Everything posted by zKars

-

Quiz Of The Day

Somebody, anybody, tell me the answer! I need to get back to work and have that cigar.

-

Quiz Of The Day

Spring rate metric to SAE conversion units are inverted. Kg/mm to in/lb rather than lb/in. Numeric part is right, 1.48 kg/mm is 83 lb/in

-

Quiz Of The Day

“Without standard load” should be “with standard load”

-

Need a tooth count. Vehicle Speed sensor calibration underway!

You can also continue to use your speedo cable to drive your stock speedo and use a GPS based speed sensor to drive your ECU. I had an idea to build one of these last year, but I found out Haltech and ECU Master came out with one. As long as you don’t auto cross in a parkage or tunnel, this could work. https://www.haltech.com/product/ht-011310-gps-speed-input-module/

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Given the tough position so many of us are probably in or going to be in soon, you can have 6 for $4k. Canadian. Good news is I’ll lots of time to make plenty. Got a big sheet of 18 gauge to gobble up.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Final stage, a bit of dremel work to clean up any burrs and rough edges. Scratches on the back side need to smoothed from contact area on the mandrel. Quick abrasive rub, then sandblast for consistent finish. Off to plating with the next batch of hardware. Hopefully not too far in the future....

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Part two. Use die to drill 21/64 hole Install on custom mandrel on the lathe and remove excess. Parted off to right length. Quick sand paper polish while it’s spinning. Flash clean up on the inner edge of the parted cut complete.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Had a chance last night to go through the process and take pictures for posterity. Won’t be taking them in for plating any time soon. Get ready Use a little bushing I made to center. Squish! Cup made Turn die over, put cup underneath and squish the wings flat. Makes the machining steps easier

-

Checking correct fuel level at Round Top 3 screw SU CARBS Float bowls

I got in touch with Randalla. He has a big batch of new Float-Sync product coming.

-

Early vs. Late Series I 240Z's

@Randalla, please message me. Thanks

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

I was thinking of getting a Greenlee punch set to make easy round blanks. I noticed when I cut my square coupons into a hexagon, there was less distortion. I haven’t actually tried to start with a truly round blank to see what happens. I’m happy with what I’m making. And yes, I have seen the youtubes of people spinning HUGE aluminum disks in HUGE pots pans and other receptacles. Very long lever arms and very large lathes spinning them. Very impressive. I will not be trying that, even on a small scale on my lathe. I see another 3 week boondoggle coming up....

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Quick update. Lot going on at home right now. I have a good solution going. Made the first group of 20-ish. Size is great, appearance comparison to original is pretty good. Drilling the hole after the initial forming is the only option. Any hole in the piece to start with is a) too hard to center, and tears out immediately, pretty much like the fender washers. Using a center hole in the FM part of the die makes drilling the hole in the middle very simple. Once I got the dies centered to each other consistently, I can make millions of identical little wrinkled creatures that only take about 175 finalization steps each. Easy peasy. I’ll have pictures to post of the whole process stages later in the week.

-

New Oil Cam Spray Tube

Nice and simple. As long as the oil streams all aim at the right place, it’s all good. If “I” were advertising such a thing, I would be posting video’s of the spray patterns at 10 psi (Idle) and 60 psi (operating) to give such a critical piece some semblance of trustworthiness.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

I initially tried using a fender washer that had a 5/16 hole, and die parts that pass through the hole. Seemed like the right thing to do. This didn’t pan out very well, as the distortion that happens caused the material to rip around the hole. I now have a 5/16” hole in the female side of the die, so I’ll use that as a drill guide to put a hole in the part after it’s formed. I measured the original washer base thickness. It is as suspected a bit thicker than the walls, at 0.050. 18 gauge sheet metal is 0.048, guess that will do.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Three guesses what I did today. Dang process is very sensitive to several parameters. Centering of the dies turned out to be the biggest challenge. Lubrication was also a real helper. Corners are radiused. Once I got it right, I can duplicate . Twice anyway. I’d like to get the depth of the female die just right, so it stops and makes a nice flat bottom. It’s a bit deep at the moment Notice the pile of test pieces in the background. Next tricks are drilling the 5/16 hole (starting with 5/16 fender washers did NOT work) and cleaning up the excess. I plan on drilling the hole first, then using a 5/16 bolt and nut to make an arbor to mount it in the lathe, the clean up the flash there. No doubt there will learning moments along the way with that too. I currently only have 0.035 thick tin, the original washers have a .045 thickness at the turned up lip. Will have to go shopping Monday. I will have to reduce the diameter of male part of the die, to make room for the thicker material. I have .035 gap in the dies at the moment to match the material. They feel like they would be too thin and cheap feeling with 0.035 material. So making is possible it seems. More news on Monday.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Well that was too easy. A lesson on hardening, a lesson on materials, a lesson on drawing, what more can a guy ask? Thanks! Now I have to go try. I got the project car in the garage easy, parts gathered, getting all gung ho. Gotta slow down and turn a little stuff on the lathe first and take my time. Think I’ll use 5/16 fender washers as the raw materia (assuming they are 1” or more in diameter)l and put a 5/16 nose on the male side of the press and a matching 5/16 hole in the FM side of the pocket to guide the process. Need to make a nice flat bottom 7/8 hole for the FM side to get started. Hope the radius of the corner is nice and tight like the originals. Should be able to press hard enough with my 15 ton press. Fun! Looking for hardware, I even found some nice metric wing nuts with the right kind of “mickey mouse” ears that look like the originals. Apparently they are “German” style... Maybe I can work toward making replacement for the whole bolt assembly.

-

Checking correct fuel level at Round Top 3 screw SU CARBS Float bowls

I've contacted Randalla and asked if I can help with supplying my version while his is un-available. I'm awaiting his reply.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Sure, but I’d like you to show me how, not so much do it for me. I really need to stop getting distracted with fun little projects like this and get the next 510 in the shop and finish it’s resurrection. Heat treating. Heat until yellow, then plunge in oil right? Then call 911. I’ve been watching those knife maker shows....

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

- Source for the Cup washers on the SU Air cleaner Wing Bolts

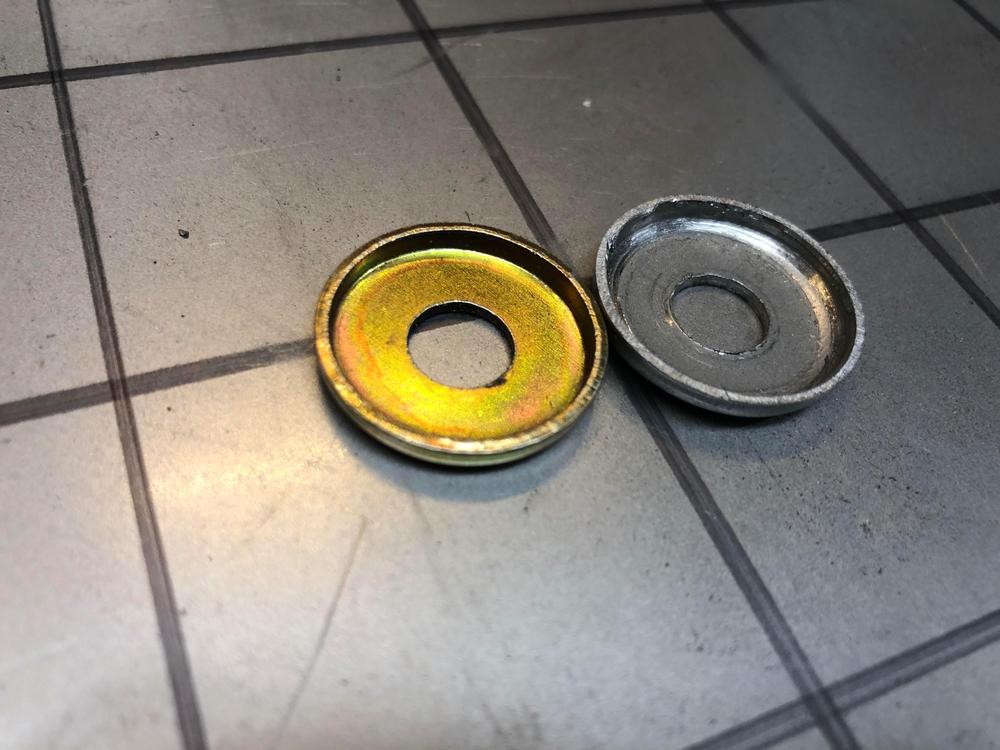

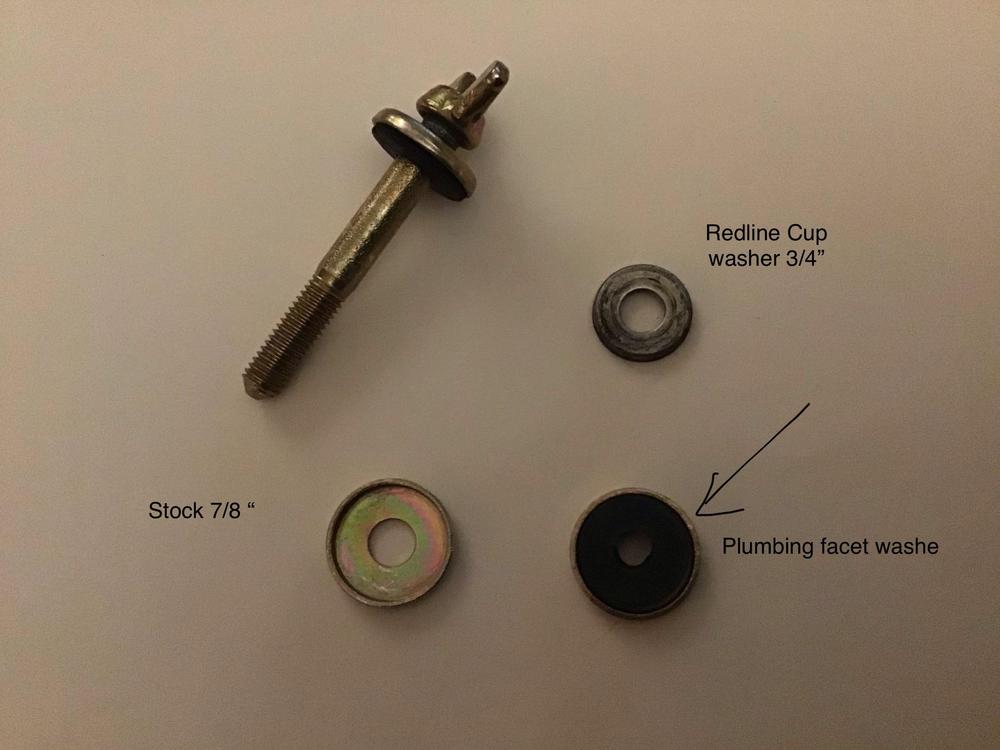

I have a decent little collection of the long wing bolts and the mating long “nuts” they thread into, but the one part of this assembly that I am lacking in is the little cup washer with the rubber grommet underneath. Been hunting for a replacement in the generic hardware world and have come up virtually empty handed. About the only thing close is from RedLine Performance in Auzzie land. Many of you may have touched these over the years if you’ve done side draft carb installations. Redline 52-110K Those cup washers lower right are perfect, well, they are 3/4” diameter while the real ones are 7/8”. There is one in the first picture top right. I contacted Red line and they do sell the cup washers separately, in fact they make them in-house! The Sku is 52-571B $2.58 I even asked them to please make them 7/8” See what they say. I had previously found a plumbing washer that duplicates the rubber washer in the stock cup washer so that part is easy. Now this leads to three things. First, everyone go search the interweb and see if YOU can find a supplier of cup washers. Second, Caption Obvious, machine me up a die to press flat 1” washers into lovely 7/8” cup washers! Simple. Third: You hoarders with a thousand of these already, contact me. I need a dozen.....- FS5W71B Rebuild Thread - Tips tricks and discoveries!

