Everything posted by zKars

-

Bolt size

30mm long. Round pan head philips (JIS?)

-

Loss of acceleration when hitting gas hard

Change the fuel filter too. Sure feels like fuel delivery to me. Plugged lines, plugged filter, pump going bad. Also check the dizzy hasn’t come loose or the vacuum hose to it hasn’t fallen off.

-

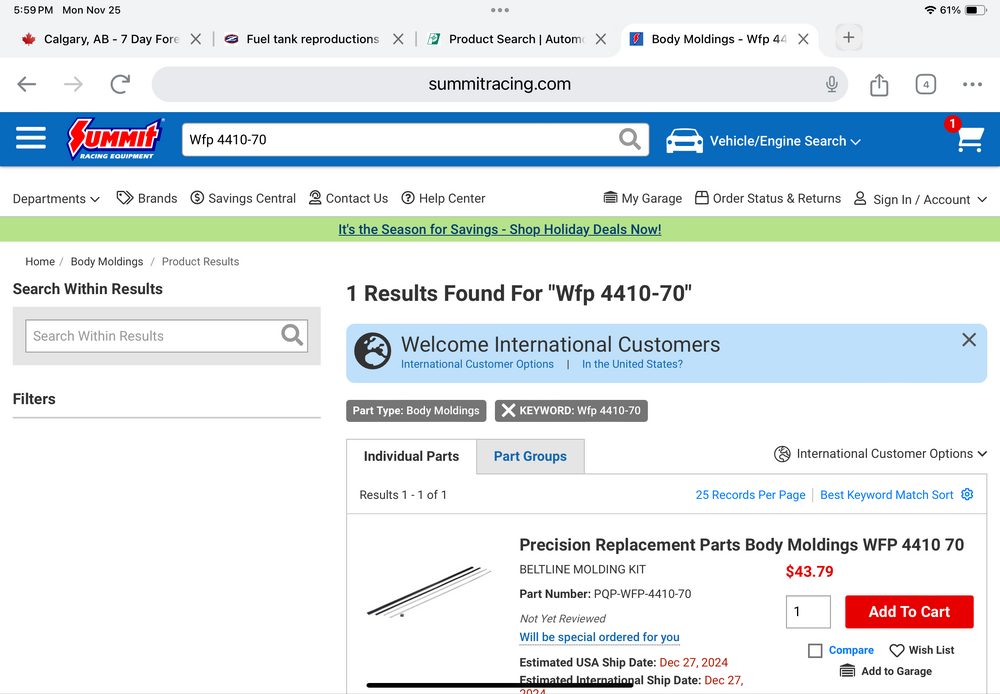

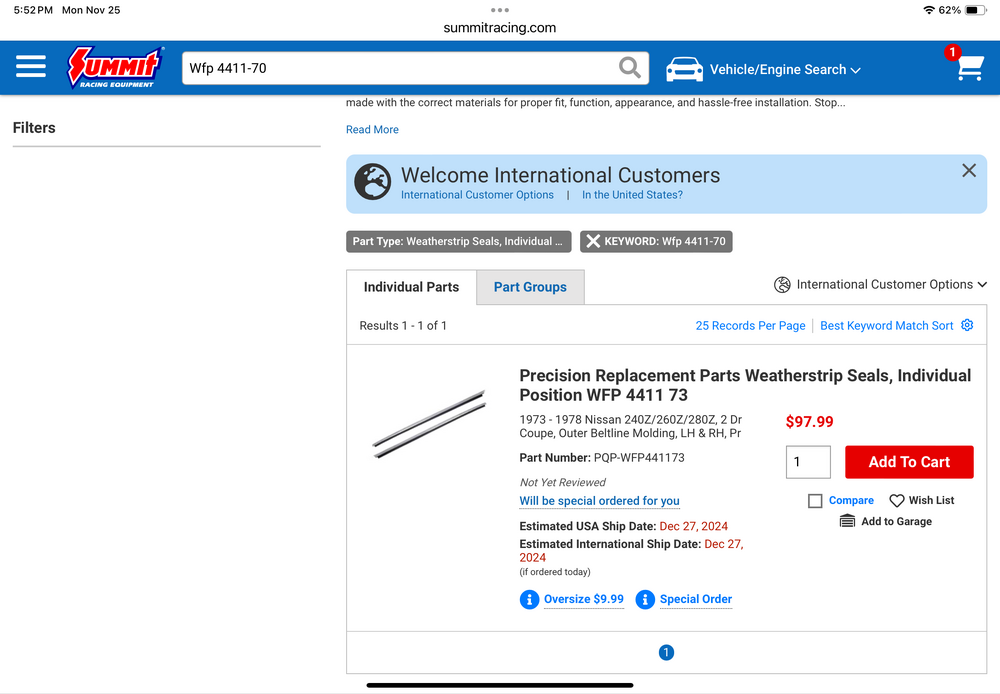

Precision Comes out with new Belt Moldings.

