Everything posted by HS30-H

-

Datsun-240z Vs Fairlady-z432

Agreed, but - beyond that - 99% of the discussion around the Grande Nose of the HS30-H model seems to treat it as though it was some kind of aesthetic makeover. It misses the whole point. Its real reason for existence was to homologate parts to which other - more extreme - parts could be hung off for race purposes. The fact that some of us (me included) find the HS30-H model attractive is probably by-the-by. It could be argued that the 240ZG was somewhat out of date in its styling, consciously or sub-consciously referencing the curves of 60s cars like the Ferrari 275 GTB when the more angular Ferrari 365 GTB had already outdated it in aerodynamic terms as well as aesthetics. The homologation specials which came after them for Group 4 and then Group B would look more angular and more brutal, but that in itself has its attractions.

-

Datsun-240z Vs Fairlady-z432

And it is much appreciated, Kats. Your presence and participation on classiczcars has been invaluable and a vital conduit to helping us understand the cars themselves, the history behind them and the people who created them. You are one of their best ambassadors. Thank you. It goes over a lot of heads but I've believe that, to properly appreciate and understand any single one of our cars, it is necessary to understand its siblings; the cars which were conceived, designed, engineered and produced alongside it. I own both RHD and LHD versions. Japanese market, UK market and USA market S30-series Z variants. Taking each one of them completely apart and going through the process of reassembly is both fascinating and educational. It is possible to observe the great efforts the designers and engineers went to in ensuring that each variant worked well whilst accommodating the other variants in their contemporary family. Look closely and you can see details that were incorporated in the fabric of the cars in order to cater for one particular market or one particular variant, hiding in plain sight. A good example being the preparation for factory air conditioning that was present on all models whilst it was only available in one of them. Most owners don't notice... Kats, we have discussed in the past how ownership of both Domestic and Export variants has helped both of us to understand and appreciate the cars more fully, right? It would be great if more owners and enthusiasts could share that experience or, if not, at least take note of the possibilities it offers.

-

1970 240Z Works Rally - the road to restoration

Lancashire Automobile Club have uploaded another of navigator Mike Wood's films to YouTube. This episode covers Mike's participation in the 1971 Monte Carlo Rallye with driver Tony Fall in Nissan Works 240Z rally car 'TKS 33 SA 986'. This very car...

-

Does an LSD need better cooling?

The R180 alloy rear covers were manufactured using the pressure die casting process, so there will be some fundamental differences in comparison to any of the casting techniques being discussed here.

-

1970 240Z Works Rally - the road to restoration

I believe the long-term previous owner of your car was an amateur aviator? My impression was that he stuck the Works key tag Kanri number on the car's dash in the way that a civil aircraft's registration ID is often seen on its dash: Using it to cover the hole left by the Grayston pen holder would kill two birds with one stone. Here's a photo of one of the Works cars from the 1971 RAC Rally of GB. Key fob tag just about visible under there, and with rounded corners like yours: Works 'Kanri' (maintenance) numbers are a tricky topic by their nature. These were Nissan's internal ID codes for the individual Works cars, not for us to use or necessarily to understand. Even the service barges had them, but sometimes they did not appear on the cars. Here's a photo I took of the Kanri number on the '71 East African Safari winner, before the car was 'refreshed' a few years ago (in my opinion it didn't need half of what they did to it, but there you go...). The number is on a clear oblong sticker with the letters and numbers in a kind of golden reflective material:

-

Does an LSD need better cooling?

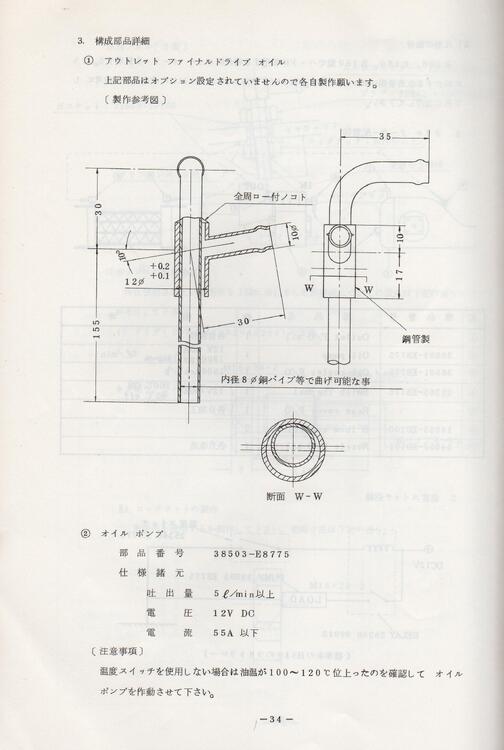

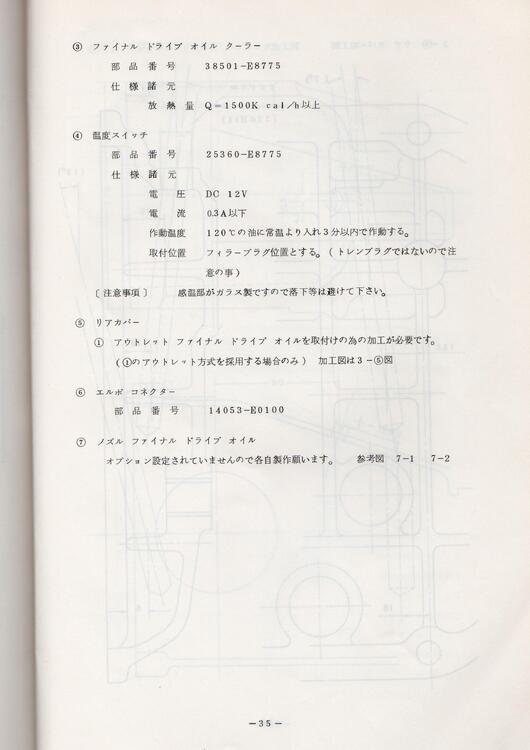

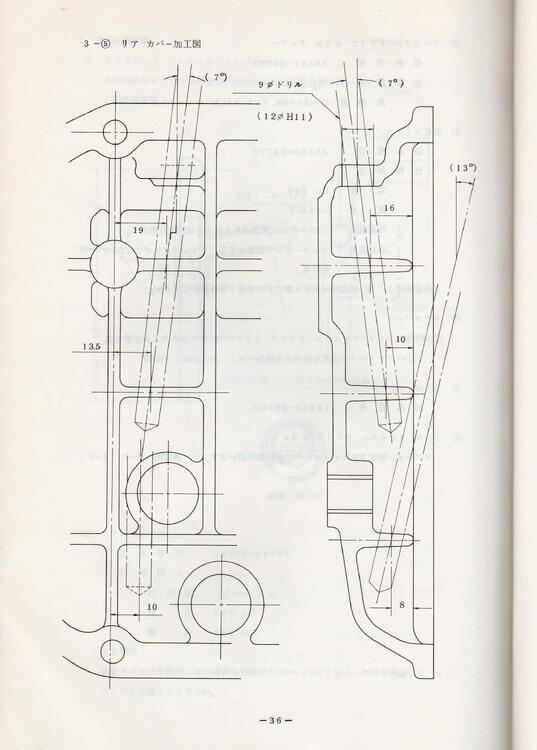

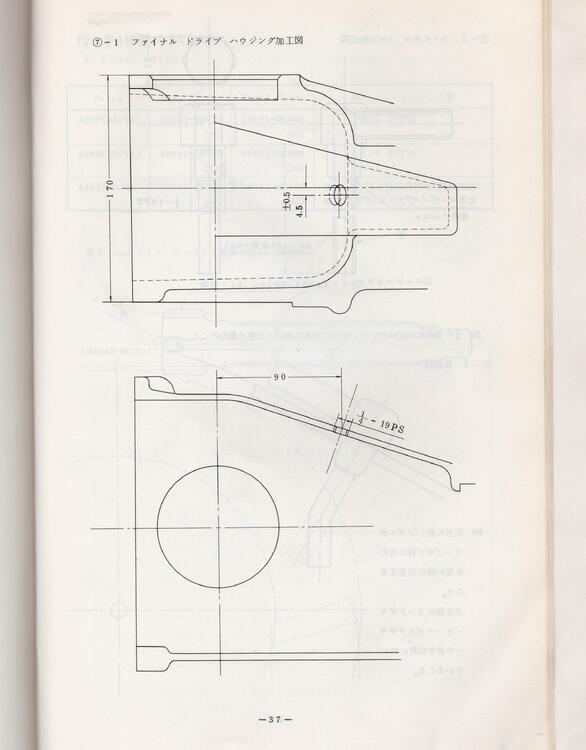

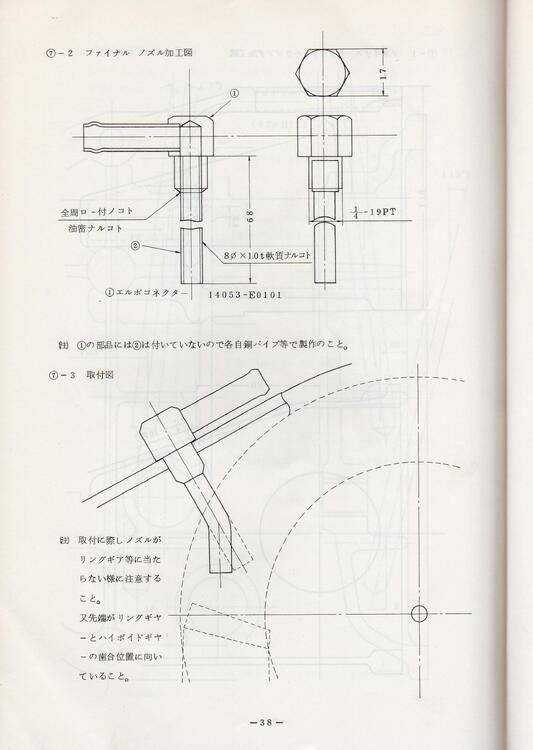

Some quite hare-brained 'solutions' being offered here. The original question was answered in period by the factory in their Race & Rally Preparation manuals. They recommended cooling of the oil by means of a pump and small heat exchanger, giving data for drilling the diff housing and rear cover for the insertion of tubes to collect the oil and then spray (cooled) oil on the CW&P: A similar electric pump & cooler system was adopted as standard equipment on some of the S130-series variants and up into S31-series. Rear covers with extra oil capacity and cooling fins are all well and good, but positive circulation, cooling and the directed spray of cooled oil are going to be more effective. A lot depends on on how 'tight' your LSD setting is. Generally speaking, high breakaway settings generate more heat.

-

Z's on BAT and other places collection

And you are an active participant who has quite clearly taken sides. Own it.

-

Z's on BAT and other places collection

This "insult" you refer to was simply an analogy for consistent belief held in the face of a mountain of evidence to the contrary. Hardly enough to spark an international incident, is it? Your post #2547 was far more divisive for the forum, and personally insulting. You are encouraging the taking of sides against people rather than against matters of opinion or the interpretation of historical anecdote. You have made absolutely no attempt at engaging on the actual subject being discussed. And all this when you can't even get my username right. A good look in the mirror might be appropriate at this time.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

Don't want to break a butterfly on wheel, but your post illustrates the problem that many of us outside the territory of North America have with the whole 'Series 1'/'Series 2' etc thing. We might own '240Zs' that don't comply with the rubbery, blurred definitions of the terms. Not wanting to be confrontational or anything, but do you perhaps see where we might have a point?

-

Z's on BAT and other places collection

Boobs!

