-

Posts

3,742 -

Joined

-

Last visited

-

Days Won

107

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by zKars

-

Will be interesting to see where the auction goes. Let free enterprise and the capitalist way do its thing.

- 17 replies

-

- 5 speed

- close ratio

-

(and 1 more)

Tagged with:

-

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

Well I tried my fancy azz press tool on a “fresh” tail housing pin. Not quite perfected. It was not pushing dead straight and the threaded portion began to bend. Quite happy it didn’t snap. resorted to more heat and a punch with the fancy azz new support tube/angle iron. Still no joy. Still too much bounce in the system. Decided to try the air hammer. Machined one of the tips with a flat and 1/4 hole to catch the end of the bolt. Well I have to tell you, it popped free in about 2 milliseconds of pounding. I suppose I had loosened it up a bit with previous attempts. Let’s just say that’s true... For me, the right thing to do is to just use the dang air hammer, making that hole in the side of the case first if you have to, and plugging later. Having decent backup, even a chunk of wood wedged in there, would be plenty. -

Aha! PM=Personal message. Click on my screen name, zKars, then when the new window opens, find the message button. Click it and type your message. That way we can discuss details without polluting the thread.

-

I can fix you up. Send me a PM.

-

That’s a new one on me. Looks like that main shaft nut has been off and replaced at least once. Looks like a spot weld has been added...

-

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

So here is a simple solution to the shaft support issue while whacking. The pipe is a chunk 1/2” electrical conduit with a 17/32 hole (perfect fit on the shift rod BTW), 1” from the edge. The pipe is 0.8” diameter. It butts up against the 3/4” angle iron real nice. You could drill a 1/2 hole and file it out to 17/32” to save buying that bit. I have more pipe on the right than you need. The “punch” is nice and straight on the wedge bolt (its dangling free in the pic, ie not straight) and more or less in the center of the reverse lockout hole. Note that the 1/4 extension has the end cut off some to make sure it traps the end of the bolt, but leaves enough exposed to let it move when you hit it. That’s a 3/8 plate spacing the shift casting off the bottom. Helps keep things in place while you place the angle iron and pipe. The rear shaft pin is out of the casting, and the other guide/spring are out as well to all the shaft components to move in and out and rotate to get everything lined up. -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

If it weren't 6 inches down a 1" hole..... -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

Thanks for that, I wasn’t clear. I have the rod out via the tap it through the end cap idea, and I now see the seal inside the bore. How to remove that seal? I can think of some crude ways.... What has worked for people? -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

Air hammer would work too. Have to find one that hits 90 degrees at the tip to make it work on cases without the reverse lockout hole. And can someone give me a bright idea on removing that inner grease seal that the shift rod passes through? There’s a dang metal ridge right behind it that prevents a punch from reaching it. Some kind of hook from the front? Going to have to invent a punch/holder thingy to re-insert it without hurting it too. Will this transmission challenge ever end? -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

Aha! Push the tip of the wedge bolt using the case opposite as the base. If you can get it to seat nice and tight against the case where it can’t slip, this could work. There is lots of rotation so you could find the spot where the case surface is orthogonal to the turnbuckle axis, or a ridge to catch against. Would need to find a good quality turnbuckle with fine threads. Naw, just make one. Drilling holes and making threads is basic work. And yes, the backside would need to be well supported just like the “whacking it out with a pin punch“ case. I think I have a better solution for that too than a chuck of angle iron crudely propped behind it. Something that slips over the shaft and has a threaded bolt in it that you unthread until the bolt head touches the case. Probably still easier to drill the hole, whack it, then plug the hole. But not as much fun! -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

Ok, here is the beast. Bit rough, it has been through many changes on the way to a working model. Here is how it fits and sits on and around the rod and lever arm. And here is it in action inside the tail housing/ The nut on the threaded pusher is 19mm, so had to make a custom bend on this 19mm open end wrench to allow access and at least 1/6 turn. The nut is very close to the raised casting area around the reverse lockout assembly hole in the case. Had to get the length of this pusher bolt just right to allow you to put it on the wedge bolt tip and still get you enough room to push it off. The tail housing without this reverse lockout thingy would have much more room. You might even get a box end wrench on it. Here is the SFT’s for the project The bottom chunk is the part of an intermediate plate from a junked 4 speed. It has the hole for the end of the shift rod. Helps to keep the shift rod supported if you using the 1/4 socket extension whacking method to remove the wedge pin. I still needed a firm support behind the wedge pin area to the case to prevent the rod from just flexing when you hit with the sledge. That is what the 3/4” wide 1/8 thick angle iron piece does. Sits in there real nice. Design wise, the biggest change I had to make to the original tie rod end puller was to cut the legs off close to the threaded end and shift the whole body down about 3/16” then re-weld. This is due to the fact that the wedge pin sit below the centerline of the shift rod by about that much. Your threaded pusher bolt has to be in-line with wedge bolt or you risk bending, well actually, snapping it off. You will be applying considerable compression on that little M6 threaded pin.The 1/4 hole in the end of the pusher bolt makes sure the pin end stays straight and engaged. Now the real test is to try it on fresh untouched pin in another housing. This test pin was never re-inserted with the same pressure as it had from the factory. At least there was zero, and I mean zero signs of rust or pitting, or roughness on the pin. Being bathed in oil its whole lift kept this one clean. If you have a wet rusty one, you’re in for a fight. Heat, penetrating oil, time, the usual.... I still think the “best” approach is to use the pin punch (1/4” socket extension) from outside the case through a hole. Easy on a trans with the reverse lockout, but you’d have to make a hole in the same spot for the earlier ones. I don’t think this such a big deal. We have the exact location from any trans with the reverse lockout, and making NPT threads and plugging it is pretty benign. 1/4 or 3/8 NPT is a plenty big hole. Or you spend a day or two making a custom puller. Your choice. -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

I’ve been slaving on a proto type. Room is tight in there, but I have something that seems to work. Lots of trial and error. Yes a welder was required, cut off wheels, carbide bit in a die grinder, used a lathe but you don’t “need” to (to make a nice centered hole in the end of the threaded press screw) Started out as one of these. Pictures of the final thing in action coming. I used a tail housing from a late zx trans with the reverse lock out thingy, so getting the pin out initially to have an assembly to play with was easy. As long as you support the shift finger casting on the shaft very solidly against the inside of the housing, you can smack the end of the pin with the female end of a 1/4 drive 6” socket extension (so it stays on the end of the pin) with a 3 lb hammer and it pops right out. Any amount of bounce in that shaft and you’re banging on a loosing proposition. I used 1 minute of propane heat on it first. -

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

I’m imagining a tool to make this easier. Imagine a forked body that hooks over the shaft, each side of the bolt, and a threaded bolt like thing that presses on the end of the stud to push it through. kinda like this tie rod ball end remover thingy, but with bigger better wrap around fingers spaced further apart. Nice cupped end that snuggles over the threaded end of the stud to keep it on. Gonna go ‘play’ tonight and see if I can make one. -

left side tie rod is the one with left hand threads. Right side is right hand thread. That assumes no one has replaced the left side with a right side inner rod (common since left sides are hard to find), which would make them both right hand thread. Look at the threads and how they lead into the lock nuts.

-

1978 5-speed transmission Tail-Housing Removal?

zKars replied to chaseincats's topic in Engine & Drivetrain

Removing that. Wedge bolt is a trick indeed. Best way is to drill a 21/64” (will explain in a minute) in the case to the left of the pin (in the picture) so that you insert a punch and drive it out. Use heat on the pin area to help break it free. You also have to support the outer end of the rod so when you hit the bolt with the punch, it doesn’t just flex the rod. Chunk of wood between rod and case will do it. Then tap that hole for 1/8NPT and plug it. Guess what size hole is needed for 1/8NPT tapping... -

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

Did the final assembly this morning, went pretty smooth. Have to work on my technique to get the tail housing on and the shift forks aligned at the same time. Good trick here is to take the reverse lock out assembly out and look in there with a flashlight. It’s in line with the shift forks and the tip of the shifter rod, so you don’t have to guess much. The other part of this is to make sure you have the through/retaining pin that is just ahead of the shifter in place, and the detent/spring thingy with the 19mm hex cap by the shifter in place as well. This keeps the shifter “kept” within the correct confines of its movement while you get the shift fork finger in “just” the right spot. My fancy 62mm front counter bearing “schnicked” perfectly into the front cover. The C type front cover went over it without issue, needed 4mm of shim. I can happily select all 6 gears. There are no extra parts laying around. AND I tried the reverse switch function with my slimmed down shift rod. It works! Only comes on in reverse. Bought it a new switch as well. I stripped the cases and repainted with 2k epoxy primer (Eastwood stuff in a can) then VHT aluminum color caliper paint. -

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

Last bit of ingenuity is in regards to using a 4 speed bell housing, and the issues it raises. Back a few pages, I spent a lot of time creating a way to may a 56mm hole into a 62 mm hole. I did my first test on a somewhat expendable 4 speed bell housing. It went better than expected, and I decided to put a 62mm front counter shaft bearing on this gear set to hopefully improve life span. So I of course feel compelled to use my new bell housing with the 62mm hole. The worst thing about the 4 speed bell housing, is that the reverse switch hole is in the wrong place. It's about an inch too far back. Location on a 4 speed \ Location on the 5 speed, further rearward The proposed solution is to make a new hole in the bell housing in the right spot, and plug the wrong spot. Not a terrible thing to do, it's a M14x1.5 threaded hole, I have a tap. When I looked closely at it, I noticed the hole does not pass through the case at 90 deg to casting. I threaded an M14 bolt in the hole to show you the angle. This doesn't look fun to drill or tap. I'm afraid if I go through at the wrong angle the tip of the switch won't hit the shift rod properly. So..... So I looked at the two shift rods. 5sp on the right/top. 4 sp on the left/lower. The depression where the tip sits when in neutral or 5th is of course farther forward on the 5sp rod (down in the pic is toward the front of the trans). Why not just extend the depressed area on the 5 sp rod farther back (up in the pic, sorry) so it ends at the same place as the 4sp rod and lets me leave the switch where it is? So that's what I did! I first created an identical pocket in the 5sp rod in the same spot as the four speed rod. Then realized that would/might keep the light on in 5th too, so I flatted the area between the old and new pockets. Just imagine that the full diameter bit in the middle is gone, and its flat all the way across between the two flats you see here. Now the switch will turn "on" when the tip rides up the slope from the flat spot to the rod full diameter, as the rod moves to the right (forward) going into reverse. Will stay down when going to the left to get 5th -

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

There is always at least one really grumpy part of every job, like spindle pins, and for this job, its a very tight bearing sleeve that lives under the 5th gear cluster. It is pretty easy to pull off, you use a bearing splitter in front of the 5th gear syncro hub , and a set of 18" rods to draw it all forward until the sleeve is over the threads, then its free. Back on is more grumpy. It sits just ahead of the threads on the main shaft for that big nut, so if you can get it far enough on to start the nut, then just tighten the nut down to drive the sleeve to the end. Well, not quite, the threads run out just before you get to the end. You can use the thick washer that goes on at this spot (the one with the ball or little dowel that sits in a groove to prevent it spinning) to add a bit of thickness to finish driving it all the way with the nut back on. I build a pipe with a hole in the end just the right diameter to hit the end of the sleeve. It slips over shaft that sits against the sleeve and lets me beat it in place with a mallet. You will need something like this if you can't get it on far enough to see threads that then allow you to use the nut to finish the job. This is not the pipe tool thing I built, but it is the world's deepest 38mm 1/2" drive socket. Probably about 18" long. I built to let me do and undo the big nut easily. Bought a 1-1/2 socket, cut it so just the hex was left, then welded it a 1-1/4 black iron pipe (standard hardware store gas or water line) and then welded the back half of a 1/2 drive socket to the other end. -

FS5W71B Rebuild Thread - Tips tricks and discoveries!

zKars replied to zKars's topic in Engine & Drivetrain

Well shocking but true, I actually assembled ONE whole transmission over the last couple of days with new bearings and syncro's. It is also the one I chose to do the hybrid mix of close ratio 5 speed gears (4th gear pair) with all the other 720 truck transmission gears to give me a .65 OD, while retaining ratio's for most of the other gears that still quite reasonable. See the posts a couple of pages back with the spread sheet. Anyway, the 4 gear main and Counter shaft gears and associated bits went right on with a hitch into the other wise truck destined parts. I was able to put the main and counter gear pair sets in and get the shafts pressed, well actually pulled, into the intermediate plate bears using the threaded nuts that are one both shafts, with a tube of just the right length. 3.375" long (1.25 ID tubing) works just fine for both. I had all the gears on both shafts, didn't do the front set separately like the FSM suggests, way too much work. Just takes a tiny bit of juggling of both shafts with one hand has you get the two shafts started in the bearings with a soft tap of a rubber mallet. Then tighten the two nuts (the big 1-1/2" one and the 27 mm smaller counter shaft) one, then the other to draw the shafts in sequentially until seated. Since the two shaft gear sets are mated yet, you can't throw both 1/2 and 3/4 into gear to lock the shaft, so you have to use an old drive shaft yoke and some pipe or whatever to lock the main shaft. There are plenty of "Special tools" in my arsenal now, and having old driveshafts to harvest bits from is critical. As is various lengths of pipe in handy diameters. I'll make a post later that shows all my "SFT's" as I call them (special field tools) and what I used them for. -

Never had to replace them, just clean and repack as mentioned. Maybe in extreme cases if the balls are badly pitted. Rockauto shows many aftermarket replacement options; https://www.rockauto.com/en/catalog/nissan,1972,240z,2.4l+l6,1209169,suspension,strut+bearing,7460

-

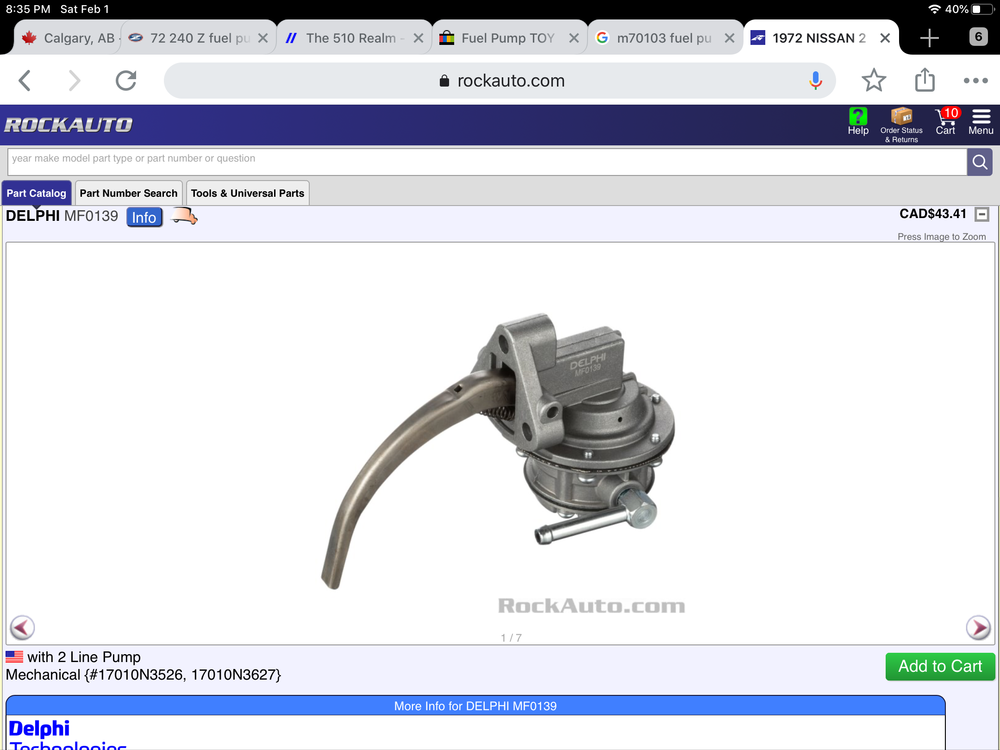

mechanical fuel pump 72 240 Z fuel pump rebuild kit

zKars replied to swflaz's topic in Fuel Injection

Checking RockAuto for 72 240Z, there are a couple of pumps that look like stock ones, a GMB and a Delphi. I wonder if their diaphragms and valves are interchangable with the old stuff. For $43 CAD, might be worth a try. I should cull through my old pumps, disassemble and get all the old diaphragms and valves out and see what looks usable still. -

mechanical fuel pump 72 240 Z fuel pump rebuild kit

zKars replied to swflaz's topic in Fuel Injection

I also remember a post about using a certain Toyota pump that is still available through parts dealers, like RockAuto. Identical internals, just steal the diaphragm and valves and plunl them into yours. I ordered and used one once when that thread came up. At least 5 years ago I think. I wonder how far back my RockAuto order history goes.... -

I have a few old 240 senders, I could send you one and you could use it's float. I'd splice the metal rod close to the float, don't try to "remove" the float per sey. I'll see if the 240/280 floats are the same size.

-

I see Amazon.com has something you might like Manual Steering Rack & Pinion For Nissan Datsun 260Z 280Z S30 1974 1975 1976 1977 - BuyAutoParts 80-70087AN New https://www.amazon.com/dp/B01M3XT0M3/ref=cm_sw_r_cp_tai_SIGlEbGKJAGJ2

-

Ok, early are about 1” wide, late about 1.25”. Very different. You don’t want to put a narrow bushing on a wide flange rack, the rack with slide around. There are threads on here about folks have lots of fun getting the poly rack bushing to seat properly. Do some searching to see the solutions. You can shim a narrow bushing to fit on a wide rack, but I dare you try fitting a wide bushing into a narrow flange rack.

Subscriber

Subscriber