-

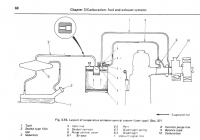

vacuum diagram

There are several diagrams in the Haynes Manual. This one is for the evaporative emissions control system: - What exactly are you wanting?

-

Medical Procedure In San Francisco

As far as the prostate test is concerned, NEVER, NEVER, EVER ask for a second opinion:finger: I did and the GP proceeded to repeat the test with TWO fingers:tapemouth:tapemouth

-

Alternative PCV Filter material in the block

Probably, but you can fold up a replacement out of metal fly wire and it will last the life of the engine. It is a very efficient oil/vapor separator so don't be tempted to use anything that may clog up and render it useless.

-

Inflating the Spare Tire on an 83

1. Compressed air? 2. I doubt it.

-

Anyone know what the heater coil thing is in the heater unit?

When you say you fried it, does it still read resistance? It might have glowed red hot but may still be OK. You could fit one from a late model car and it will work fine.

-

UGh more vacuum issues

-

Battery won't charge with headlights on

My initial guess is the brushes in the alternator are worn out. When worn down they have very little spring tension on them and, providing the Voltage Regulator is doing the right thing, the exciter current doesn't increase in the rotor therefore the stator doesn't increase in output voltage. So once again, providing the VR is good, I'd suggest pulling the brushes out to check their integrity:bulb:

-

engine block question

Yes, I've never had any problems getting the soft plugs or the pressure relief valve. The valves I have seen and used are a self contained device with a spring loaded ball captive in it. You just slip the new valve into the hole in the oil filter boss in the block and gently tap it home. Yours is I gather something like this attachment, later versions are, as I say, a self contained device

-

engine block question

Removing the valve is a good idea, it allows the tank solution to circulate thoroughly. However, you should also remove the soft plugs from the front and rear faces of the block for the main oil gallery. Remove one plug by drilling through it, threading the hole and insert the appropriate bolt. Then lever under the bolt head with a flat lever, king size screwdriver etc. Protect the block with a scrap of wood. The plug will come out fairly easily. To remove the remaining plug I use a length of steel rod. Slip it into the open end of the gallery and tap the rod with the percussion device. Be careful not to spear the next door neighbor. The plugs and valve are cheap to replace, Nissan used zillions of them in all kinds of engines.

-

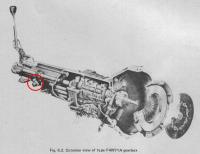

Stuck as hell: tales of a transmission drain plug

There are a couple of options for you, if the trans. is to remain in the car. If the fill plug is stuck, the trans can be re-filled through the gearstick hole. If the drain plug is stuck, I'd be tempted to drill out the centre of the plug as large as possible, say 12mm, and after the oil has dumped out, thread the hole to take the appropriate cap screw fitted with a copper washer. If the bottom surface of the original plug is rough, smooth it out with a grinder so that the new "plug" can seal properly.

-

blower fan under dashboard not working

Check the relevant fuse for the blower motor. Have you tried it on all speeds? There is a dropping resistor inside the housing that provides the various speed settings.

-

rear hatch hinge seals

Yes, I can do some measuring for you. While I am not disputing what you suggest, bear in mind the guy who is producing these has spent a LOT of time perfecting the moulds and material. If you can do it in RTV, good job, but I'm sure it won't be easy to produce a boot with the correct thickness and strength to handle the wear and tear of the hinge movement.

-

rear hatch hinge seals

-

coolant in #3 intake

I tend to think that the coolant got there during your dismantling work:ermm: If you measured 175psi compression in #4 then I'd take that as a good sign. I would put it all back together with the new manifold gasket and see how it goes. When/if you see that it runs OK, do a Leakdown Test on an engine that is at operating temperature. That is really the only thing you can do IMO, apart from ripping the head off now, which I don't think is necessary:beer:

-

speedometer not working!

The drive pinion is located on the RHS of the rear extension housing of the transmission. You should see the speedo cable screwed into it. You should be able to get to the rear of the speedo and unscrew the cable nut with everything still mounted in the car. If your hands are too big you might have to enlist a smaller person:ermm: The nut is circular and knurled so it is easy to grip and undo.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.