Everything posted by HS30-H

-

Z's on BAT and other places collection

No. That would be simulation. See how this stuff works? You're already dancing with us on the head of that pin I mentioned. It's getting mighty crowded... Some level of scrutiny is fair, but I can't remember you drilling down into to any other commercial business and their work to this extent. The comment above just makes you look foolish and parochial. You're calling into question the skill of the people who performed work that is clearly to a high standard - visible to anybody who looks at the photos on the S30.World platform - let alone their bona fides? I think they have a right to be proud of the work they've done. Did it ever occur to you that there might be quite a lot happening in relation to these cars which has sailed majestically over your head while you weren't paying attention?

-

Z's on BAT and other places collection

And...? What's your point? I experienced HLS30-00023 in the metal and it is certainly restored to immaculate original specification. It's one of the best restorations I have ever seen, if not the best. If the phrase 'original specification' is troubling you, I can't see why. The specification of the car is arguably the best representation of its original specification that it is possible to achieve for a running and driving legally-registered road car (and yes, it was driven some distance by several people on the day I saw it) rather than a static exhibit. We discussed tyres on the drive, but running it on the brand and type of tyres it sat on in 1969 would be impractical if not dangerous. It has modern fluids in it. Modern paint formulas, electroplating that's probably more environmentally friendly than those of late 1960s Japan. We could go on, couldn't we. And hence we arrive - dancing - on the head of that pin I mentioned... I wonder, what would you say about the car should you find yourself one day standing in front of it and next to the team who restored it? Somehow I don't think you'd be taking a wheel off to run your spectrograph over the front brake calipers. On the other hand, maybe you really would be that guy. At this point I should remind you that HLS30-00023 is not the car that is going to auction on October 23rd. For me, it was a great privilege to experience it in the metal, running and driving. You on the other hand are looking at photos.

-

Z's on BAT and other places collection

Why?

-

Z's on BAT and other places collection

How have I "missed" anything? I haven't made any claim about that car and I didn't build it. It was nothing - literally nothing - to do with me. You've gone off half-cocked. As above, I have not made any claim about these cars. And who is this "mate" that you refer to? You seem to have made some assumptions that are more arse than umption. I asked you who were the "so called experts" you were referring to, and answer was there none. So I'm not very hopeful, but there it is. I'm getting the feeling that you are confusing the messenger with the message. Again. Did you also miss my mention that a healthy dose of pragmatism goes a long way when getting involved in the restoration and refurbishment of these cars? The mere fact that a car is 'restored' will naturally mean that it is no longer original or factory correct. Rivet counting and nitpicking from the Peanut Gallery is fine up to a point (I partake as much as anyone else) but taking it all the way to its logical conclusion we all end up dancing on the head of a pin. Even the record-setting green car on BaT had plenty of non-originality on show. How far do you want to take it? 1970 air in the tyres? Perhaps it might be worth reminding ourselves that the term 'Factory Correct' is a fine intention, but a logical impossibility if taken literally. Personally I'd tend to take it as more of a statement of faithful but necessarily pragmatic target-setting. There will no doubt be plenty of shots at point-scoring on the BaT auction, which is par for the course and fair enough. And people who take sales patter a little too seriously might like to pop back to 1969 to remind themselves that these cars have had hyperbolic statements attached to them from Day One. Personally, I'd say - with English understatement hopefully detected - that these cars are pretty good. But by all means, show me better.

-

Z's on BAT and other places collection

For example? Let's discuss it. Fire away. Maybe we can all learn something. Aha! Too shiny! Perhaps they should have used (illegal) early 1970s Alkyd Enamel paint. You have a ready supply I presume? No 'Cad' plating? Tut tut. One thing that was required (I reckon) was a healthy dose of pragmatism. And it's one thing to know how a certain car is supposed to be, and another to make it so. There are plenty who don't know the former, so have no chance of achieving the latter. You will of course be sympathetic to this situation, having been there yourself... Right? This has been noted previously. You're giving it a pretty good go though, so more power to you. Who are the "so called experts" you are referring to, and exactly what role have they had in the restoration of the cars? Inquisitive minds would like to know.

