-

Posts

3,742 -

Joined

-

Last visited

-

Days Won

107

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by zKars

-

-

I find myself in an unusual situation today. I’m re-assembling a nice post body restoration early VIN 240 and put the engine/trans back in yesterday. It doesn’t fit. Well, the transmission mount doesn’t fit. The mount is now much wider (by two freaking inches!!!) than the transmission tunnel mount holes thanks to the lunk head that did the floor replacements couple of years ago. (Not me!) They’v even welded the old transmission mount plates on the side of the tunnel in the wrong position longitudinally as the holes are a good 3/4 inch behind the trans isolator mount stud. Custom trans mount here we come. I can’t even trust they welded the mount plates it back in the right vertical position. Can someone with an A type 4 speed mounted in a known stock position, that just happens to have the console out and the end of the shifter thingy sticking up, tell me how high the tip of it is above the tunnel sheet metal to give me an idea of where to put the end of the transmission before I build the new mount?? Purdy please. Here is a picture of where I currently have the trans lifted to. Not suggesting its anything even close. Just to give you an idea of the what to measure. To top of the bushing where the shifter goes in, down to the surrounding tunnel sheet metal, at the back, just cuz it’s closer. Thanks

-

I’ve had a 5 sp “B” trans that had a lovely whine in 3rd and 5th that magically silenced when I did nothing other than change the shift knob to a much heavier version. Changed the harmonics of the thing completely.

-

https://www.amazon.ca/Molotow-ONE4ALL-Acrylic-Marker-703-102/dp/B01E7EG3NM/ref=sr_1_1?crid=1RMFWSO5SD0DS&dchild=1&keywords=chrome+paint+pen&qid=1608215841&sprefix=Chrome+paint%2Caps%2C205&sr=8-1 This stuff ain’t bad for doing the “chrome” lines on the console and HCP etc.

-

i am in love with the Jenvey’s. Having nicely tuned EFI is a blessing. Touch key, start, drive away. Running Haltech 750 for da brain. I have a local Haltech expert that owns a Z, so we put each other to good use. I am very lucky. But still love tuning nice SU’s a stock Z motor. Certainly simpler and infinitely cheaper.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

Nope, sorry. -

Oh yes. It ran that way for a couple of years. I’ve since changed it all to EFI using Jenvey Heritage throttle bodies. I’m not good at build threads.....

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

Then that's a bad thing. It is the correct design..... Sorry Let me see if I have a 23 tooth reverse idler... -

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

Both of those look like you hit the jackpot! -

I’ve had good luck with these falken azenis rt615k+. In 195/60-14 size I think. Pretty sticky but not the firmest sidewall, so not a harsh ride.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

I’m sure none of the 4 speeds reverse gears are interchangeable with the 5 speeds (B) and having looked at the reverse/5th gear setup in the C type 5 speeds (with admiration about how you can make it so complicated), I’m going to say with some certainty that they do not have compatible components either. -

Options: 1. Get a a plastic 280z liner and use it. It just slips in, but needs some plastic surgery around the opening to fasten and fit it. Let me know if you want to try one. 2. Modify the 240z cardboard liner so it’s easier to remove. Slit the bottom in the center from the front to the rear, and do the same to the top or remove the top entirely. The top does nothing and you can’t see it’s absence when installed. Makes it easier to collapse it to get it in and out of the opening and to get the glove box light hooked up again. I add a new snug fitting bottom floor panel that slips in over the cut bottom to restore the structure and to make a nice looking interior. Get creative and cover it with velour/felt or vinyl to make it look classy. Lesser mortals will use a nice wide piece of dark Gorilla tape to re-join the cut section. Someone should come up with a new 3d printed plastic insert box that replaces the stock cardboard that slips right in and fits without modification. Could add a USB port, LED light, cappuccino maker, BT speaker, cat carrier grooming aid.

-

The remaining section length is 0.7” I believe. Let me go check a couple I have cut already. Better to be a bit short, you can add shims to push the alternator back and forth to position the pulley alignments

-

-

Here is what I have left of the towing bar I removed. If anyone really wants them, just ask. Bit heavy. Price of shipping.

-

I just brought home a 71 Z that had a tow package attached. it consisted of a 3/4 x 3” thick tow bar that attached at two points. The front was bolted through the spare tire well via a cross bar and two 7/16” stove bolts, and the rear was hung from the rear bumper with a 5/16 bolt. Yup, nice long bolt, straight through. Ouch This is the only picture I have handy. You can’t see the big a$$ bar that runs under the spare tire well. It looks to be made for the car, the bar is bent in very specific places to fit tightly against the bottom. I have removed the bar from the car. It’s in the recycle bin at the moment.

