Everything posted by HS30-H

-

Z Restoration Progam

I'm sorry - and this is a straight question, no spin - what exactly are you seeing on a VZ Program car that tells us the difference between Cadmium and Zinc plating? You've pointed out that the VZ Program documentation cites 'Cad' plating, so it follows that we would be seeing 'Cad' plating in the photos of a VZ car on BAT. I don't see the significance. What's in dispute is what was used when the cars were originally made.

-

Z Restoration Progam

But what has that got to do with the plating materials used when the cars were originally manufactured? That's what is being discussed here. Are you citing the 'Cad' plating used on the VZ Program as proof of what was used when the cars were originally manufactured? Will you also use the paint used on the bodies of the VZ Program cars to cite the paint that Nissan Shatai used when the cars came off the factory production line? Hopefully not. I simply don't see any mention of Cadmium in Nissan's technical specifications - according to Nissan Engineering Standard - which they quote for the fasteners on the S30-series Z range. However they specifically mention Zinc ( ' 亜鉛 ' ). It's as simple as that. If anyone can come up with an official, period, Nissan document which specifically shows that Cadmium was used for plating the fasteners and fixings on these cars when they were made then I'd like to see it. Otherwise we will just go around in circles. I'm all ears and eyes and every day is a school day with these cars, but I'd like to see a document which contradicts THIS:

-

Z Restoration Progam

What science are you referring to? The "science" in Carl's story is of the 'Trust Me Bro' variety at this point. 'Maybe' doing a lot of heavy lifting there. There can be any number of maybes once we decide to take an anecdote as empirical truth over the written evidence of a manufacturer. The data in the Nissan literature isn't conjecture, nor is the Japanese ban on Cadmium use in commercial automotive manufacturing. My money's on the likelihood that people got used to calling yellow gold coatings on auto parts 'Cad plating' and it simply stuck. A habit. Understandable, and not without precedent. Contortions performed to justify it - even to make it somehow true - will tie us all up in knots. ISWYDT 😉

-

Z Restoration Progam

Nissan themselves told us - it's LITERALLY written in their technical literature for 'our' cars - that the electroplated finish on the non-chrome components was Zinc, either 'clear' or with other passivated top finishes. Cadmium plating was already banned for commercial automotive use in Japan before 'our' cars were made, so - naturally - there's no mention of Cadmium in the technical literature. People have talked about 'Cad' plating on cars for decades - especially in North America - and it simply became part of the vernacular. Just like 'Mag' wheels that weren't actually Magnesium anymore. Old habits die hard. Did the VZ Program cars receive actual Cadmium plating on specified components when they were rebuilt, or was that too an example of vernacular use? If they did receive Cadmium plated components then we can chalk it up as yet another non-original finish on cars which were never claimed to be such. I will continue to call out people who cite processes and specifications on the VZ Program cars as somehow being evidence of what Nissan and its various suppliers did when the cars were originally made. Hardly logical, let alone scientific. I've had to deal with 50+ year old fasteners on these cars too, and the single biggest factor involved is the environment that the 50+ year old fastener lived in during its use. Fasteners on a car that spent those 50+ years in southern California may well be happy to cooperate, but a fastener that has spent the same period in regularly cold, wet and often salty conditions will look - and behave - very differently. Pretty much any electroplating with a sacrificial coating will succumb under such conditions. I'm sure Honeywell Space and Strategic Systems should rightly command our respect, but far from "putting men on the moon and probes on other planets" we are dealing with a question that can be answered simply by looking at the technical literature that the manufacturer published when the cars were made. To coin a phrase, that's not rocket science.

-

Z Restoration Progam

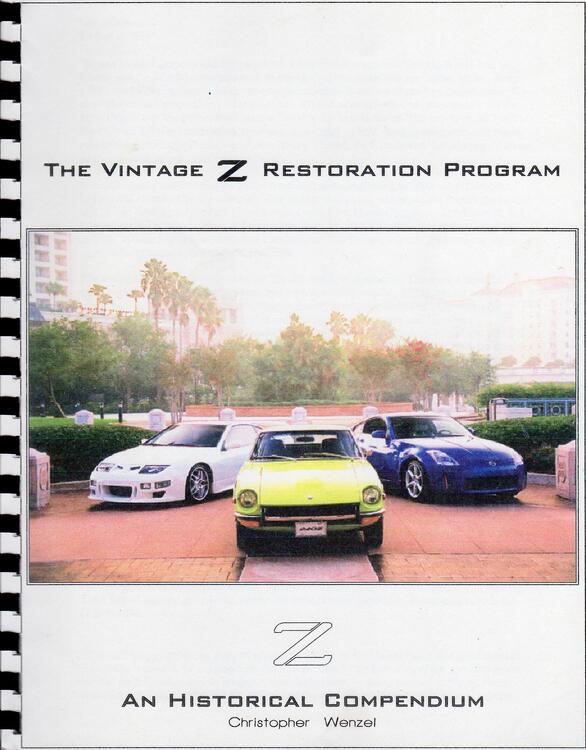

@Patcon Having said that, I just looked through the excellently-researched 'Vintage Z Restoration Program Historical Compendium' put together by Chris Wenzel @26th-Z and he too specifically quotes powder coating as having been used. From the Compendium: "Nissan literature talks briefly about updating some aspects of the 240Z. A 3-row radiator was used and the tire specification was updated. In an effort to provide more durability to suspension components they were powder coated "to factory colors" so as to "ensure that you will enjoy your 240Z's performance for years to come"." Obviously it's a quote from NMC USA's VZ Program sales literature, so I don't know if that was the reality or not, but the fact that the independent Japanese journalist who visited Pierre'Z in person reported the same thing might suggest something. Of course he could simply have been quoting the literature, I don't know. I've always found powder coating to be much too thick on such parts, and there's always an issue where the powder coating transitions to a wear/bearing/mounting surface. I've seen it peel away in those places, so I much prefer paint (as per original manufacturing). Inspection of a few VZ Program cars would probably settle the question as to what was actually applied on them.

-

Z Restoration Progam

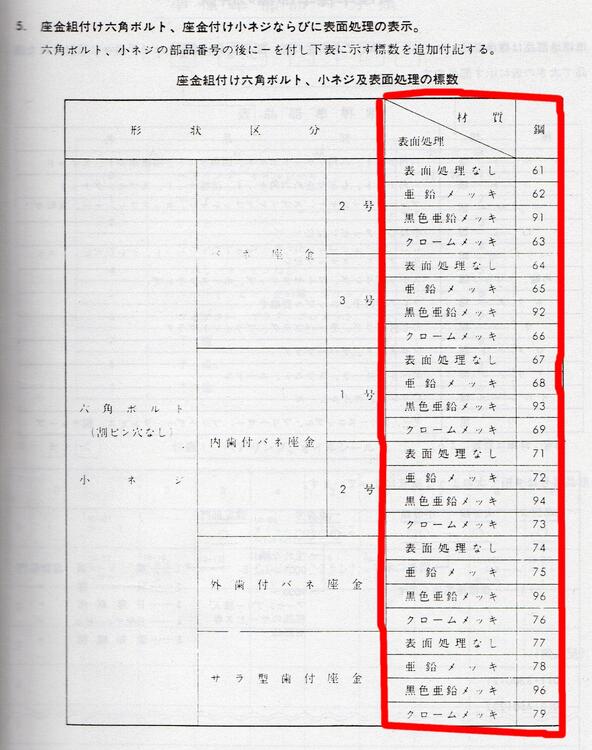

In Japan the use of Cadmium electroplating in auto manufacturing was officially banned in 1969. Before that it wasn't widely used on higher-tensile fasteners due to the phenomenon of Hydrogen embrittlement. Nissan (Japan's) own documentation for the S30-series Z's componentry - according to and conforming with N.E.S. (Nissan Engineering Standard) - states that most of the non-Chrome electroplated parts were Zinc ( 亜鉛 ) 'Aen' galvanized, with various passivated finishes. Here's just one example page of the quoted N.E.S. finishes for fasteners from the C-236 Nissan parts catalogue for the S30, HS30 and PS30 models: Heading translates as: 'Indication of washer-assembled hex bolts, washer-mounted machine screws and their surface treatments. The part numbers of hexagon bolts and machine screws are followed by a ' - ' and the characteristic in the table below. Washer-assembled hex bolts, small screws and their surface treatments'. I have roughly outlined the relevant example surface treatments in red. They read, from the top: NO SURFACE TREATMENT GALVANIZED BLACK GALVANIZED CHROME PLATED ...and this pattern is repeated for each sub-classification of fastener down the page. The Japanese for 'Zinc plated'/'Galvanized' is 亜鉛メッキ ('Aen Mekki').

-

Z Restoration Progam

You totally missed the point being made. Randy Jaffe was talking about 'factory-correct authenticity', even to the point of hose clamp orientation. He clearly thinks Cad was the original finish. https://youtube.com/clip/UgkxAwPdmHPp1GDcsSL09MAx51Ak2gUs4hRh?si=S2GAydRujBcJszu_ Put your own reading glasses on and pay special attention to the word FACTORY: On the other hand, you deserve special points for ""...that may have been the case in Japan...". LOL. Do you write one-liners for Larry David, by any chance? Edit: Ha ha! You edited your post! Backpedalling.

-

Z Restoration Progam

In the Larry Chen YouTube video with Randy Jaffe, Jaffe was pointing at the engine bay component plating on his yellow VZ Program car and talking about "Cad plating" as though that was the original factory finish. Not the case. Most of it was Zinc, with a few different passivated finishes. No Cadmium.

-

Z Restoration Progam

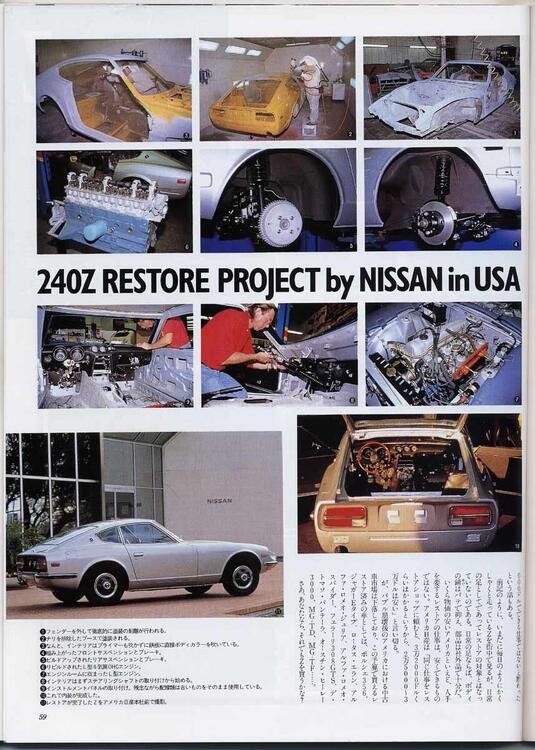

A pair of cylinder heads and other engine parts - including an early type oil pan, painted Nissan engine blue, on a bench at Pierre's. Caption says that "...from now on, all engines and transmissions will be rebuilt at an NMC USA contracted factory in Texas. The proud staff at Pierre'Z were not happy with this decision. It seems they would prefer that everything was left with the car's 'foster parents' (ie in-house) if possible."