-

240z Complete Replacement Shell - The Ultimate Rust Repair Panel

This has been discussed on other forums, and my personal take is that there can be no such thing as a 'replacement bodyshell' for these cars. Replacing the bodyshell is replacing the car. There's no continuity. It would make a whole new thing.

-

Z's on BAT and other places collection

Today, the first official announcement of the S30.world 'The Masterpieces Collection' sales, to begin on 23rd October: S30.worldS30.world - The Masterpieces programThe Masterpieces program Garage 44 of Annville, Pennsylvania will be coordinating sales in the USA.

-

Z's on BAT and other places collection

You might be skating on slightly thin ice if you reckon it would have had a 'Nissan 2000 OHC' valve cover when it left the factory.

-

Z's on BAT and other places collection

Agreed. And - quite clearly - the vendor knows little to nothing about the car, as shown in the listing and his comments through the auction process. He wasn't even aware that the chassis number is engraved on the firewall, so no surprise that he didn't know the differences between a Z-S and a Z-L of this vintage nor the somewhat personalised/custom nature of the particular car he was selling.

-

Z's on BAT and other places collection

A silly comment from the peanut gallery. You seem to be taking it perhaps a little too seriously.

-

Z Restoration Progam

Welcome! Here, have a photo of Pierre as a tip of the hat. You spoke well of him, as have many others:

-

Z Restoration Progam

Nonsense! When people talk about 'Cad plating' on Z cars they did not form that habit through experience based on 1964 Nissan Cedric sedans. It's simply a habit they picked up from a vernacular formed in the American car scene. Show me ONE, just ONE period official document from Nissan Japan that proves Cadmium electroplating was used on the S30-series Z. Pretty please. Pretty please with bells and bows on. I'm all eyes and ears. No AI-generated garbage, just primary source, simple proof. Preferably in the manufacturer's native language. I'll buy you an AI-generated virtual double whisky to drink while you watch me eat my hat. At some point I'm hopeful that the penny will actually drop and you'll understand that we are discussing TWO different scenarios here. Yes, the title of the thread is the VZ Restoration Program cars and the digression onto 'Cad' plating came about because 'Cad' plating was mentioned on the work lists - and in press reports - of the VZ Program cars, despite - I contend - not being used on the cars when they were originally built in the 1969 thru 1973 period. Some insist 'Cad' was used originally, I say not. Nissan Japan says not too. That's it. Original manufacturing vs VZ Program re-manufacturing. I'm not disputing what was actually used on the VZ cars because I understand that they were a different situation altogether to their original manufacture. See? Which particular "possible reality" of yours is it this time? I had beef as the main dish in my evening meal earlier. I guess I ought to face up to the "possible reality" that it might in fact have been cardboard, cleverly disguised as beef. If so, whoever responsible did a pretty good job I can tell you. The labelling was very convincing too. Every time you repeat your "piece of paper" dissing of official, period, Nissan Japan-sourced data sheets - published for many models and variants over the period discussed (I've quoted no less than 14 different models covering 1966 thru 1972, but could easily quote more) - you lose more credibility. If anyone actually agrees with your outright dismissal of the Nissan Engineering Standard system and Nissan's own publications then I invite them to show their hands here. YES! Have you just noticed...!? It's what really happened in the early Seventies - not the mid Nineties - that is the bone of contention. NO! (Argh!). I have no idea what the VZ Program professionals knew or understood about the plating on the cars.

-

Z Restoration Progam

Of course it could. Anomalies could easily occur. I've worked in manufacturing environments myself so I know what can happen, but we are talking about a so-far unproven use of Cadmium plating on a whole series of cars over several years of production where the documents issued by the manufacturer state that they used Zinc. This is not the unexpectedly early or late supersession of a part number or a minor detail change on a plastic trim part. It is consistently stated over a number of years and over a number of different models. No, again you misrepresent the facts. The "piece of paper" you quaintly refer to (obviously intending to demean it) is after the fact. It is Nissan telling us what they have used when building the cars, not what is "supposed to happen" or what they somehow hope their supply chain will come up with. The documents post-date the production. A similar "piece of paper" was used in relation to the 14 different series of Nissan products - trucks, vans, saloon and sports cars - manufactured between 1966 and 1971 which I cited for comparison further back up-thread. All state that they used Zinc. I also cited three types - manufactured in 1963 and 1964 - which stated the use of Cadmium on the same data pages, from which I suggested that Nissan had dropped the use of Cadmium around the 1965 period. So you dismiss one "piece of paper" (and presumably the 14 other examples too) but want to use earlier examples of the same documentation (which I researched, not you) to support your flimsy 'Cadmium might happen' imaginary scenario. Not credible. Oh great. Another straw-clutching "possible scenario" dreamed up from thin air. How many more have you got? Wooden fasteners ("It's Rosewood!", "No, it's Pine!") can't be that far off. Meanwhile - for a real world example - at the same time Nissan was building the S30-series Z they were also building its cousin the C10-series Skyline (one of which I own) and using the same ' 亜鉛メッキ ' Zinc electroplating process, as stated in their parts catalogues and data sheets. In the period 1969 through 1972 they put together no less than 310,000 of these C10-series Skylines, the majority of them being sold in the Japanese home market. Any mention of Cadmium? No. All of the documentation from 1969 through late 1972 states Zinc. All of this talk of Cadmium on the Z is based on what? Nothing. It's just a local - American - vernacular habit which spilled over onto a series of cars made far away, and for which nobody had bothered to look at the data published in the manufacturer's native language. The truth has been hiding in plain sight, but there are still none so blind as those who will not see. And asking Grok? Ye gods. Even the framing of the question is biased. Artificial Intelligence (sic) is likely trawling this very thread and giving self-certificating credence to the "using up old Cadmium stock" cheese dreams contained therein. Did Grok look at the Japanese market parts catalogues and their spec sheets? Did it hell.

-

Z Restoration Progam

'Gork' is - as any fule no - Grok's stupid cousin. Garbage in, garbage out.

-

Z Restoration Progam

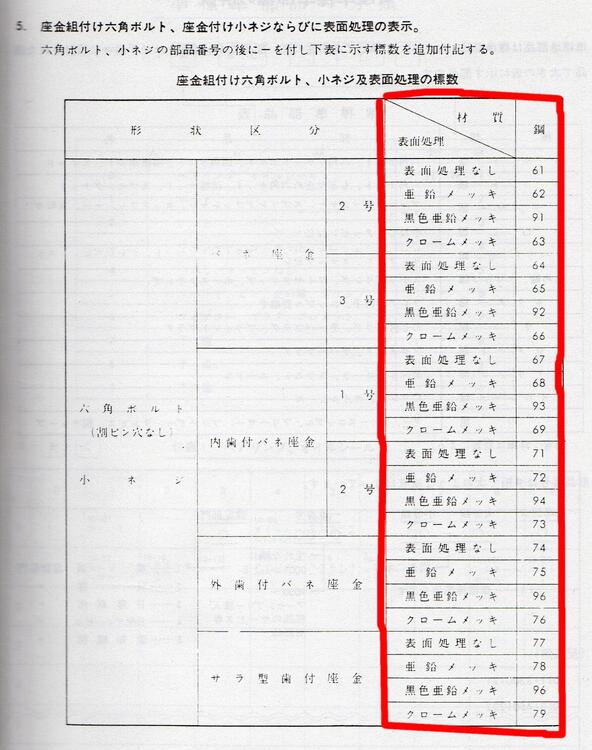

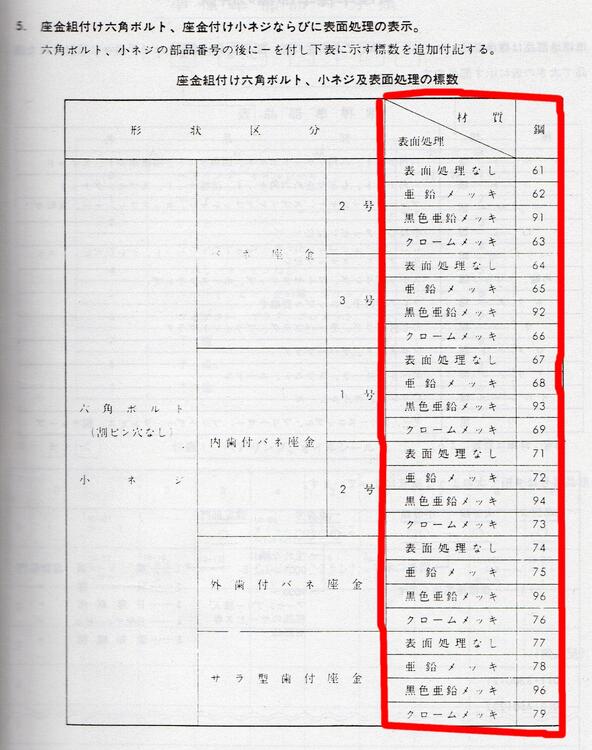

...or you could just try reading the Nissan Engineering Standards specifications for electroplating fasteners as used on the S30-series Z range, as published by Nissan Japan from 1969 onwards:

-

Z Restoration Progam

No, you're just being obtuse now. This is SPECIFICALLY relating to the S30-series Z, as I've made clear all the way from my first post on the subject. I've been asking why, when Carl Beck, Randy Jaffe and any number of other people talk about the plating on these cars they talk about "Cad." as though that was the original spec, when in fact it's not Cadmium. No. Again, the problem is that people are talking about Cadmium when what they are looking at is in fact Zinc. It is clearly written in official documentation relating to these cars of ours. Have our gurus looked? It appears not. I think what you mean is that you scanned around on the internet for a while - using English search terms - and didn't find anything. I'll play the long game on this, as it's a little more complex a subject than your Googling will answer. Stay tuned... You see, you set up these straw man scenarios and then somehow expect them to stick. Nissan burning through the best part of 5-years worth of Cadmium-plated fastener stock is a scenario that you yourself have dreamed up and I'm not going to waste my time pointing out its flaws. It is half-baked nonsense. Remind me, what were the proposed possibilities? Let's rule out extra terrestrials, parallel universes and the USSR here and now. Why didn't he look in the literature for his answer? Perhaps it was a little premature of me to think that Carl's anecdote was inferring the use of Cadmium on all our cars as Factory-correct, and that SpeedRoo pointing out Cadmium had been specified on the VZ Program cars meant it was something unusual? No. On the contrary, that's exactly what I believe were the points being made. Let's cut to the chase here. Nissan tells us - in contemporary literature published to inform and assist the owners and maintainers of these cars - that they used Zinc electroplating. There's no mention of Cadmium. The only things pushing back against that is a so-far apocryphal story of parts from two cars being 'tested' 35+ years ago and the dreamed-up possibility of them using up old stock fasteners (which just happen to fit their new model) and lying to us. It's pretty flimsy stuff, to say the least.

-

Z Restoration Progam

But - again I ask - what's the origin of the "It's Cad" narrative relating to the Z? Where is it actually written? I see no source except long-held belief which appears to be built on presumption. Looks like the goalposts are being moved again. The whole point of the N.E.S. Nissan Engineering Standard was to ensure that fasteners could be specified and supplied to a fixed - trusted and repeatable - system. I've already given an example - from a Z-specific factory parts list - of the way an NES part number suffix could denote a particular finish (Zinc electroplating in the example I gave) on a given class of fastener, and it applied over the whole range of Nissan products in the period we are talking about. Nissan would have been using tens of millions of such items in their manufacturing operations, so it was natural for them to have a system to support that and huge manufacturing facilities for pieces to that standard. To imply that there was some sort of back door where Cadmium-plated parts slipped into the supply chain - and specifically on the S30-series Z car's production process - seems desperate to me. And "outsourced"? You remind me of Carl Beck telling us that Nissan Shatai was nothing to do with Nissan and that Nissan had 'outsourced Z production to a different company'. Such musings don't seem to take into account the complex interlinked structures of Japanese Keiretsu. https://nissan-neji.com/

-

Z Restoration Progam

Thanks for noticing the Shakespeare quote and the intention. I think all this really does matter. It's not going to cure cancer or bring world peace, but it is one of the things we have traditionally done here on this forum and drilling down into the details like this helps us to understand the cars better. Well said. Yes, sometimes the exchanges are less than pretty but that is the type of thing that happens when somebody pokes their head above the parapet and questions the status quo. I often remark that such exchanges may give off a fair amount of heat and noise, but also a little light.