-

Look under “edge trim” on McMaster Carr’s site https://www.mcmaster.com/catalog/126/4052

-

They are about 10 “ long, and 1/2” wide. The underside is a bit thinner than the top face. The slit is well under a 1/32 “ pretty close to a tight fit on the sheet metal. The bend is formed by cutting out a pie wedge and re-gluing or so it seems. There is a distinct cut there.

-

McMasterCarr has tons of stuff like that. Love that place. I wonder if I can find a piece and measure it for you.

-

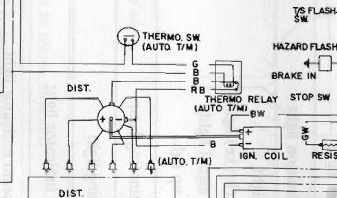

I believe it has to do with turning on the second set of points under certain conditions, for cars that have two sets of points, like auto's. BE-5 in the 72 FSM shows the relay doing this job, but not its location.

-

Heat it up, put it between two 3/4" sheets of plywood, then park your Z on it for a week. 😉 Time and temp will flatten it as well!

-

I also made my own. It’s called $1.00’s worth of rubber hose. There is nothing wrong with the OEM design except the strap is too loose or gets stretched with time and allows the diff to lift too far tearing the rubber in the isolator. Just add a rubber spacer to remove the slop. Yes I should zip tie the hose in place so it doesn’t work it’s way out. So $1.50

-

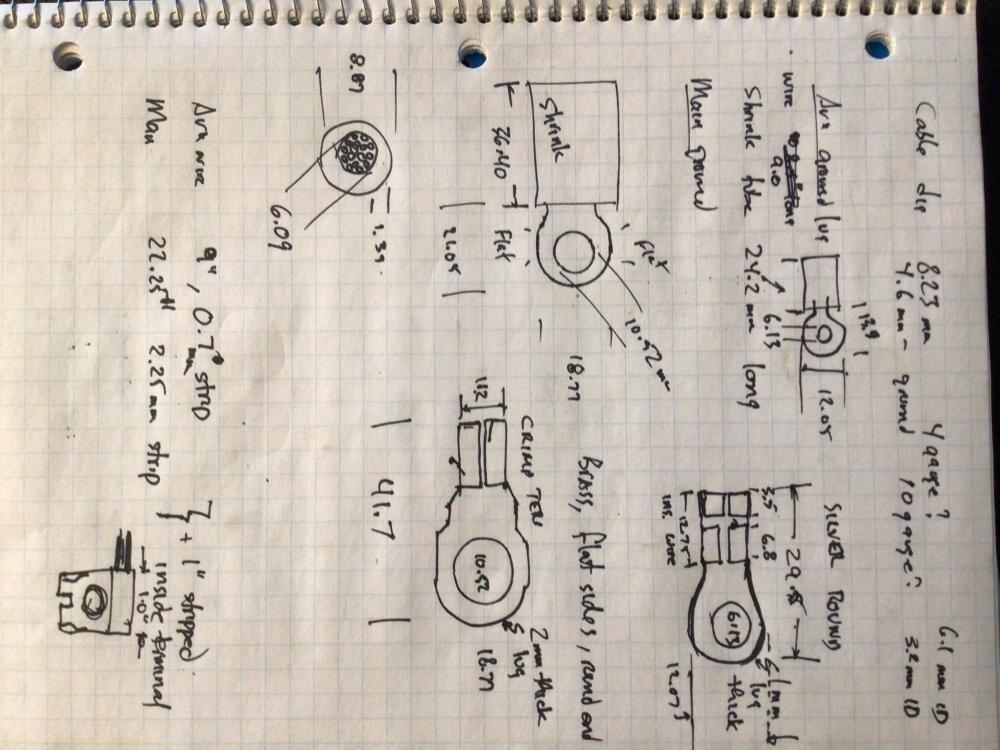

I really don’t want to get in the reproduction parts business, at least not yet. I do want to produce “reasonable” items that come close to the originals at first glance at a reasonable price for my own projects. I will include my rough notes and doodles of the detail measurements of my negative cable. Sorry for the not-perfectly readable scribbles. No I’m not a doctor.

-

Given the price, I’m kinda thinking they may be OEM cables. The Fiche does show different cables starting 72-07. Going to have to call them to get details if you want to see the difference I can imagine nothing location or lug size, or grounding difference. Might be a “better” battery terminal end upgrade or style or something

-

I realized I have one good original negative cable on the new to me 71 I just picked up. Now “we” need one of those original blobs to use to make reproduction blobs.... I’ve taken detailed measurements of the cable, lugs, wires etc. Finding the very heavy lugs that Nissan used is going to be a challenge in todays cheap crap marketplace. The big cable lug is a brass or copper monster made with 2mm thick metal and has a lovely crimped connection done with a serious tool.

Subscriber

Subscriber