WELL I finally got a chance to take the “new” (to me) fancy hybrid extra yummy tranny out for a drive tonight. The roads are clear here, temp is +5C, beautiful night for a cruise. I have to get this thing out of the shop tomorrow anyway to get the next project car in there, and we have a good cold snow dump coming this weekend, so now or never. I am happy to report the trans works very well. MUCH quieter over all than the old rattle box (better be with new bearings and such). All gears change easy, new synchros are doing their thing just fine. Up and down all gears. That fancy 62mm front bearing in my gingerly machined out bore seems happy, but only time will tell about how well the counter shaft bearings stand up to the abuse I will be giving it over the next few years. Even the reverse light is happily coming on with my modified shift rod with the 4 speed bell housing. Remember this is the one with mixture of a 720 truck ratio’s stirred with a 4 gear set from a close Ratio ZX 5 sp. The idea was that it gave a 0.65 ish 5th while retaining reasonable 1-4 The lower four gears are essentially identical to what i remember “feel” wise. 1st is maybe a tad taller, the 2-3 gap feels just a tad wider, but that 5th. OMG I love it. 2200 RPM at 100 KPH. The mighty 2.4 LZ has no trouble moving it right along. Going to make an excellent highway cruiser for this years planned trips. Feeling good. Now there’s a chance all my other one’s that are now re-built will also move a car down the road with little drama.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

When all you have is a three jaw puller, the whole mother of invention thing kicks right in. I'd be proud to have built that.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

If I had one recurring observation about my experience with working on all these various transmissions, is how little force is required to remove and replace the bearings. There was one day when I was removing one of the bearings from the counter shaft in my press, probably the front one, I took a picture of the pressure gauge on the press. I tried to capture the peak pressure. Pretty wimpy. After the initial "snap" when it starts to move, the guage barely registers for the rest of the motion. You make a good point though, I would be surprised if they were as strong as a "real" nut, it will interesting to see if there is any problem with thread retention when I next use the puller with these new nuts. I'm not expecting much problem.- Sourcing A/C Drier Bracket

Sorry don’t have one. - Source for the Cup washers on the SU Air cleaner Wing Bolts

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber