Everything posted by zKars

-

Under Dash Vent - Mount Screws For Pull Knob

Maybe these are a bit more economical shall we say if you are not concerned about originality in this application https://belmetric.com/m5-5-pan-phillips-tapping-steel-zinc-plated-din-7981-c/?sku=MSM5.5X16 I’m not positive if these are the exact correct size (they have many other sizes), and you have to provide a flat washer, but they will serve the purpose.

-

Burnt wire on voltage regulator

Fried random ground wires are often caused by bad ground connections to the frame and battery. Current will find a path if you don’t have a low resistance path where you intend. Imagine starter level current that can’t use the battery cable but uses that ground wire instead. ZZZZZZZ Start with the fat black negative battery cable inspection and cleanup (both ends) and the body ground between the battery and the firewall. Then the engine harness ground screw on the frame across from the starter. Then the ground connection on the back of the alternator.

-

Correct Gear Shift

Other than fitting through the tunnel and letting you get to each gear without hitting the hole or console, you have to use one of the shorter tipped shifters or you won’t be able to get 5th gear with that transmission. Many have been caught with this issue. You “think” it moves into 5th when you’re on the floor testing it, but once under power, you find out “NOPE”

-

Tiger Tools - Recommendation for U-Joint Service Tool - Tiger Tools

Update on the wonder U-joint tool. Today I went to use it to do a Z driveshaft u-joint for the first time and much to my dismay, it is too big! By this I mean the U shape receiver area that you place over the end of the yoke (where the cups sit) slips right past the yoke. Barely. Useless… Dang. Unless you have a welder I just ran a couple of beads along the lip to make it smaller, and it worked just fine. Now I haven’t tried it on the half shafts to see if I made it too small now, if I did, I suppose I’ll have to get another 10105. Oh well

-

ZCCW Maryhill Loops Drive 2024

I keep forgetting about this run every year. It’s so close to home (relatively) it would make a great spring excursion. Maybe next year. Thanks for the great pictures and sharing them with us.

-

A Review of Modern Technology Upgrades for Classics

Interesting. I initially found it on some aftermarket automotive parts website, then looked at TanksInc directly where it was cheaper. And now you found a cheaper one yet. Both devices are identical with different labels. Techno versions is the cheapest for sure

-

Fan Hits Radiator

Dang, have to acquire more fans, must keep ahead…… Seriously I have seen quite a variety of fans and noticed that some have reversed curvature of the blades compared to others. Same puller blade angle, but blade is cupped the other way. Aerodynamic/airflow modeling advances apparently … Also I believe that the mounting face of the plastic fans is not in the center of the hub, make sure da fan is on da right way….

