I have a 1976 280Z that was converted to SU carbs by the previous owner. The mechanical fuel pump was crap, so I replaced it with a GMB part which didn't seem to work very well. I replaced that with another GMB pump which seems to work fine. I am aware that some have reported problems with them, so I also installed a NISMO electric pump. In reading on this site about how to wire this up I saw lots of advice about adding an inertia switch for safety. From the FSM and wiring diagram I also learned that the factory fuel pump in my car was controlled by the fuel injection relay, which had been deleted long ago from my car. This article describes one pretty clean way of wiring in a relay and an inertia switch to provide power to a low-pressure electric fuel pump in a carb-converted 280Z.

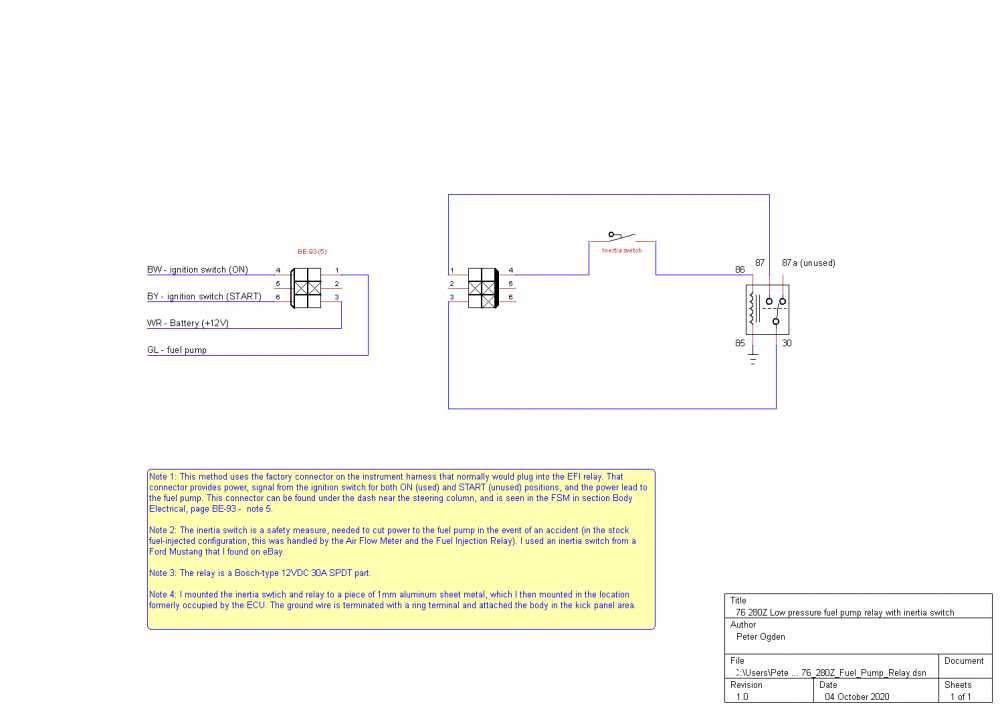

Background: In the 280Z the fuel injection relay is actually two relays packaged together: the EFI bible refers to these as the Power Relay and the Fuel Pump relay. When the ignition switch is in the ON position, the power relay sends sends power to the fuel injection system (ECU, fuel injectors, AFM); the fuel pump relay sends current to ... yep, the fuel pump. The current sent to the AFM doesn't power the AFM; rather, the AFM closes a set of contacts when the engine is running and air is flowing, and it opens those contacts when the engine is off. The current required to operate the fuel pump relay runs through those AFM contacts so that the fuel pump relay closes only when the engine is running and air is flowing. If the engine stops, the AFM contacts are opened and so is the fuel pump relay. It's a little more complicated than this (related to how the Start position of the ignition switch sort of overrides all of this so that the fuel pump can run in order to start the engine), but that's not really important for this discussion - I want the fuel pump to run when the ignition is in the ON or START position, unless I've been in an accident.

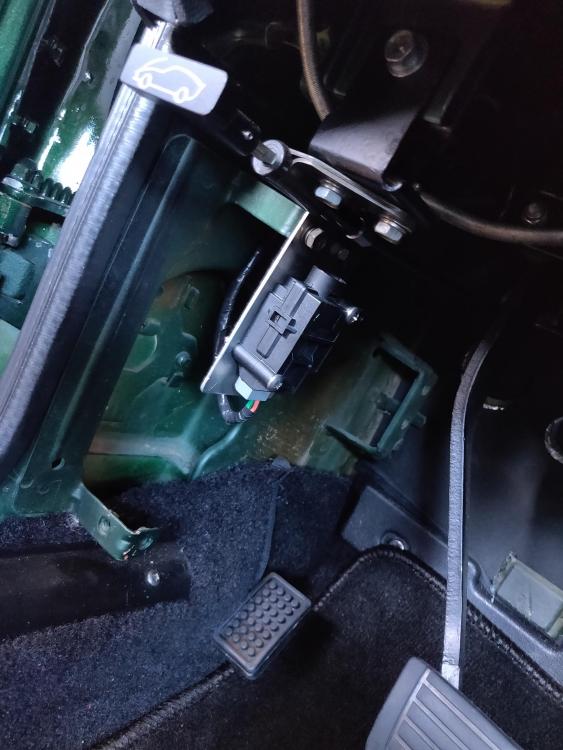

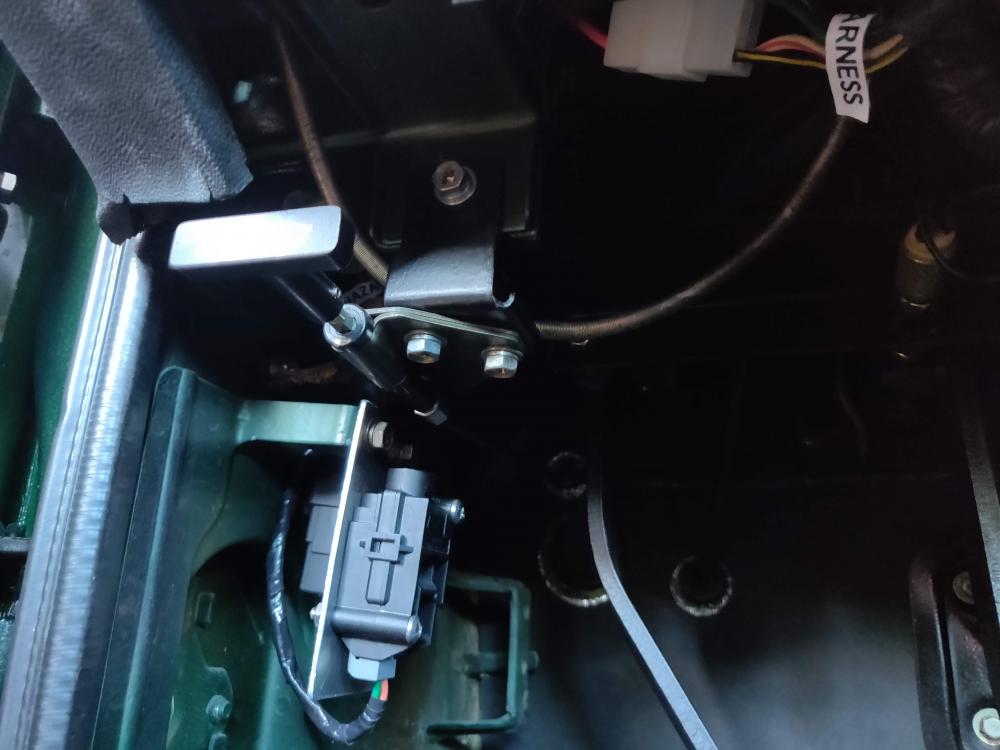

It turns out, there's an easy way to do this. The connector that (formerly) ran to the Fuel Injection relay is part of the instrument harness and is found under the dash by the steering column. I just replaced the female 6-pin connector (only 4 pins are used) with a similar one from Vintage Connections and then wired the male part to the Ford-type inertia switch and Bosch-type 12VAC 30A relay as shown in the diagram and pictures below. I just mounted the relay and switch to a piece of 2mil aluminum plate, and mounted the whole thing by where the ECU was located.

It seems to work: the fuel pump comes on with the key in the ON position, and if I tap (well, smack) the inertia switch to get it to open, the fuel pump turns off. I haven't driven it enough yet to know whether the inertia switch will "break" when I don't want it to (going over bumps, etc.), but it's easily reachable from the drivers seat.