Everything posted by mgood

-

Is this a 280z brake booster

-

ok z running like a time bomb and trans is really sticky

silvey19k, the symptoms you are talking about is exactly what my car did for about 3 weeks before the master cylinder for the clutch went bad. I am going to replace all the parts the master the slave and the hose on the car this weekend. You can see the discussion in this thread. Here

-

Clutch goes to floor, not engaging.

zKars no copper washer. I will see if I can get one form a auto parts place. Zed Head I will look into checking the interiors of the parts, thanks for the heads up.

-

Clutch goes to floor, not engaging.

I received all three parts today. Total for all three parts and shipping was $81. See picture, planning on do the work this Saturday.

-

Clutch goes to floor, not engaging.

Thanks for the input, ordered all three parts from Black Dragon. Maybe this weekend I can get back on the road.

-

Clutch goes to floor, not engaging.

I was at a car show this weekend and driving back the car was getting harder and harder to put into gear. I finally could not get into gear so I coasted to a store/ gas station. I had some looked at the operating cylinder as I pushed the clutch and nothing happened. I checked the fluid level in the clutch master cylinder and it was full but very black looking. The clutch master is not leaking. I have a 11/75 - 76 280Z and was wondering if I should replace the clutch master cylinder or get a repair kit to fix the one I have? If the repair kit where can I get one? I see there are 6 different ones listed on Rock Auto for my car. Not sure which one to get. For the operating cylinder there is a bleeder screw, should I get a speedbleeder for there when I change the Master? What size if I get one? This way I can do all the work my self. I have speedbleeders on all the breaks and they are great. thanks for any help Michael

-

My Z build

They look kind of like mine, Mine are Appliance and not factory. I purchased them when I bought the car in 76. The centers have an A on them for Appliance. Keep the centers they are very hard to find. I have after market centers because mine rusted very badly.

-

Time Capsule 1976 Car

Very nice car probably made in 12/75 or 1/76. mine was in 11/75 ans is HLS30 - 281114. Has seen lots of sun because of the carpet turning tan on top of the transmission tunnel.

-

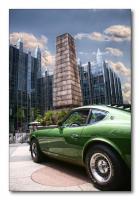

[2012] What did you do to/with your S30 today?

Big car week here in Pittsburgh. The Vintage Grand Prix has been going of now for 30 years. Getting bigger and bigger. There is a huge car show with mainly foreign cars of all shapes and sizes each nationality were divided in to areas around a golf course. Lots of racing of mainly foreign cars that are pre WWII. Two Z were raced this year, I don't know who the drivers were. The race is in a large city park on the park roads, the course is 2.33 miles with 3 turns close to 180 degrees. We had in the Datsun/Nissan at the Asian location about 17 Z cars, there were 4 - 73's, 1 - 76, 1 - 77, 1 - 82 and the rest were 2003 and up. We had one 1600 roadster. Here are a couple of picture's from that. This years Mark car was the MG and there had to be around 300 on Saturday, the car big show day. On Wednesday before the weekend there is a parade with cars driving through the city going to 4 different location in downtown. I drove my car to the location at PPG (Pittsburg Plat Glass office building) Place a couple of pictures from there. Only Japanese car in the parade.

-

Got new tires and now the front end won't align!!

Have you checked the wheel bearings. 35 years ago I hit a pothole with the passenger front tire and blew it out. It took about 6mo for the steering wheel to wobble at around 50 mph. I took it to the dealer at least 4 times and they eventually replaced the whole strut, did not fix it. They said the the wheel (Appliance) could be the cause. I eventually tracked it down took about 2 years. It was the outer race on the outer bearing that had started to wear and was not a press fit any longer. there was about a 1/16 inch of play. You could not feel it with the car off or wheel the ground when you pushed on the tire. I fixed that and that did fix some of the problem, the rest of the problem was that that wheel was out of round ever so slightly and when I put that wheel on the back of the car the shimmy vanished. It only took 30 years to fix it.

-

My Datsun Spirit L28 Build.

-

My Datsun Spirit L28 Build.

That little shim I believe is from the alternator. http://farm9.staticflickr.com/8156/7460135352_2e17810d95_b.jpg

-

Horn Assembly diagram

Tomo, the inside parts I took out and kept them together and did nothing to them and then replaced them the way they came out. I did not replace the paper gasket. The screw I did nothing to except to plate it with the other screws and plots and nuts.

-

Horn Assembly diagram

Here is a picture of mine dis-assimbled. Not too complicated. Mine had a paper ring between the two rings, it was pretty much gone, I did not worry about replacing it. the work fine.

-

[2012] What did you do to/with your S30 today?

Had to take the car in for state inspection and turned over 50,000 in OD at 8am today June 26,2012.

-

New here

That is why I like my big bumpers. Also that is the way it came, it's a 280 not a 240 "want a be".

-

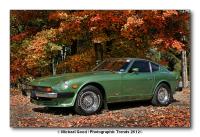

Gold or Green?

Here is my 76 in original 302 green leaf metallic. You don't see too many in this color. It's my favorite. I added the gold as accents, front grill is gold, back tail light surround is gold and I put gold pin strips down the length of the car.

-

horn not wokring, help?

Here is a shot of mine after cleaning and reinstalling, left side from front. My car is 11/75 or 76 - 280z.

-

How to attach Rear Panel and Lights

-

Door jam I.D. plate

Try here: http://www.editgrid.com/user/mlwilliams/Z_Car_Registry Got to line 545 for HLS30-87163 form 6/72.

-

My rear LCA - dents or not?

-

Spindle pin removal tool survey

Just drill a 1/4" hole 1 1/2" from the left end, then you can use a screw driver to help turn the all thread.

-

$10 Additional LED Break light

Tamo3, did you get the light installed? Some pictures would be nice to see.

-

Video: Datsun Z Drag Race & Photofinish

To me it looks like the driver reaction time on the light.

-

Spindle pin removal tool survey

This is what I had made at a local machine shop. Cost around $25 plus the pipe. The end that attaches to the spindle pin is the same thread as the wheel lug studs. Worked great, I used a large boxed end wrench and hit it with a hammer to help turn the nut at the washer end. One of my rubber bushings did split down the middle and I had to saw the sleeve out of the frame.