Everything posted by zKars

-

R180 without a ratio stamp

sometimes its hard to see when the stamped numbers are full of "nasty". Just count the teeth if you can't find it.

-

Curious ? on early 240s

The holes are likely a weight saving feature. Or a way to tease you. You look in there and realize there is space to squirrel things away, but you realize can’t get there from here…. Someone was a hero when they suggested using that space for tools and doing away with the behind seat storage.

-

door holes

The bumper mounts got bigger, the doors got bigger intrusion bars, the hazard switch and HCP’s grew illumination, the gathering storm of safety and emissions requirements was just gathering steam.

-

door holes

You’re missing the internal safety bar that is normally inside that door. It is attached with three bolts through those holes on this end.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Well, I stand corrected. And thinking about it after having driven this trans for many miles, first is not as low as I thought. Thanks for setting that straight

-

Look what I found

Something about “Thou shalt not covet thy neighbor’s Datsun….” comes to mind, but… I’m coveting like crazy here. Nice find indeed!

-

Passenger door does not fully latch

These late 77-78 latches are different than the earlier ones, but the single most powerful thing I done that often changes a door that won’t latch into one that latches easily is to lubricate the mechanism. It HAS to rotate freely or it will have trouble getting to the “2nd stage” latched all the way position.

-

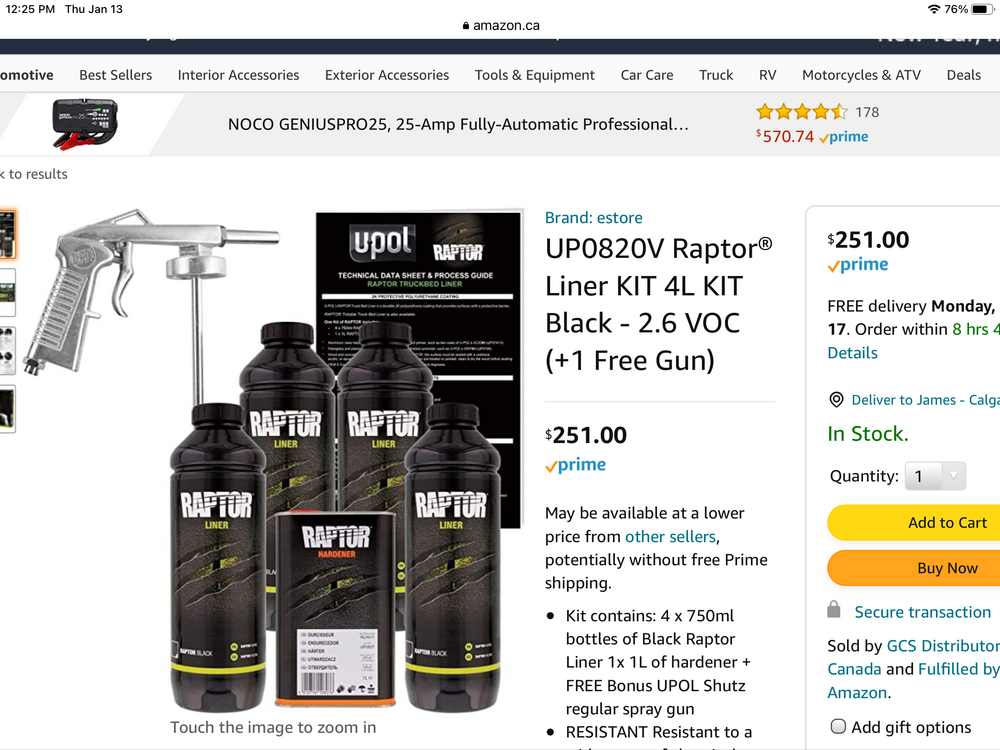

Replacement Gas Tank from S30.World has arrived.

About the only thing I’m putting on the bottom of my Datsun’s now is a pro quality 2-part “truck bed liner” like Raptor. It has proven itself on the bottom of several heavily driven cars in my sphere of influence…. As with anything you apply to your bottom, proper prep and attention to detail are the key to staying stuck for a long long time. My first experience with this stuff in the bed of my various ford 1/2 tons, and with all the scrap metal and datsun junk I have abused those boxes with the ONLY damage I have ever done to the coating is with a single small chip that I caused with an sharp engine block corner crashing into the deck one day when “putting” (more like tossing…) it back there. With the current truck we are 7 years in and the coating looks new, other than not being shiny and black anymore.

-

'75 280z - trying to set timing

Yes this is always an option. I haven’t measured it, but the total adjustment in the two slots on the dizzy base seem to be about the rotation distance between the 6 towers. The only issue is assigning wire lengths that “fit” well with your new dizzy ‘TDC” position for each plug.

-

Wheel sizing

Datsun stud pattern is 4 x 114.3mm. What bolt pattern are the wheels you’re looking at? +25mm wheels will require spacers to clear the tire away from the strut, maybe 15mm (5/8) is enough spacer.

-

Looking for a Gas cap + retainer ring for a 1972 Datsun 240Z

I can beat totalZ and ebay pricing. Send me PM and we’ll discuss

-

Wanted: Nikki 271070 Fuel Pump

Glass beads will work, as will a wire brush. Brass or SS. Cleans up aluminum very nicely. Then an oil based sealer like Gibbs to preserve the finish. I’ve even used the cast aluminum caliper paint from VHT.

-

Hypothetical Power Increase

How many times have we heard “the power is in the head”. Still true. Cam, lift, porting. Make’r flow like a hurricane!

-

Fuel Tank Sender Lock Ring

-

New to me, 280Z...

https://kfvintagejdm.com/product-category/datsun/ Search for “Firewall” and or Battery Tray.

-

Fuel Tank Sender Lock Ring

Flat blade screw driver and hammer has always worked for me. Tap one tab, then next, it comes off. I did make a tool to help, which it does, especially when the tank is still in the car. Based on a short 2” steel pipe nipple that I welded little tabs on that hit on those four little tabs. Then added a bar and 17mm nut welded in the center to put a socket or wrench on. Great if you have a welder. Interesting that the Honda ring is so similar. Good find.

-

Interesting (new?) Money Saving ‘Feature’ on Ebay Noticed

You know, we all do it, browse through some marketplace, ebay, craigslist, Kijiji, looking for Datsun goodies, sometimes you find something interesting and you put it in your shopping cart for later. Gives you a chance to ask that eternal question, “Need” or “Want”…. Makes you feel like you’re in control of your purchases. Right… Anyway. Well I’ve done that on ebay lately, put a couple if items in my cart for “later”, A headliner for my latest 510 project, some key blanks for Z locks, etc. Both items were simple purchase, not auctions. Well, the key blanks were in the cart first and by themselves for about a week when I get this un-expected notification from ebay that the seller has given me an a special discount offer of 10% off if I agree to buy in the next little while. Interesting! Decided not to push the button just yet. Then after adding the head liner, about 3 days later I get a similar message about a discount offer of 11%! This one I jumped on, as I was just waiting to decide who to buy it from. (Goliners, respected well know Datsun headliner vendor, not a scam) So next time you want to buy something on Ebay, and you can wait a few days, put it in your cart and let it “ferment” there for a few days and see what happens! Maybe you’ll get a discount too!

-

Wheelwell

The thing that freaked me out was the day I discovered the hatch lock striker bar isn’t in the center of the slam panel. The release button up on the hatch deck is in the middle, but not the actual catch Sometimes we assume symmetry where none exists.

-

fuel rail installation question

Never seen a published solution for using an extrusion on an SU manifold, but I bet it’s been done. Heat wise, I’d be tempted not to mount the rail to the head. There are plenty of un-used mounting points on the balance tube that I would likely press into service. The stock fuel rail return line has a tiny orifice hole in the tip where the 3/16 hose gets clamped on, this is the stock pressure regulation. I’m hoping you plan on running some sort of regulator on your system on the return side of your rail.

-

Closing holes in trunk when removing crash bumpers

Or seriously, some Killmat or Dynamat foil with butyl backing sound insulation sheeting provides excellent adhesion and permanent seal. Put lots of it down while you’re at it.

-

Colorado Springs Datsun Club

Wasn’t there some big Z shin-dig going on earlier this year in Colorado Springs? Some little party called ZCON or something? Must be a few Z people hiding under the bushes you could rustle up.

-

Temperature gauge sending unit question

The “thing” on the left looks to me to be an aftermarket temperature switch, the kind of thing you use to trigger an electric fan on the rad. When the temp gets to the right temp that spade terminal is connected to ground, which you use to trigger a relay to turn on the fan. The 1/4 spade connector is the type of thing I’d expect to find on an aftermarket switch of that type.

-

Parts Wanted: 240Z boot lock press

Sean I have a bunch of these. I’ll send you a good one. Send me a PM and we can discuss. I’ve had several that stick like yours, it was a pain to take it apart and file in the just the right places to free it up. It was also very unclear as to how this stickiness developed in the first place.

-

My FUJITSUBO Exhaust is hitting my rear control arm

Start by grinding away the flange on that control arm mount saddle to make more room. There is tons of material that will have no effect on strength if removed. Then loosen all the exhaust mounting points and see if you can get another 1/4” of clearance.

-

Metal Throttle linkage Ball Joints?

I discovered this place quite a while ago and have shared it in the past. Has an amazing array of tidbits for just this type of construction. I’ve bought tons of the 8mm x M5 ball ends and various linkage parts to build carb and throttle cable goodies. They also have larger spherical rod ends to build bigger things. Midwestcontrolproducts.com https://midwestcontrol.com/shop/DMCBH-5 https://midwestcontrol.com/shop/products/ball-studs?tierTwo=Threaded&tierThree=M5 x 0.80 RH

Subscriber

Subscriber