-

Z Restoration Progam

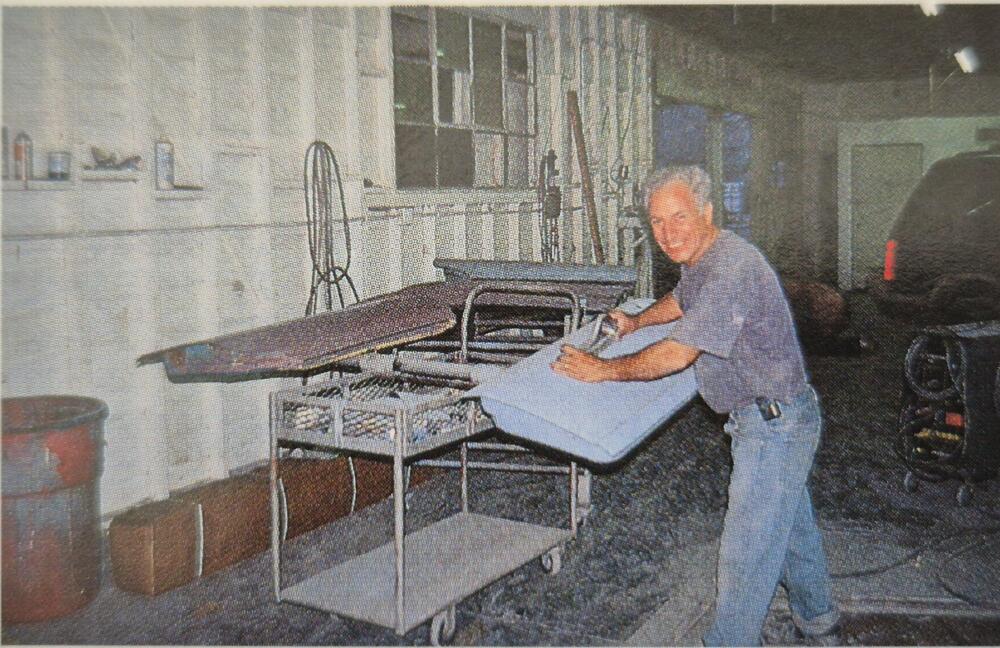

A few more: Caption for the above photo says that the guy working on the door is an Armenian, and that Armenians are historically renowned as being skilled metalworkers ("in their DNA").

-

Z Restoration Progam

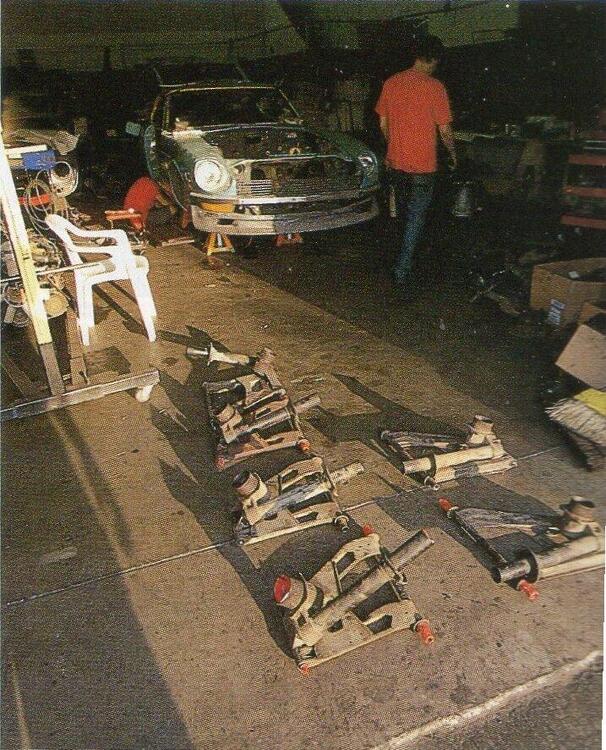

The Japanese caption specifically says powder coat, but that could easily have been a miscommunication (or, heaven help us, an assumption...) between reporter and the people at Pierres. I would think it much more likely that they were in fact painted, as per the original factory finish.

