Everything posted by zKars

-

Vinyl Seat Repair

Fibre New has been around a while as well http://www.fibrenew.com/

-

Cool Flaring Tool And Line

I have this tool and use it extensively. It works like magic. Makes using the cheap harbor freight/Princess Auto POS feel like a toy. The one time I had to use it on a car to repair a broken brake line was a pain, as it relys on being clamped in a vise. The copper/nickel alloy brake line is magical as well. The stuff that Fedhill sells is priced really well, and it was all I used until one day I ran out in the middle of a job. Called around and found an outfit in town (Greggs Distributing) that stocks some of the BrakeQuip tools and lines (they also make SS braided and standard brake lines to order), including their version of the Cunifer soft line. It was even softer and easier to work with than the FedHill stuff. It was more expensive, like x2....

-

What Is Going On At Whitehead?

Oh no you two, don't be tempting me. This winter is filled with other kinds of Datsun fun. The square and homely kind!

-

What Is Going On At Whitehead?

It's little wonder that your paranoia has been peaked given that you've had dealings with a body shop recently! So he's looking for a Z mechanic eh? Wonder if I could commute? My wife works for WestJet, must be 15 flights a day from Calgary to Toronto, should be able to work something out.... Guess I need to retire first too...

-

How To Get Out Of Used Car Deal (Suspected Freud)

I completely agree with the responses. You are in no danger of any legal problems. He is simply mad at you. If he were in fact an honourable person, he would be doing everything he can to satisfy your concerns. Run, don't walk away.

- Check Out Miss January

-

Steering Coupler

Technically the two ujoints in the steering shaft should be phased 90 degrees apart from each other so that you balance the acceleration oscillation that happens as you turn the shaft, but only a true anal OCD nutcase would go to the trouble or even claim to be able to feel the difference. Just take the wheel off and center it. If that doesn't get it perfect, you have to tweak the tie rod ends a bit (both same direction, same amount) to shift it half a spline. When my wheel isn't perfectly straight, I tell my passenger I'm holding it crooked 'cause I'm bucking a strong crosswind.... Funny, the wind always blows from the left side of the car.....

-

Sidedraft Central

Patcon, send to me, I'll post it for you. z240@shaw.ca You could try, click "More Reply Options", then the " Browse" button, then find the file and select it, click "Open". Then click "Attach This File", then finally (yes one more step), click the blue "Add to Post" link that shows up below the name of the file you loaded, this will add some text to your message. here is how this stuff looks

-

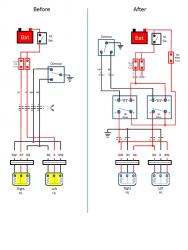

'75 280Z Headlight Relay Upgrade

Here is another way to look at it. Gives you the before and after picture so you can visualize the changes. Headlight_relay.pdf

-

240Z Race Car For Sale In Portland Or

Gone. Now I'll never find out if it came with "goat tracks" or "coat racks".. ..

-

Stock Compressor Bracket For Sanden 508

Does not exist. Has to be fabricated. both Vintage Air and other custom AC vendors sells the basic brackets that fit the Sanden, then fabricate plates etc to mount it to your particular application. There was another thread either here or hybridz just last week about this. Do a bit of searching.

-

240Z An Endangered Species?

Now there is what you call a total waste of published space. Nothing to be learned or gained from it. Please don't make them feel any more important or informed by clicking on that link... No wait, you mean someone is getting PAID to write that crap? Maybe my next career is staring me right in the face! I can put together stories about un-related cars and make up some BS connection all day long!

-

New Look

As soon as I start typing a reply, a two row tool bar appears above the typing area. "My Media" is center on the top row of button. My attachments are all in there. Not sure if there is any other way to get to it. Seems like you should be able to without it being part of a "reply" action.

-

Vacuum Manifold/balance Tube

Granny, you're on the right track. That 123dizzy can do it for you. Use as many cylinders as you can AND use a fuel jet or something similar to make a small orifice to further smooth the signal.

-

Arrrr!

I've looked at some R//C engine silicon fuel line. Its very soft. It's rated for some pretty volatile fuels, like nitrous. Depending on which you choose, some have 400F/200C temp range. Cold end as well, like -112F. Just about right for around here. crap I hate winter.... Like this stuff: http://www.coleparmer.ca/Product/Tygon_Silicone_Tubing_1_16_ID_x_3_16_OD_50_ft_pack/RK-95702-02 At the very least, why not hook up what fuel line you choose in nice loop or coil rather than insisting on making that 180 bend and being bothered by kinking and hardening? Just rambling..

-

Fantastic Use For The Missing Fast Idle Lever

Advance is something that gets applied/removed with varying load conditions. I'd like to play with it too to see what I could achieve, but in general, I'll let the vacuum do the advancing.

-

1970 240Z For Sale - Stunning Restoration

- Wraps

The wrap is a very very thin poly sheet that conforms exactly to the body. I can only imagine that any flaws will show right through. If you want to hide imperfections I think the only way to do that with a wrap is to use a very busy pattern. I'm thinking plaid.....- Looking for tips on how to approach getting to the heater core on my '72 Z

This issue of bypassing the heater has come up many times. The correct way is to BLOCK/PLUG the heater hose connections at the head and lower rad hose fitting at the front. Do NOT just join these inlets/outlets effectively short circuiting the rad and putting hot water at the back of the head. I know it is super tempting to just connect the front and back heater hose fittings with a nice piece of hose as you don't have to find two big bolts or equivalent to use as plugs, but DO IT. It will save your engine or at the very least prolong its life. That said, if you have to do it as an emergency on the road when you heater core or valve suddenly blows, do the jumper hose/short circuit thing, and get home safe, its not an instantaneous damage thing, but remember to fix it right SOON.- Harness rebuild general consensus

This is the stuff I bought. 2 Rolls Factory Electrical Non Adheasive Wiring Harness Friction Tape M | eBay Decent price and good seller. The tape is made by Elliot tape. Michigan Tapes | Adhesive Tapes | Adhesives | Detroit Michigan | Auburn Hills This product page will give you a good idea of the various types of tapes that are available and their intended usage It does not have adhesive, it sticks to itself once wrapped. Electrical tape and its adhesive turns into a gooy mess after a while, and is definitely not the correct product for harness wrapping. The ET stuff feels and works like the stock Datsun harness wrap as far as I can tell.- A better Auxilary Air Regulator

Just to clarify why it won't work, the AAR is an air bypass to the throttle blade, which affects (increases) idle speed when the engine is cold, but ALL air going to the engine must pass throught the AFM or it cannot set the fuel mix correctly. That little filter will pull air from atmosphere that cannot pass through the AFM.- Another clutch ?

All L24/L26/L28 flywheels bolt to the crank, but not all clutches bolt to all flywheels. 225mm clutches use 6 mount bolts, 240mm use 9 bolts, in a different pattern. Sorry, the clutch pack has to match which ever flywheel you decide to use. Only the Fidenza aluminum flywheel is drilled for both diameter clutches.- Dual Points Electrical Diagram Help

The simplest way to essentially defeat all this is to rewire the distributor so that the "advance" point contact goes directly to the "-" side of the coil, and remove the "retard" wire from the distributor. This essentially puts you back to a simple one-point distributor. Unplug and discard the relay. Frankly either set of points can be used, you choose. Just set your timing after you're done. Hey, this leaves you with a "spare" set of points! If one set burns up on the road, just connect the wire to the other contact and carry on! (with either + or - 10 degrees advance initial....)- '77 runs for about 5 min. then dies. Cools down and runs again for another 5 min.

While these are excellent and well tested methods to diagnose very common ignition problem areas, I would preceed these checks by a simple check (immediately after failure) to see if you have spark or not. Just pull the high tension lead from the center of the distributor and hold the metal contact in the boot about 1/8-1/4" away from a clean bolt head (shock tower nut is my favorite). Crank the engine and see if you get a nice regular blue-ish spark. If its absent, weak or erratic, proceed with the above checks. If you do have spark, then checking ignition components falls down the list of "what to look for" quite a bit... I agree that in all likely hood the issue is spark related given that the fuel pump is running. Mind you only a fuel pressure check can really tell that story with any reliability. Gunked plugged up fuel systems have been all over the forum lately too.... Good luck in your troubleshooting.- Off to ontario!

The shop lightening will have an effect on the preceived color. Get it out in the sun before you start wondering about correct shades. Might have to wait until next spring for sun though.... - Wraps

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber