Everything posted by zKars

-

Best Birthday Present. Broken Head Bolt

I’m totally doing this! New bolts are a fortune! Thanks!

-

Best Birthday Present. Broken Head Bolt

And today, the final stage of my birthday present, I was able to put a vise grip on the stub and easily break it free then unthread it by hand. Yahoo! It never goes this smooth.... What do you think? Buy new head bolts or just re-use the old ones?

-

Best Birthday Present. Broken Head Bolt

So I wire brushed the stub clean and set up a rag pad around it to hold penetrating oil and let her sit for 24 hours with hourly application of more weasel squeezings....

-

Best Birthday Present. Broken Head Bolt

It is common I have found to struggle with the removal of two particular head bolts. Left side, #4 and 5 from the front. Coolant seems to get there and rust them into place. So the recent engine (N42/N42) needed the head off, and sure enough, all were easy to break free, but #4 was a struggle, and #5 broke. Here we go again. Took the head off, and found stage one of the birthday present. The bolt broke a good 3/8” of and inch above the block! Yahoo! Look at the crud around that bolt. The head gasket was mostly eaten through here. Old engine, old coolant.

-

280Z pedal box in a 240Z

The pedal box is from a 75. No changes on this piece in the 280 year range that I’m aware of. Maybe check the parts fiche to be sure, but can’t think of anything 77-78 specific that would affect it.

-

280Z pedal box in a 240Z

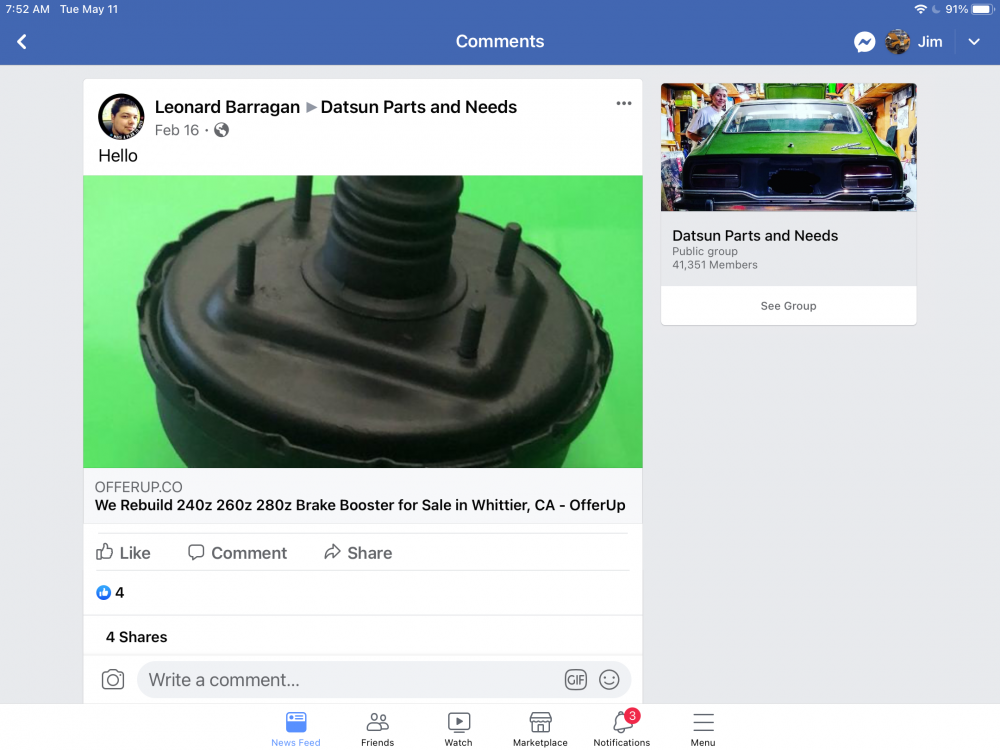

Here are pics of them side by side. 280 box is obviously wider (larger booster), yes two holes under the dash at the front vs 4. 280 box is also deeper from fire wall to dash mount. The two tabs that stick out the side look about the same.

-

280Z pedal box in a 240Z

I’ll put the two side by side and post a picture and you can decide. My guess is there is enough dimensional difference that it would not be worth the effort. What exactly is your problem with the current setup? There is a booster rebuilder somewhere in the US that can make your present booster new again. Search for “Brake Booster rebuild datsun” MSA and probably Zcardepot sell alternative boosters. Even going with a more aggressive pad compound (hawk or porterfield has some options for stock brakes)

-

1974 260z air cleaner hardware

Did you find a wing bolt yet? Can you measure the one you have pls?. There are two different lengths, and if you have the later flat tops and its matching “larger” air cleaner, I think the bolts are shorter than the earlier ones. Send me a PM and we can take it from there.

