-

Wind tunnel testing on the S30

I've been looking at the wind tunnel post from time to time. I've been involved in car testing a number of times over the years in a number of tunnels. I was the guy making the changes. They basically set the model on supports under the wheels without the wheels actually touching the ground plane. There are then very sensitive gauges attached to these mounts called strain gauges. Thus whatever loads that are put on the four corners are measured by a thing called a balance. The car can be run at yaw angles as well as straight forwards. It's usually difficult to change the ride height quickly. I'm not into the actual math used but by using the frontal area of the model and the area of the tunnel they compute blockage and then ultimately the drag. By doing it this way you can compare different cars, trucks, etc using the same scale. It's possible for a v an to have a better drag coefficient than a sports car. The speeds that are used are usually determined by trying different speeds and making a graph to see where the top of the curve is where it levels off and becomes reliable. The lowest speed that works is where they want to run because of the heat generated by the moving air. It takes a lot of air conditioning to keep the temperatures down. Basically you start at the front and work towards the back. Any changes that are upwind of other changes can make you start over. The biggest improvements are usually at the front. There they have the potential to affect more surface. I have made headlamp covers only to find that they didn't help. Finally, I'm only knowledgeable with working to achieve the least drag. If you want to go racing, you have to use a completely different set of goals. (That's where I don't think their wind tunnel exercise will be too effective. For everyday driving there's a lot of leeway in what the loading can be. If performance is considered it has to be coupled with tires, power available etc. The more power available the more you can trade off for performance. The variables are endless. Larry

-

Matching Paint?

Mike, I just had the same problem with my SER that got damaged in an accident. I asked the dealer for a recommendation and they sent me where they have their work done. I did mention to the owner of the shop that his work had to pass rather tough scrutiny. He said it would be perfect. His work was great except for color match. I pointed it out to him and they repainted. Color match is now perfect. I believe that shops that work on valuable cars should be able to match color or tell you up front that the color might not match so you can go someplace else. That's the service they're in business to provide. The paint provider will do an eye-match if necessary. I don't know the circumstances but it seems reasonable to expect a color match. Larry

- 73 Z

- 73 Z

- 73 Z

-

Compression 71 240

Also, have you checked your valve adjustment? It could be just a tight valve. Happened to me. Luck, Larry

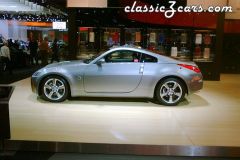

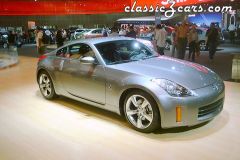

- New Z

- New Z

- New Z

- New Z

- Yellow

- Yellow

- Yellow

- Yellow

- Yellow

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.