Leaderboard

-

Av8ferg

Free Member5Points1,538Posts -

Captain Obvious

Free Member5Points9,850Posts -

Patcon

Subscriber

Subscriber 4Points10,925Posts

4Points10,925Posts -

Blubber

Free Member4Points3Posts

Popular Content

Showing content with the highest reputation on 12/20/2020 in Posts

-

A little help with my first 280z

4 pointsMade it onto the trailer thanks all for the tips gonna be getting a locksmith to make the key when I get home thanks all for the help I am sure I will need more when I start this project. Excited for my first z4 points

-

Ebay shipping time machine

3 pointsNice to hear the pilots who fly our airplanes like them, and yes, FedEx is currently buying more 767 freighters than any other company. We just finished up the 101st FedEx freighter forward body section, it is going through shake and will be off to seal and paint by the first of the year. I was reassigned to the 767 program last September, having worked the 777 (legacy, metal wings) program for nearly 6 years, first in wing majors (the wing final assembly shop) building the upper trailing edge of the wings, and then the 777 (again, the legacy plane) spars, on the front spars for a few months, then rear spars for 4 years. With the 777X going into production, the production rates have slowed as they integrate the two lines (when I started the rate for 777 was 2.5 days, then dropped to 3 days, then 6 days, then 7 days, and last winter it slowed to 14 days), coupled with the 737 issues, and this Covid 19 thing the company has been trying to avoid layoffs by shifting labor to other programs where staffing needs a boost, so quite a few structures mechanics have been moved from 777/777X to the 767 program. They have moved me 5 times since last February, including spending the summer on the flightline doing refurb work on a 777X that was built last year and has been in storage, and a short stint as a provisioner for the 777X systems integration final assembly, and been sent home 3 times for Covid contact tracing quarantine. I wasn't too enthusiastic about having to work bodies on the B deck, as my knees don't tolerate the crawling around on the stringers and floor frames, but the crew I landed on is a great bunch of guys and gals, the work isn't as physically demanding as the wing structures work, and the actual work packages are not as demanding with respect to the time given to complete the jobs (the 767 program is at a 7 day rate at the moment). Add to that the privilege of working on the KC-46 tankers, and that I only have about 8 months to retirement, I feel I can manage and be content there. And I really like what I do, which makes it less like work, and more enjoyable. It is awesome being part of the teams that create these fantastic airplanes. The best of the best. Every time I see one taking off or coming in to land I have to stop and watch it. Airplanes are second only to cars for me, magnificent machines that look great coming and going, or just resting quietly on the ground. In three and a half months I have seen more FedEx planes than UPS, and every second plane is a KC-46. So there is variety to the daily routine.3 points

-

240z VIN

3 pointsDitto. Carl has committed an enormous amount of time and effort to our collective passion for Z-cars. And all of this done free of attitude and ego. He deserves 'Founder' status.3 points

-

Ebay shipping time machine

2 pointsVery cool what you do. Airplanes have been part of my life since I was a young kid. Like you, having a passion for what you do makes it almost not feel like work. I’m currently flying the 757 but I am type rated in both the 757 and 767. I almost moved to the 767 last month because there is a really nice pay bump but I’d lose seniority and control of my schedule. Quality of life over money, it’s a value decision that many don’t understand. Most guys chase the $$. I commute on our 767 and everyone loves them, minus the bathroom in the cockpit. That was a UPS build spec that we didn’t want to pay to change but that’s the only complaint. The rest of our aircraft have the bathroom behind the cockpit door. We did have an accident in LAX in a brand new 767 about 8 weeks ago. One of the main landing gear failed to extend and the emergency system failed also. Really a 1.000,000 to 1 odds. Pilot climbing out of the window of the cockpit had a minor injury. These plans are a joy to fly and so reliable it amazes me. In the four years I’ve been with them, I’ve never had a flight cancelled due to a maintenance related issue, only declared an emergency once when a throttle cable got water in it and froze one the throttle levers. When I flew fighters in the USMC the jets broke about 30% of the time you tried to fly and I declared an emergency about 3 times a month. Sent from my iPhone using Tapatalk2 points

-

First start today!

2 pointsAs well as identifying what needles are in there, it may be a good idea to see if the nozzles are stock 100s. I see that Ztherapy sells different diameter nozzles. I know little about the different nozzles available or how to identify them, but if the PO installed larger nozzles it would run pig rich.2 points

-

Advice on Recent 1978 280Z Purchase

2 pointsBrowse over this page on BAT and you can see, pretty much just by looking at the pictures and prices, that deleting the big bumpers doesn't add much. Maybe even hurts. If you're planning to put it back on BAT in the future, and make a profit, best do what the actual buyers will pay for. You can even read through the comments on a typical BAT auction and see that most of the comments come from people who aren't buying. Your car is very original and in great shape, by the pictures. The cars that make the money are either the original cars or the heavily, professional level, modified cars. There are many half-done cars that don't do well at all. Make sure you know what you want the final product to look like and that you can actually get it done. It would be a shame to ruin a nice car like yours. https://bringatrailer.com/datsun/280z/ https://bringatrailer.com/listing/1977-datsun-280z-48/2 points

-

Advice on Recent 1978 280Z Purchase

2 pointsThat really is an untouched car, I don't see any repairs to the bottom of the car, you did well. But by the time you do the exchange rate and shipping costs you will have paid your fair share. You say you will keep it for a while, if you are thinking just a couple of years then I would keep it all original, if you are going to hang onto for longer then all of those modifications listed above will really wake it up. Although the engine bay looks a mess at the moment I think you will find under all that ziebart and cosmoline pristine surfaces that will clean up very well. I hope you will post more pics as you take it through the clean up process.2 points

-

First start today!

2 pointsThe factory standard needles are N-27, but a lot of people install SM's instead. That decision works out well for some people and some others report running rich. The number is either stamped or inked onto the hilt and is only able to be seen with the needle removed from the suction piston. However, if they are inked (and not stamped), the ink printing is pretty fragile and is often destroyed with handling or chemicals. In other words... It would not be unusual for you to pull the needles and find only remnants of the number stamp and not be able to tell what they are from the ink printed mark. It's easy to make the carbs run lean, but it's usually a little more difficult to make them run rich*. To run rich, it takes deformation of a needle or a nozzle, or the installation of incompatible parts. Did you ever get in touch with Paltech and ask what needles he used? * Assuming, of course that the float levels are OK and the nozzles are not sticking down with the choke.2 points

-

1976 280Z Restoration Project

2 pointsSo you're looking for captions for that pic? How about "Hey!! How 'bout you put down your beer and come help me with this tree?? This thing ain't gonna decorate itself up you know!!"2 points

-

1976 280Z Restoration Project

2 pointsBeen so busy lately. Glad I have a grandson to help get the tree this year!2 points

-

Starting Carb Conversion: Flat Tops to Paltechs

2 points

-

First start today!

1 point

-

Advice on Recent 1978 280Z Purchase

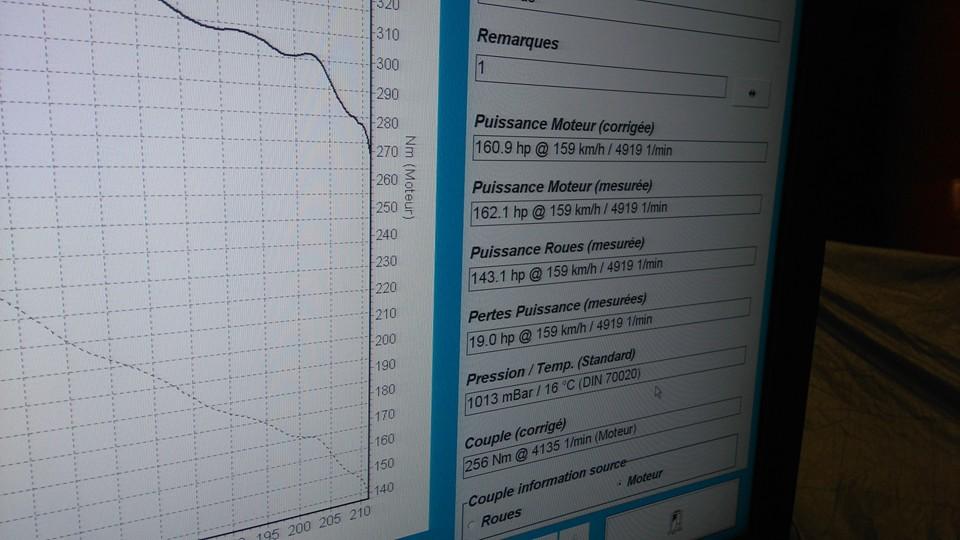

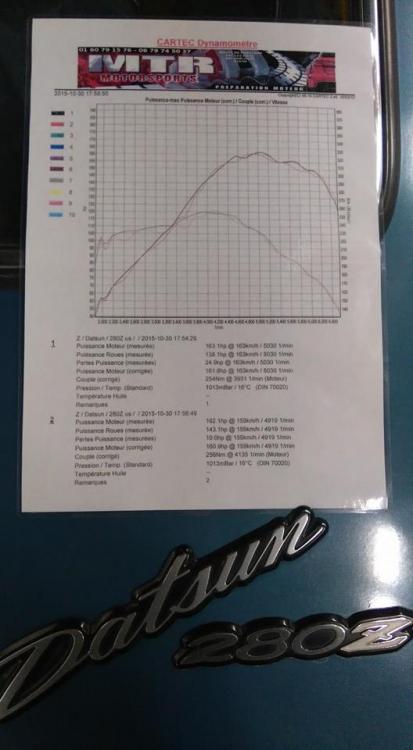

Fast-Road headers, line and Street muffler @Zstory. Previous 280Z here with the Street-Sport headers and Classic muffler made 162HP DIN with the EGR and CAT deleted and no smog issues : beautiful car inside and out.1 point

-

Advice on Recent 1978 280Z Purchase

1 point

-

Advice on Recent 1978 280Z Purchase

I concur with ZH, but in the end make the car what makes you happy not others. What I meant about changes is things like cutting the wheels wells to put fender flares on and such. That is better done on a car that needs lots of love and has rust there already. Not saying the bumpers are an afternoon job. Front is pretty easy, back requires removal of the drip edge by drilling out spot welds and then filling holes where bumper shocks came out, followed by paint I’ve seen many that leave the holes but it’s much better looking when they’re filled. In the end it could be reversed if a later owner liked the rail road ties. The big bumpers grow on you so as ZH said have the vision of what you want before stepping off. My first order of business would be mechanical. Go through it, and make sure all your hoses are good, look for leaks, give it a tune up, change fluids and then drive it to find any bugs or quirks. Don’t throw away anything as you make the changes you want. Congrats Sent from my iPhone using Tapatalk1 point

-

Zx 5 speed rebuild

1 pointI didn't check them all because that seemed moot. But the 5th gear and 1st gear were spot on those ratios. We may start breaking it down next week1 point

-

Zx 5 speed rebuild

1 pointThey are the ratios for the 79 to 6-80 280ZX coupe early close ratio 5 speed. Strange thing is the photos in your first post show the tell tale signs of a wide ratio. I was under the belief that the early close ratio boxes had the brass synchro. This project could shed a lot of light on this fairly rare transmission.1 point

-

Just Another Damned Z Car Project Thread

Hey, sorry to disappear like that. I had work Friday and Saturday, my retirement work week. Plus, I have a vulnerable family member with Covid19 and I get 4-5 calls a day asking about symptoms and treatments. He is my son-in-laws father. Fingers crossed. So my son did a rework which I haven't seen. I suspect it was to properly position the holes. He says that he just put visual holes in the drawing for now. He doesn't want the holes put in until I decide I'm using the 350Z DBW for sure. I guess, I'm driving him nuts. I told him it's payback for having to go through his adolescence with him...1 point

-

First start today!

1 pointLike the Captain said it could be the nozzles too. If you have a couple of good matched sets, you might want to swap out both1 point

-

Advice on Recent 1978 280Z Purchase

It’s a beautiful looking car, I love the color but I’m biased because it’s the same color as mine. Your’s is in way better shape than mine. I agree with many of the above comments. Definitely change out that tranny. I’d hold off on pulling the engine, unless you plan on making it a winter project. I think it will clean up nicely. My approach was to never do anything that can’t be reversed. So make the changes that make you happy but think twice about a change that is permanent. Example is the bumpers, many like the 240 style bumpers and you can always be put the railroad tie bumpers back. I don’t necessarily agree that these cars won’t increase in value and become collectibles in the coming years. Many cars that I’d never expect to be collectibles are demanding high prices. I just watched a 1984 Blazer sell for $38,000. Really!!! Sent from my iPhone using Tapatalk1 point

-

A-Type 4 Speed Mounting Position Help!

Not sure. I’m going to be putting the old exhaust system up there today, we’ll see if it still fits. It has no resonator at least, so it shouldn’t be a big deal, but when I replace it with a system that has one, it might be a bit snugger. We’ll see. He can probably kiss any hope of a CD009 350Z 6 speed conversion goodbye.Not much chance of that though with this car. Turned out to be closer to 1.5” narrower between the mount holes. If it weren’t for the 1” front to back offset, I could have just lopped the ends off and redrilled new holes.1 point

-

A-Type 4 Speed Mounting Position Help!

1 point

-

First start today!

1 pointSwapping in a pair of known stock needles would be a good test, and something relatively easy to try. I know you said you are already positive that your float levels are on target and your chokes are not sticking down at all. And with those two things not causing a problem, I'm having a hard time coming up with a scenario that would result in running rich without some sort of damage to a nozzle or a needle or a wrong part installed. Like I said, lean is easy. Rich is more difficult assuming you have already ruled out the easy ways to run rich (float levels and sticky chokes).1 point

-

240z VIN

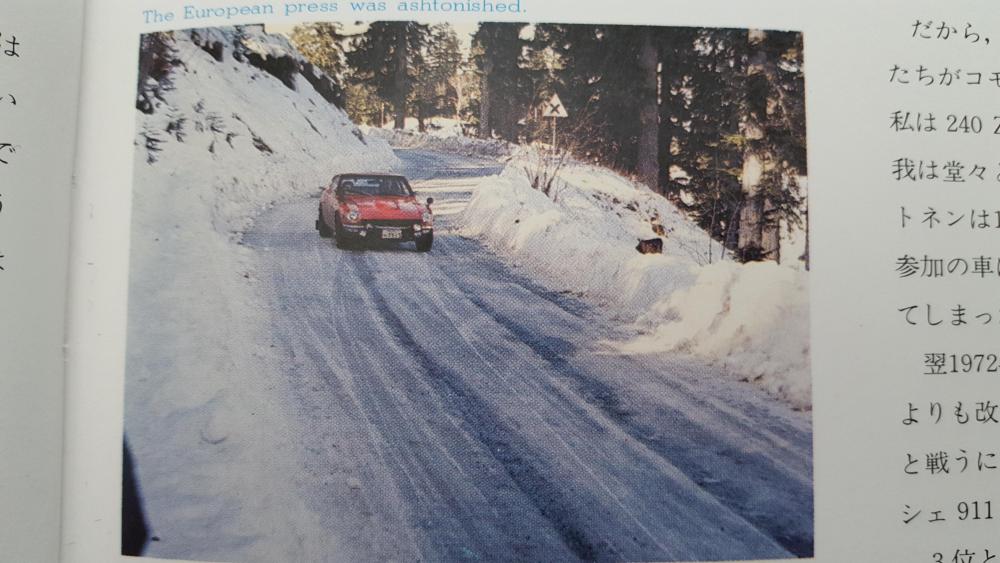

1 pointThis presumes that 100% of those 1969-production HLS30-prefixed cars were USA/North American market variants, which is certainly not the case. Even if a very small percentage of them were effectively 'European' market variants, they still deserve to be mentioned. Here's a photo of an HLS30-prefixed Nissan works rally test car being used in the south of France during the month of January 1970. It will - by definition - have been one of those 543 cars produced in 1969, and it wasn't a USA/North American market car:1 point

-

First start today!

1 pointI’m going to text him tomorrow and see if he’ll get back to me. I actually have the stock needles from my original carbs now that I think about it. I’ll try swapping them in tomorrow while I’m waiting for Jeff to get back to me.1 point

-

First start today!

1 pointI believe SM's are the standard needle. I don't know if they are all stamped. If the float level is right and holding then needles would be my first suspect1 point

-

Advice on Recent 1978 280Z Purchase

Yes @Zed Head I did! Slimeydime didn't really drive it or do anything to the car since he bought it. I'm going pull the engine and do a major clean-up of all that Ziebart in the engine bay and overspray. And clean-up the engine and all the accessories. I haven't seen the car with my own eyes yet, but it looks amazing for an original 42 year old Z. I was looking for a 5 speed, but couldn't pass this one up.1 point

-

240z VIN

1 point@Patcon @Namerow Hi Guys, thanks for the kind words and Marry Christmas wishes to you as well. I think this has been a tough year for everyone, but so far we are doing well. Mostly staying home, but did attend Jim Frederick’s Z Mecca Christmas Party earlier this month in Lutz, Florida. Great turn-out with Bob Sharp as an Honored Guest. Florida weather co-operated with a bright sunny day. Stay safe and healthy to enjoy the holidays with your friends and family. Carl B.1 point

-

A little help with my first 280z

1 pointThe keycode is also stamped on the passenger side lock cylinder. You have to do some disassembly, but it's not too difficult. Download the Factory Service Manual for your year.1 point

-

Ebay shipping time machine

1 pointFedEx...our new 767’s are fantastic, keep up the great work. We’re buying a lot of them Sent from my iPhone using Tapatalk1 point

-

240z VIN

1 point

-

240z VIN

1 point

-

240z VIN

1 pointSome Early HLS30 Vins for North America were held up in the factory and dated later. Here is 503 in Nov 691 point

-

Zx 5 speed rebuild

1 pointHi Charles, Most important before you strip it down is to check end play on all the gears. You can not check it properly once you dismantle it. The clearance varies per gear, so check the manual for the tolerances. If it exceeds the maximum tolerances, you can fix it by replacing the gears or a machine shop. The clearance on the baulk rings can be checked after dismantling. They should have a clearance of 1.25 to 1.60mm. If they are getting close to 1.25mm I would consider replacing them. It's one of the clearances that effects the way changing gears feels. If you do need to replace the baulk rings, I would strongly suggest using the genuine Nissan parts. Yes, I'm sure there are aftermarket units out there that will perform as well, but there are a lot that don't and I can't tell the difference through a simple photo on a website. The next important thing to giving your transmission that new snappy gear change feeling. Replace the shifting insert springs on both hubs. There are 3 in each synchroniser hub. P/N: 32602-32200 The other springs that should be replaced are the checking springs in the selectors and the return spring behind the return spring plunger. The reverse gear does look pretty shabby, but if you can't find another to replace it you can "repair" it. The most important thing is that the teeth are clean and not chipped. You can have the reverse gear machined back until the teeth are cleanand bevel the ends. Not cheap, but if you have nothing else it will work fine. The only thing you will notice is your gear stick will travel just a little further before reverse engages. If you need help on this, I can explain further. First choice is try and locate a replacement.1 point

-

First start today!

1 point1 point

- A-Type 4 Speed Mounting Position Help!

I wish it were so simple. All these parts came out of this car, but now the driveshaft is too long. Been measuring and comparing to my other Z, and have a buddy with 2, and the verdict is in. The engine is an inch too far back in the car. The new front frame rails are installed an inch back too far. No big deal, just shorten the drive shaft an inch, and carry on. Except the wheels are an inch too far back in the wheel wells.....0 points- A-Type 4 Speed Mounting Position Help!

Gang, I need another measurement, from several of you. Easy to get. Firewall to the back of the valve cover. Or firewall to block/adapter plate/front of trans, down by the starter. Trying to put the driveshaft back on and its too long, by, wait for it, an inch.......0 points - A-Type 4 Speed Mounting Position Help!

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.