Everything posted by JimmyZ

-

What the hell is this???

What the hell is this?????ROFLROFLROFL You mean you've never seen a convertible Z before. It was a factory option... And if you beleive that then I've got some other stuff I'd like to sell you. Years ago I had a friend who visited New York. He came back with quite a story and having seen the first convertible Z. (Quite possibly the first) All I could think was "WHY would anyone want to do that?? Maybe a tree fell on it or there was some severe hail damage. Maybe he rolled off a hill while driving the dragon:)

-

What would you pay for a dohc 4 valve head

If someone made a head like OS Giken used to what would you be willing to pay? Yes, it's a hypothetical question and the performance gains are disproportionate to the money spent vs other ways BUT it is something to brag about. What would it be worth and would you want a N/A head or one designed for forced induction? Any special features you'd like to see on such a head? I imagine many people would hop on it if were between $1500-$3000,00 for a bare head. By bare head I mean a casting minus valvetrain having seats and guides installed. It would utilize the stock rockers which would not be included. (All major machining operations completed) Herringbone gears for the cams would be included and the stock chain could still be utilized. On Z-car.com there was a fellow who built up such a head and there have been a few places doing variations of that over the years. It seems to have generated some interest. Jim

-

No Heat

The later Z's had dashpot actuated heater valves. (Yes vacuum is needed for the dashpot) This issue has come up before so I'd do a search. I'd start with making sure the V-line is hooked up. If it is then unplug it and check for vacuum. (car running) If it sucks then that limits you to a , bad controls, bad dashpot, broken/clogged valve, clogged heater core, no water in system (). Hope this helps Jim

-

Gas Tank Problem ????

I turned some new bushings for mine on a lathe with about .001" clearance from the shaft. There is virtually no play in the shaft now. You will have a smidge of play in the cam tower of the distributor. (Which equates to nothing measured at the cam) The "cam tower" is the partthat holds the rotor and has the cam. It slides over the shaft in question. When I say "wiggle" I mean from side to side not twist. If you are getting 3/8" of total side to side motion when you grasp the rotor and push/pull then you are way out of tolerances. I think you're twisting the rotor in which case you will get about 3/8" or 10 degrees of travel or so. (Normal) You're just turning the centrifugal advance when you do that. Years ago, I had a distributor with so much slop the rotor was machining the cap! It ran a bit rough and didn't start well. (Go figure) Here's a page I made for gas tank refurbishing. It is dangerous and best left to a shop. I wanted it "done right" though. http://warbuddies.homestead.com/gastank.html I'd square away your fuel problems first. They can act and sound like ignition problems. 2c Jim

-

Gas Tank Problem ????

It may very well be a fuel issue but... I'd still pull at least two plugs and check. If you're burning any oil it is possible to foul them before 6K. I once had an engine that was passing so much oil the plugs had to be changed halfway through the week! If you have a timing light with an inductive pickup you can use that to see if the plugs are firing/misfiring. Try taking the cap off and seeing how much play there is in the shaft. (grasp rotor and wiggle side to side) My line of resoning is that checking these things first is cheap and easy compared to the fuel system. 2c Jim

-

Gas Tank Problem ????

I see you have a 1977 280Z. Have you verified the health of the ignition system? Check or replace the plugs. This would be the first place to start. Also check for vacuum leaks/unplugged lines. I own a 240 and am not as knowlegable as your fellow 280 owners will be RE the stock fuel system. Perhaps after we have verified the above they can zero in on it. Do you have FI or carbs?? Jim

-

Sal No Longer with MSA

I've heard mention of him before but am unaware of his position. Is he an owner? Hope MSA sticks around. Jim

-

My baby's water pump is going

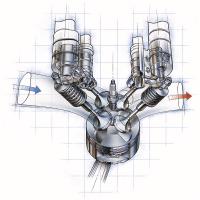

Sorry about the picture. (Oops) I inserted it from a previous post and had no idea it would turn out that way. Darned 5 minute edit rule:) Jim

-

Close Call this Weekend

Photo #4's skid marks seem to tell me that he may have tatoo'ed "MACK" across his forhead if the S-10 weren't there. Having the Z taken out by a lowly wanabee ricer would be the worst way for a Z to meet oblivion. IMHO the BEST way to end a Z's career would be anything done with heaps of your adrenaline pumping not someone elses. I can almost see the Z wiping it's brow and saying "schew".

-

My baby's water pump is going

Flushing the cooling system won't help but it is reccomended before replacing the pump if your coolant is full of particulate. (rust) The seal on the new water pump will last longer if the coolant is clean. I've owned my Z for 18 years and have replaced the pump four times. The first two were due to the heavy metal fan which was replaced with a newer/lighter plastic fan like you have. I drove mine hard which may have contributed o the W/P's demise. IF your water pump does "go" then the bearings inside will allow your fan to impact and destroy your radiator. (This is very expensive) To check the condition of the pump loosen the belt driving the pump and wiggle the fan. While wiggling the fan observe whether there is ANY play in the pump shaft. There might be a little play in your fan clutch but you can ignore this. If there is any play in the pump or you see water coming from the pump's spill hole then the bearings are bad and the car should not be driven until fixed. Changing the pump is fairly easy. On the ZX there are several things you need to remove to get to it but it's not that bad... Just time consuming. When reassembling use anti-seize compound on the W/P bolts and be sure that all of the old gasket material is off the mating surface. There are threads here with opinions on how a pump gasket should be treated prior to installation. I use anti-seize on the engine side of the gasket and loctite water pump silicone on the W/P side. The loctite is really just an aid in securing the gasket to the pump face IMO. Don't over torque the W/P bolts when installing. If one should break it's not fun. (Ask me how I know these things) Hope this helps, Jim PS Here's a picture of the W/P taken head on. Obviously there's no fan or pulley attached.

-

Can't properly set point gap -- help!

Are the screws that hold the baseplate assembly missing? This would cause what you're talking about. (To a small degree.) The baseplate is the part that the points fasten to. It is made up of two plates.. One fixed and the other moves when vac advance kicks in. How many degrees does the baseplate rotate? Is it the entire baseplate or just the top half? Jim

-

Anyone use colortune?

Just curious if anyone has used colortune on our Z's. After finding that certain SU's float adjustments differ from front to rear it got me wondering about how one could verify the mixture between two carbs. Sure, tuning the carbs only addresses idle mixture and we are relying on the needle to provide the necessary mixture curve with RPM increases. It would be nice to know the precision in mixture adjustment gained by using colortune. Another question is whether two C-tune's could be used at higher rpm to verify ideal mixture? One could always use multiple EGT/CHT pickups or to get a really accurate idea but that is going a bit far. Jim

-

park light fuse blows out

The obvious.. Check along the length of the harness for exposed wire. If your rubber grommets are gone it's very easy to have the wires abrade the firewall etc. I had this happening up front where the harness enters the front crossmember. 2c Jim

-

Carbs set full lean, still running rich

Nice Geezer! I like stuff like that! Was that out of an FSM or another publication? What caught my eye was that the fron and rear carbs had different heights. Beats the sh!# out of the Haynes manual. Thanks. Jim

-

park light fuse blows out

Years ago I had to disconnect my marker lights to keep the parking light fuse from blowing. It seems the marker light bulb holders rot pretty quickly. As mentioned above, try disconnecting all the lights and reconnect one at a time while on until you find the bad one. It will fry the fuse when you find it. 2c Jim

-

Engine Bay Harness from scratch ... I'm planning to build it ...

Just did a quick search and couldn't find much. Where does one get color coded wiring which matches the colors we already have? Connectors can be worked around but it would be nice to at least have something anyone could work on using a manual.

-

Engine Bay Harness from scratch ... I'm planning to build it ...

Thanks Arne A few months ago I was faced with the possibility of loosing my harness. (Something got hot) I didn't like the prospects of not being able to find another. While we're at it what were the ignition wiring differences? Is there a way to isolate the tach to a different subharness? What I/we should really be asking is do the FSM's cover things generically like the Haynes manual? Although my Z is a 2/71 I have a '72 FSM which has some good drawings/line art of the wiring harnesses. As far as I could see the 72 FSM had the same type/number of connectors. Curious, Jim

-

Engine Bay Harness from scratch ... I'm planning to build it ...

MT 240's only.... Just a question.. Wouldn't it be possible to make a whole car generic 240Z harness for MT style only? Are the wipers that different? Really, if you can buy and adapt a generic harness to our Z's then shouldn't we be able to construct something? I'd love to come up with some CAD drawings if I could get hold of a free harness or two. This way anyone could pick up where the last guy left off. As for the dash, I'm thinking that most MT 240's are the same?? At least when it comes to ignition, guages, instruments etc. The signal and light switches are another story but that could be a sub-harness. Arne, I'm sorry you didn't get your T shirt but could you enlighten us some more. Even if the details are fuzzy with time things like this are good to know. Jim

-

Another "good as chrome" product?

There was an Italian/franchise process which required special equipment and essentially was the same thing. (Read about this years ago) It was just as durable as paint but the chrome could take on any color you wanted. Ah! Here is one such setup. Pretty cool! http://www.goldtouchinc.com/cosmichrome/index.html

-

1971 240Z Family Treasure & letting go decisions

I can't tell you how many times I have met someone who says "I used to have one of those" and was immediately followed by... "I should have never let it go". That is a beautiful car you have. $3K seems quite a bargain to me. If you really must let it go at least make sure it gets a good home. I agree w/ MikeW above. Pouring money into old cars is usually more of a one way street. You'll be out all the efforrt and $$ and probably break even or worse. Easier just to clean and sell/cut losses. If you spent about a day or two on the engine compartment cleaning and polishing that would really help. Too bad the engine bay wasn't sprayed when the car was last painted. 2c Jim PS Do you still have the original block or did it get chucked when the 260 went in?

-

Just bought a 1973 240Z, won't start

Let's hope it's not a cracked or coroded head casting allowing coolant to pass. Great to hear that you got it running otherwise though. As part of a hobby I do metal casting and end up cutting a lot of cylinder heads up to make ingots. It's amazing how thin some of the jackets are inside these castings. Of course the heads I obtain are scrap heads from the local engine shop so this helps explain why they were on the "way out". I've found a few heads which exhibit exactly what you seem to have... A nice crack in either the exhaust or intake runner. (emphasis on "seem") Hope it's just a head gasket. Jim

-

240Z resto video

This takes me back to being 20 again... The first time I took my Z all apart.. Spare change, surprise finds, learning etc.. http://www.youtube.com/watch?v=wFPc6VCnHSc

-

Sharing my own 2 Z related peices of artwork

That should be on a shirt, poster, SOMETHING!!! Very nice!

-

Tank rust

The problem is that he does have a screen unlike our 240's. Chances are the screen will not fare well even if it is blown. His best bet is to have a new line installed (sweated) and the old line sweated shut. I wouldn't want to risk paying all of that money/spending time just to find that the screen won't flow and then have to redo the enitre thing. Once you sweat/apply heat any sealer will need to be completely stripped and replaced. Now, IF he could somehow mask the screen...

-

z car frustration!!!!

I imagine you tested your plugs on his Z by laying them on top of the valve cover? The real test would have been unscrewing his and replacing with yours. A plug may fire outside an engine but once you install it the compression in the cylinder may not allow the spark to jump on a defective plug. Your best bet is simply replacing at least three of your plugs with brand new plugs. I know you're young and broke. I was there too at one time and feel your pain. When faced with problem like this it is best to remove uncertainties and replace with certainty until the problem is solved. Is your battery low? Slow cranking will greatly reduce the number of sparks because the engine is turning slower. Also, an electronic distributor will NOT operate below a certain voltage. (This was my experience with 1980's cars and not with Z's) I'm hoping someone who owns a 280 will chime in and tell us what the lowest voltage they were able to start on was. Usually if I run my battery near dead with the points ignition a simple push start will get it running again. Cya, Jim