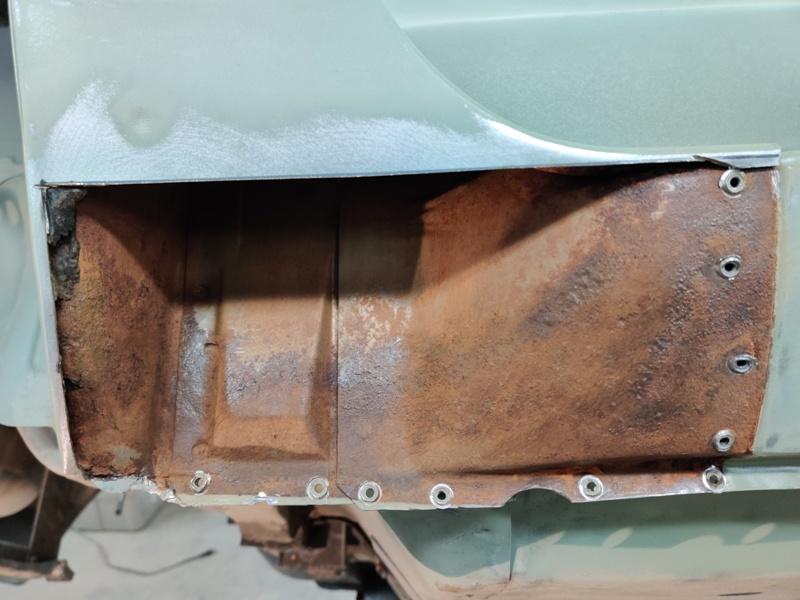

Restoration of BringaTrailer 240z - HLS30-35883

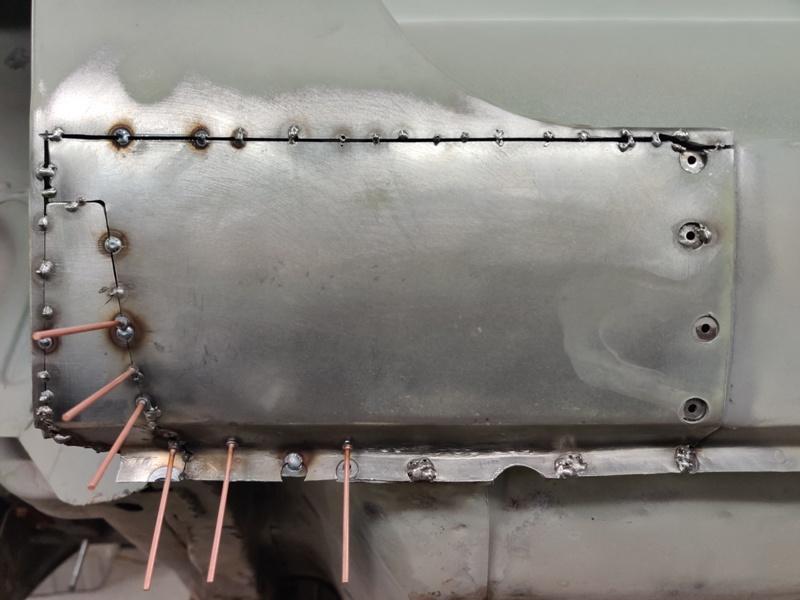

Work to straighten out the misaligned rocker panel (at the factory) has begun. In addition to the problem I already showed pictures of, the top of the rocker panel had some misalignment as well. The outer panel was noticeably low along the top edge, but only for the center portion of the rocker panel. This caused a dip in the top surface that the aluminum threshold goes over top of: You can even see where the spot welder completely missed in attempting to join the inner and outer panels. Seems the workers at the factory had to adjust the welder downward to hit the outer panel, and even then, they could only pick up the top edge. I didn't show how I corrected it, but I just drilled out the spot welds, then used the stud welder to put some pins on the weld flange, and then used a crow bar and piece of plate to protect the top surface of the rocker, while prying up on the pins. This allowed me to put enough lifting force on the weld flange to raise the low area of the rocker. I then welded, with my Mig, the holes left from cutting out the factory spot welds, and ground everything flat again with the surface of the outer panel's weld flange: It's not perfect, but it is much better. Metal work like this is a big time suck. Lots of tedious grinding of welds. I finished them off with my hand held belt sander. I hope to experiment with the spot welder I bought on this flange, but the electrodes may be too large in diameter to align well on this flange. We'll see. Next up was the part where the quarter panel folds over the rocker at the back. Interesting to see what is inside. After a light dressing with wire brush... and the outer