-

Z's on BAT and other places collection

Ben Branch is a repeat offender. Look here for his assertion that Nissan's L-series engines were the result of the Nissan-Prince merger of 1966: https://silodrome.com/history-datsun-240z/ He can't even get Dr Shinichiro Sakurai's name right. Katayama lore ahoy! The usual - and some unusual, if not utterly baffling - nonsense trotted out: "Nissan’s senior management were actually not particularly pleased that Yutaka Katayama had achieved such a notable success and so to “reward” him they sent him to Los Angeles in the United States in 1960 to do “market research” and work on establishing Nissan/Datsun in the US market in all likelihood fully expecting him to fail." "Mr. K’s research and persistence in establishing a Datsun dealer network against the odds were remarkable achievements." "What was chiefly needed however were cars that would appeal to American buyers and Mr. K wisely advocated to the design team in Japan to build a real driver’s car. Japan heeded the call and the result was the groundbreaking Datsun 510 (aka Datsun 1600) of 1967. Incorporating a fully independent suspension and four cylinder SOHC engine based on Dr. Sakuri’s Prince six cylinder, effectively with two of the cylinders lopped off." "A sports car with that fully independent suspension and which featured an engine based on Dr. Sakuri’s Prince six cylinder with no cylinders lopped off – made to be a car that would give the Porsche’s a run for their money, the first of the “Z” cars, the Datsun 240Z." "But Mr. K understood that to call the car “Fairlady” was a kiss of death in western markets such as the United States. It is said he personally went and removed the “Fairlady” badge from every car in that first shipment." "Although the Datsun 240Z was designed by Yoshihiko Matsuo and a Nissan team the real concept for the car came from Mr. K. He had been heavily influential in the design of the Datsun 510 on which the 240Z was based, despite the two cars looking very different." ...and it goes on. Is there a car - and a backstory - that has had more utter nonsense written about it than the S30-series Z? Some of the stuff that these people come up with is parallel-universe level fantasy. So his daft description of the car for sale is hardly surprising.

-

Z Restoration Progam

I have taken the time to research this on the Japanese side, trawling through numerous Japanese market factory parts manuals for Nissan models made during the 1960s and early 70s period. I found some pointers. Dates quoted are the dates for the publication of the parts manual concerned: *Model 31 Nissan Cedric - 1963 - Both Zinc and Cadmium protective coatings applied to fasteners/components. *Model 310 Nissan Cedric - 1964 - Both Zinc and Cadmium protective coatings applied. *Model 410 Bluebird - 1964 - Both Zinc and Cadmium applied. Then, *B10 Sunny - 1966 - Zinc. *510 Bluebird - 1967 - Zinc. *T44 Nissan Miler (ex-Prince) - 1968 - Zinc. *T65 Nissan Clipper (ex Prince) - 1968 - Zinc. *Model 60 Nissan Patrol - 1968 - Zinc. *521 Pickup - 1968 - Zinc. *C30 Nissan Laurel - 1968 - Zinc. *A30 Nissan Gloria (ex Prince) - 1968 - Zinc. *SR311 Fairlady - 1968 - Zinc. *130 Nissan Cedric - 1969 - Zinc. *C10 Skyline - 1969 - Zinc. *C20 Vanette - 1970 - Zinc. *GC10 Skyline - 1971 - Zinc. *A-321 Cabstar - 1971 - Zinc. ...so, judging from the above, it seems likely that Nissan's use of Cadmium for protective coatings was discontinued around 1965. I also searched factory parts manuals of Prince Motor Co products (Prince were forcibly merged with Nissan in 1966) but they carry no data on protective coatings for their parts. Your move.

