Everything posted by zKars

-

Fuel Injection Relay connector issues

The pins can be removed from the connector blocks for cleaning and inspection. There is a tiny slot in the connector cavity at the back of each female connector where you push a very thin "something" into, to depress the sticking-out tang on the connector to free it. I use dental tools or a very small flat blade eye glass screwdriver. Once you get one out, the rest are a breeze once you see how it works. Do them one at a time or make a careful drawing and label wires or you risk mixing things up. I have a couple of spare FI relays too if the problem turns out to the relay. Let me know

-

Carb & Exhaust Backfire at the same time

Leon there are clearly short cuts to dianosing his timing problems, but given the history, I felt it best to really get back to basics and to do a full "from square one" process to maximize his chance of finding the core issue. Fast Woman, good catch on the valve lash settings being a possible contributing factor. The settings are 0.008 inch and 0.010 inch just to be clear, in case there is a metric/english conversion confusing you Ronaldo. It must also be done with each lobe pointing nearly straight up to ensure you are measusing between the base circle of the cam and the top of the rocker. And I'm ZKars not K-Cars. I'm a Gemini, not an Aries

-

Aluminum car expert Shin Yoshikawa making 240z

You have to check out his aluminum 2000GT. This guy is a mad genius! My favorite part of his website. "This website has a lot of broken English. If you do not like,please do not see my website. This website show how enjoy car life or special tech for your car and not teaching perfect English"

-

Carb & Exhaust Backfire at the same time

I knew you couldn't resist Bruce....

-

Carb & Exhaust Backfire at the same time

Its a timing problem almost for sure. You have convinced yourself some aspect of the time system must be ok, but it is not. Do not be afraid to challenge every detail of your assumptions. I suggest you start from absolute square one with the timing. Really. Remove the valve cover, remove the oil pump, remove the oil/distributor drive shaft. Put the engine at compression TDC, confirm with both #1 cam lobes "up" and look in spark plug hole for piston at top dead center. Then re-assemble the oil pump/drive shaft lining up the marks on both. Notch on the side of the oil pump just below where the drive shaft enters, and a punch dot on the drive shaft. Put the pump back on the motor, straight in. It likes to go in a tooth off, might take a couple of tries. Wish I could find a post that shows the correct position looking into the dist. mounting hole from above that shows the correct narrow/wide side of the drive tang relative to the the engine, I think its tang aligned to 11/5 Now put the distributor back in. Put the rotor back on (not the cap yet). Where is the rotor pointing? Better be forward toward the rad. The advance diaphram is pointing the same way. Look at the cap. The #1 tower is marked with a line cast into the cap. Put the cap on. That tower better line up EXACTLY with the rotor inside. Now put the plug wires on, one at a time, remove them all from the cap, starting with #1. Go counter clockwise, 1-5-3-6-2-4 (not 153426!! Anyone who knows me knows that story....) There are many many posts here describing this proceedure in excruiating detail, do a little searching, you will find very descriptive pictures. Report back what you have found. You will overcome this problem.

-

Transmission hard to shift into first and grinds going into reverse - Need help!

Is the clutch friction point very close to the floor? if so, the problem may be with the clutch hydraulics, ie that clutch is not or just barely releasing.

-

Anyone ever dissemble a flasher?

Ok, I thought I was the only one who would spend an afternoon trying to refresh or re-build a $1.79 part for the sake of originality.... Guess I'm not the only crazy person on the board with too much time on my hands after all..... Now if you're doing it for the sake of learning how one works, that's a whole 'nother thing.

-

Calgary Z Club Fall colors run part 2

Well the gang just couldn't resist one more drive before the white stuff comes, and the forecast for Saturday was looking mighty fine. So off we went. For those of you who don't know the area, Calgary is just 30 or so miles East of the Rocky mountains, so this is always a great destination. We took off for Kananaskis country. Google it, you'll love it. In proper Canuck fashion, we ran across a small snow storm at the highest pass (Highwood pass, 7200 ft). Road was just wet. Temp around 2C, (35F). 15 minutes later it was +14C and sunny. Typical stuff here. Anyway, enjoy a few pictures of the fun!

-

280z with sloped hatch deck

Well I'll be horn swaggled.. Ok, I'm now an official believer that there are in fact two kinds of raised 77-78 rear hatch areas, one flat with a regular tail light trim panel, and one sloped with hidden tail light access area with no trim panel. While I have personally only seen the sloped type, and did not believe in the existence of the other or thought that those who claimed to have seen a flat one also believe that the earth is flat, my eyes have been opened as I have now seen an un-retouched photo graphic evidence of the flat type. There is a lovely 78 for sale, just placed in the classified, with a nice picture of his hatch area (the very last one), with the hinged portion of the raised floor open for all to see. And there it is in all its beautiful flat-ness, with even the tail light trim panel in plain view. Halleluia! Jim

-

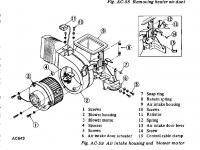

73 240Z Air Vent Diagram?

The 75-76 FSM (I know you have a 73) has diagrams that are acutually useful and descriptive for things like this. The fan case/vent flapper part of the system are nearly identical in form and function to the 240's. Look at www.xenons30.com for the FSM download. THis picture is from the AC section of the 76 FSM, page AC 58 Yours won't have the vacumm pot (part #6) that actuates the lever, yours is a cable.

-

Suggest a cheap, quiet, fuel pump for my triples.

I've had this problem too. The noise is due to not being able to flow enough volume, its sitting there pumping through its internal bypass. No return line I bet. Its get hot and locks up and eventually fails. I ended up going back to a stock mechanical pump with a small electric for backup/ boost when needed. I feed my 44 mikuni stroker with a stock pump... Compare the flow rate of that pump to what you engine needs at full throttle. 50 gal/hr drains your tank in 15 min ay WOT? uh uh... take the pump out and hook up a test system pumping water from a pail back into the pail and listen to how quiet it is and much flow that thing can move.

-

Low profile kick panel speaker pods now available

Other than the ECU on the left and the fuse block and relay bracket up on the right, neither of which are particularily important as grantF suggests , these lovely panels will slip right in. You can sit in your driveway and listen to great tunes... If you wire the stereo directly to the battery cause the fuse block is well, gone.... Sorry for the sarcasm. Don't think these are useful in a 280 at all unless you have a megasquirt in your glovebox and a new fuse panel on the firewall somwhere.

-

Pull motor with or without transmission?

Either way works. What seems to sway people to doing it altogether is the problem of putting the trans back onto the engine and getting it to line up and back on, if you have to do it with the car on jack stands, by putting the trans on your chest then up and into place. uggg. No fun. I always do them in and out together now. I don't even take off the drive shaft. Slips right off on the way out, and just takes a second pair of hands to guide it back into the tail on the way back in. Remember what will come pouring out when the driveshaft exits the tail too.... Drain it first.

-

280z with sloped hatch deck

Andrew, Grant is asking about the 77-78 280 raised rear hatch floor and its components. The back 1/4 or so is sloped up from the raised floor to the hatch sill on a hinge, held down with two plastic knobs at the edge to allow access to the tail light bulbs behind. The micro fiche of the Body section for L26& L28E has very detailed pictures of the four hardboard pieces and raising support brackets and assorted bits and pieces that make up this "improved" rear floor area for the August 76 and later (77-78) 280's starting at section 135A-1, about page 50 in the PDF. The FSM on the other hand, has almost nothing about it. Fiche and FSM at xenons30.com as usual.... Hopefully someone here with a 77-78 may be able to give you pictures of their hatch area.

-

Missing console bracket

I must have one some where, let me look. Bug me at z240@shaw.ca

-

"Space Saver" spare for the S30 spare compartment

I use a zx space saver spare in my 73. I keep a little 12v air pump to inflate it. Its held down with the same screw in clamp. It leaves enough room in the spare tire well for all of the "other" spares I carry around just in case. ...(fuel pump, E12-80 module, coil, a few plugs, baloney sandwich, the usual stuff).

-

Most hidden rubber part.

And it attaches to that stand through a hole, using one of the same metal clips that attaches the door panels to the door on 240's. Really fun to get in place. I've been known to put a sticky back rubber thing from the hardware store....

-

Jdm exhaust muffler

Its not often that I'm star stuck with automotive "flash", but this stuff is just plain purdy.... Maybe its the incredible build quality that attracts me. Just a few hours of nip here, tuck there and all will be well. Now somehow I must surpress feelings of "must have..." Just have to remember I won't be the one polishing that SS to keep it purdy...

-

Shift Knob Threading?

I'm reasonably sure the thread is 8 x 1.25 mm. Not many, if any 8 x 1.5 mm threads on a Z.

-

Side Vent Hoses

Get some replacement 2"" ID vacuum hose and replace it. Patching it is tough. VintageAir.com has a couple of sizes of their A/C vent hose that is excelllent stuff too.

-

wiring a 2 wire bulb into the 3 wire front parking light

Hey Raltz! how's it going, eh? Still working on the project I see! You cannot accomplish your requirement with that two-connection bulb without additional circuitry. Instead you should put the original two filiment, 3 wire bulb with its stock wiring (should have enough wire to reach) into the socket of your new light housing. No wiring to do. I think I have a set of 260/280 signal lights if you get really stuck...

-

240z value question

Rick: So sorry to hear about your dad. Not the best way to get a car, no matter how nice. Value on old cars is determined primarily by comparison to recent local sales of the same car in similar condition. The classified section of this forum has many examples for you. Check here http://www.datsunclassifieds.com or go throught the Members > Classified Ads link at the top of the page here. Feel free to post an ad for your car as well. Another popular way seems to be ask $20K, then keep dropping the price until someone finally buys it or you get an offer you can live with. Not very time efficient, but it works. The main issues to anyone who knows these cars will be rust status and mileage. I'de get that thoroughly evaluated by someone near you who knows how and where to look. Can make $1-2k or more difference in the price. There are many Z nuts and businesses in your area, be assured. Surely someone here will pipe up. And before someone else says it, there were no "factory" 240 louvers, only dealer installed ones... Same for alloy wheels and AC. (at least in North America) Good luck with the sale. Jim

-

DCOE 40 Idle mixture screws are stuck/broken off HELP!!!!!!

Brilliant solution!!! Great to hear you found a fix. You have to find out what that acid is. Extremely useful stuff. Won't use it often, but when you need it, you need it!!!! This makes me think of applications like melting a broken off steel exhaust manifold stud out of an aluminum head... Probably overkill, but any chance to work with fire, explosives or dangerous chemicals must not be missed!

- Fuel Pump Relay

-

Having trouble installins ball joints on my 240Z 1971

Whoa! youre assembling. Eithwr you have installed the steering arms upside down or you have the wrong ball joints. Wait! Are we talking tie rod ends or ball joint at the base of the struts? There are differences in the early ones. There is a great thread on here somewhere...

Subscriber

Subscriber