panel piece receiving some attention in the glass bead cabinet: The sandblaster was again employed to remove corrosion and get to nice metal. Got several pictures while this area was seeing the light of day: Close ups showing pitting (light pitting, in my opinion): My first 240z was missing the entire dog leg corner (inner and outer). So nice to see this area in such nice condition. Pic showing up inside (bare metal from the factory and the seam sealer they used in the wheel arch). A few more minutes in the glass bead cabinet with the panel. The dark corner (upper left in pic) was pitted too much, so I made a section to replace that. Taping for application of weld thru primer. I've never used it before. It is kind of transparent (has been applied in second pic): Tape removed and outer panel tacking in progress with new fabricated piece also (bottom left) As the welding occurs, the panel wants to move around. I used the stud welder to yank on low areas, trying to keep alignment as best as I can as welding continues: Alignment is not bad. Lots of time involved with keeping alignment, tacking, and eventually grinding. I easily have more than 30 hours of time with fixing the rocker and removing and reapplying this panel. The end result of the main effort, to straighten the bottom of the rocker panel/quarter panel along the bottom of the car is "better". Sometimes I can't get things good enough to my liking. I've ground the welds in the last picture down and filled small voids etc. More pics will follow, but it's time to get out there and work on the car again. ?3 points

-

Rockets from Iran hitting US bases in Iraq now

Yeah, that is the problem with jerks. They seem to be sprinkled all over the place. Given enough time and you will find them.3 points