-

Z Restoration Progam

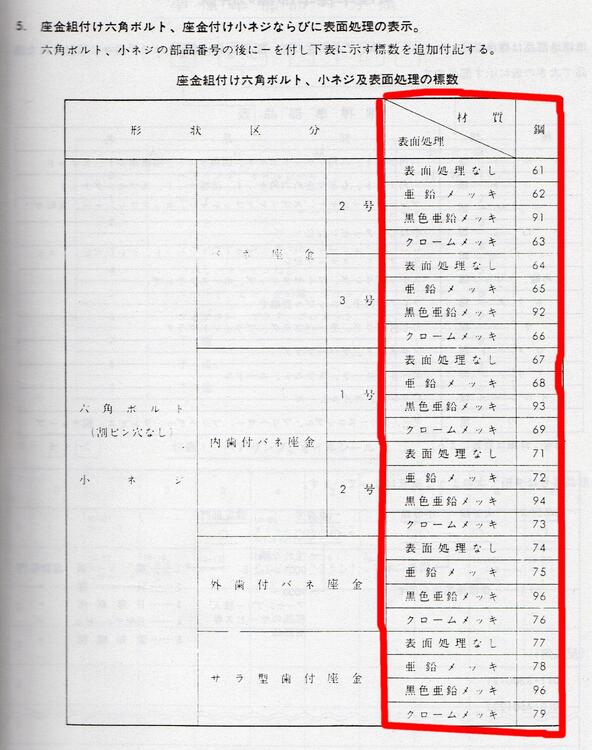

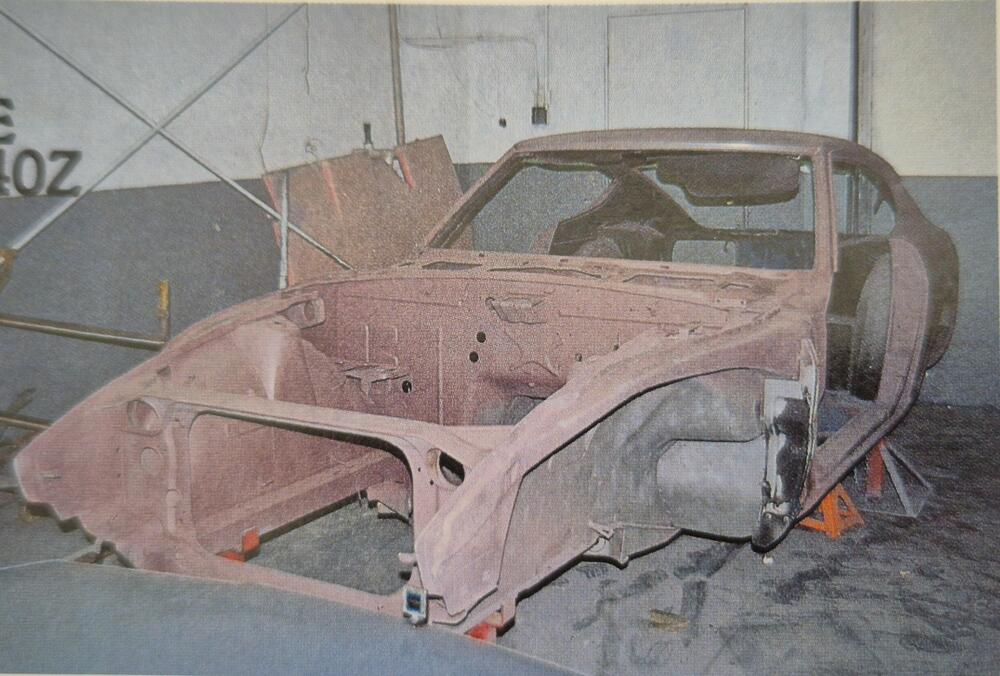

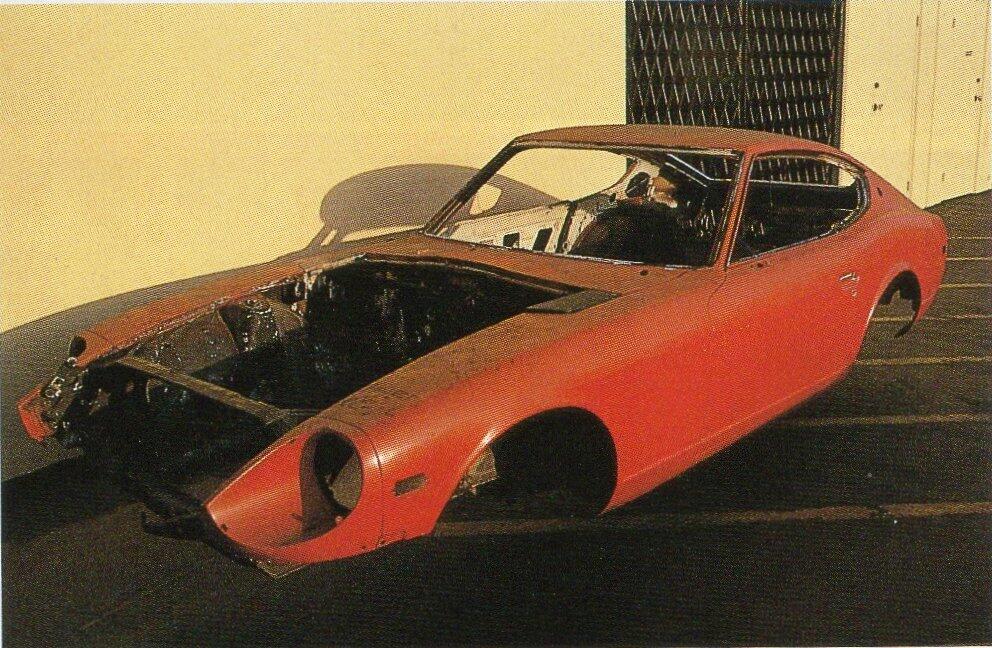

Just for fun, I've dug out the JUNE 1997 edition of OLD TIMER Magazine - published in Japan - to scan some photos from the 8 page article in which they covered Vintage Z Program-related activities at Pierre's, Z World and the lobby of NMC USA. The original photos are many, small and scan up with a noticeable Moire pattern, but people still might like to see them. 'Donor' cars sitting in the parking lot behind Pierre's, waiting to start the process. Original caption says that they counted 13 in this row alone and that Pierre's had a total of 25 base cars and 8 cars for parts, so a total of 33 cars 'in stock' at that time. Any lack of ambience is made up for with Ambulance: Caption says this is a stripped bodyshell, waiting to be collected by the bodyshop: Caption says that this lineup of suspension parts have been stress checked and delicate areas taped up prior to collection for blasting and "powder coating": I'll scan and upload some more tomorrow...

-

Z Restoration Progam

I don't know how you've made the jump to "...the parts were inspected by employees of AER."? Isn't that (careful now...!) an assumption on your part? I think you're not allowing for a little chaos. We've already heard anecdotal evidence from people actually involved (rather than Armchair Enthusiasts TM) that not all of the engines/engine components were processed at AER. Whatever the number - however small - it has to be included as part of the story. The incomplete engine and two cylinder heads pictured in the Japanese magazine articles (NOT at AER) suggest that we should tread carefully around what actually happened with AER's early involvement. And yes, I stick by my "Clearly - and fairly obviously - the engines were rebuilt and warrantied", unless you honestly believe otherwise? Are you again suggesting that some of the VZ Program cars didn't get engine rebuilds? If so I'd like to see any supporting evidence you might have.

-

Z Restoration Progam

I'm an advocate for the likelihood of ****-up over conspiracy. And educated guesses based on cross-referenced evidence are for sure better than assumptions. I make an effirt to go with the former wherever possible, but conversing with you is sometimes like herding cats. On the contrary, I have an ever growing capacity to believe and accept - if not expect - that our beloved Nissan of today can make a mess of anything it gets itself involved in, especially so when considering the caliber of some of its current feted international 'personalities' and representatives. But I've not been citing any Nissan-sourced "images for marketing purposes" in our recent exchanges, so you can park that one in the next available space. There go those pesky cats again. I was referring to the parts/components photographed on location by independent photographers working for two different Japanese magazines. Seeing as the articles were specifically about the VZ Program process it seems to me a fairly high probability (shoot me if you think it's an assumption too far...) that the parts would end up on VZ Program cars. Clear enough? Hope so.

-

Z Restoration Progam

It also seems very likely that at least some of the components you describe as 'props' went into the restoration of the VZ Program cars, so they are pertinent. If we are discussing odds & probabilities, my bet is that many of them ended up on the cars in question.

-

Z Restoration Progam

As above, he's in Maine. I'm sure he'll comment when he returns.

-

Z Restoration Progam

-

Z Restoration Progam

No. Quite simply, I'm pointing out that "the engines were built by AER" is not the whole story. As was shown in the Pierre's shop photos - and has been related anecdotally - some engines were also rebuilt on-site (with machining likely done by contractors), so it's the usual case of story being more complex than bald statements - and VZ Program PR blurbs - can convey. This VZ Program engine build digression started because a VZ car owner asked about valve seats. It was you who made the suggestion - bizarrely, in my opinion - that the engines may not have been fully rebuilt, or even not rebuilt at all! I posted contemporary photos from Pierre's workshop which I hoped would help to contradict that and I think it's clear that the VZ cars would indeed have had proper engine rebuilds - one way or another - and yet, having made the suggestion of a lesser scenario (your 'alternator rebuild' simile), you don't own it. Where's your retraction? Now you've got another Straw Man scenario going where I'm somehow suggesting that "...Nissan engineers worked alongside AER employees or..." or, or, or. Where does this come from!? Where does that "Nissan engineers" quote come from? I haven't seen anybody make that suggestion. I and I'm sure many others appreciate your valued input on this forum - especially on technical matters, in which you use your expertise to help a lot of people solve issues they would otherwise be lost with - but you have a habit of complicating discussions on matters historical with alternate, hypothetical, if not totally imaginary scenarios. It doesn't make for good detective work.

-

Z's on BAT and other places collection

No. Quite simply, I'm pointing out that "the engines were built by AER" is not the whole story. As was shown in the Pierre's shop photos - and has been related anecdotally - some engines were also rebuilt on-site (with machining likely done by contractors), so it's the usual case of story being more complex than bald statements - and VZ Program PR blurbs - can convey. This VZ Program engine build digression started because a VZ car owner asked about valve seats. It was you who made the suggestion - bizarrely, in my opinion - that the engines may not have been fully rebuilt, or even not rebuilt at all! I posted contemporary photos from Pierre's workshop which I hoped would help to contradict that and I think it's clear that the VZ cars would indeed have had proper engine rebuilds - one way or another - and yet, having made the suggestion of a lesser scenario (your 'alternator rebuild' simile), you don't own it. Where's your retraction? Now you've got another Straw Man scenario going where I'm somehow suggesting that "...Nissan engineers worked alongside AER employees or..." or, or, or. Where does this come from!? Where does that "Nissan engineers" quote come from? I haven't seen anybody make that suggestion. I and I'm sure many others appreciate your valued input on this forum - especially on technical matters, in which you use your expertise to help a lot of people solve issues they would otherwise be lost with - but you have a habit of complicating discussions on matters historical with alternate, hypothetical, if not totally imaginary scenarios. It doesn't make for good detective work.

-

Z's on BAT and other places collection

Another weird flex from you. I have no idea who the people you speak to for your "background information" (woohoo) are, nor did I assume to know them. If you think I did then you might like to do some re-reading. Arrogance? The person talking about "resident armchair experts" might want to look in a mirror occasionally. And what's this "across the pond" thing about? Is it supposed to be some kind of slight? This forum has active members from across the globe and is much the better for it. I mentioned the author of the two books in the context of certain sources being - arguably - less reliable witnesses than would be ideal, even given their proximity to events. The point being made seems to have sailed over your head. The whole reason I posted the photos from the magazine reports - with the engines/engine parts at Pierre's - was because of the post from Zed Head throwing doubt on the idea that they had been fully rebuilt. Obviously they were. But then the claim was made - baldly, without qualification or caveat - that AEM rebuilt them. Dangerous if swallowed whole. Both positions were wrong. You get my point about gurus? Probably not... Huh? Again, I posted the photos in response to a suggestion that the engines were not properly overhauled. The inference was that corners were cut (specifically in relation to valve seats) and the period magazine shots from Pierre's workshop tell a different story. Documentary evidence, for which I was thanked (gracefully) by an interested party whilst the person who made the suggestion of non-overhaul blithely moves on, otherwise unchallenged (LOL). I don't know what the fact that the magazine articles happened to have been published in contemporary Japanese titles has to do with anything, except that you seem particularly exercised - if not slightly overexcited - by it. They showed the point I was making. Simple as that. Oh and "...worships at the house of Japanese superiority..." is a good one, even if it exists solely in your imagination. These are, after all, Japanese cars so it seems germane to take the Japanese side of the story - at the very least - into account. I certainly wouldn't recommend ignoring it, even though the cars and the people who built them came from "across the pond"... Blind spot for you, perhaps? Ha ha ha! Classic. One for the archives there. Comedy gold. Thank you. Thinks: I'll park it up next to 'The Factory'.

-

Z's on BAT and other places collection

The classiczcars.com knowledge base was pretty much built on the experience, expertise and forensic investigative curiosity of "armchair experts". Much of the historical data and official documentation you now take for granted - and quote from - made its public debut here thanks to enthusiastic amateurs. In contrast, one of your "people involved in the program" has knocked out a couple of hardback books - to great fanfare - but which are packed with enough misconceptions, mis-captions and plain old mistakes as to make them all but worthless for entertainment let alone reference material. You'd be well advised to take care in choosing your gurus. Just a few posts ago, the claim was made that "AER Manufacturing in Carrolton, TX remanufactured the engines." Sounds quite definitive, doesn't it? But... Thanks for the, er, clarification but the word "may" is doing a lot of heavy lifting there. Is it anything more than a guess that the incomplete engines photographed by two different Japanese magazine photographers just happened to be some of these "early ones", rather than any other explanation? At the very least the contrast between the two statements illustrates that a little pragmatism is required when investigating the 'facts' behind the legend. The more I've read about the 'VZ Program' over the years, the more it seems to be revealed as something less than the well-planned and executed operation that its PR at the time would have us believe. A really great idea, less than ideally planned and executed, ending short of its original targets. The resulting cars are great in and of themselves and the story has paid dividends in terms of column inches, but overall the 'Program' seems like the proverbial swan - floating serenely on the surface whilst paddling furiously below...

-

Z's on BAT and other places collection

So the engines were reportedly 'remanufactured' at AER Manufacturing, but the photos from two different Japanese magazine articles on the VZ Program show a partly assembled engine (in one) and two in-process cylinder heads (in the other), clearly not at AER. There often seem to be missing pieces - or pieces that don't fit - in the VZ Program story...

-

Z's on BAT and other places collection

A couple of pages from period Japanese magazines which covered the 'Program' show engines and engine parts (see attached). Clearly - and fairly obviously - the engines were rebuilt and warrantied. It's not like overhauling an L24 was rocket science or anything. No rare earth elements involved. Putting forward the idea that that they were just given a spruce up and a coat of paint is fairly, er, out there...

-

Seiko Datsun Watch

The big irony with this latest Z-related Seiko limited edition is that - despite the big SEIKO stickers on a few of the Works rally cars (in some cases applied post-event...) the cars themselves were usually fitted with Kanto Seiki 'stopwatch' clocks and a matched pair of a HEUER 'Master Time' 8-day clock and 'Monte Carlo' stopwatch. The Heuers were there simply because that's what the international crews - especially the navigators - were used to trusting. Accurate stage timing - leaving and entering controls, special stages, road sections and service halts - was absolutely vital in the big events and HEUER were the go-to. No disrespect to Seiko - I've got a small collection of vintage Seikos and I wear one every day - but there were no actual Seikos in the cars this new limited edition links to.

-

New Fujitsubo Exhaust System to be Released

The latest complete Fujitsubo 'Legalis' twin pipe systems will fit your L26 engine and your Australian market RS30 Datsun 260Z perfectly well. The newest type works with your RS30's R200 differential (earlier systems were only configured to fit cars with R180 & R192 differentials). It will also work well in terms of performance (suiting your triple carb setup) and will sound great. Recommended.