-

Brake Pedal Bumper?

Yes there is supposed to be a little rubber pad on there.

-

does this look like 918 to you?

And because looking at orange Z pictures is never boring... https://bringatrailer.com/listing/1971-datsun-240z-165/

-

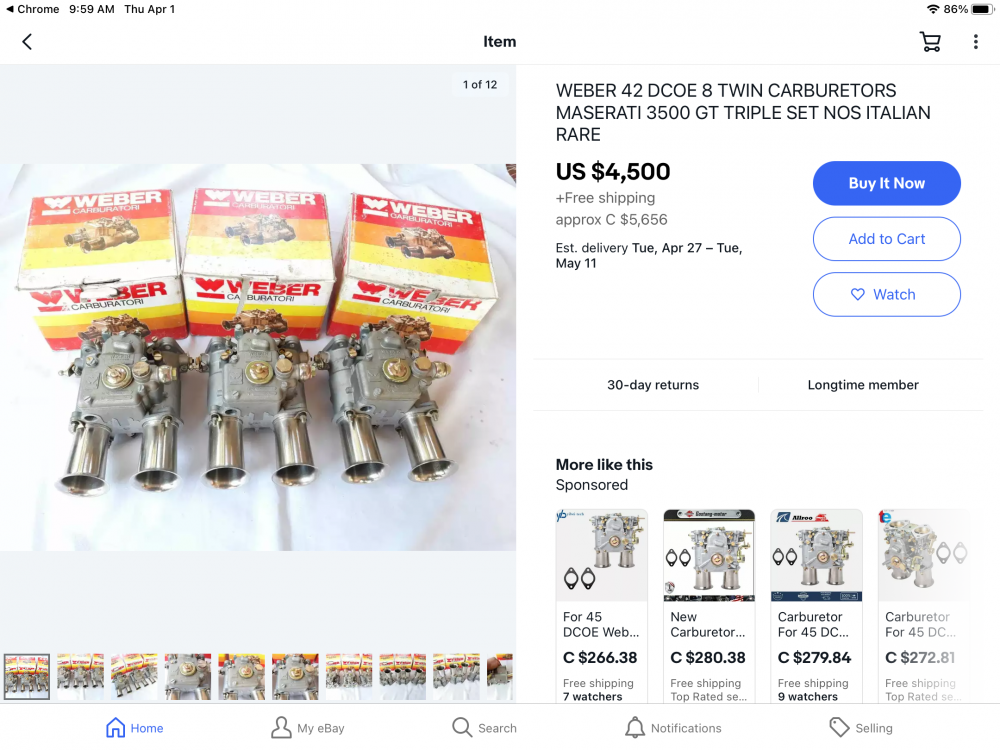

FYI: Flip these and make $5k

When you google them, they are associated and spec’ed to ridiculously expensive exotics Ferarri, Mazeratti etc. Hence their crazy value. Quite rare and quite valuable. $1800 would be a steal. Ebay has a new set at the going value, no intake etc.

-

Timing cover plate bolts

This has been an area of annoying persistent leakage for me in the past. Now I always use a sealant on both sides of the gasket. The ones I get in most gaskets sets are thick and hard as a rock, no way they are going to seal without some help and perfect surface prep. I hate drilling and extracting bolts like that, but there may be enough meat there to go up to M8 if things go sideways.

-

wide ratio FS5W71B slipping out of 3rd & 4th

Yes, without a reverse lock out port to poke a 1/4 socket extension and air hammer into, that thing is a witch to remove. I built a crazy complex U shaped thing to push them out, worked ”ok” but tough to get all the angles right. Dang wedge pins can be very tight. Drilling an access hole then NPT plugging it after would be my goto solution, but not everyone is comfortable doing that.

-

does this look like 918 to you?

See “Peachy”

-

differences between 240 and 280 steering racks

The 75 rack moves 1.51 inches for one pinion revolution. Feel free to convert that steering angle any way you like.

-

differences between 240 and 280 steering racks

When I get a free day (2025 at the rate I’m going) I’ll measure my vast array of steering racks and let you know! At the very least, I have a known 75 rack that I can measure and tell you about. I don’t understand rack and pinion ratio’s anyway. One turn of the wheel produces a certain amount of rack movement. No ratio of nothing.