-

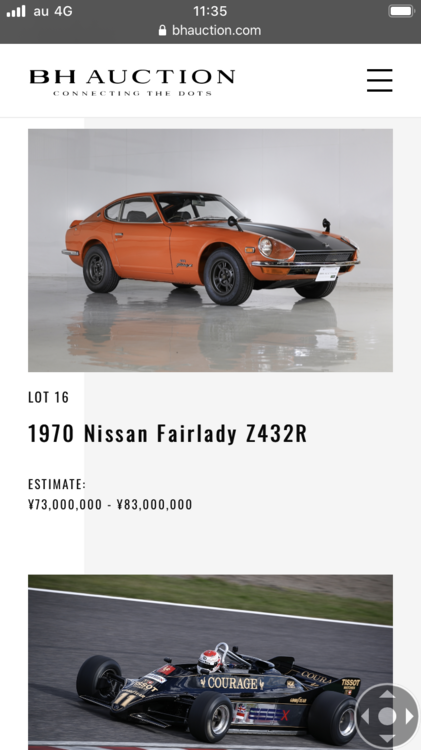

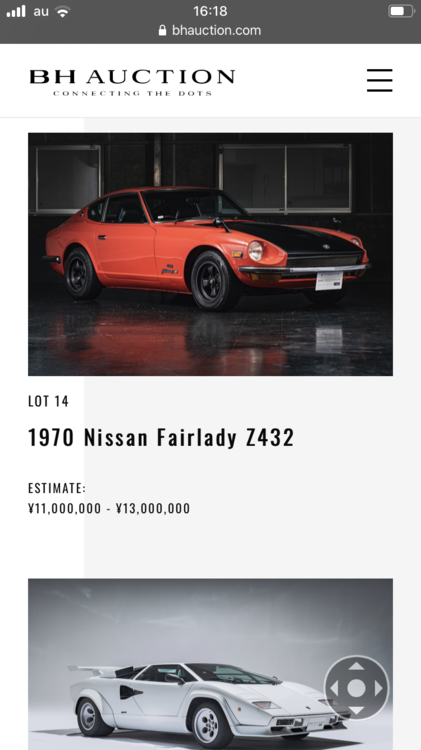

Fairlady 432 at Auction

3 pointsQuick report, 1970 Z432 hammered price is 1480 0000 JPY 1970 Z432R hammered price is 8050 0000 JPY . Z432R had only three bidders, phone bidder won just in a few minutes . Kats3 points

-

correct suspension black

1 point

1 point -

correct suspension black

1 point

-

Fairlady 432 at Auction

1 pointhttps://bhauction.com/en/auction/tokyo-terrada-january/lots/432-r https://bhauction.com/en/auction/tokyo-terrada-january/lots/1970-nissan-fairlady-z4321 point

1 pointhttps://bhauction.com/en/auction/tokyo-terrada-january/lots/432-r https://bhauction.com/en/auction/tokyo-terrada-january/lots/1970-nissan-fairlady-z4321 point -

Mint '71 240Z - More Fun Coming to BaT

I really love this car , super clean tan interior , I have never seen such a beautiful, original tan seats , and other pieces. To keep it stay original is difficult if the owner wants to maintain the car better . This car has been taking care of incredibly. I want to see the jack and tire stopper if they have a matching date stamp on them . Kats1 point

-

280z 78 Wont idle, Running Rich, out of ideas.

Ouch. You can move the crankshaft by putting the car in high gear and rolling it. Future reference...1 point

-

280z 78 Wont idle, Running Rich, out of ideas.

You might be getting cam timing confused with ignition timing. It's a common misconception. You groove and notch have nothing to do with ignition timing. You should confirm that the ignition timing mark is at zero when the #1 piston is at TDC of the compression stroke. That's the starting point for ignition timing. Not uncommon for the marks on the damper to be in the wrong place. Could be a bad damper.1 point

-

GQ.com Power of Z

1 point

-

Mint '71 240Z - More Fun Coming to BaT

Also, the buying demographic for those cars has aged into their 70s and is unloading and downsizing. Transient collectables tend to lose value when the buyers/enthusiasts age out and younger collectors aren't interested. Dennis1 point

-

240z - fabbing new front rails

1 point

-

240z - fabbing new front rails

1 point

-

Rockets from Iran hitting US bases in Iraq now

I know an Aussie in the process of moving him and his huge Datto collection to Onterrible soon. Moving to Canada is such a commonwealth thing to do.... ask Harry and Meaghan!1 point

-

Cataloging 240z factory manufacture paint marks

Thanks 240260280 and all, such great responses. I only wish that I had paid closer attention to these details when my car was new (who knew?). Here are a couple of pics/white paint dot on fuel pump center cap screw, and red paint mark on throttle control set screw along with small green mark on same.1 point

-

correct suspension black

1 pointWell I finally came up with something I think will work. It took several test panels to get it where I think it's right. I used Nason FulCryl II single stage mixed 8 : 3/4 hardener 483-11 : 1 1/4 reducer 441-21 when mixed to 6 sprayable oz's add 1 1/2 oz of Limco LF-10 flattener So a couple of weeks ago we scuffed everything down... Hung it all back up in the booth Made it all black this morning The sheen is pretty good. Has some sheen that you can see but not real glossy. If I had to do it over I might use the Eastwood satin but I have seen some issues with people having adhesion problems. The Nason has never been any issue. Sprays well and sticks really well. This is shot over Omni epoxy primer.... Time to order some bushings and get moving on reassembly1 point

-

280z 78 Wont idle, Running Rich, out of ideas.

I will send pictures first thing tomorrow morning with piston #1 at TDC, I am taking a break. busted my hand on the radiator pretty badly while cranking the motor setting to TDC0 points

Subscriber

Subscriber