Everything posted by Nissanman

-

Dead Tach??

A fault like you describe may be due to a dry joint on the circuit board. Hot weather may cause the wire/joint to expand and not make contact:cross-eye The chances of having a bad component are rare I would say, more likely a bad joint due to vibration. I had a tach in my P510 which exhibited random not working sessions. Eventually got sick of it and pulled it out. Using a fine tipped low wattage soldering iron I re-soldered all the joints I could find. [There is not much inside an impulse tachometer.] Hasn't missed a beat since:)

-

oil pan drain plug

To get the plug out you could try levering under the head of the plug while turning it in an anti-CW direction. Hopefully the threads will re-engage and the plug will start unscrewing. Once you get the plug out, and all of your fresh oil, you can then determine which threads are damaged, plug or sump. If it is the sump, you may be able to clean up the threads with a tap. If it is the plug, bin it and get a new one.

-

What are your favorite Quotes?

A couple from the movie, "An Inconvenient Truth", "An eye for an eye will make us all blind". "It is difficult to make a man understand something when his salary depends on him not understanding it". How very true!

-

Electric Fan came today....now what???

You got it, in PULL mode it rotates in such a direction to PULL the air through the rad. to cool it. Therefore, your wiring of the fan motor needs to be the correct polarity to ensure the fan can achieve this. Unless the wires are labelled for this option as opposed to the PUSH option, all you can do is suck it and see. It is a simple matter to determine if the rotation is correct. If it isn't, just reverse the motor wiring connections to choose the opposite direction of rotation. As for making physical space for the fan, I would say you have that sussed too. Once the original fan and hub are removed, there should be enough real estate to mount the electric fan. Just make sure that the water pump pulley is firmly attached to the pump flange. Another little quandry is, how are you going to switch the fan on and off? Thermostatic switches are the way to go but I just don't like the idea of poking a sensor bulb inside a radiator hose. I had a copper tube fitted to my top radiator tank to accomodate the sensor. The tube was closed off at one end to make it water tight. Then I slipped the sensor into the tube. With the adjustment knob I was able to set the thermosat to operate the fan motor at whatever temperature that I desired. When I saw 90deg.C. on the coolant gauge, I set the fan to ON and job done. Once the setting is done to a direct reading mechanical gauge, you can mark the position of the adjuster and know that it is a repeatable setting.

-

What are your favorite Quotes?

Henry Kissinger allegedly once said, "Even paranoids have real enemies"

-

What are your favorite Quotes?

And if we are going to delve into Latin: - "Nil carborundum, bastardum" Translated means, "Don't let the bastards wear you down!"

-

What are your favorite Quotes?

From the movie, "2010: The Year We Made Contact". American Astronauts woken from hibernation on the trip to Jupiter: - "Are we there yet??"

-

Where can I buy the o-ring for the steering knuckle arm?

This is one area where it is 100% safe to use RTV sealant:) Run a 3mm bead around the corner of the knuckle arm and drop the tube on, job done.

-

Blower motor to switch wiring (1973)

Excellent!! Nice to here you had a successful outcome!

-

dry batteries

Yes sir, overcharging will do it:ermm: If it has gone dry so quickly, I would suggest that you run the risk of having a battery explosion if the fault continues. It is imperitive that you determine what the charging voltage is when you instal a fresh battery. Nominally 13.8V - 14V. Any more and you may re-enact the "China Syndrome":nervous: It is a good idea to have a reputable supplier instal the new battery. They will usually do a check of your system then for voltage and regulation of charge. Only a couple of seconds work but well worth the effort.

-

one shoe was enough

Is the wheel cylinder supposed to be double ended or does it have that sliding shim arrangement on the backing plate? Either way it appears that the rear shoe is "enjoying the ride":ermm:

-

so i bought another pair of watanabes

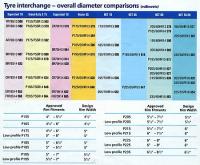

This is a really old brochure but it does show what the design width rim is for various tyres up to a 235. Doesn't get up to 9 and 10" rims though! The Yokohama A539 brochure, for example, lists the 235/45R17 tyre being able to fit to a 9" rim, design width is 7.5". In the 15" range, 8" is the widest rim mentioned. Most tyre brochures will provide this info. The tyre fitter must comply with the manufactures design rim width specs. or be liable for damages. What they list in Japan may not be possible/legal here in Oz:cry:

-

1971 240Z - won't start - help!

Your starting woes may be due to dud fuel:( . Try draining the float bowls and then re-filling them with fresh fuel.[Assuming you have carbs. not EFI] Providing it cranks and has spark it should fire:rolleyes: As for the flattery going batt over a month, not normal. However, storage batteries don't like getting cold. If you have a cold climate, store the battery in a moderate temperature area and re-install it when you need it. If there is a small current drain on the battery, over time and coupled with no input charge, it will go downhill. Check that the rear window demister[if there is one], clock, interior light etc. are not draining the battery. Overall, disconnection from the electrical system and regular trickle charging should keep a battery fresh for starting, excluding fuel issues.

-

old zman

Thanks Carl. At the time of the engine conversion, I was not a turbo person, so it is a N/A FJ20E with Haltech F9. From what I have heard, the better choice for all round performance and economy. Cruises beautifully at 110KPH[65MPH] wih plenty of reserve for overtaking, in 5TH:love: Couldn't bear to get rid of it!

-

rear disc brake conversion?

The welding that is "verbotten" by the authorities, is on calliper brackets, which is what I was referring to at the time. I think all States in OZ have a similar rule. "Engineering" them is a way out but it is not cheap.

-

Cool Ebay auction, designing your own custom Z shirt

-

Cool Ebay auction, designing your own custom Z shirt

For general interest, I have had dealings with this person. Absolutely fantastic:love: I assume it is a he, not really relevant, but he was very co-operative and professional. I ordered a Roadster shirt, "1965 SP310", Cherry Red with blacked out Watanabe style wheels. He sends images to you for checking and not until you say the word, does he push the button. I asked for the headrests and side markers to be removed and it turned out a treat. Just my experience, no regrets:knockedou

-

engine ignition issues

Hi Ryan, when you crank and start the engine, the ignition ballast resistor is bypassed, thus providing the full battery voltage to the ignition circuit. Once it fires and you [normally] return the key switch to the "ON" position, the ballast resistor is switched into service, reducing the ignition voltage to less than battery. Sooo, if replacing the ignition switch didn't help, you need to determine if that ballast resistor wiring is good. If you have a multimeter, check the continuity of the resistor, disconnect wiring first. Alternatively, check at the ballast for correct voltages, wiring connected. You could prove the resistor faulty by simply bridging it out, but don't run it for long like that, the coil will overheat. It appears great minds think alike AND at the same time!

-

1971 240Z - won't start - help!

Apart from the electrical problem, does the engine actually turn over? I mean, can you turn it over with a socket and bar on the crank pulley? It may be well and truly locked, for whatever reason, and the starter has not a hope in budging it. You may need to remove the spark plugs and lube the cylinders if the engine has been sitting. Then try rotating it with the bar. If it spins OK then you are back to your starter problem:rolleyes:

-

not starting

Well, if you are happy that the starter does function when you jump the contacts, my guess is that the solenoid contacts, the high current ones, are kaput. It might just need a clean but worst case is that they are burnt out:( Might be just as easy to replace the entire starter with a goody and get the faulty one fixed at your leisure

-

sandblasting cabinets

I agree with previous comments. I have a table top cabinet which is fine for most items but it can only do so much. You will need a big sucka compressor to power it. I have a 3HP motor filling a 58L tank and when grit blasting at 90 - 100psi it runs flat out. Cabinet sealing is paramount. I use garnet sand [40/60 mix] and it will get everywhere when reduced to a dust:rolleyes: I replaced the seals on my cabinet and now it doesn't fart any dust when I work. For large items, like the air plenum on my '73 240Z, I used another gun which you just run out of a bucket of sand. Now that WAS messy, but it did the job. After the event, I swept up the grit and re-used it in the cabinet Depending on how much real estate you have and how serious you are, I would go for a free standing model. One pain, which is a never ending problem for me, is visibility. I use plastic sheet tear offs over the window, on the inside of course, to protect the perspex from damage. Unfortunately, they don't last that long and you can't see JACK until you replace it. Beads may not cause this problem, I can't say because I've never used glass beads.

-

Celica axle chunk?

CHUNK:cheeky: It is obviously an acronym for, er, Can't Handle Universal Negative Komments:rolleyes:

-

rear disc brake conversion?

I knew I had some pics. somewhere:classic: The handbrake mechanism on the R31 callipers is so simple, easily the best choice in an upgrade:knockedou

-

rear disc brake conversion?

I have designed and built adaptors to mount R31 rear callipers to an MR30 Skyline rear control arms. Unsure if the 240K is similar:ermm: Two 6mm thick brackets side by side had the calliper in the right spot for the disc rotor. No welding involved, which is verbotten anyway. If you are interested, I'll post some info. Try and steer away from the R30 callipers, compared to the R31 they are just horrible in the hand brake area. There is some info. in the Z car forum on the R31 callipers: - http://www.classiczcars.com/forums/showthread.php?t=25240

-

Need picture of Fuel Evaporater Canister

From Haynes Manual: - Looks like it should go right up against the radiator adjacent the filter.