Everything posted by Diseazd

-

Datsun 240Z 1972 Restomod from Germany

Fabian....Looks like a really nice Z..,,,,Congrats!

-

Rotisserie Mounting Points

You guys are awesome....I love your creativity.....grannyknot, I'm impressed....Careless...where is the final shot of your first Resto? I know how you feel....once restoration is done, you're ready for the next.....the fun is in making something ugly beautiful again. How's this for a before and after.....

-

240Z vs 280Z Hood Hinges

No....couldn't make the race....nice to see 46 winning again....congrats to Steve Bonk and Sam Neave too.

-

240Z vs 280Z Hood Hinges

Thanks, thanks! BTW zKars......our names crossed the finish line first at VIR last weekend with Morton at the wheel!

-

240Z vs 280Z Hood Hinges

Anyone know if 240Z hood hinges are identical to the hood hinges used in the later 280Z's?

-

[2016] What Did You Do To/with Your Z Today?

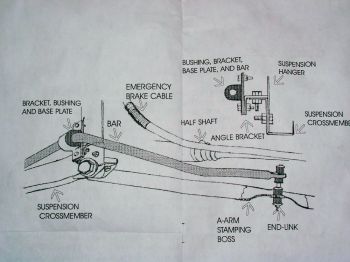

No Mike no drilling holes in the floor boards....just a 3/8 inch hole in the lip (over hang) of the rear suspension cross member. I used a 9 inch extension on my drill so I could drill the hole without taking anything apart or removing the big suspension bolt or the other two small bolts....that's it....the whole job literally takes no more than an hour to hour and a half. Here's a pic from underneath...,you can see that I put the bolt through facing up instead of hanging down like in the instructions. Really ingenious way to get a nice rear bar without destructing anything! Look closely and you'll see the silver head of the bolt .......that's it....everything else just bolts up (all provided in the kit).

-

[2016] What Did You Do To/with Your Z Today?

........no noise.

-

[2016] What Did You Do To/with Your Z Today?

Here's the diagram....you drill one 3/8 inch hole up through the suspension cross member (I used a nine inch drill extension so I could drill through without removing the suspension cross member), then bolt the"L" bracket onto the cross member, then the flat base plate and bracket (with bushing). The end link goes through an existing hole in A arm. .......and yes Patcon, I have driven it and it really flattens out your hard turns IMO.....cheap handling improvement and an easy installation.

-

[2016] What Did You Do To/with Your Z Today?

Go to the Futofab website.....click on 240Z rear sway bar.....they have a diagram for installation. You have to drill one 3/8 inch hole. Only takes about an hour and a half. No fitting issues.

-

[2016] What Did You Do To/with Your Z Today?

-

[2016] What Did You Do To/with Your Z Today?

Your car's looking great Steve....is that the same car you took to Savanah?

-

Black Dragon Closing

-

Black Dragon Closing

The bumpers are a perfect fit........

-

Black Dragon Closing

Ask Brenda (lol).......she knows how important Z STUFF is to us Classic Z Car guys! Just wanted to show me that it had finally arrived.....she actually tipped the driver for his effort!