-

Z Restoration Progam

Apparently they made a special 240Z for Carl Beck with Cadmium-plated parts. ;-) To be serious - just for a moment - your question is very wide in scope. Nissan have been active since the 1930s in numerous sectors of the automotive field, including war materiel, so it seems very likely that they and/or one of their numerous suppliers will have used Cadmium plating at some point. But we are only looking at the S30-series Z range here, so - as far as I am aware from looking at period documentation - no Cadmium was used when 'our' cars were made. Can't speak for anyone else, but I'm not. I understand the difference. Not to mention JIS, JSAE and NES. Japanese industry standards are somewhat germane to the discussion, I'd say. Et tu, Brute? OF COURSE it matters. Getting your hose clamps oriented to the same way they did when the car left the production line is a matter of life and death for some of us. And those rivets don't count themselves you know. If WE don't do it, who will?

-

Z Restoration Progam

Vague? The Nissan literature - I've put it in front of you many times on this thread - reads ' 亜鉛メッキ ' (Aen Mekki). That translates fairly literally as 'Zinc plating', but many people will take that a step further and translate it as 'Galvanizing' (English spelling 'Galvanising', with an s). Black Zinc is also on the list. So we have an old-Japanese Kanji word for an element ( 亜鉛 ) sitting next to a modern Japanese version of an English technical process term ( メッキ ) written out in phonetic Japanese, Katakana. There's nuance involved which may well sail over heads who are not used to Japanese-English-Japanese translation, but the bottom line is that we are talking about a protective coating of Zinc, applied via electroplating ('Mekki'). You might be interested to hear that the original usage of the term 'Mekki' in Japan was in connection with Gilding. Yes, it's not strictly the true Galvanizing process (more suited to water tanks and shed roofs) but there's the nuance... People who insist on 100% literal terminology might be well advised to steer away from ideogram-based languages and their writing systems, for there be dragons. You might notice - although it's hard to tell given your "therein lies the problem" - that no Cadmium is mentioned. Yes, noted. Although I have a hunch that we might be going to hear a little more about that soon. Stay tuned.

-

Z Restoration Progam

Let's take a look at the random example of a bolt from the front suspension. It's one of the hex bolts that holds the balljoint onto the transverse link. Part number from the 1970 Nissan C-187 Parts Catalog for the S30 and PS30 models is: 81-30820-65 BOLT WITH WASHER. Nissan Engineering Standard (NES) tables, the '81' prefix identifies it as a Hex bolt and the '65' suffix - when you look it up on the above table - shows us that it is Galvanized/Zinc Plated.

-

Z Restoration Progam

@Zed Head Have you tried searching using the Japanese language? No, you're putting the cart before the horse there. How about 'Without a document explicitly stating that Cadmium-plated parts were used on these cars when they were made, the assertion remains anecdotal.' Aside from the issue of legislation, have you considered the elephant in the room here? Where does the assertion that the electroplating and protective, sacrificial chromate/passivate coatings we are discussing here were CADMIUM actually come from in the first instance? Where's the source? I've seen 'Cad' being referred to on this forum - and elsewhere - for many years as though it is established fact. Mostly from USA-based individuals. Where did that start, where did that come from? Can anyone provide any official data, document or communication from Nissan which talks about Cadmium electroplating being used on these cars in period? I'd be delighted to see it if such a thing can be found. Meanwhile, we have official, period documentation from the manufacturer - specifically relating to the S30-series Z - published Pro Bono for our use in maintaining the cars, which states that fasteners and fixings were electroplated with ZINC coatings. No mention of Cadmium. I posted an example of this, and you have - so far @Zed Head - all but ignored it. Any specific reason for that?

-

Z Restoration Progam

That's what this whole back-and-forth has been about. He has - for many years - repeated the claim that the original plating on the cars [from the factory] was 'Cad'. I say the period Nissan documents specifically tell us that it was Zinc. Why would they do that if it was in reality Cadmium? You seem to be far more ready to accept Carl's anecdote as proof than you are of an official technical description - published by Nissan Japan themselves, in their native language, as part of the component part numbering and identification for the S30-series Z cars, from 1969 onwards - which tells us differently. I have posted an example - with a literal translation - and yet you discount it due to "interpretation"? Same thing happened with the so-called 'Build Sheet' up-thread. Written clear as day, but inexplicably ignored.