Everything posted by zKars

-

This is got me scratching my head.... Speedo Pinion?

Assuming the old pinion worked before, you have the pinion housing in 180 degrees wrong. Typically there is one slot where that little hold down plate engages, but someone previous may have used the "other" pinion type and added his own slot to make it work. Have a look of there are two slots on yours there are two types, the slot is 180 diff from the other. The pinion is offset in the body so you have to have it oriented correctly or it will not engage.

-

Is there a list for fasteners?

Seems I have a little macro building to do a bit of parsing on a few "08" parts numbers and fill a few new columns with some details! Then remove all the 08 part numbers to a separate sheet. Swore I'd spend less computer time after retiring. Oh well....

-

Is there a list for fasteners?

Ok, so here is an interesting little spreadsheet. Somehow I managed to harvest all the S30 part numbers from a certain on-line resource... Now you can do a little sorting and searching a bit more easily. CPM_Fiche_S30.xls

-

Is there a list for fasteners?

Thanks Zup for sharing that picture library I built back then, pretty much forgot I had done that. I seem to remember a wish to build an app that uses the parts fiche database in a spread sheet so you can click on a part and get a real life picture of it, starting with the hardware pictures in that file. Somewhere I realized how a big a job that was and you know.... I have a couple of other files I guess I should share. Like my wish to build a reference document that shows all the variations between parts over the years. How many times have "we" had to explain "again' that 77-78 doors aren't like 74-76 doors aren't like 70-73 doors. Again, large effort, but I've been blessed over time to have examples on hand of all the varieties of fuel rails, and consoles, vinyl, and gauges, etc etc. that would make this possible, just not the co-ordinated effort of taking and organizing the pictures and then building the website or populating a massive "one of these things is not like the other" or similar CZCC Topic. Anybody got a smart tech savvy young'en they can lend me for a year?

-

Veterans, thank you!

Tanks these louts and to all that serve!

-

Anyone have any extra 240z door striker bolts?

I just gave 6 to Wheee, but I have some left. Send me a PM and we'll share contact info

- 1976 280Z Restoration Project

-

Steering Column Cover

I know there are least four different column covers. 2 240, 2 for the 280. The 240 ones are interchangable with careful wire tucking inside The 77-78 is viturally huge compared to the 74=76 version to allow lots of room for larger connectors on the wiring harness inside.

-

New Micro Big Brake Kit

The rotors sure look like the same ones used in the Z Stage 3 Toyo 4 pot conversion that uses a four bolt Z31 vented rotor, spacer and the toyo truck wide calipers S12W. Haven't checked the PN yet, but I'll put money one it. The rotor is 270mm, pretty decent.

-

New Micro Big Brake Kit

- New Micro Big Brake Kit

At last the package arrived and has been installed. I used the ZX kit on my 510 with ZX struts and spindles. Great quality parts. Installation was a bit of a head scratcher. You definitely have to do the bolts "just so" and in the right order or they ain't going together. The bolt that attach the adapter bracket to the spindle have to put in "backwards" (in my mind) with the nut on the inside. Bit tricky to start that nut up inbetween the rotor and spindle, but it can be done. All in the name of a small caliper and tight spaces. I was able to give them some feed back to change one set of fasteners to hex rather than socket head to aid in the assembly. I've been able to fit all my 15's and almost all of my 14's (stock ZX alloy and standard 5 D slot mags). One set of Z steelies would fit with a bit of spacer. Can't fit a stock 13" 510 steelie though. I have a set of 13" classic Libra's that are on another car that I pray fit these brakes as well. I know those wheels just BARELY fit stock ZX brakes, so they "should" fit these. I even have a Nissan Sentra donut spare (15") that fits! And all testing was done with NO spacers. Got my dime jacked up a couple of inches and running a set of Yoko winter's on my Swaztika wheels. Been out bedding the brakes and setting bias. Gonna be FUN this winter.- Parts needed for 280Z R200 CV axle swap?

Just sold my last set. I have a set of the 280ZX tripod inner stub adapters yet if you decide to go that way. Only one thing I know, CV conversions are not cheap, there are no cheap solutions unless you are doing ALL the fabrication yourself. People's time material expertise and development investment is worth every penny they are charging. Best "Value" is still DatsunRestomod.com. Simple, remove old/bolt in new setup with same 8 bolts. No 200 bolts with safety wire and 3 sets of loose splines on both sides with the crappy Porsche 930 CV stuff...- Drive-by-wire

Generally I see no point in drive by wire for "routine" use. If you have a good TPS, that's all the ECU needs to know about gas pedal position. Setting up a drive by wire is not trivial from what I've read. Also factor in the obvious old guy factor that wants a hard mechanical connection between my right foot and the throttle blades and you might need to temper my comments some...- Sunroof replacement panel

Apparently never heard of 3m panel bonding adhesives (or one of several other brands). Welding is SO yesterday..... (said the man who thinks EFI is something new and cool....)- Happy 2019! A lot of 50 year milestones coming up!

