Things are moving quicker on the body front, so I've turned my attention to long-pull items which need to be ready in time for the shell's return. Tops on the list is the wiring harness, which I typically install first when a car is rebuilt. The harness itself thankfully needs limited work - it was in decent shape coming out of the car, although I suspect there are a few breaks I need to trace and take care of. I'm also planning on replacing all the connectors, as they tend to get corroded through exposure. I wont go into that process, as it's is fairly well understood by the community.

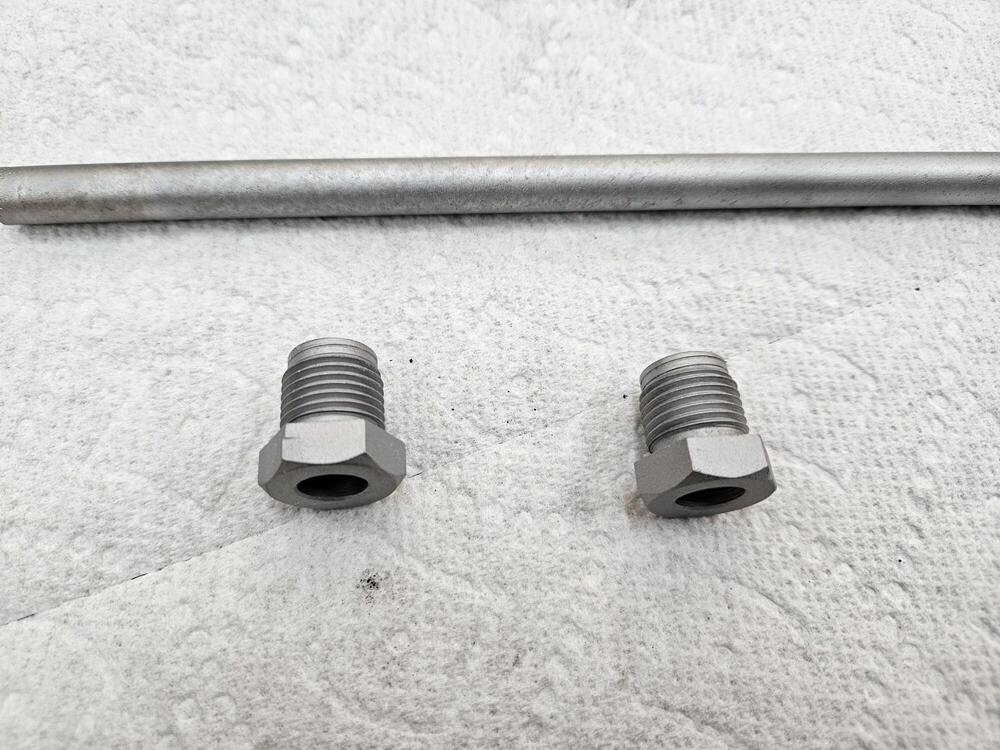

The fuse boxes require a bit of TLC, however (picture 1). On my car, they are comprised of a pair of modified Niles 8-position boxes, possibly hand-made from a Niles FB87A box (or similar). Pigtail wires were soldered in place, terminating in a connector to the main harness. Some of these connectors show signs of maintenance over the many years. The lids are also showing signs of age (picture 2), so I'll put them on the 3D scan list as well. It's worth noting that someone took the time to scribe the lids with appropriate fuse sizes, which is likely unique to only a handful of early rally cars.

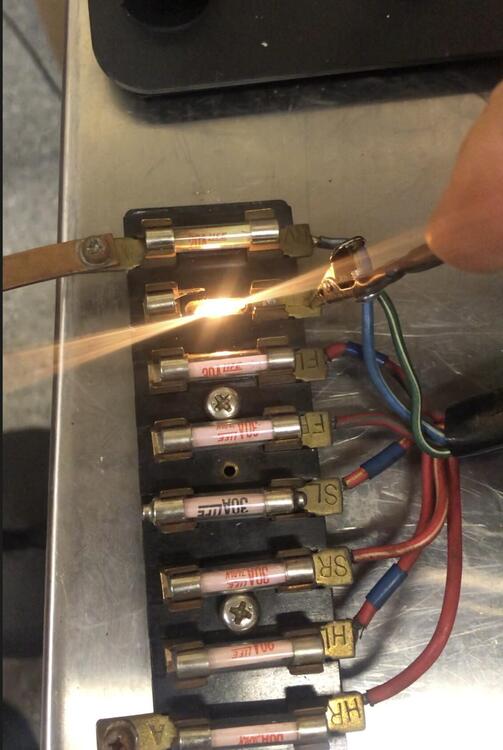

On close examination of the boxes themselves, I found that each of the fuse locations had a pre-wired axial 12v bulb bridging the fuse terminals from the back (picture 3). Much like how a dead short blows a fuse, this outrageous modification really blew my mind - the Works team had considered the potential difficulty in tracing blown circuits and identifying shorts in dark foot wells in the dead of night. So they designed a novel solution: a blown fuse allows current to instead flow through the bulb, causing the specific fuse location to glow (picture 4). I can't speak to how well it worked in competition, but it probably only needed to work a single time during a race for the modification to be worth doing!

Subscriber

Subscriber 7Points10,929Posts

7Points10,929Posts