-

new here

thanks. yeah she's got some work ahead of her. The passenger side of the car isn't quite as nice as the drivers side. Some small dents, surface rust, and a missing headlight bucket. And obviously the missing bumpers. But the bulk of it is there and no apparent major rust (we'll see how accurate that statement is when I start tearing into her though ). I take delivery on the 7th. I cant wait. I've owned a couple 280zx's but never an S30.

-

new here

This took a little longer then expected but heres a pic: Judging by the turnsignals it's definitely an early version.

-

idle setting on 83zxt

yeah it's been a while. I've only actually had to deal with it one time and that was when I initially set my turbo motor.

-

1977 280 2+2

what about where the grounds attached to the chassis? did you check and clean those?

-

What makes Zs great

amen......

-

1977 Z Rough idle and more!

make sure the battery grounds are clean and tight. Make sure nothings corroded and chassis grounding points are not rusted.

-

setting idle on 83zxt

check your other thread on this subject. I posted how to adjust it in there.

-

idle setting on 83zxt

there is a stopper screw on the passenger side of the throttle body. It threads up from underneath and is what controls how far the throttle sits open at idle. It's very small and should be a phillips head. To find it just look where the throttle linkage is stopped from rotating (in the closed position) on the throttle body. There is not a manual idle adjuster like on the non turbo models.

-

lash pad question

It's hard to just say which way to error. You'd need to perform a wipe pattern test to see which thickness would be best for you. Get one of each thickness and check the wipe pattern. Whichever thickness puts it the closest to the center is the one you want to go with. Test this on all the lobes to make sure you have the right size all the way down.

-

digital dash mystery

I replied in your other thread on this topic.

-

Digital dash problem

The analog is not a direct swap. You'll have to swap over the wiring harness for the gauges as well. The digi dash uses a different harness then the analog. The analog dash harness is a direct replacement however with no wire splicing or anything of that nature. Just remove the digi harness and replace it with the analog harness and plug everything back in and you're good to go.

-

1975 280z Factory Service Manual in PDF?

Not the whole manual but here is a PDF of the '75 wiring schematic: http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/75_280z_wiring.pdf This used to be a place to get the entire manual on CD (for a price though):http://www.courtesyparts.com/Merchant2/merchant.mvc?Screen=PROD&Store_Code=CP&Product_Code=CD28075A But it appears they're temporarily out of stock. Might try calling them to see when they'll get them back in stock. The site says they're only temporarily not available due to them being updated. The CD's aren't nearly as expensive as the hardcopies that are available (the ones you can still find anyways).

-

Alright, more engine rebuild questions

Dont use Plasti gauge. The best (and only way IMO) is to use a micrometer to measure internal engine parts. To get a rough feel for the size of something (cross referencing parts) you can use a set of dial calipers. but dont use them for final clearance measurements. As far as seeing visual difference in the size of oversized bearings: No not while they're installed. Not unless you held them side by side to a standard size bearing to compare which was slightly larger. But at that point the bearings would be free of the engine and they should have their thickness stamped on them so you can just check that. But the best way is to measure the crank journals with a micrometer. Then measure the bores of the mains, and the rods to determine the clearance. That will tell you what size bearings you need.

- Zx Alternator Swap

-

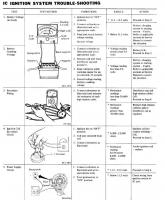

280ZX E12-80 ign module service data?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.