Leaderboard

Popular Content

Showing content with the highest reputation on 03/11/2020 in all areas

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Quick update. Lot going on at home right now. I have a good solution going. Made the first group of 20-ish. Size is great, appearance comparison to original is pretty good. Drilling the hole after the initial forming is the only option. Any hole in the piece to start with is a) too hard to center, and tears out immediately, pretty much like the fender washers. Using a center hole in the FM part of the die makes drilling the hole in the middle very simple. Once I got the dies centered to each other consistently, I can make millions of identical little wrinkled creatures that only take about 175 finalization steps each. Easy peasy. I’ll have pictures to post of the whole process stages later in the week.2 points

-

Ignition Timing Mechanical Advance

2 pointsThe combustion is happening both sides of TDC. With low engine rpm, most of the combustion and gas expansion happens on the downside after TDC. As engine speed goes up, in order to keep peak pressure at 22 ATDC, more and more of the gas expansion has to happen on the upside, before TDC. Somewhere around 2500 to 3000 rpm the benefits of increasing advance and the downside of increasing combustion before TDC cross over and so Nissan (and everyone else) decided to limit the mechanical advance at that engine speed. Imagine the ignition has been advanced to 80 deg BTDC at 6000 rpm. (I'm just guessing at numbers!) combustion had to complete between 80 BTDC and 22 ATDC. That means approx 80% of combustion has happened before TDC, and that's a lot of gas pressure trying to stop the piston from coming up, and the gas is under very high pressure and any remaining fuel mixture is going to detonate. So you get serious knock and lots of heat but no more power. Something like that anyway :)2 points

-

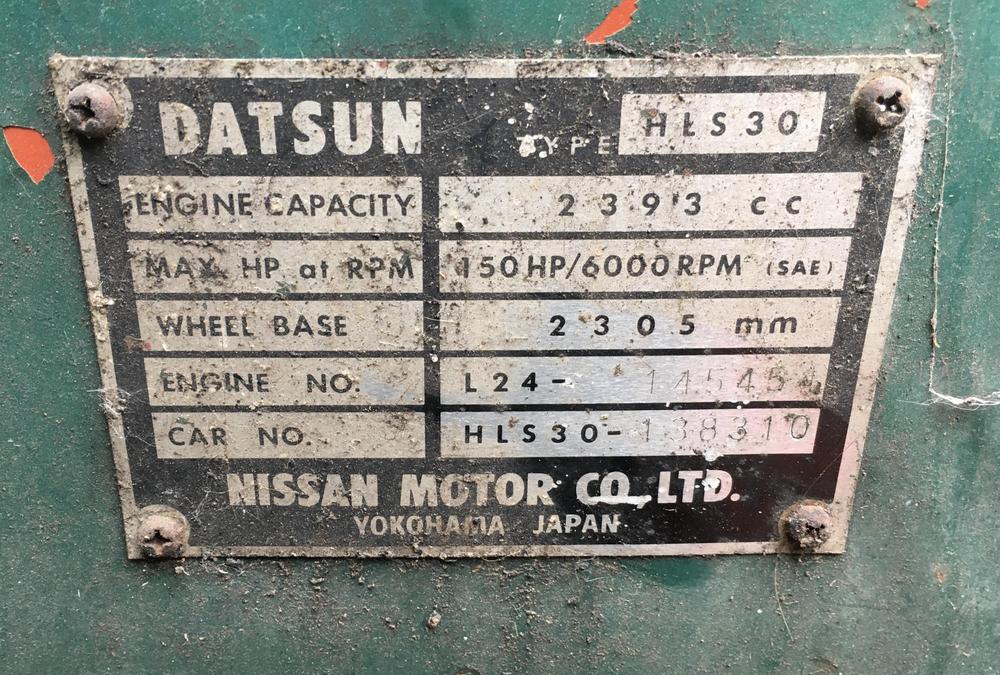

Re-Emergence of HLS30-00903

1 pointI was driving back from Portland on Friday and saw this on the side of the road. I circled back to at least check it out. Glad I did.... Do you see why??? It was HLS30-00903 disguised as HLS30-1383101 point