-

Seat Belt Release Access Solution

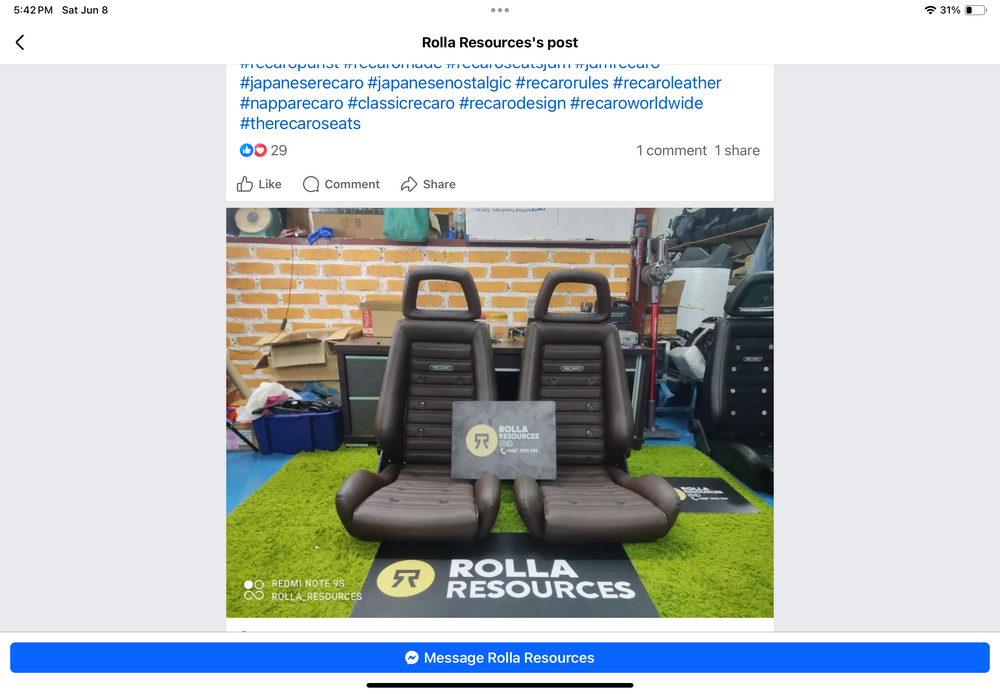

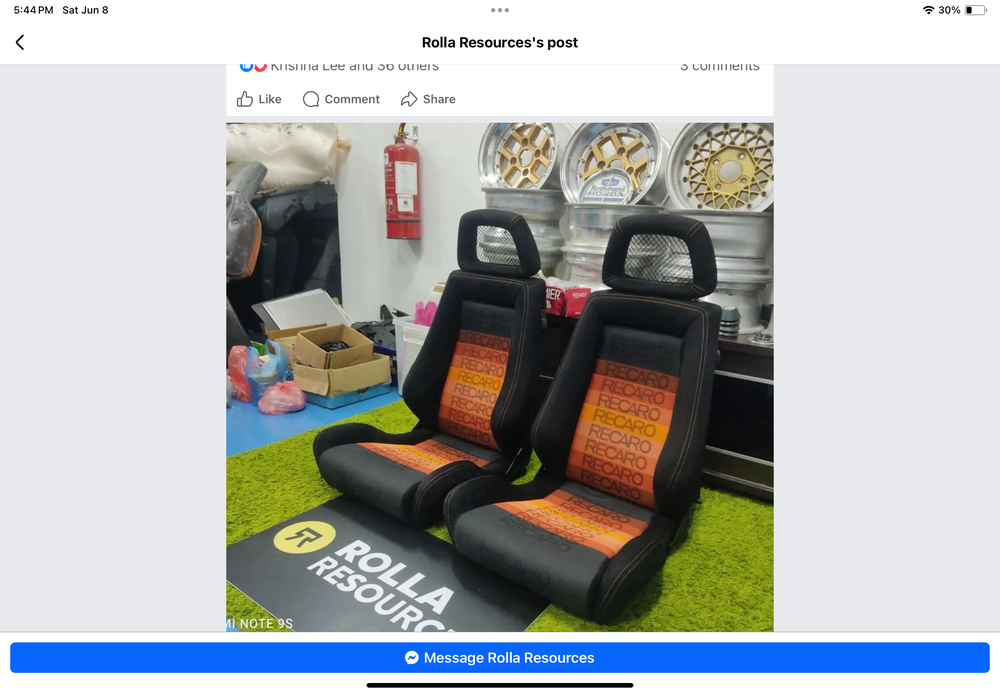

Here is a full shot of my seats. Thin flat bottoms. Simple four bolt mounting. Light and comfy Beware of statements on their site about “Leather”. They mean “Really really great quality synthetic leather”, but not leather…..

-

Seat Belt Release Access Solution

-

Seat Belt Release Access Solution

The console is from a late model Subaru Impreza. Just cuz it has seat heater buttons does not mean they are hooked up…. Better than than empty holes in the console

-

Seat Belt Release Access Solution

LX-B seats. Rolla Resources on Facebook does them. They take old ones and make new ones.

-

A Review of Modern Technology Upgrades for Classics

Next up is a topic we are all familiar with to some degree, getting an accurate fuel level reading on your stock gauge. This is true whether you have a stock sender or not! I have a 240-33 ohm (E-F) aftermarket sender in my tank, (90-10 is stock), and desperately want to maintain my stock dash gauge. Gotta keep that special early sweep style 69 510 dash. So I discovered what appears to be the only aftermarket resistance converter/calibrator out there. And it’s a good one. It small, well priced, and VERY well engineered. Highly recommended. https://www.tanksinc.com/index.cfm/page/ptype=product/product_id=748/category_id=-1/mode=prod/prd748.htm

-

A Review of Modern Technology Upgrades for Classics

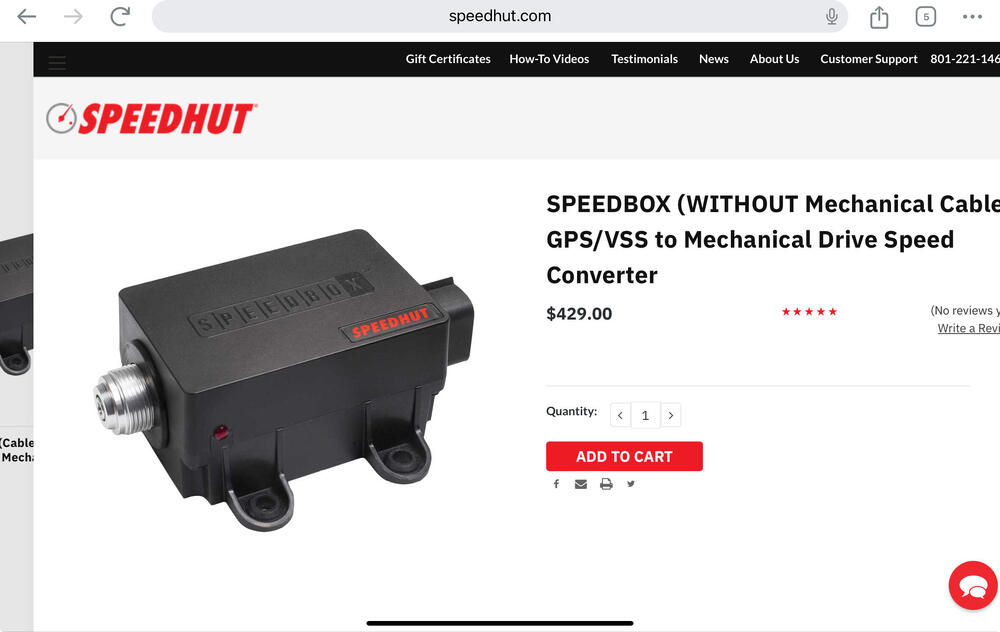

Ok, a few minutes for an update to what’s going on technology wise on the 510 project First, an update on the speedo cable drive. I couldn’t get the Dakota DIgital box to read the VSS out of my ECU for reasons I have not resolved, so I went the lazy route and bought the one from Speed hut that uses GPS as an input. It has been operating flawlessly, EVEN on a recent trip through the mountains (unlike my satellite radio….). While it can be calibrated to any speedo, somehow this work of art managed to read PERFECTLY out of the box on my Metric KPH marked 69 510 sweep style 50+ year speedometer. Maybe the RPM/MPH thing is pretty standard across speedometers….. https://speedhut.com/supershops/speedbox-without-mechanical-cable-gps-vss-to-mechanical-drive-speed-converter/

