-

Posts

3,742 -

Joined

-

Last visited

-

Days Won

107

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by zKars

-

-

Seems I may have a few. Six are available. They are diabolically tough to extract from a drip rail. Unless you cut the end off and slide them out. In would easy, Just push straight in Quite amazed at how many of the drip rails I have contain none. Some contain a couple. One contained six. Many I have removed have none and were staying on just fine without them. The Fiche shows them across all years. I once thought they were added later when drip rails were falling off. Given the fun they are to remove, I find this hard to believe. Perhaps it’s their propensity for rusting away under the gutter that made them vanish.

-

-

Still struggling with car at idle after 8 years

zKars replied to Johnny wick's topic in Open Discussions

Hard to tell at the picture angle, but is (was) the fluid level ~ to the red line on top of the bump out on the float bowl as marked by my red line? Looks "pretty" close... -

Well it ain't Halloween candy! Ha!

-

Well the Precision weatherstrip is the same 29.75 with four holes.

-

Ok. 29.75 inches long, 4 pins, holes at each end are with 3/4” of the ends. I have a Precision kit downstairs waiting to go on this car. I’ll measure those seals next

-

Of course i have to ask, how are they “short”? Do they have less than the 4 or 5 holes they are supposed to have? Do you have to stretch it more than 5% when you install it to get the holes to line up? Or are you assuming it’s short because it “should be longer” in your view? The ones I’ve installed in the past (Precision and VintageRubber) both had to stretch ever so slightly to get all the holes to line up but it spanned the first and last hole + about an inch on each end. In fact I have an original 1/71 car in shop I can check. It has it strip in place on the bottom of the door. I can go look and measure and get this settled now. Hang on.