-

Ignition Timing Mechanical Advance

Yep, if you only pay attention to the interest of having peak gas pressure at 22 ATDC, you would keep advancing the timing forever. But there are competing interests. First, although the combustion takes a reasonably constant time, that combustion doesn't proceed linearly. It starts slow with a small flame front and grows and gets faster. Second, keep this in mind: gas pressure when the piston is on the way down is good. gas pressure when the piston is on the way up is bad. At 1000rpm with 15 deg advance, the 1.3 ms of combustion takes 37 degrees of crank rotation. 15 BTDC and 22 ATDC (say). most of the burn and and nearly all the gas pressure happens when the piston has passed TDC (ATDC). At say 5000 rpm, the engine is going 5x faster but the combustion still takes 1.3ms. So you need 5x more degrees of rotation to give time for that 1.3ms burn. So we need 5x37=185 degrees for that 1.3ms. If it is to complete at 22 ATDC then it has to start at 163 degrees before TDC. So now nearly 90% of the combustion and a lot of the gas pressure happens before TDC, while the piston is still on the way up. So although peak pressure will still come at 22 ATDC, very significant pressure has happened while the piston is rising, which slows it and will cause some of the fuel mixture to explode. (detonation) so the negative impact of so much gas pressure before TDC outweighs the value of having peak pressure at 22 ATDC. Caveat: I am guessing at the causes and science here (although the article zedhead posted seems to agree with me) . But.. I am sure it is impirical fact that there is no more power to find by having more advance than that approx 35 number, and actually you get a broken engine instead through detonation.1 point

-

Checking correct fuel level at Round Top 3 screw SU CARBS Float bowls

Before the age of float syncs, I set the float levels using a 9/16" drill bit. That crude measurement and 2 1/2 turns on the mixture screws always gave me light tan plugs. Go for it. I'm betting you'll find yours are very close to 9/16". Be sure to tell us what you find.1 point

-

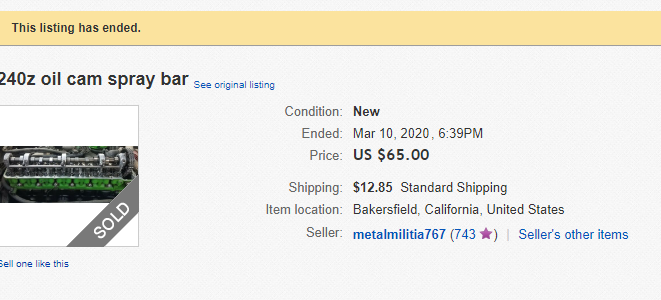

New Oil Cam Spray Tube

1 point1 point

-

78 280Z rear strut removal

1 pointUnless you just want to own a set of spring compressors, check with your local auto supply such as Auto Zone or O'Reilly's that have tools to loan at no cost. If the last set of shocks was installed into the strut without some oil, you may find they have become rust welded to the inside of the tube.1 point

-

Ignition Timing Mechanical Advance

Piston speed, and combustion chamber volume, varies dramatically with crankshaft position. If you created a plot of chamber volume with time, there would be a long stretch where it was close to its minimum, almost unchanging.1 point

-

Ignition Timing Mechanical Advance

Volumetric Efficiency must come into play.... that is the amount of air (and fuel) filling the chamber. As the throttle opens wider, more air and fuel enter the chamber. Somehow this must be part of the reason why advance is limited at higher RPM WOT.1 point

-

240Z rear disk brake conversion

1 pointYes, I replaced the bearings when I did the conversion. The car has only "been driven on Sundays" since then. 10 - 12 autocross events per season. ? Thank you for your input!1 point

-

Ignition Timing Mechanical Advance

Thanks again for the input. I appreciate the discussion (which is clearly academic in nature). You said above "the speed of combustion is reasonably constant." If that's the case, then the same amount of time after a spark would develop the same pressure at the same rate regardless of the rotational speed of the engine. That's the whole point we both made above (and it's the theory behind adding centrip advance at all in the first place). I'm saying don't think degrees. Think TIME. The problem is that "degrees" changes with rotational speed. Time does not. If the burn takes 1.3 milliseconds to develop optimum pressure at 1000 RPM, wouldn't it take 1.3 milliseconds at 2000 RPM as well? And 3000 RPM? And 6000 RPM? Why would the burn occur faster at 6000 RPM that would necessitate backing off the advance* at that speed? If the burn rate is constant (in TIME), then shouldn't it be the same regardless of RPM? In other words, the fuel mixture doesn't know or care what the engine RPM is. All it knows is at what TIME it was lit off. If it burns at a constant rate you should adjust the light off to the same TIME regardless of how fast you're approaching TDC. * I say "backing off" because the speed goes up, but the amount of advance does not. It's like volunteering because everyone else in the line steps back. Just a different point of reference.1 point

