Everything posted by zcarnut

-

Timing kit differences?

The difference in the curved guide was mentioned by Gene Crowe (Bob Sharp’s head mechanic) way back in 1977 in a print article he did about blueprinting a L24 race engine: “ …The curved timing chain guide should be moved toward the chain to take up [any] excess slack and the heavier 280Z guide should be used…†The fact that there are two kits is probably because Nissan continued to use the 13091-A3500 guide on the later L24E engines (found in the 810 and early Maxima models). But I don’t know why Nissan would have continued to use two different guides during the 1976-1983 time period. BTW, the L24 and L28 straight guides have the same part number (13085-21002), so I can’t see why they would be different. I’ve never seen the fuel pump cam included in one of the [L24] aftermarket kits.

-

Timing kit differences?

The only different I’m aware of is that the L28 curved timing chain guide (13091-N4201) is more sturdy than the L24 one (13091-A3500). This is the guide on the slack side of the chain. Because of this, I have always used the L28 one, even when re-building a L24 engine.

-

Spindle pin removal tool survey

zKars is right. If the spindle pin is "rust-welded" to the strut, no tool will save it. You will have to cut the spindle and press out the pieces. Yes, the special pullers will help (along with lots of heat), but it’s no guarantee. What I would like to see someone make and sell stainless steel spindle pins (and the small locking pin as well). Yes, I realize that this is a critical suspension item, but a good mechanical engineer should be able to specify the details. This would also allow having a larger diameter for the end nuts, say 14mm instead of 12mm, or even use SAE 9/16 inch fine pitch threads because fine pitch stainless metic hardware is difficult (and expensive) to get here in the U.S.

-

AC/Heater stuck Mode door

Remember, the air intake door (which brings in either fresh air or re-circulated air) and the “mode†(heat or ac) door are vacuum controlled. Look for cracks in the vacuum lines on the solenoid valves and the vacuum bottle in the engine compartment. A defective check valve can also cause this.

-

Differential Output Shaft Stub Question

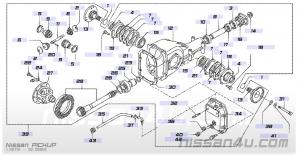

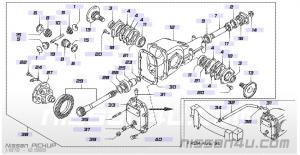

If you blow up and lighten one of the pics from jmhtx in the OP, I think I see a center bolt, so I believe that these are the R180 bolt-in axles. BTW, I checked on the 1981-85 Maxima and the one with the CV axles used clip-in axles with a R180 diff. Likewise for the 280ZX which had the R180 with CV axles. I actually have the Maxima R180 and its CV axles installed in my 1979 810.

-

Differential Output Shaft Stub Question

The R180 diff used in the front of the 1979-80 720 4x4 truck used bolt-in axles, but the 1981-85 version had clip-in axles. I need to check on the R180 used in the 810's and Maxima's.

-

Differential Output Shaft Stub Question

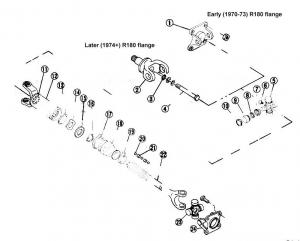

The early R180’s had bolt-in axles whereas the later R180’s used “snap-in†axles secured with a C-clip which is what you have. To remove the axles simply pry up evenly with a large screwdriver. A wealth of info on the HybridZ forum: http://forums.hybridz.org/topic/49194-differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount/ You may have to be a member to view the photos.

-

Choke lever mount broken under console

-

Could someone post a pic of a stock '72 hubcap

http://zhome.com/Classic/Restore/HubCaps.htm

-

76 280Z Compressor alternative

The government mandated changeover to R134a was 1994. However, Nissan was one of the first to switch with some 1993 models using R-134a. The 1981-85 Maxima would have used R12 refrigerant.

-

76 280Z Compressor alternative

The 1981-85 Maxima one will bolt on to your 280Z. I’ve got one on my 260Z. It is larger in capacity and the lack of an oil sump means less oil is needed. The 280ZX/Z31 will also fit but the inlet (S) and outlet (D) fittings are reversed so you would need custom hoses to use it. Also the later Z31’s used a serpentine belt instead of a V-groove belt.

-

240z fuel and brake line insulator sets and steering rack expansion reservoir

I just received the brake and fuel line insulator kit and I must report that the quality of the insulators is absolutely top notch!! Thanks Steve!

-

Source For Captive Washer Hardware

http://www.ebay.com/itm/Zinc-Plate-6mm-Hex-Dog-Point-SEMS-1-Bolts-Fender-Body-M6-x-1-Metric-Thread-/221646973461?pt=LH_DefaultDomain_0&var=&hash=item339b306a15

-

1969 HLS30-00182 on Ebay

It's back!! Datsun Z Series 240Z Series 1 | eBay Previous deal fell through (imagine that!).

-

240z fuel and brake line insulator sets and steering rack expansion reservoir

Handbrake handle and pushbutton. These were never available separately and since NOS handbrakes are NLA we are forced to restore the originals. Unfortunately, these parts are destroyed during their removal. Early 240Z wiper motor cover. Before there was the “bag†Nissan used a plastic cover. Speedometer cable and hood opener cable grommet. The very early 240Z’s lacked a separate hole in the firewall for the hood opener cable, so Nissan combined it with the speedo cable.

-

So if You Found a Wallet?

I was at the Sebring race about 15 or so years ago. While visiting a Porta-Potty I discovered a wallet wedged between the seat and the side of the unit. No money, but it had credit cards and a driver’s licence ID. I don’t remember the exact name but it was not a common name (I think it was Sparkman, or something like that). Anyway, I showed it to my friends and we decided to make our way over to the ticket office and turn it in to lost-and-found. On the way over I spotted a pickup truck stopped in the infield traffic with the words “Sparkman Construction†painted on the side door. Taking a serendipitous chance I approached the lone female driver and asked if she knew the owner of the wallet. Not only did she know the owner, but she was his sister and she was on her way to meet him at the race! After she correctly described some of the wallet’s contents including her brother’s address (down to the house number), I gave her the wallet. Very strange coincidence when you consider that this was a typical race with thousands of people milling around.

-

Pull motor with or without transmission?

If you decide to pull the engine with the transmission then use a “load leveler†which makes it so much easier to control: http://www.harborfreight.com/2-ton-capacity-heavy-duty-load-leveler-5402.html

-

'73 braided fuel line

The German cars also used rubber fuel lines with a braided cloth cover so a VW or Porsche restoration parts store would be a good place to start. Goggling “German Cloth Braided Fuel line†produced many results: http://www.wolfsburgwest.com/cart/DetailsList.cfm?ID=111209183 http://www.thesamba.com/vw/classifieds/detail.php?id=1158506 http://www.porschetechnik.com/8mm-cloth-braided-fuel-hose

-

240Z in movies

Morphing Z in The Fury (1978). Starts out as a 280Z but changes to a 240Z and then back to a 280Z as the actors run past! And they thought no one would notice...

-

1" master brake cylinder

It’s the Wilwood one-inch master cylinder. Wilwood part number 260-8794. The Wilwood master requires modification before you can use it on a S30, but the Ebay ad states that the one they are selling has been modified.

-

Zbarn.com

- no idle screw?

- 240Z steering rack

Yes, depending on the condition of the rubber, the stops may not survive being removed. I have several spare used ones if you should need one. I think you can still get the rack bronze sleeves (fiche #4) the pinion bearing (#10) and the pinion bushing (#3) which should be replaced or at least inspected during a rack re-build. The holes in the rack allow you to use a Zerk grease fitting so you can lube the inner ball socket joint. If you blow out the holes with a air gun you can see where they connect to. Of course, you must remove the Zerk fitting after adding grease because it would hit the rack housing.- 240Z steering rack

Richard; The “third piece†is indeed a steering stop. It is just a hollow rubber sleeve within a metal shell. It’s a tight fit on the rack, but it can be moved away from the lock nut by simply prying over with a screwdriver. This will allow you to remove the lock nut and then unscrew the inner ball joint.- Struts Needed for 1979 Datsun 810 2 Door Coupe

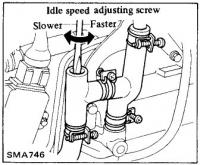

Have him cut a turn off the front springs when he changes the inserts. This will lower the front by one inch, improving the looks and providing some handling benefits. - no idle screw?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.