PRP has new (to me anyway) options to rebuild or replace your door belt moldings. WFP4410-70 kit with LH and RH rubbers only. Install on your exist WFP4411-70. LH and RH complete with SS strip with new rubber 70-72 WFP4411-73. LH and RH complete with SS strip with new rubber 73-78 Not sure what the difference would be….. Summit seems to have good pricing PRP.COM is $161 for 4411-70 vs $95 at Summit

-

Fuel tank reproductions

I also have seen and installed their tanks. First rate. There is also a company making plastic tanks, https://www.vintagetanksolutions.com/products They also have one that is molded to allow the installation of an in-tank pump and level sender in a recess on top for EFI applications.

-

HLS 30 hub caps

Monkey early bottom, non monkey top. Poor mounting system often results in very loose shifter shaft after the fork spreads and the pin wears out. Reminds us of walking Gibbon monkey with floppy arms in the air. Makes changing gears feel like a suggestion rather than a definite answer

-

Plastic Windshields!!

-

Plastic Windshields!!

I was just googling FW241 for a buddy that needs a windshield and what should appear? https://www.plastics4performance.com/datsun-240z-hardcoated-lexan-polycarbonate-front-windshield

-

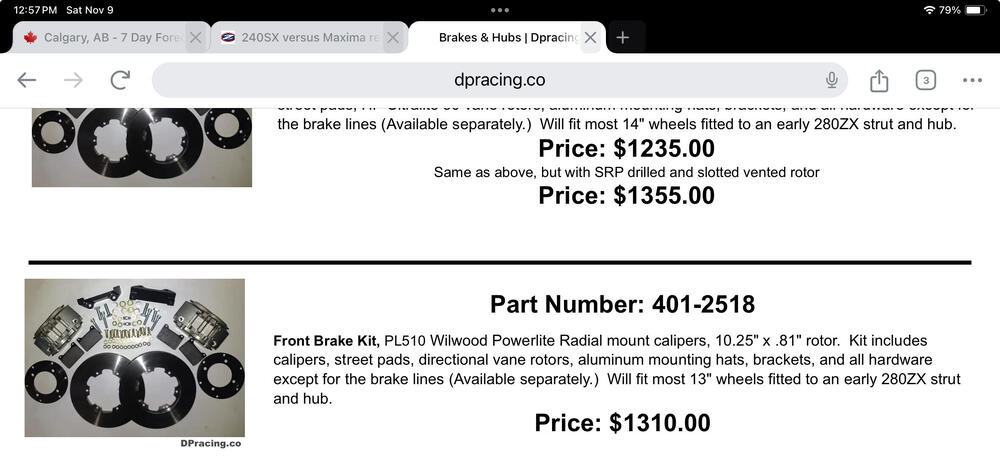

240SX versus Maxima rear caliper

There are SO many great brake kits out there now, I would no longer deal with the Maxima/240sx caliper options. My experience with buying Rockauto calipers was so disappointing that I said never again. Ebrake cable attaching is a nightmare at best. The BEST experience with rear disk brake kits lately is with DPRacing, though admittedly for 510. Quality of brackets, outstanding. Quality of Ebrake adaption cable etc was nothing short of astoundingly good. They list kits for Z and 510 with plenty of options. They were all based on separate brake and ebrake calipers, all from Wilwood. Just my two cents. This is some examples. They feature kits for small wheels too, front and rear. I think I have the 401-9520 rear kit for 13” wheels. They do fit 14” ZX alloys, but for 13, would need aftermarket open barrel wheels, but they would fit

-

Steering rack bushings - Resurrected Classics

240

-

Steering rack bushings - Resurrected Classics

I have a set of them. I bought their whole kit to check it out. Especially the long un-available moose-stash bar bushings. The rack bushings feel very “Stock” in my hand. I have not installed them yet.