-

Seat Belt Release Access Solution

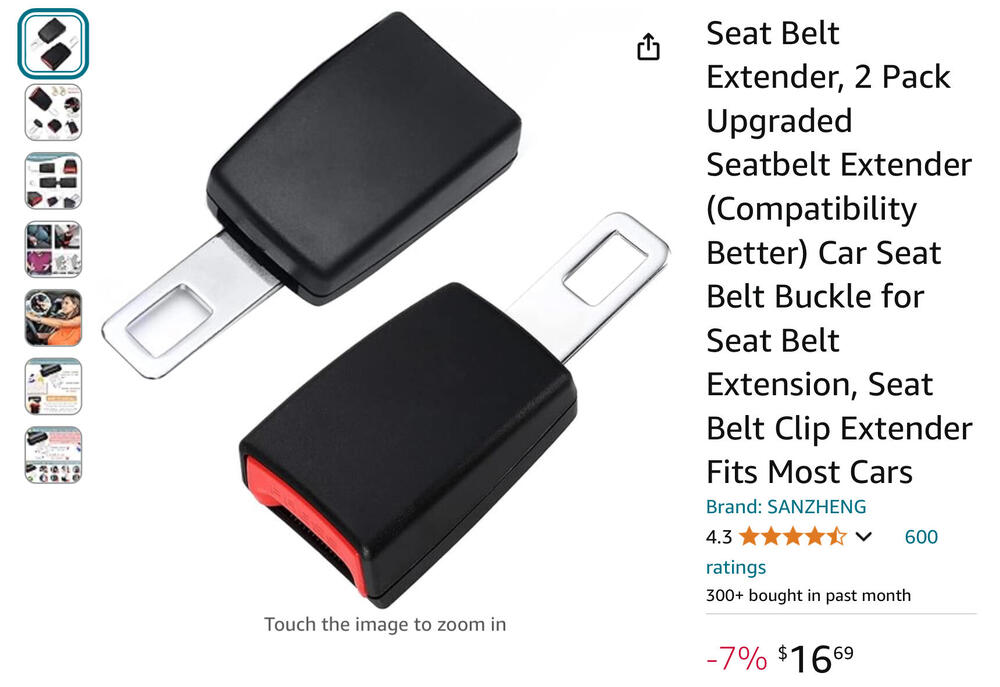

I knew “Seat belt extensions” were a thing, but in a bit of a uncomfortable way for the “circumferentially challenged” shall we say, but did not realize you could get really short ones. Well you can. Here are the proof of the success of these little gems. All $17 bucks worth Another solution to yet another challenge in the custom car world. And check out the pretty seats…

-

Seat Belt Release Access Solution

Well here we are again. I put some lovely new seats in my 510, and a new console (whole ‘nother thread) and now find it hard to get my hand or finger down between the console and the belt buckle to push the big red button to release the belt. The ol’ thumb will fit kinda backwards and push it, but not without a scrap or rub. So what to do about it? First thought was to add a small extension to the end of the belt where it bolts to the floor to lengthen the mount and get the end up higher. But then, one day while perusing Amazon, there magically did appear, the solution to my problem. No I did NOT discuss out loud giving Google a chance to help me. Did not realize these would exist.

-

240Z SU Throttle Cable Kit

Love it! I’ve been tinkering with a cable throttle for a long time for SU’s and triples and this is the cleanest solution I’ve seen. I love the bracket that bolts to the carb mounts to provide the under-carb pull cable mount. Brilliant. Three things to check and be aware of. Cable key seating. If the gas pedal ball position isn’t “just” right, the cable won’t be pulled through the exact center of the sheath it will eventually wear into the sheath lining and will lock up at some point, or wear through. Carefully inspect how the cable moves as the pedal is pressed through its full range of motion. Add lubrication to the cable to prevent premature wear as well. I have had to relocate the ball on the top of the pedal or bend the end of the pedal rod to tweak it into an ideal location. The hole in the firewall on 280’s is larger than the 240, so as you make and sell these, you might have to make a larger OD version of the firewall bushing. SU conversions on 280’s is pretty common. 1.125 comes to mind, but I can check. With the change in actuator arm length, advise to set the pedal stop after installation to ensure the throttle blades are not being stressed at full throttle. Gotta hit that stop just before the blades are full open.

-

Parts Wanted: Hitachi TM-1081ZB - AM Radio

I have one as well @GoldAir

-

Period Correct Tires

Have a local here the Vred’s on his 73. They look great and handle well.

-

Machine work on SU for roller bearings

Not sure if this has been discussed above (to lazy to read every word (but not too lazy to type endlessly here…)) but is the usual “leak” caused by bearing wear or shaft wear or both? Just replacing the bearing is fine, but how are we building the shafts back up to 10mm? Or is the fact that the new bearing have seals now, that these seals now rub on what’s left of the shaft, and maybe at the very edge of where the old bushing touched it which might be still mostly 10mm, effectively sealing it? Which begs the question, are new shafts and butterflies available anymore?

-

Machine work on SU for roller bearings

McMaster will ship to me, they do it all the time. I just have to be registered as a business. They won’t ship internationally without that check box being ticked. Thanks!

-

Need a stock front valance

Here are my pictures. There are some welding repairs on the two outer “wings” to account for poor factory assembly. These are raw and only primered, some body work is expected.

-

Need a stock front valance

Sure do. Let me find them and post a picture

-

Need a stock front valance

I have a brand new after market set. I can dig them out for you. No idea what manufacturer they came from.

- Which Oil Pan Will Fit?

-

Machine work on SU for roller bearings

Anyone brave enough to reveal a source for said 10mm ID sealed bearings?

Subscriber

Subscriber