-

Black Dragon Closing

- Too much power for current clutch

- Too much power for current clutch

-

Too much power for current clutch

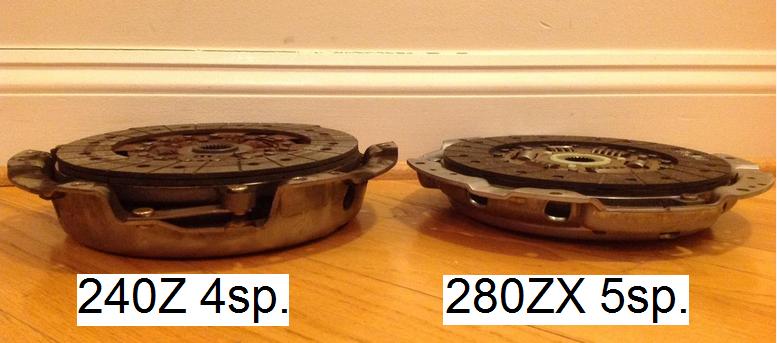

Right....code 21-2330 is 70-74 240Z and 260Z......use 21-2121 collar for 70-74 240Z and 260Z. Code 21-2331 is for 75-83 280 Z or ZX non turbo.....use 21-2122 collar for 75-78 coupe 79-83 non turbo.....as Zcars mentioned above these will give you approximately 92 mm from friction surface to collar fingers. 280 or 280ZX use 280 collar.....240 Z and 260Z use 240Z collar as stated in a great big paragraph above. 2+2 and turbo's are different combo.

-

Too much power for current clutch

Cliff....IMO, everyone tries to make this more complicated than need be. No matter the tranny (240Z or 280Z or Zx, 4 or 5 speed, A or B ) they are all the same dimension. The important fact is that the geometry of the clutch arm is correct. Simply stated if you use the shorter 280 Z or ZX clutch, you need to use a 280 collar (taller)to get the proper distance from the flywheel to collar fingers that ZH mentions. Since the 240Z's clutch pressure plate is taller, you need a (shorter) collar to get the same distance......simple as that. You don't need to worry about measuring anything.....280 clutch used with 280 collar works.....240 clutch with 240 collar works....simple as that....in any of the above mentioned trannies (2+2 not included). I have had success with the taller 240 clutches and use them in all my cars since I don't want to mix and match. I've never installed a 280 clutch, so can't comment on which is better.....love my 240's though. Cooper didn't know where the slave cylinder was, so I think we should keep it as simple as possible. He needs to buy either a 240 or 280 clutch with a matching collar. He can measure the collar that comes out and buy the corresponding clutch if he wants to save $12.00 for the collar....his choice. And as far as a flywheel goes, I think he should stick with a refinished stock flywheel IMHO since remember not only he couldn't find the slave cylinder, but still hasn't even adjusted it yet to find out if that fixes his problem! BTW....Throw out bearings are the same for either clutch you use. Also, he should order from MSA IMO....they can match his order with the correct collar whichever route he goes.....and regarding your question above....yes either Amazon clutch will work in the 240Z tranny with the correct corresponding collar......short is 280 ......tall (more expensive) is 240.

-

Too much power for current clutch

Not true.....The 240Z 4 speed (early and late) trannies, the 280 and 280ZX 4 speed and 5 speed trannies......all are exactly the same dimensions. You can use either the 240Z clutch or 280Z in any of them. The important thing to remember is if you use a 240 Z clutch, use a 240Z collar and if you use the 280Z clutch use the 280Z collar. This is because the 280 pressure plate is narrower than the 240. I use the 240 Z clutch arm (with the hole) with the 240Z clutch and the 280Z clutch arm (for the self adjusting slave cylinder) with the 280Z clutch, but that's probably not necessary.......you can probably use the self adjusting slave cylinder and arm with either clutch....just not sure. All of my 5 Z's are F54 blocks and some 240Z trannies and some 280ZX trannies, but all use 240 Z clutches, 240 Z collars, early arms and adjustable slave cylinders......

- Too much power for current clutch

- Too much power for current clutch

-

Too much power for current clutch

If you need a clutch (adjustment doesn't solve the problem) , you should IMO install a stock Exedy 240Z clutch pressure plate and clutch disc. You will need to have a 240Z collar ........(MSA) will know which size that is. You also need to replace the throw out bearing if you do have to replace the clutch. If it were me, I'd just use the stock flywheel (get it resurfaced). You have a type B tranny if it is the original transmission. It doesn't matter what tranny you have, if you keep the clutch and collar 240Z, you can use that combo in any Datsun tranny.....collar and clutch must match.....240Z clutch needs 240Z collar.....280Z clutch needs 280Z collar......but like I said....adjust the clutch first....see if that solves the problem.

- Too much power for current clutch

- Too much power for current clutch