Everything posted by zcarnut

-

Struts Needed for 1979 Datsun 810 2 Door Coupe

I am suggesting that you use the 280ZX front strut insert on your 810 and not the entire 280ZX strut assembly. All the 280ZX's used the same aftermarket replacement front strut insert, regardless of year or body type.

-

Struts Needed for 1979 Datsun 810 2 Door Coupe

You're welcome! I bet you have the black interior with the "checkerboard" fabric seats. All the light blue 810's I have seen were outfitted in this manner.

-

Struts Needed for 1979 Datsun 810 2 Door Coupe

Hello fellow 810 coupe owner! There are several other two-door 810 owners out there. Most of us post at the HybridZ forum or the Japanese Nostalgic Car forums: http://www.japanesenostalgiccar.com/ http://hybridz.org/ To answer your request I will inform you that the 1977-80 810 and the 1981-84 910 (Maxima) and the 1979-83 280ZX all can use the same rear shocks. The 280ZX shocks should be easier to locate. I am even using 280ZX rear springs on my 810. I assume that you need a front strut insert for your 810. The strut is generally considered the entire tube with the insert (dampener) and the spring. Your 810 uses the KYB 365012 (gas) or 665011 (oil) insert and the Tokico catalog lists part number HZ3002 (gas) for the 810 front insert. But the last time I checked, these were not readily available anymore. However, you can use the 280ZX front strut insert on your 810. The difference between the 810 strut and the 280ZX strut is only in the length. The 810 strut insert is longer than the 280ZX by about one inch. So, you can use the 280ZX strut insert provided you make up the difference with a suitable spacer (or a stack of washers) in the bottom of the 810 strut tube. Attached is a photo of my 810:

-

Who needs rubber?

I used McMaster part number 86225K51 on my flap doors. It's very similar to the original stuff.

-

Rear wheel cylinder difference?

The 1977-78 rear brake wheel cylinder is a completly different design than the earlier ones. No interchangeability.

-

Electronic Ignition Waveform -- abnormal?

I apologize for my tone. I’m sorry my knowledge of something I work with everyday comes off as reeking of arrogance. I only stated my qualifications so as to give my response some substance. In the 1980’s the company I worked at (a division of Magnavox) was a supplier to Delco for the “six pack” coil that was used on the first production DIS. We also designed an ignition unit but Delco choose one from Motorola. Yes, the clamp diode is there. It is even in the schematics of the ignition units. Even if the clamp diode is omitted (not a good practice) the collector-base junction would clamp the collector waveform. If you’re happy with your test set up, then so be it.

-

Electronic Ignition Waveform -- abnormal?

(post deleted)

-

280Z hub vs 240z hub

Use the 280Z hub and rotor. The 280Z (along with the 260Z one) hub is stronger (thicker casting) as it was designed for the increased weight of the 2+2 cars. The 280Z hub wheel mounting surface is also thicker and it does not have the “scallops†like on the 240Z hub. However, using the 280Z hub requires you to use the 280Z (or 260Z) rotor as well. Nissan changed the rotor offset (made it smaller) to allow the rotor max run-out spec to be lowered. To compensate for the different rotor offset Nissan changed the hub offset to match it. And yes, this issue has been well discussed on the HybridZ forum. BTW, the 240Z brake caliper is the same one that was used on the 280Z.

-

Looking for a great restoration manual?

-

Air or no air....

I’ve seen several “hybrid†ac systems in 240Z’s. Use your 280Z compressor, condenser, and receiver-drier along with an aftermarket 240Z evaporator and controller (thermostat). The refrigerant lines would be combination of the Nissan hard lines and the aftermarket rubber (soft) lines. Tip: Use the 280ZX compressor mount. It’s aluminum and much lighter than the 280Z “boat anchor†mount.

-

Refurbishing the HVAC vacuum selector valve in a 1978 280Z -- useful info

I had the same conclusion. That’s why I removed the magnetic control valves from my 260Z (which has a transplanted 1978 ac system). I considered the “fast idle actuator†an eyesore with my aftermarket triple carbs. I also determined that the plastic vacuum reservoir tank was also redundant and I use the brake booster as a steady vacuum source. I’m still working on configuring the selector valve so I can run the heater and the ac at the same time. This would help defrost the windshield much faster in cold weather and most post 1980 cars have this feature. I would use the (useless) BI-LEVEL switch position for this.

-

Differences in Gas Tanks?

No. I meant to say "only the early 1974" tank.

-

Differences in Gas Tanks?

Even the 1974 gas tank will swap into your 1970 as well.

- A/C compressor won't switch on

-

Tach resistor

I seem to remember that the tach resistor was 20KΩ 1/2W. Just be sure you use the correct type of resistor. The voltage pulse across this resistor can exceed 350V in amplitude. The replacement resistor must be pulse rated to handle 500V regardless of its power rating. Use a carbon composition (carbon comp) resistor if possible. This type of construction is well known to be able to handle high voltage pulses and this was the type that Nissan originally used. However, carbon comp resistors are getting more difficult to locate as very few resistor manufactures offer them anymore. A second choice would be a metal film resistor then maybe a metal oxide resistor. Avoid carbon film resistors for this type of application.