-

Looking for opinions of this set up

These do two things. It raises the effective top of the strut hydraulic top mount inside the isolator. It does thus give you an inch of addition compression stroke. The other thing it does is eliminate the rubber in the stock isolator. I’ll bet that really softens the ride, wouldn’t it? Where is that tongue in cheek icon when I need it? The thing it does NOT do is give you an advertised “softer” ride. IF you are bottom out the shocks due to lowering springs, it gives you another inch of compression travel so you MAY not get that great jolt when that happens, but that’s it. Overall, I bet you get more road noise and vibration when driving without the upper isolator rubber. Just my impressions from what I see.

-

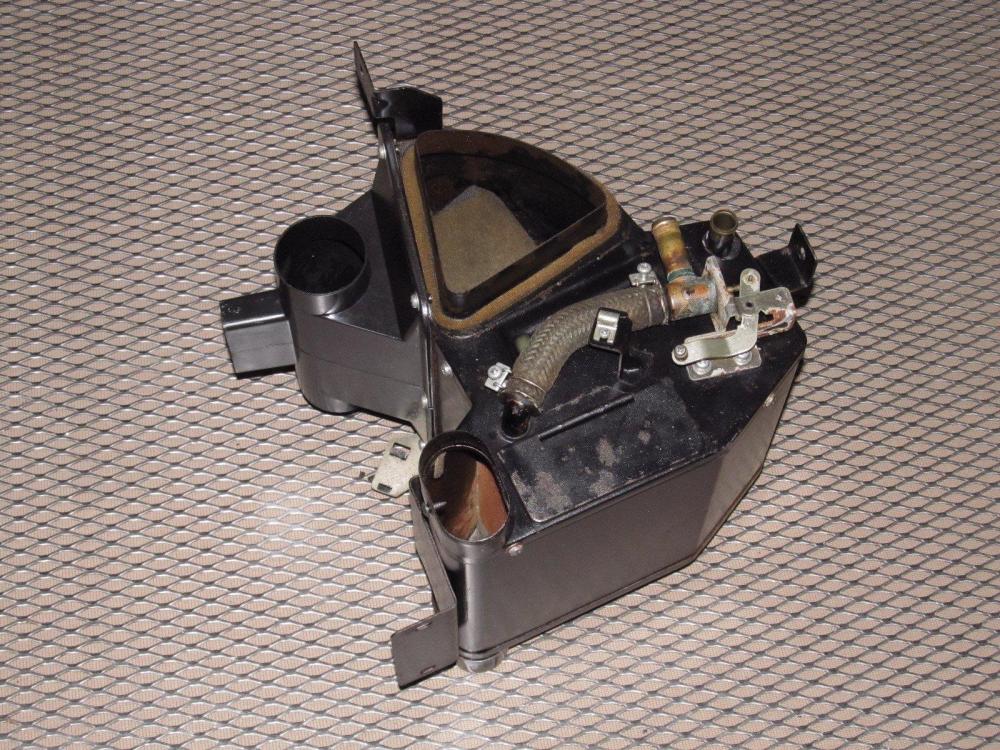

Help IDing under dash device.

Its part of the front of the 240z heater box that sits behind the center dash vent that directs vent air forward and to the two eye ball vents on the ends of the dash. Doesn’t exist on a 74-78 260/280

-

Options for engine fresh air ducting

-

Captive nuts near the dome light

Factory roll bar mount points IIRC. More of the same on the sides below the quarter windows. https://zclub.net/community/index.php?threads/240z-factory-body-brace.23013/

-

Hand throttle

Yes, the choke lever mechanism is designed to add both richness AND higher idle speed. If you look at the SU’s, the little metal rod with the kink moves with the choke mech and moves a little arm the prevents the throttle blades from getting back to idle hence adding idle speed. You have to adjust the kink angle with pliers to add or subtract the amount of idle increase you get with choke handle motion. Takes a bit of fiddling around. I use one pair of needle nose vise grips on side of the kink as backup, then bend the other side of the kink with another pair. Yes you have to take off the air cleaner to have any prayer of getting in there I too have dreamed of separating the richness and idle control to get those both “just right” depending on conditions. But that’s what EFI is all about!

-

6/1971 correct valve cover bolts?

-

6/1971 correct valve cover bolts?

Let the exhaustive discussion begin on which one is right for what year range. GO! Actually I have no clue. I just looked in the valve cover bolt bin and pulled out four unique examples. There may be more.... That one on the right might not be a valve cover bolt at all...

-

What is this in the 1971 240z ??

Someone added a relay panel to run whatever it was they added to the car. Fan, driving lights, big bright headlights. Something. Not stock for sure

-

Dash Differences : Under the skin

Subscriber

Subscriber