-

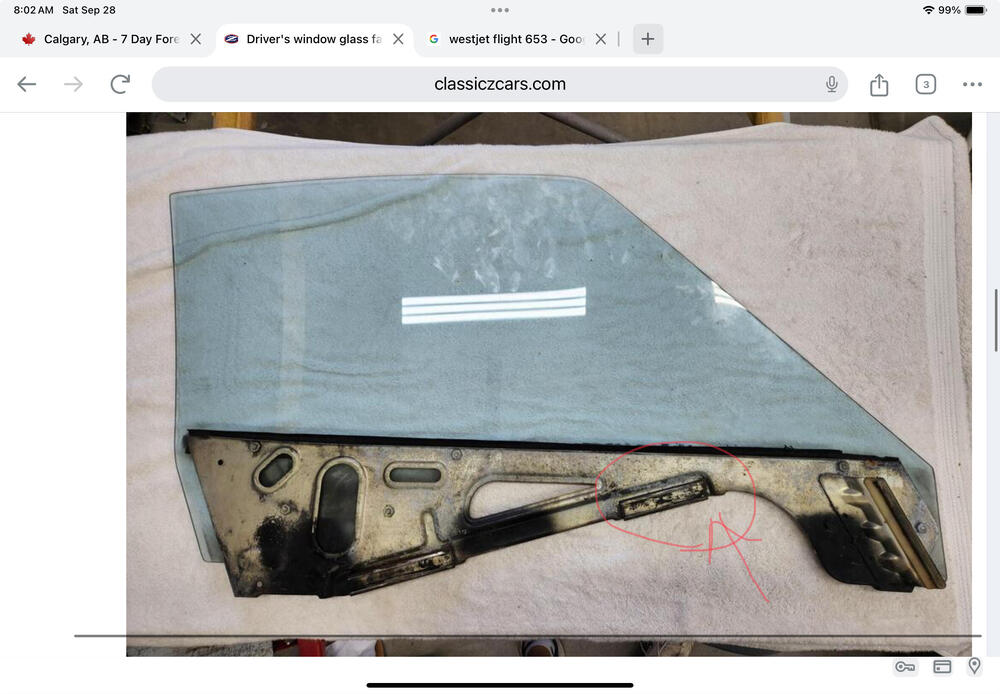

Driver's window glass falling off track

You’ve had this glass in the car before the restoration and the window worked correctly then? Or is the car new to you and never used the window before? Fully agree to put the frame back in as well, since the back of the glass rides in the frame at the rear. The picture of the glass out of the car showing the two roller tracks tells me this window is from a 240, and I know that using 240 glass in a 280 will cause the “fall off the track” issue. The location and length of the two roller tracks is slightly different between the two. They changed the regulator in the 280 as well to offset it further into the door. The way I quickly tell them apart is by looking at the front track. If it is butted up to the frame so that the roller cannot escape out the front, then it’s 240 glass. This appears to be the case, see my red circle. 280 windows allow the roller to enter or leave all four ends of the two tracks. They are also slightly different lengths.

-

Canadian Window Sticker

Great topic, great read, lots of stuff I am happy to learn about. Thanks fellow Canucks. “En Grand VItesse Avec La Datsun 240-Z” Magnifique!

-

I Need a Door Striker Part

I have a couple dozen of these, somehow they all migrated to my basement making them hard to find for the rest of you. Sorry about that. In the USA, I'm betting Sal Ceja has plenty and all plated purdy. He lurks on FB in S30 Life or similar.

-

Grill bolt finish

I’ve always seen the same color on the grill no matter where I look so I assume the grills were painted everywhere in the same gray. Never seen any hint of old plating on those long bolts.

-

Need picture of missing part

-

Need picture of missing part

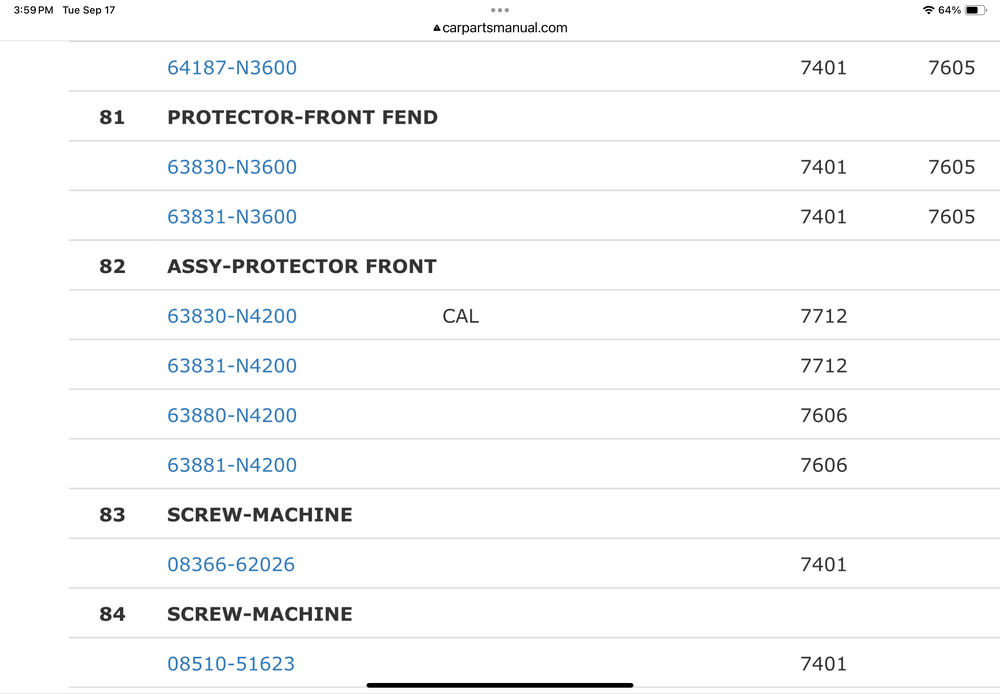

Somewhere in the 260/280 range, they added entire front wheel well liners in plastic. I imagine they install where you indicated. There are two versions. Not aware there were any such thing on 240’s (all North American references)

-

Looking for cylinder door clips

Those are not related to the lock or door mechanism. As noted they are meant to accept a screw for something. Look a bit small for the M6 bolts the license plate bolts need. The bent arm on the back of the lock cylinder shown “used” to have a little rubber sleeve on the necked down area. Bit of noise abatement. Not needed, you could put a short bit of very small heat shrink on there if you like.

-

Looking for cylinder door clips

Can you post a picture of the thing you are looking for from the other side please. I can rummage through the horde…

-

Odd Bolts in Balance Tube

Well, “Velly Intellesting”…. The back of the two plugs is usually a 71-72 location for the vacuum fitting out to the brake booster. Only the early balance tubes had that fitting going out the end horizontally like yours. What I see is a bit strange. The hose fitting in the back of your balance tube with the hose that I assume goes to your brake booster, looks suspiciously like a PCV valve….. Can you take the hose off and show a pic with the whole hose going over to the booster? You have the PCV in the regular place in the center of the balance tube where it belongs. I cannot figure out what the other plug is meant for quickly. Couldn’t see any picture on Google with it used. Your balance tube is NOT the later 73-74 style for sure

-

AB Valve Question

Nice! Feels to good to solve some problems and make progress

-

Door latch stuck

Lube the liveing daylights out of it, especially the outside bit that comes in contact with the striker. Operate by hand until it works like butter. Alignment wise, the C shaped opening into the striker where the door latch has to fit through as you close it is fairly close tolerance, as long as it go more or less straight into the striker you have that part right. It’s the in-out alignment that determines how your door fit flush wise. Will have to weather strip on to complete that alignment. And then if your door hinge pins are sloppy the door might have to be lifted a bit to get into the latch cleanly.

-

Can anyone identify this?

Parts of the fancy electric fuel pump cut off sensor wiring and relay sub harness specific to the 73. There is a thread on here somewhere that explains it all. Basically they wanted to turn the pump off in case the engine quit, so had to sense that, via alternator voltage and oil pressure?

-

240Z SU Throttle Cable Kit

Coincidently, working on a different throttle cable arrangement but with the same Lokar cable. Here is my solution to hold the fitting on the cable end. An M4 grub screw through the thick hex part of the fittingl This bites the sleeve below. You also need a way to bond the sleeve to the braided cable sheath. I found this one slipped down the cable! I use some UV cure resin.

-

AB Valve Question

-

AB Valve Question

I have a couple. Will test what shape they are in.

Subscriber

Subscriber