There is still a Harvey's or two in Calgary! And they are great.- Stock Valve Cover Finish

My guess is they want one that looks like it did on the day it left the factory or shortly thereafter on dealer delivery. We may be going just a bit too far sometimes to make our details look a bit too fresh and consistent.- Leather fuel flap, anyone sell one?

Easy to make. It's flat with some holes. And you get to pick the leather you like, or have it dyed to match or contrast your paint! Adjust the size to your liking, add fancy engraving, make it look like a saddle, go nuts!- Stock Valve Cover Finish

I have an NOS L4 valve cover that looks a lot like the ebay cover. The finish really appears like un-finished raw aluminum, and there is lots of variability in the finish. It is not shiny, but has some reflective qualities. It does look a lot like freshly fine bead blasted, but more variable and smoother if that makes any sense. This cover has been in open air for 40+ years on an NOS L18 SSS motor on display. I'll try to get some sun lit pictures that show the variations. There has I believe been some continued oxidation with time while in my possession.- Sizing and Offset of new wheels for '78 280z

Just a note here, but I recently solved a wheel shake issue by buying spacers that were actually flat, unlike the POS cast pot metal ones I was using that were anything but flat. Zero offset seems to work on most z's. If the ones you like only come in small + offset's then a thin spacer can make up for that. I'm talking +12mm and smaller. Assuming tires = or under 225 in width to fit inside the fenders.- Relay of some kind....what is it...?

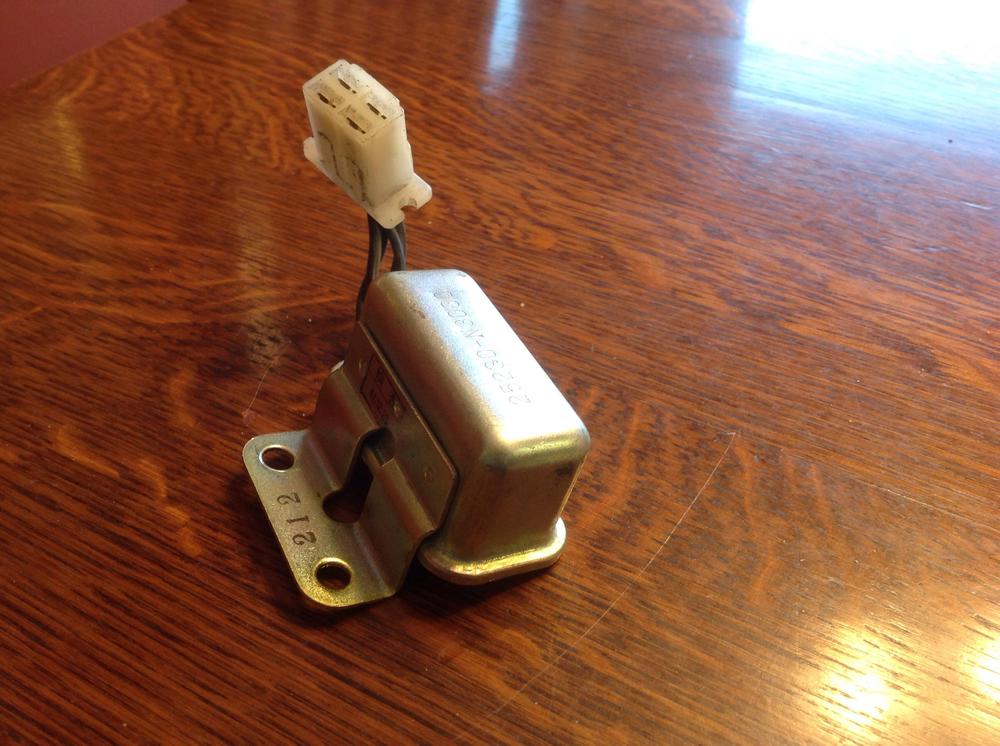

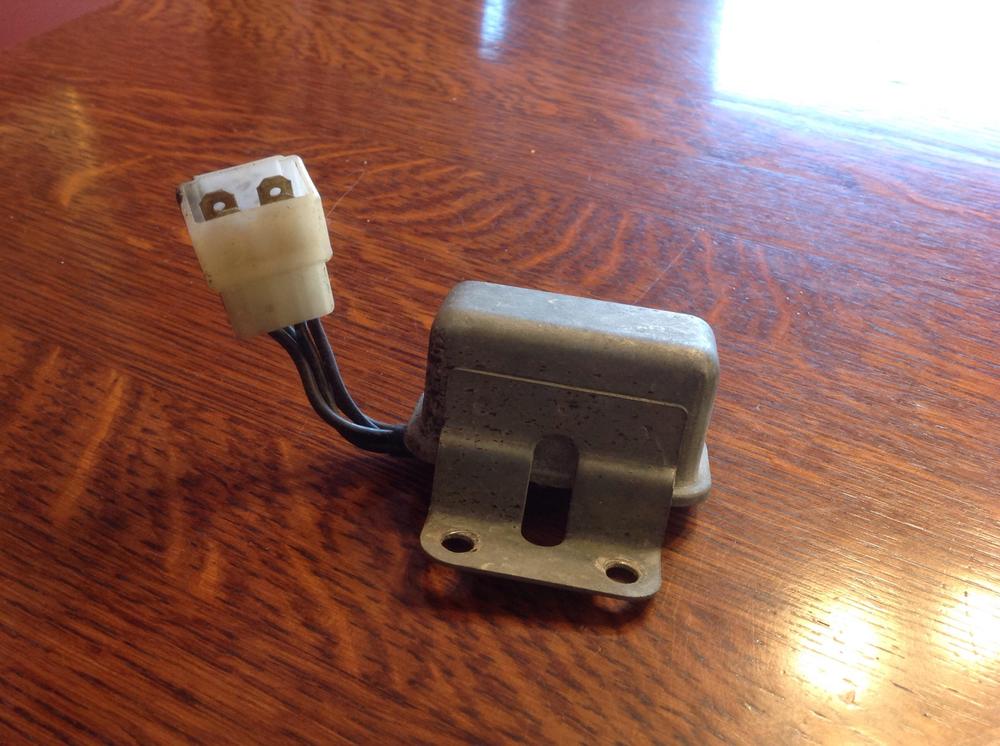

So close. I could put the male plug on it and it would do just fine. I do have the right relay (but its ugly), so I can either exchange housings or just put a plug with new male pins and new shell and even get the right pin in the right position using the correct relay as a guide.- New Micro Big Brake Kit

BAMMMM. Trigger pulled. I have SO many sets of lovely wheels that don't fit my overkill TTT BIG brake kit on my 510 it's making me mad. No more. Anybody want a set of Big front brakes for 280ZX? (And 510, but nobody here cares.... snifff). Gonna be available in a couple of weeks.- Bent Aluminum Wheel

I've had several aluminum rims with quite severe and deep rim dents fixed (curb impacts) without them being cracked in the process. They use heat to soften then manage somehow to remove the dent. They can then machine and polish as required to return the rim looking perfect. I'm sure that if you just take a hammer to a dent in an aluminum rim you will likely crack it. I've been SO tempted to just tap a LITTLE and see what happens... Still make me wonder how such high force "instant" impacts make such a nice consistent and BIG dent without cracking it Right then and there. Maybe the aluminum alloys they use are more malleable than we assume.... I'm getting my ball peen.....- 1976 280Z Restoration Project

I have replaced the "blade" style OEM seals with a "Bulb" style weatherstrip like the door seals. The bulb has to be on top of the pinch weld rather than on the side like the door seals. I got mine from McMaster Carr. I can find the part number. 1120A122 for 1/16" edge, 7/16 bulb diameter https://www.mcmaster.com/catalog/125/3615 The OEM style seems to be about the least effective way to make a seal I can imagine. I think I kept a few of the OEM clips that hold the OEM weatherstrip on if you decide to get the reproduction of them.- 240z hood hinges

I have a couple of decent tight hinge sets left over. I went through my stash last year and threw away 2/3's of them because of excessive pivot point slop. There is just about no way to keep you hood aligned with sloppy hinges. PM me and we'll get some on the way.- Source for BRAND NEW Gear Reduction Starters

Found it! http://www.tsimportedautomotive.com/gearreductionstarters.html - New Micro Big Brake Kit

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber