Everything posted by kinfish

-

Where to find this fitting?

That fitting and similar one in the intake manifold have "BSPT" threads (British Standard Pipe Thread). There is a slight differance in thread counts from NPT and hence are not interchangeable to purists. Plugs are available and made by Parker fittings ....... can be ordered thru speciality stores dealing in hydraulic hoses.

-

Energy Suspension bushing kit

I encountered same problem with the Energy Suspension Poly bushings back in May. Solution is to measure the mating parts and calculate how tight they are. Target for line-on-line fit and sand the flange of each bushing to remove material. Best to do it with bushing out of transverse link ..... use a 100 grit paper on flat surface and move bushing in circular motion. I reduced flange thickness on each bushing by .030. Assembly of link to hub was no problem after rework. I did call Energy Suspension in San Clemente, Ca and their Tech agreed with the sanding solution.

-

breakdown rear end

-

240z pull strap screw covers

Lotsa demand for those chrome-look plastic covers. Everybody who owns an old Z probably would buy two. Tooling cost would be minimal and somebody with initiative to market them could make some bucks. Won't get rich but would make a lot of people happy if they sold for a reasonable price.

-

Rear Suspension Urethane Bushings

I just installed Energy Suspension polyurethane bushings on my '71 240Z 6 weeks ago and encountered the same fit problem. The chamfer solution suggested by Carl will work if the fit of the two mating parts is tight but close to line on line. Anything with a tight fit will cause headaches during assembly and distortion of the bushings. I took detailed measurements to assess how big the problem was. The strut hub housing measured 5.315. The transverse link inside dimension with bushings fully seated checked 5.270. Hence, my assembly had a .045 interference fit. Impossible to assemble. My solution was to remove the two bushings from the link and sand the flange surface to remove about .023 from each. The flange thickness checked about .130 as delivered so there is adequate material remaining to remove some. Best way to remove material is place sheet of sandpaper on flat surface and rotate bushing in circular motion until you achieve desired thickness. Assembly went smooth after this fix. I did call Energy Suspension in San Clemente, Ca and spoke to Steve Blakely in New Product Development. I questioned whether there was a design problem on flange thickness. He said they do not have access to original prints so they do best effort using scrap parts. His solution to this problem was to sand the face of the bushing.

-

Fan Shroud

-

Hoodless

-

Rear Control arm bushings!

Just completed replacing rear inner and outer bushings with the Energy Suspension kit. At the wheel side of the control arm (tranverse link) you must remove the outer sleeve. Best method is to use sharp hacksaw to cut slot along the length of the sleeve. Take your time and be careful to keep the blade parallel to the sleeve surface and do not cut into the control arm surface. Cutting thru to 80-90% of the thickness will suffice. When done make another cut parallel to the first cut about 3/8 inch away. Now take a punch to that 3/8 inch wide piece and roll it thru the hole. When you get close to the other side the sleeve will pop out. Suggest you measure the inside dia of the sleeves for the poly outer bushings. The ones in my kit were deviated and measured .628 dia which is the same size as the spindle pin. Will never go together. I got replacements from the factory in San Clemente, Ca which were sized at .644 dia.

-

Where to get NPT plugs

If you are looking for plugs for the intake manifold look in the yellow pages for a store specializing in hydraulic equipment. I bought SST plugs for my 240Z but had to order them. The threads are not "NPT" ...... they are "BSPT" which has slightly different thread counts. BS is not Bull $^!# it is British Standard. Plugs are made by Parker fittings. They do have different types and materials in the catalogue. Do not use brass due to galvanic action with aluminum.

-

Gear oil from speedo?

Gear oil running up through speedometer cable inidcates a bad seal on the shaft of the speedo pinion. I just pulled this assy apart to replace the speedo pinion and had also purchased a new shaft seal and the o-ring which fits on the outside of the housing and seals assy to tranny housing. The seal is tiny and very difficult to remove from the housing since there is no lip to punch or pull it out. I wound up using a chisel to cut thru the metal ring to remove the hoop and eventually got the thing out. I put replacement seal in freezer for an hour and used deep socket sized to seal OD to tap it in place. Takes a little patience to get the housing assy and pinion aligned on reinstallation, especially working on your back with minimal ground clearance.

-

Spindle Pin Bushings

Tore into backend of my '71 240 to replace a bad bearing on the right side stub axle. Decided to inflict more injury by replacing the 33+ year old spindle pin bushings. Managed to remove pins using the K.Blough method using washers to pull em out slowly. The metal sleeves in the Energy suspension poly kit were deviated with undersized bores and had to get replacements from their factory in San Clemente. Installed outer bushings in transverse link with the replacement sleeves. Mating the link to the spindle pin housing shows a .040 tight fit with the link bushings fully seated. No way it is going together! Anbody experience this problem and what was done to fix it? Could Murphy have struck twice with my kit and also provided me with poly bushings with thick flange? A design fit of line-on-line would be tolerable considering some flex in the bushing.

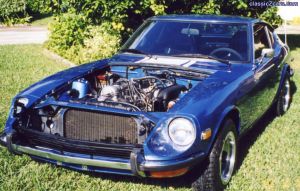

- Original 2400 cc Engine

-

howl

I also have been nursing a cyclic howl from the backend on my 1971 240Z. I believed it to be the differential but when I pulled it apart last week found a very rough noise from the rear wheel identified after disconnecting the axle shaft. Source was the outer bearing on the stub axle. Rough universals in the driveshaft or axle shafts may also generate a howl or clunk.

-

Header installation problem

Common problem in that MSA header flange is thinner than the stock intake manifold. Using stock washers tilted between adjacent flanges will not provide any clamping load for sealing and may damage the studs in the head. Best solution is to make special washer with step to accomodate the difference in flange thickness. A machined version would be optimum but a quick fix can be achieved by finding washer same thickness as step, grind off side leaving about 225 deg arc and tack weld it to the stock thick washer. Orient the step on the washer to contact the header flange. Torque to spec and should seal perfectly. MSA could improve Customer satisfaction if they supplied these special washers when they sell the header .... but they don't. Even better would be to change the header design to elimiate the step. ...... Duh, that would be too simple.

-

Opinions wanted: Window Tint (black/mirror!)???

Be careful considering the "mirror tint" option because it is illegal in many states where the sun shines most of the year. Some states also have limits on how dark the tints can be. If it is too dark you will limit your visibility from the drivers seat and create a safety issue.

-

Barrett-Jackson 240z

I inspected that white '71 240Z before and after it went on the stage auction block Sat morning in West Palm Beach, Fl. The VIN number was about 15, 800 and had South Carolina plates on it. It was recently painted and looked good at a distance. However, I suspect it was victim of front end crash since hood fit was horrible and both left and right fenders were rippled along inside edge that runs parallel to hood when closed. It was far from purist stock ....... not original engine, ran webers, no distributor .... electronic system triggered off crank, griffin radiator, electric fans, 5-speed, '72 or later interior console, classic rust under battery (engine compartment was not repainted), etc. Did have new tires mounted on Panasport rims. It sold for about $9,000 which blew me away. However it must have been a bargain compared to the '68 Shelby Mustang GT Coupe that sold for $175,000 and the '56 Mercedes 300 Gullwing that fetched $302,000.

-

Installing BRE "Spook" spoiler- helpful discovery

I have consumed two BRE type spoilers on my '71 240 over the last 33 years. The existing holes make installation easy. However, I did drill an additional hole in the left and right valence to secure the ends. Make sure you use a large washer under the bolt heads to distribute the load. Also reprogram yourself to avoid hitting those concrete bumpers in parking spaces since they will destroy your spoiler with one whack. My first spoiler was destroyed while hitting a Mojave Desest jack rabbit at about 110 mph while racing a motorcycle. The bad news was the motorcycle driver was behind me and his helmet and body was covered with rabbit guts and hair. The good news is that he didn't lose it and crash. Another BRE spoiler is on my "to-do" list.

-

Unusual set of triple...

Better buy two more Z's now since all three girls will want one when they reach drivable age. Enjoy their company while they are young since they will grow to mature "jeune fille" in no time (pardon my french which is weak). Au revoir!

-

Quarter window seals

I replaced the weatherstrip on my quarter windows and found the reinstallation difficult to get it seated properly. Your symptoms sound like one or more of the tiny attachment bolts (2 top, 2 bottom) may have failed or were not pulled up evenly. Suggest you pull off the interior panels and examine these bolts and mating brackets. Take your time pulling the frame off the window.

-

close one!

I experienced similar problem on my '71 but didn't catch it in time and the lack of oiling destroyed the cam lobe for the #6 exhaust valve and its mating rocker arm. End result was a very annoying tick due to the scored surfaces. It was caused by failure of the braze attaching the cantilevered tube to the distribution block. You may have the same problem and suggest you carefully inspect the braze joint. A bent distribution manifold may also be the driver. The solution is to replace the manifold immediately since it is alot cheaper than replacing the cam. Ron '71 240Z - original owner :classic:

-

Old Style Master Cylinder?

Regardless of which master cylinder is used, you must make sure the pushrod on the brake vacuum booster is compatible and adjusted correctly. I recall that that there are at least two different lengh pushrods and they are not interchangeable. To make the system work properly the pushrod must be adjusted to match the piston in the MC. Set at line-to line or leave a small gap (.032). You need to take precise measurements to do it right. If your pedal went to floor after bleeding air out of the system I suspect your gap is too large ...... hence depressing brake pedal is not moving MC piston until gap goes to zero.

-

Timing cover

I recently removed the timing cover on my '71 without removing the head and the oil pan ...... the cover is sandwiched between the two. Trick is to loosen all the bolts on the oil pan and then very carefully pry the front edge of the pan downward, away from the timing cover. Don't bend the pan flange ..... you must make it separate from the block ...... gasket should stay with pan. Don't need to move it much, just enough so the gasket is not holding it to the cover. By some stroke of luck the gasket (never replaced since new in '71) on the pan was not damaged for reassembly but I did use some brush on permatek sealant to make sure it did not leak. I had no problem with the head gasket at the top since my head was recently refurbished and I did not use any sealant where it contacted the timing cover. Good Luck.

-

Performance camshafts

I also bought a Schneider cam from MSA but it was the 10-2002 version. All these cams are internally oiled ....... look for small holes in the lobe surface. Installed cam in my stock 240Z last year but I also trashed the external oiling manifold and installed blockoff plates which are available at MSA. Rapid wear may be caused by marginal lubrication ....... feeding oil inside and outside to the manifold effectively lowers supply pressure. If you did nothing to the oil pump or the oil supply hole in the block, this may be your root cause.

-

1971 240Z

I refurbished my neglected Appliance mags starting with "Never Dull" mystery cloth. Followed that with "Blue Magic" polish. Recently added "Mothers Mag & Al Polish". All was done by hand over a period of time. To do it right remove the rim from the car and don't be in a hurry.

-

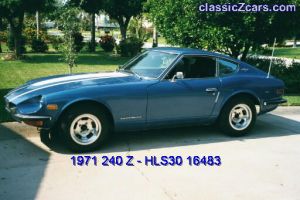

Original Owner '71 240

Wow ..... for a moment I thought my kids decided to sell my garage toy when I wasn't looking. It is also a '71 240Z, I am the original owner, and my name is also Ron S...............! However, the mileage is only 180,000.