-

Rear Spindle Pin

1 pointI finally got to try my spindle pin puller last night. I made it years ago using high quality 1" acme threaded rod and a front strut bearing. Granted, the car isn't super rusty, but it worked great. I had the RH pin out in less than 2 minutes once I got the wedge bolt out. I'm doing a rear disc conversion on my race car, so I pulled the stub axle and spindle pin. I will replace the wheel bearings and outer control arm bushings while it's apart. I was pretty happy with the job. The hardest part was cutting the peened sections off the axle nut without touching the stub axle threads. Tonight, I will pull the LH side apart and then start pressing bearings. The real test for the puller will be on the spare corner modules I have in storage. Those came off a really rotted car and they are likely going to need to be cut and pressed out.1 point

-

78 280Z rear strut removal

1 pointthe only way i was able to remove my front driver side was to drill out a hole in the bottom then stick a allthread rod inside and beat it out of the housing. Once you get it out its going to be super nasty and a pain to insert a new strut tube inside, so i took one of these https://www.harborfreight.com/power-tools/grinders-sanders/grinding-cutting-wheels/2-inch-polycarbide-abrasive-wheel-brush-94013.html extended it on a rod then through it into a drill to clean the inside of the tube. After that weld up the hole you made and your done. If you're talking about the glant nut that ZedHead is refering to, i welded a tube onto the top of the nut, then used a pipe wrench on the tube, which combined with the heat from the welding, and a 6ft cheater bar it came loose. heres a thread i had about it.1 point

-

Re-Emergence of HLS30-00903

1 point

-

New Oil Cam Spray Tube

1 pointI think I’ll pull the trigger on it. I’ll let everyone know later if it all goes south!1 point

-

New Oil Cam Spray Tube

1 pointThe size of the outlet holes would determine pressure. Can't tell if they're too big or not. Not really much data to tell if it will work correctly. The cork gasket seems too thick and not right for the application. Good concept, functionality unknown. Send the guy a message and see if he has some more info. Even a video or picture of the bar squirting oil.1 point

-

Ignition Timing Mechanical Advance

1 point

-

Ignition Timing Mechanical Advance

The purpose of firing the spark before TDC is to get max cylinder pressure at the optimum point - I believe I read that the maths works out at about 22 deg ATDC is the optimum point. If combustion was instant, then 22 ATDC would be the spark timing, but combustion takes time and so the ignition is started at the appropriate time before hand. Since the speed of combustion is reasonably constant, as engine speed goes up, you have to start ignition earlier. I.e as the engine goes faster, you need more degrees of rotation for the time it take for combustion to reach its peak at 22 ATDC. So that's why the advance curve is set to give about 15-20 advance at idle and 30-35 at 3000 rpm. The question then is, why not keep advancing the ignition timing after that? The speed of combustion is still pretty constant and the engine is getting faster.... And I think the answer is something to do with by the time you're igniting at much more than 35 BTDC, the amount of cylinder pressure you've developed while the piston is still rising becomes significant and a problem (detonation) , so you have to compromise and accept that peak pressure must come increasingly after 22 ATDC as the engine speeds go up beyond that.1 point

-

My two swiss S30Z Fairlady Restoration build thread

Well the last week have been pretty busy at work, and i'm still working on some details of the house. but everything is finally calming down now and i have plans to kickstart the Z-project again soon and get some long overdue work done over the next months. So i got in touch with my Bodyshop guy to discuss a few details and then i just got an update from him from today. The old seat brackets got removed and sandblasted: Primered: And test fitted on the old cutout floorpan: And theis is how they look on the new floorpan, ready to weld it all back together:1 point

-

Ignition Timing Mechanical Advance

1 point

-

5 240z's and an R30 Nissan Skyline

Took the skyline over to my dad's (Diseazd) for a family photo. Missing from the photo is my Z31, his Z32 300zx and his NSX. Was definitely too bright out but it was the only time we had.1 point

-

5 240z's and an R30 Nissan Skyline

1 point

-

Only $1,700.00 for this Solid '73 240Z Project Car in Tucson, AZ

In todays market that is no longer a parts car1 point

-

Only $1,700.00 for this Solid '73 240Z Project Car in Tucson, AZ

I can't take it any longer… i'll take a few days off.. away from this site..1 point

-

[2020] What Did You Do To/with Your Z Today?

Battery Bling! Finally got around to installing new battery terminals that have sat around about 4 months. I like the way they look and will be great for the eye candy part of car shows but the functionality will require more effort. Instead of just a 1/2" (13mm) wrench, I'll have to add a full set of Hex keys and a 9/16" to the tool carry kit. The plastic covers look good too but there's Nooo Waay that I will ever let an Autozone guy replace the battery without me removing them first.1 point

Subscriber

Subscriber