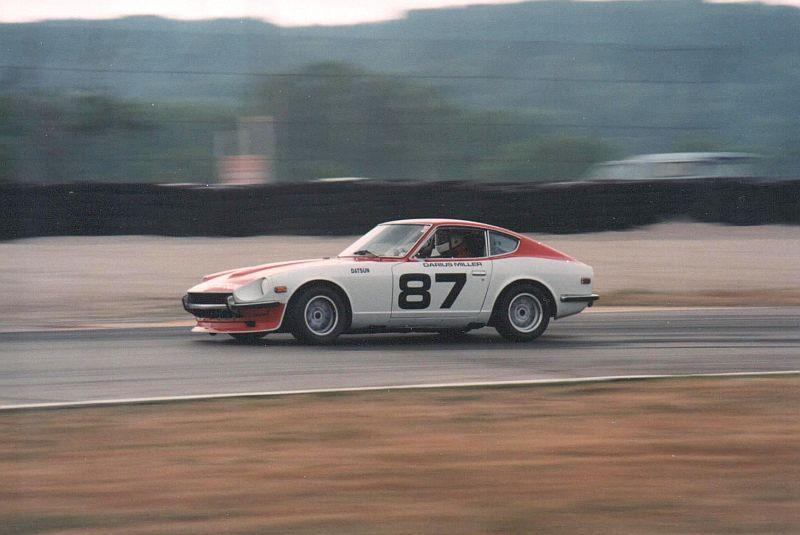

My race car is right around 200 HP at the crank and I built it as cheap as possible.

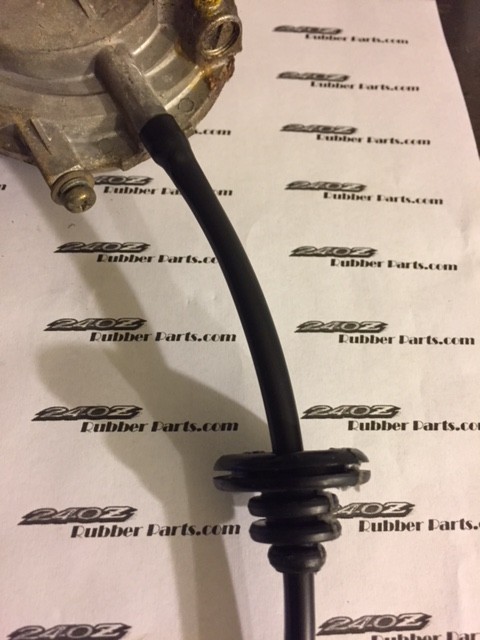

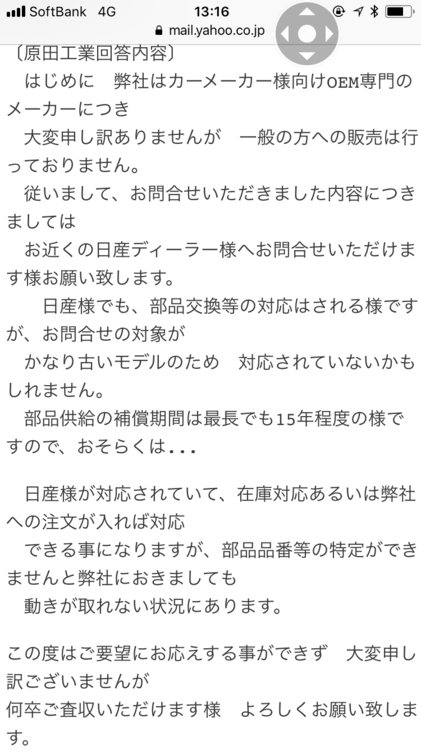

I started with an '82 F54 block/P79 head. I got a great deal from a friend and only paid $500 for the engine (with matchbox distributor), 5 speed trans and 3.90 diff. I had the machine shop measure and clean everything, hone the block, polish the crank, install new freeze plugs, do a valve job and mill the head 0.050". My machine shop bill was about $500 and the bearings, rings, gaskets, oil pump, water pump, timing set, head studs, etc. were another $750 ish. I already had an old header and the cam, rockers, springs, and lash pads, though if I had to buy new, they would have been about $700 more for all that. The crank damper is between $150 for a rebuilt stock and $600 for a BHJ. Finally, I had good SU carbs, intake and air cleaner housing, but that's another $500 if you need to buy a good set of rebuilt ones. I didn't need pistons, but that's another $250 minimum if needed. I added another $225 to get the flywheel lightened and $125 for a clutch. Throw in another $200 for misc stuff like belts, hoses, plugs, thermostat, air filter, etc. etc. and you will be at roughly $3,000 minimum if you already have a good engine to start with and don't buy a fancy damper or lighten the flywheel. Obviously, if you already have good carbs, it's a bit cheaper. I have built dozens of Z motors, so I only had to pay for the machining and I didn't go overboard on any component.

I'm not saying you can't make 200 HP cheaper, but you would need to already have a vast stash of parts which I'm guessing you don't have and you'd have to cut back on some pretty important items like oil pump, water pump and crank damper. If you start with a N42 block/N42 or N47 head, you can make the same power, but you will need flat top pistons and then the head isn't as knock resistant as the P79 or P90. If you shave a P79 or P90 head, most people choose to change the valves and shim the cam towers. I did not go that direction which saved money. I modified the cam gear and chain guides.

Good luck with whatever you decide to build!