-

Posts

3,742 -

Joined

-

Last visited

-

Days Won

107

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by zKars

-

ZCON 2020 Date & Location

zKars replied to jfa.series1's topic in National Zcar Convention's Discussions

A mear 3400 km from here. 5 days 4 hours 7 minutes travel time. Easy Peasy. -

Other than to facilitate cleaner removal, if that's something you do a lot, dry is the correct process. The last thing you want is that goop in the oil holes around those copper sealing rings around the two oil passages, The center one seems to have a large blob really near it. Heavy Danger is the term that comes to mind. Flat head, flat block, and cleanliness are all you need. The gasket does all the work. If you have corroded water passage holes that extend beyond any gasket hole, take care of those the right way, not with goop.

-

Since the problem goes away after a bleed and returns after a certain amount of use, I'm thinking it's bad seals in either the slave or master. Time to remove and inspect the bores and seals in both. If they are rebuilds of old castings, expect to find pitted bores.

-

If I had a choice of quality parts I'd buy them. I have no idea where to find such things. There are no such stores here or anywhere I know of. There is a Dollar Store on every corner however. They have great cheap paint brushes I can use once to clean parts and toss. My parents still have the same paint brushes they used and cleaned since 1956. I still have their working toaster as well. Me think we are doomed.

-

I was just surfing trying to find a replacement pertronix module to see if the cost is crazy or not, and discovered I DO NOT have a Pertronix conversion, it's some other brand. Looks different, no actual markings. My apologies for besmurching Pertronix's fine name here. Pertronix V1 had an issue with them if you left the key on for too long without the car running, it would fry the module. V2 (been out for a long time) has that issue solved. Anyway, I'm running again on a old school E12-80 style dizzy with a GM HEI module and spares....

-

Heat is indeed the enemy, perhaps time to invent a heat shield for the back of the dizzy that blocks direct radiant energy from the exhaust manifold. One issue that Pertronix is very vocal about is using a coil with at least 3 ohm resistance. I do have that. With lower ohm coils the trigger current is too high which heats up the module to rapid destruction. Same warnings and issues with the 123 dizzy's. On a whim, I stuck the dead thing back in to test if there is any spark today, in case heat WAS the culprit that may have reversed after cooling down. Nope, it's dead.

-

So the older I get the more of a crumudgeon I become. I need to rant about first world problems. So today I experience yet ANOTHER failure of a relatively new car part. Back in 2014 I bought a variety of distributors, including the 123 Dizzy for both the Z and the 510. We now know the issue with the crappy caps on those dizzy's that came up, that left me and others stranded. This is another dizzy failure story, for the 510. A friend with a roadster put me on to a guy in the US that was building EI distributors for various inline 4 Datsun engines including the Roadsters and as it turns out the L4 as well. It is a rebuilt body with in this case a Pertronix ignitor in it. Best thing since sliced bread for points plaqued Datsun owners. I bought one, actually before the 123 craze hit me. It sat around with other Nissan E12-80 style dizzy's that the 80's trucks came with. Being running that style mostly, after my Z 123 dizzy cap issue, I never did use the 123 for the 510. I sold it. Well I recently have been converting my 510 to EFI (a WHOLE 'nother story) and again for reasons not to be discussed here, I had to go back to a regular dizzy for a while, so found and grabbed that nice new Pertronix based dizzy from the "pile" and plopped it in. Ran great. That was 6 weeks ago, put on about 2000 km since. Not a hiccup. Today while coming back from Invermere BC with it, guess what. One minute I'm blasting along at warp 9, the next, WHAMMM... Spark goes bye bye in a heart beat. Coast to the side of the road. No spark. DOSOR. (Dead on side of road). Not wiring, power to the coil and dizzy, cap is fine, dead module. I had a spare in the trunk, (E12-80 style) with GM HEI module, put it in, spark came back. Magic. Ok, just what is a guy supposed to do? I am SO FREAKING TIRED of NEW parts crapping out WAY TOO EARLY in their life. Dizzy's alternators, starters, fuel pumps, the list goes on and on and on. It's starting to take the fun out of driving these old pieces of crap. I drive in fear now instead of joy. What's next? Do I swap to a modern engine and stop trying to keep an old one running? Get into counselling and calm down? Just carry more spares and tools? Anybody else losing their edge?

-

Then they shall be yours.

-

The 3012 and 3038's are both 1.70 OD and have 14-13/16" long bodies. All I got

-

A pair of HZ3012 and four HZ3038's. From a 76 280 apparently. I wonder if they fit in 2" tubes....

-

Guy I have a few used Tokico struts laying around. Let me go see what PN's I have.

-

I can find you the right hazard switch in my stash and not break the bank. Send me an email to z240@shaw.ca and we'll take it from there.

-

All great ideas. One more tip from me. How to get the rope/twine/monofiliment/floss into the pinchweld channel in the weatherstrip. I use 3/16 line, so I grabbed a 6-8 inch long 1/4" ID piece of tubing (brass from a hobby store is what I used I think) and thread the rope through it, leave about 12" inches sticking out. You can then insert the tip of the tube with the 12" bit of line into the rubber channel (leave the end of rope sticking out, it's the end you will start pulling on) and draw it around the weatherstrip perimeter keeping the tip inside the channel. Start center bottom or top, your choice. The rope will magically be deposited inside the channel. Should take about 20 seconds and feels SO good when you do it! Since lube is a hot topic, you could lube the rope before you insert it and get the channel lubed at the same time! Here is a picture of the commercial tool I found online to give you the visual.

-

-

The only thing the cord needs to be is 1. Strong enough not to break, and 2. thick enough so that when you wrap it around your hand to pull in tight spots it doesn't cut your hand in half. Leather gloves are your friend. Do little circles in the corners to get the gasket seated. Also the thinner it is, the more likely it will be to tear the rubber if you pull it wrong. 3/16-1/4" rope is a good balance, and I will try that wet trick next time. Genius! HB olfa knife blade flat against the glass to remove outer rubber flange works every time to remove the old gasket and get the glass out. Never broken one. Old gaskets can be rock hard, so it takes a bit of pressure and repeated passes, so wear leather gloves and eye protection for when the blade breaks. Got lots of tricks for putting it in, just a bit hard to explain. Most important is to get the gasket on the glass 100% all around before you put it in on the car, so that it sits down into the window opening as far as possible all around before you start roping yanking. It should look like it's almost all the way in and down all around. If you can't get it seated well to start with, it will rise maddeningly at the top especially and make it impossible to get the gasket on the pinch weld. If you do it right, your helper really only needs to keep the top center held down as you do the rope thing around the bottom and sides. Last trick is using a flat plastic tool to help you seat the gasket all the way over the pinch weld as you go along. This one is my favorite. When you push it between the glass and gasket (inside, 90 deg to the gasket)) and pull toward you , it forces the "U" of the gasket fully over the pinch weld. If you're not over the pinch weld fully at the bottom, the glass gets offset toward the top too much, making the top very hard to get it started and seated up there. Once you get to the top, using the tool also helps you get the gasket over the pinch weld and finally all seated in place. Anyway, hope this helps. The first couple I did were a bear, now I can do it myself if I get in and out of the car about 1000 times to whack the glass as I go along to keep the top in place. A big sand bag is also handy to help hold the top center down and in place if you're alone.

-

Go on, be brave, grab a philips screw driver, and remove those four flat headed screws holding on the trim cover. Never know what you might find inside.... Then let me know if you need any of those screws cuz you're gonna lose one at least....

-

Greetings fellow member of the Jim club. Me thinks the material used is very similar to the bargain basement style exhaust hanger parts I see at the local auto parts emporium. Now I think the original parts come with and installed on (ie threaded through), a new OEM cable, which makes it a bit tricky to apply "new" ones should you be able to fabricate or buy some. I may have a slightly used cable with these items still attached for reference.

-

The closest replacements I've found are from midwestcontrolproducts.com. They have 8mm ball socket ends, but they have M5 threads rather than M4 on the originals. This has lead me to using M5 threaded rod and making complete new throttle rods. They even have several styles of ball ends that lock on to the ball studs. I do have a little stock of both stock rods and ball ends as well as many of the midwest ball ends that I use for throttle cable and other linkage building projects if you want to get some from me. https://midwestcontrol.com/shop/DMCBH-5?search=Ball joint M5

-

View Advert Tokico 5020R Springs. Set of 4 I have technically two sets of 5020R rear Tokico springs for sale. Four individual springs. Fairly sure they are 240Z rear replacements, but do a bit of searching and make sure. Tokico spring info is a bit scarce now, these are discontinued I believe. Asking $160 for the set of four, $40 each. Shipping additional. Advertiser zKars Date 06/22/2019 Price $160.00 Category Parts for Sale

-

THIS ADVERT HAS EXPIRED!

- FOR SALE

- NEW

I have technically two sets of 5020R rear Tokico springs for sale. Four individual springs. Fairly sure they are 240Z rear replacements, but do a bit of searching and make sure. Tokico spring info is a bit scarce now, these are discontinued I believe. Asking $160 for the set of four, $40 each. Shipping additional.$160

Calgary, Alberta - CA

-

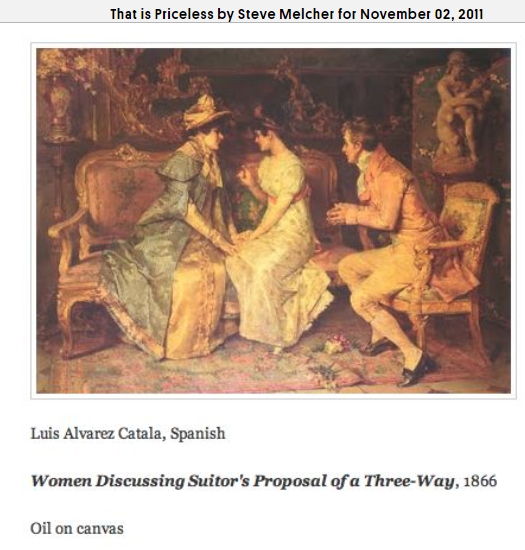

If you want a bit of a hardy-har-har to take the edge off of the day, check out this comic strip. https://www.gocomics.com/that-is-priceless Something a little different, but it certainly tickles my funny bone just the right way. Perhaps some of you will also appreciate this style. A bit of a sampler, as they say...

-

When I deliver the doors, would that make me a door-to-door salesman? Or door-to-door-to-door-to-door........ Can you tell I've taken a liking to Irish Whiskey lately???

-

Perhaps my storage bin(s) full of dash ducting hose might finally find a purpose in life. Let me know if you can't find suitable replacements, BTW, vintage air has some pretty nice duct hose you buy. I know they have 2" at least.

-

The other moustache bar bushings - the wavy rubber washers

zKars replied to Namerow's topic in Engine & Drivetrain

Great idea to reproduce these. Note that the only difference in the upper and lower washers is the ID of the hole in the middle, as the pin it thicker at the top than at the threaded ended. It's fun to visualize how and when those knubs touch and resists the movement of the M-bar as it flexes with diff movement. In the neutral position, the knubs don't touch the bushing eye, but as the bar flexes, the knubs touch and help resist that twisting motion. When the eye bushings wear out, these knubs become primary support for the bar and quickly wear.- 15 replies

-

- differential

- drivetrain

-

(and 1 more)

Tagged with:

-

The Ireland trip even generated a few ideas about my future plans for parts storage and inventory. This is the "long room" in the Trinity College library. Plainly the concept of "heaviest on the bottom, lightest on top" as seen in the ordering strategy on the shelves, also applies to car parts. Sorry having trouble with this new .HEIC files that my iphone is magically using now.... Anybody else fighting with this crap? I can't just choose files from the "Click to choose files" button anymore. Apple strikes again. I used a resize app to grab one and saved it, which saved it as a jpg, but this is not fun.

Subscriber

Subscriber