Everything posted by ph240

-

Gas tank tubes

JB weld may work. Gas will not effect it., but I agree with Nissanman. The factory soldered the connections. The pipes are soldered to a plate that is spot welded and soldered sealed to the tank. I would not heat the whole plate as you will unseal the plate to the tank. I think you would be better to solder the the tubes back. Either way you should pressure test the tank with about 5 psi and check for leaks. You may have to have a local shop do this. Do not apply more air pressure as you can hurt the tank. Welding wire or a coat hanger should dislodge any rust/debris. I would turn the tank up side down and have the drivers side (shallow end) up higher so when the debris comes out it will fall into the tall part of the tank; on the other side of the baffle, were you can vacuum it out thru the sending unit opening or the filler neck. You may need to soak it with WD40 for a while.

-

Fuel sending unit ohms

Reddog, look at the Hybird Z >techinical>Engine Components>Ignition and Electrical, " How to make autometer fuel gauge read properly" back on 11-17-2007 smoorenc gives a detailed post on this problem. I have not tried it yet but it makes sense. I am also looking at using Autometer or VDO gauges, but am still working on sheetmetal and rust repair.

-

Passenger side frame rail replacement

Making the sheet metal panels. I decided to redo this as I didn't like the 1st attempt. I will be using an optima battery and a Detroit Speed & Engineering billet battery hold down. No more acid spill and pitted frame rails.

-

Passenger side frame rail replacement

Welded but not grinded smooth yet. The engine support came out well, it is much stronger than stock. T/C mount is welded in place but not finished yet. This is taken a lot of time but I should have good results.

-

Passenger side frame rail replacement

Decided to make my onw frame rails. 2.5"x2.5" .120 wall. The battery box and firewall was so bad I had to remove it all the up to the lower cowl panel. The right floor pan is cut out and I am having to come up the trans tunnel a few inches.

-

Passenger side frame rail replacement

I notched the frame rail for radiator clearence. I am having a custom downflow rad built with twin 11" spal fans. Cooling won't be an issue. I plan to add a Vintage Air system as well.

-

Passenger side frame rail replacement

Decided to make my onw frame rails. 2.5"x2.5" .120 wall. The battery box and firewall was so bad I had to remove it all the up to the lower cowl panel. Rust is no fun.

-

240Z rotisserie

Well after too many months the 240 is on a rotisserie. Hopefully this will make the sheetmetal work much easier.

-

240Z rotisserie

Well after too many months the 240 is on a rotisserie. Hopefully this will make the sheetmetal work much easier.

-

240Z rotisserie

Floor pans, both outer rockers and an improved battery tray and frame rails are in the works. the rear 1/4's are in really good shape on this car, but the pans and rockers make up for it.

-

240Z rotisserie

Floor pans, both outer rockers and an improved battery tray and frame rails are in the works. the rear 1/4's are in really good shape on this car, but the pans and rockers make up for it.

-

240Z rotisserie

This rotisserie has had mid 50 chevies on it before with no issues. So a light 240Z is no problem. It will even roll. I'll post pics as work is finished

-

240Z rotisserie

This rotisserie has had mid 50 chevies on it before with no issues. So a light 240Z is no problem. It will even roll. I'll post pics as work is finished

-

240Z rotisserie

Well after too many months the 240 is on a rotisserie. Hopefully this will make the sheetmetal work much easier.

-

240Z rotisserie

Well after too many months the 240 is on a rotisserie. Hopefully this will make the sheetmetal work much easier.

-

240Z rotisserie

Thanks to all who answered my questions on connecting the body. It works and I can spin the body almost 360. I used what I could and fab up the rest

-

240Z rotisserie

Thanks to all who answered my questions on connecting the body. It works and I can spin the body almost 360. I used what I could and fab up the rest

-

Mayday!!! Mayday!!!Mayday!!!

My 72 had this problem, I found two things wrong. The wire coming in to the points was bad and it would idle, and run ok but it would shut off around 45 mph. Also I found both fuel screens in the inlet side of the carbs had a lot of trash in them. I removed them and installed inline filters instead, motor would pull 7000 rpm no problem after that. Good luck

-

Radiator pressure?

25 psi is too much. 280 Master is correct with 13psi. If it leaks at 10, better think about using another one.

-

3rd-2nd grinding after fluid change

Double check your bottles and be sure what you put in. It sounds like you have the wrong fluid, redline has many different gear oils in a 75/90. I am looking at using Redline MTL in mine but have not as of yet, I have run MTL in a 82 5 speed maxima and a 85 5 speed FWD maxima with great results. You should call Redline and ask them.

-

door hinge repair

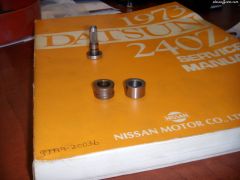

Using this link http://atlanticz.ca/zclub/techtips/body/doorhinge/index.htm I fixed my 73 240 door hinges. The pins and bushings were badly worn as was the door stop roller. I purchased 8 Nissan part# 80410-01G00 pin bushings and 4 80406-V5002 pins from the dealer. With the Z hinges NLA I purchased 2 8491 A202 steel press fit drill bushings from Mcmaster-Carr to use as the new rollers. You can see how bad the old bushings were worn. I could not get the doors to algin. I will be mocking up the striped doors soon and will follow up.

-

door hinge repair

Using this link http://atlanticz.ca/zclub/techtips/body/doorhinge/index.htm I fixed my 73 240 door hinges. The pins and bushings were badly worn as was the door stop roller. I purchased 8 Nissan part# 80410-01G00 pin bushings and 4 80406-V5002 pins from the dealer. With the Z hinges NLA I purchased 2 8491 A202 steel press fit drill bushings from Mcmaster-Carr to use as the new rollers. You can see how bad the old bushings were worn. I could not get the doors to algin. I will be mocking up the striped doors soon and will follow up.

-

door hinge repair

Using this link http://atlanticz.ca/zclub/techtips/body/doorhinge/index.htm I fixed my 73 240 door hinges. The pins and bushings were badly worn as was the door stop roller. I purchased 8 Nissan part# 80410-01G00 pin bushings and 4 80406-V5002 pins from the dealer. With the Z hinges NLA I purchased 2 8491 A202 steel press fit drill bushings from Mcmaster-Carr to use as the new rollers. You can see how bad the old bushings were worn. I could not get the doors to algin. I will be mocking up the striped doors soon and will follow up.

-

door hinge repair

Using this link http://atlanticz.ca/zclub/techtips/body/doorhinge/index.htm I fixed my 73 240 door hinges. The pins and bushings were badly worn as was the door stop roller. I purchased 8 Nissan part# 80410-01G00 pin bushings and 4 80406-V5002 pins from the dealer. With the Z hinges NLA I purchased 2 8491 A202 steel press fit drill bushings from Mcmaster-Carr to use as the new rollers. You can see how bad the old bushings were worn. I could not get the doors to algin. I will be mocking up the striped doors soon and will follow up.

-

door hinge repair

Using this link http://atlanticz.ca/zclub/techtips/body/doorhinge/index.htm I fixed my 73 240 door hinges. The pins and bushings were badly worn as was the door stop roller. I purchased 8 Nissan part# 80410-01G00 pin bushings and 4 80406-V5002 pins from the dealer. With the Z hinges NLA I purchased 2 8491 A202 steel press fit drill bushings from Mcmaster-Carr to use as the new rollers. You can see how bad the old bushings were worn. I could not get the doors to algin. I will be mocking up the striped doors soon and will follow up.