-

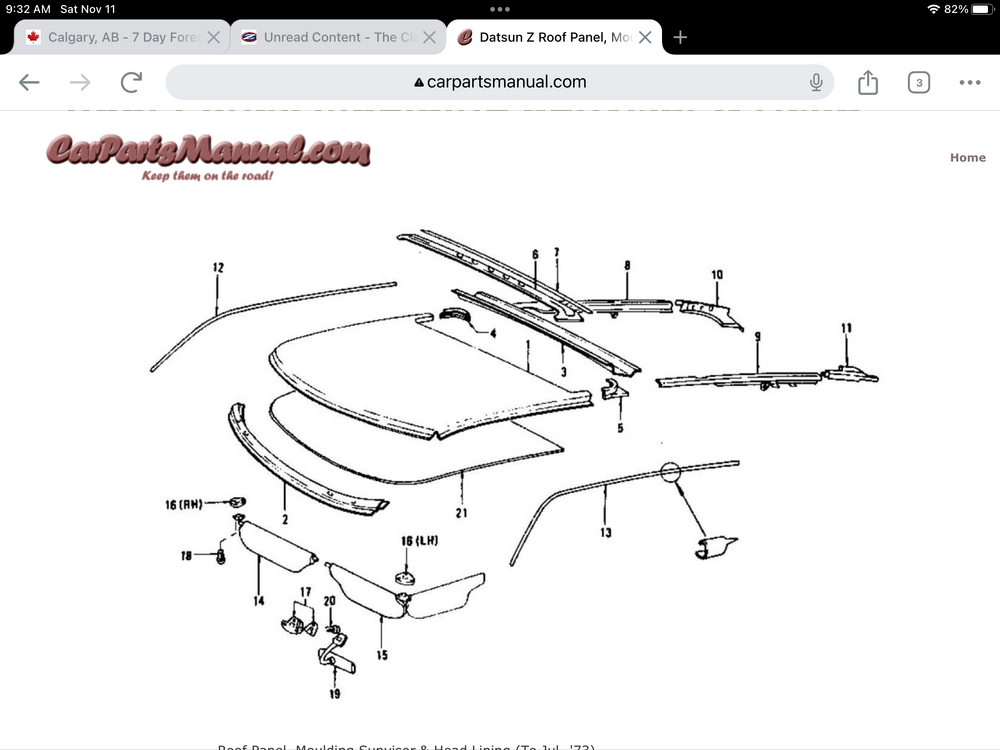

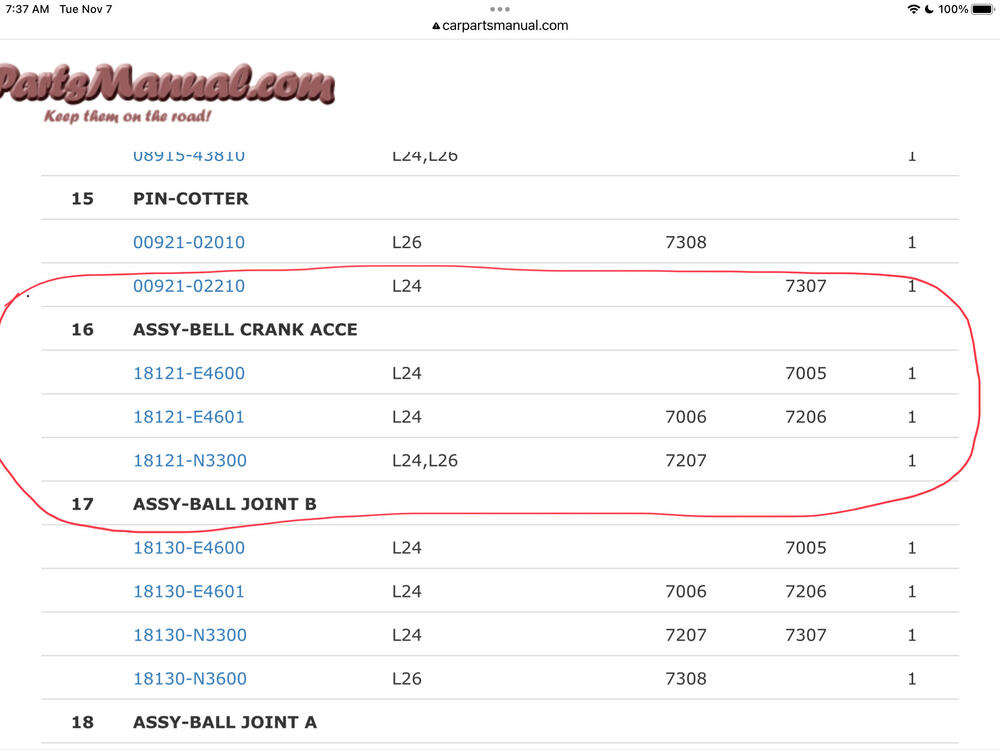

Fiche suggests there was a change on July 1972 https://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/roof-panel-moulding-sunvisor-head-lining Somewhere later than that they grew pockets too. Mirrors too??? Naw.

-

-

I be careful about referring to my wife’s hair as cat hair (or are you married to a cat?), but other than that, fantastic find!

-

Like these? Compared exactly to one just removed from 18551. Perfect match The only other on-line match that s close is a Belmetric SEMS M6x12. Exact same head diameter, but that extra flat washer is a bother to remove. Last picture below shows the comparison. Anyway, I have plenty of the right ones. Happy to send them. As you can tell, they were mistakenly CAD plated, but easily wire brushed off to reveal the mice shiny zinc below.

-

Pilot Bushing in the Crank. Installation Technique

zKars replied to zKars's topic in Engine & Drivetrain

McMaster carr comes to the rescue again! Well, you too Cap’n. So either way, officially, NO OIL NEEDED. But feel free to grease’em up. -

Pilot Bushing in the Crank. Installation Technique

zKars replied to zKars's topic in Engine & Drivetrain

So today I pulled out all my spare bushings again to compare dimensions. Generally they were all the “same”, nice loose fit on the trans shaft, not enough to make any play, just slip right on. BUT the one thing that is VERY different is the material the bushings are made of. Half were bronze, half were steel! I had one Timkin in a box and it was steel (see magnet firmly attached to the silver ones in pics below). The others were (I believe) from Exedy clutch kits. So regarding greasing or not, clearly to me at least, the steel ones would benefit from some grease. The bronze ones don’t “need” it but it won’t hurt. Going to keep doing the 4mm deep insert, which places it at the bottom of the chamfer. Even made an aluminum tool to beat it in without any fear of damage. -

After an exhaustive search for K&N E-2910 air filters, I contacted K&N directly. They are NLA as of earlier this year. Where you-all getting your stock air filters from? Nissan likely still has stock ones, but anyone finding aftermarket anywhere?

- 1 reply

-

- 1

-

-

Pilot Bushing in the Crank. Installation Technique

zKars replied to zKars's topic in Engine & Drivetrain

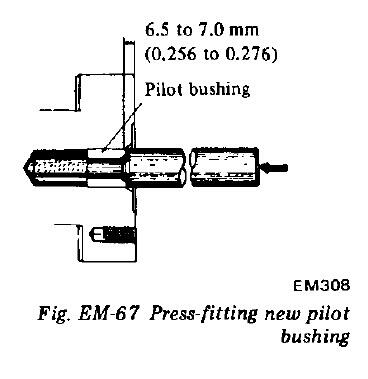

I agree. Can’t see how grease would hurt. A Little. Last question, how to install? I don’t want to pound on the face of it and deform it to reduce the ID. No way I want the shaft tip bound up in the mess I make installing it. I have a bunch of real trans input shafts that i use for clutch alignment tools (HATE the plastic ones, WAY to sloppy). Seems like a natural for installing the bushings, but the ID Change is a chamfer not a nice square shoulder so that might spread the end making it too loose or hard to install all the way. Some are tighter than others. I seem to need to make a nice driver tool with a double step. One to touch the face of the bushing, and the other 4mm (6.5-7??) back and large enough to stop the insertion at exactly the right depth against the crank face. Or just whack it with a punch…… -

Pilot Bushing in the Crank. Installation Technique

zKars replied to zKars's topic in Engine & Drivetrain

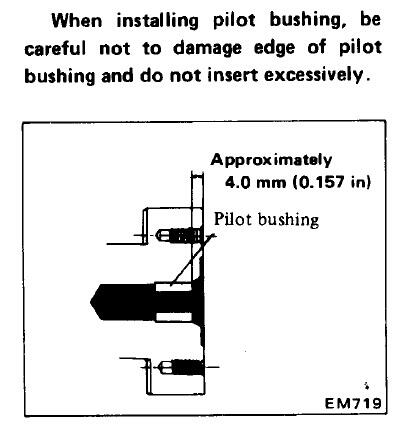

Question 2. Bushing installation depth. I usually to put them in until they were just even with the chamfer that is just below the surface of the crank face, may 2-3 mm in. I used to leave them flush, then when you put the trans back on, it would push it in to the exact depth it needs. Because of these questions and remarks in the FB posts i actually looked at the FSM about this for the first time, and found conflicting information. The 76 FSM say 6.5-7 mm inside the face, the the 82 ZX FSM says 4mm inside the face. Quite a difference. I don’t believe the cranks are any different. I sure don’t want it too deep and risk a really sloppy and barely engaged trans shaft tip. Recipe for noise and vibration I would think. I’m not happy with setting it shallow and letting the shaft push it in, as it might leave the chamfer on the larger diameter behind the tip of the shaft still in contact with the face of the bushing. Again source for noise. I suppose it might wear off quickly anyway. What is your SOP on this? -

So. Seen a thread a few weeks ago on one of the face book groups about the proper way to install the pilot bushing in the back of the crank. Actually I think it was about some trans noise the OP was trying to track down, then someone said it might be your pilot bushing, then others chimed in about that and it went on to how to install one. Then does and don’ts. You know how those discussions go. Well a couple of questions have arisen from some of the comments I read, so I thought I’d ask this collective mind about them and see what you’re experience is. Question 1. Some/several said you MUST grease the trans input shaft tip where it goes into the pilot bushing. Many of them are very experienced old timers with plenty of practical experience. I never have, looking at the pilot bushings I have handled (plenty) they look like an oilite type bronze metal which typically does not require lube of any kind. The FSM for 76 in fact says DO NOT oil. The 82 ZX FSM mentions nothing one way or the other. The fit is also quite loose, i once tried every new bushing I had once (like 10) and they were all quite a loose fit, some worse than others, but NONE were anywhere near snug where you had to push it one by hand with some force.

-

No. Reproductions. I have some used complete windows and some of these pieces from others I’ve stripped but am away for the next 10 days.

-

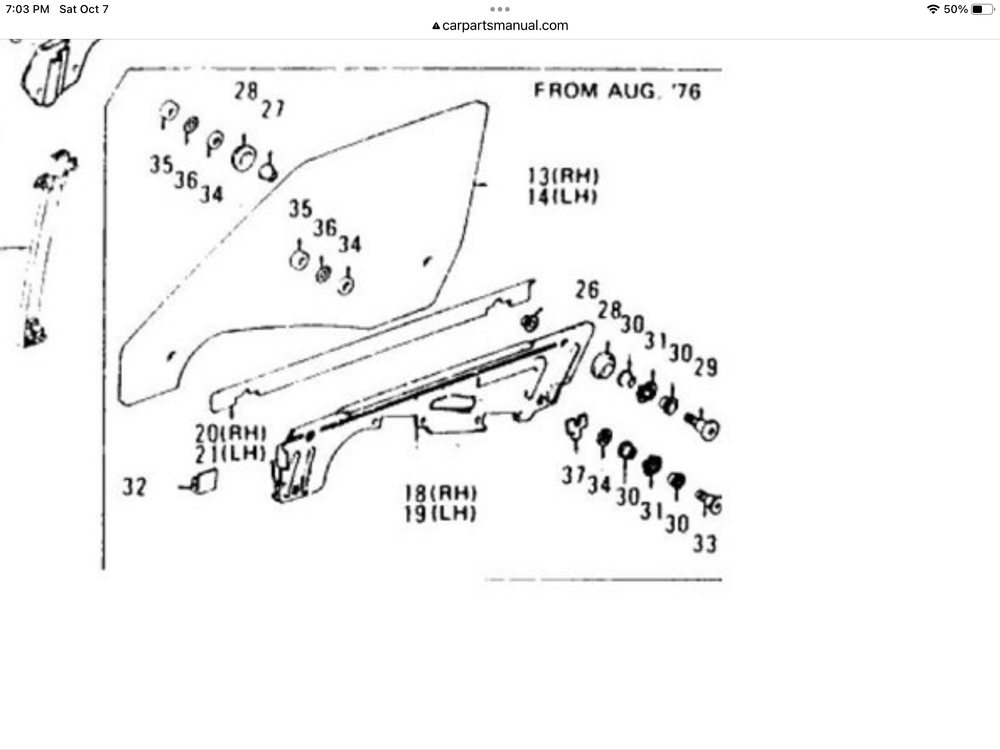

The microfiche also has a blow up of 77-78 door window track guide thingy’s. https://www.carpartsmanual.com/datsun/Z-1969-1978/body-260z-280z/2-seater/door-panel-glass-hinge

-

I thought of another mis-fire problem and the solution. Like Mark, it was related to the plugs. I used, and still use, NGK BPR6ES plugs. The issue I routinely run into with them, is that the end of the plug where wire snaps on, is threaded on to the plug, and is often loose. Several years ago (2015), a random issue with mis-fire throughout the range dogged me for a year or better, and when I finally discovered that one of the end caps was loose on a couple of plugs. Tightened them up, and the mis-fire went away. The BPR6ES-11 plugs that also spec'ed for 280's with EFI, don't have the threaded end cap. I described this WAY back in 2015. The thread lionk is below if you want to see pics. EDIT EDIT : just doing a bit of a good search. NGK plugs BPR6ES #7131 have the threaded caps, #4008 have solid caps! Jim, stop buying #7131 BPR6ES plugs you old idiot! BTW, Don’t order the Denso #4008 plugs by mistake. They are NOT the same….. Just saying…..

-

We had a case here recently with high RPM misfires that turned out to be a poor fitting distributor cap that must have been moving around at higher vibration levels at high RPM’s. You could wiggle it with your hand, wouldn’t seat square and tight. Replaced it with a new cap and viola as they say, revs to the moon with no mis-fire. Ignition systems rely on a in-spec gaps and fitment, any “Extra” energy lost with a too large gap (or inconsistent gap) and resulting spark, results in a weak plug spark and mis fire.

-

To finish up this topic, the caps suggested above have arrived, and they are a perfect fit. The chrome is perfect, they even come with the four little screws! Now to transplant the old stickers. Or get new ones. Now the decision has to be made about how to protect the amazing bare metal finish on these wheels. Polish, clear powder coat, clear acrylic paint?

Subscriber

Subscriber