-

A/C compressor always on...

The AC relay is not located under the dash. It is located on the small AC bracket with also holds the vacuum switches and the check valve. Having the compressor on all the time will only cause un-necessary wear and places an additional load on the engine. I can’t understand why you are putting off a repair that will take 10 minutes to fix? And, BTW, the easiest way to disengage the compressor clutch is to simply unplug the blue wire going to it!

-

A/C compressor always on...

The switch contacts in the AC relay have been “welded†closed. You can replace it or remove the cover from the relay and clean the switch contacts. Common problem. I have been putting a 0.1uF film capacitor across the points. This will reduce the arcing which creates the welding. The AC compressor must cycle on/off in the S30's. Otherwise you will freeze up the evaporator coils. The early cars lack a POA valve which prevents evaporator icing.

-

A/C compressor won't switch on

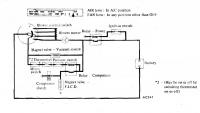

It is the AC relay (located on the small AC bracket with also holds the vacuum switches and the check valve) that energizes the compressor clutch through its switch contacts. The AC relay coil, in turn, has three switches in series with it: the under pressure switch (located on the receiver/drier); the ON micro-switch (energized by the AC control lever on the console); and the thermostat switch (located behind the temperature control lever). In addition the blower switch is also part of the circuit since the blower fan must be on while the AC is running (to prevent excessive pressures in the AC system). So, there are several items that must be checked to verify the series circuit is complete. Check the easiest-to-get-to items first: The AC relay and the under pressure switch. The AC relay can be checked for both switch continuity and whether or not the coil has voltage across it. If it is suspected then it can be substituted with a good working one. The AC relay can be taken apart to inspect the contacts for pitting (very common since you are switching an inductive load) and the contact points can be cleaned with a points file. The under pressure switch is screwed into the top of the receiver/drier. It can be tested with an ohmmeter after it is unplugged or you can short it out with a jumper wire to check it. The under pressure switch is available separately from Nissan, but it requires you to discharge the AC system first before replacing it. The micro-switch and thermostat switch can be tested after you remove the control panel on the located between the console and the dash. Again, use a jumper wire or an ohmmeter to check them. I’m not sure about the availability of NOS parts as I have never seen these parts become defective (fortunately). Since your blower fan switch seems to be working (based on your post) I would assume that your blower switch is OK. BTW, all of this info is in the factory service manual. I urge you to obtain one and do the troubleshooting yourself. You learn a lot more from doing than asking.

-

A/C dashpot won't raise idle

Measure the vacuum level at the dashpot and compare it to the intake manifold vacuum level. If there is a large difference then I would suspect the vacuum bottle check valve. It is well known that they can become leaky over time. I’m pretty sure a NOS check valve is NLA, so you will have to use a generic one (if yours is bad).

-

core plugs

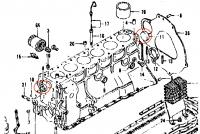

The 40mm core plug is for the front of the engine block and the 50mm plug fits on the rear of the block. Neither are for the cylinder head.

-

Tachometer Schematic Anywhere???

The Hitachi IC was similar in function to the National LM2907: http://www.national.com/an/AN/AN-162.pdf If you are dead set on re-using your original tach with a re-designed PCB, then I would start with the LM2907 chip.

-

Tachometer Schematic Anywhere???

I posted the schematic for the 240Z tachs here at the Classic Zcar forum, but it will not help you. The 280Z (and 260Z) tachs are electrically different than the 240Z one. They used a custom integrated circuit to drive the meter movement made by Hitachi that was never made available as a replacement part. Whenever I suspect that a 280Z tachometer is bad I just replace the entire tach with a good used one.

-

I need help identifying this oil pan.

The first edition of the book "How to Modify Datsun 510 610 240z Engines and Chassis" by Bill Fisher & Bob Waar has a small black-and-white photo (on page 220) of the engine bay of a boat with two triple-carbed L24 engines. The caption reads: "This is an installation in an offshore racing boat. These two Z engines built by E.B. Parkinson will be doing salt-water duty in a class that has been Volvo-dominated for several seasons." E.B Parkinson prepared cars for his son, Dan Parkinson, who raced Datsuns Roadsters in the late 1960's and early 1970's.

-

Maxima steering rack interchangable?

The unit pictured is the manual Maxima (910) rack. The Maxima had both manual and power racks. Stephen is correct; they will not work on the early Z cars (S30). They are more similar to the 280ZX (S130) manual rack except that the spacing between the mounting location is different. I know this because I have one in my junk parts room.

-

Series 1 Engine Paint Plan - Details Please

In an attempt to get this thread back to the title topic, I would like to verify the original OEM finish of the U-shaped water tube that is located behind the engine that is part of the carb heating system. The one on my Series I 240Z (HLS30-01841) was plated and then painted with the Nissan blue paint.