-

Z's on BAT and other places collection

Apparently it's OK when you do it first. EG post #2547 on this thread. Not in any way hypocritical though, right? Noted that you keep referring to me as 'HS30' rather than 'HS30-H', despite me pointing it out to you. Tic? Purposely passive-aggressive? Dyslexia? Whichever, noted (again). This is not the first thread that you've done it on, either. Curious, that. Are you perhaps a little... er, Special..? The Swift quote is - I think - perfectly appropriate. It refers to Carl Beck who, despite the careful writings of Chief Engineer Hitoshi Uemura, chooses to believe advertising and sales-related flannel over hard facts and - yes - logic. Cognitive Dissonance, perhaps? Of course, the few of us who really get it love him just the way he is. Any kind of St. Paul-style Damscene volte-face would leave us bereft. He's our Wizard of Oz and we don't really want to see what's behind the curtain. Reasons un-imagined - let alone unknown - to you, Tonto. Ever thought of that? Probably not. Both @Gav240z and myself ('HS30-H', get it?) were active on this forum at least seven years before you pitched up. Maybe you need to do a little revision? A fair bit happened before you blessed us with your advice on the best spark plug gaps. Not that the technical advice isn't valued. Just that you might want to step away from the background Japanese historical stuff before you get into trouble. The water is a little deeper than you might expect. Haven't you even got a M*A*S*H meme? Poor show. Here's the thing. You seem more interested in me than the topic in hand. You have not made any attempt to address the differences between my* claims and those of Carl Beck. I'm talking about Z-related history, you're talking about me. By all means engage on the topic and refute my claims. I welcome reasoned debate. It is the very essence of the forum format. Think of me - if you don't already - as a messenger boy, sent by grocery clerks to collect a bill. Challenge the bill, not me. (*I say 'my', but I'm quoting Chief Engineer on the S30-series Z project Mr Hitoshi Uemura. A man whom I have met and conversed with in Japan several times on the subject. The words are - essentially - his, not mine). Yes, the digression is off-topic and I have already agreed that it would be better if it was moved, but the best person to do that as far as I can see is @Mike and I defer to him if he wants to set up a new topic to address that. Meanwhile you've obviously got a hard-on for me. I'm flattered (*blush*). Maybe you need to start a new topic too? One tip: Make sure to get my user name right. It's 'HS30-H', not "HS30". Actually, here's another top tip: For Full Effect (note those capitals) read my posts out loud in the voice of Stewie Griffin. Yes, loud. Wear a diaper too, perhaps? You're probably already half way there anyway, but give it a shot. Close the door so your mother doesn't hear you though. She might think you've lost the plot.

-

Z's on BAT and other places collection

The name's 'HS30-H', not 'HS30'. Pretty much everything else in your post is in your head, and you'll have to take responsibility for that yourself.

-

Z's on BAT and other places collection

Personally speaking, I get the feeling that classiczcars.com has degraded every time I look at the New Activity and see another ten photos posted on the 'Boobs' thread. Of course, you always have the option of the Ignore User function if you don't want to see any of my posts. I don't use it myself, because I'm always trying to be open-minded (LOL).

-

Z's on BAT and other places collection

In light of Uemura san's book, do you still feel "right at home" with this quote then? ...because it was wrong when you originally wrote it on this forum and it is still wrong today.

-

Z's on BAT and other places collection

You are - at least - consistent. A quality you share with The Flat Earth Society. A further example of EXACTLY what I have been pointing out. Where does 'Datsun 240Z' come from? You are either in denial or you have not even seen the original. Which is it? Chapter 2 title in original: "Fairlady Z no kaihatsu ni itaru made" (tr: 'Leading up to the development of the Fairlady Z'). Chapter 3 title in original: "Fairlady Z no kaihatsu" (tr: 'Development of the Fairlady Z'). You quote from the 'translated' English language version as though the original Japanese version doesn't exist. I'll keep saying it, the English language version is mis-translated to the level of Bowdlerization. Changing the all-encompassing 'Fairlady Z', 'Maru Z' and 'Z' terms that Uemura san uses to 'Datsun 240Z' completely subverts his original intention. I believe you had a hand in that. You have form. Even so, anybody who reads the English language version should easily see that Uemura san and his engineering team - also Matsuo san and his styling team - were engaged to design, engineer and develop a family of Domestic and Export market variants. The family of variants is mentioned time and time again. These processes took place contemporaneously, with engineering and design consideration for each variant having an impact on the other variants in the family. Uemura san's list of the 5 Chassis Test cars and the 11 Primary Prototype cars clearly show this. I think any engineer worth his salt would understand what this process involves. You simply cannot focus on one particular variant and treat the others as afterthoughts. One more thing. Uemura san includes a quote of some paragraphs from Teiichi Hara's own book (recommended, BTW). Hara san was manager of the First Design Department at Nissan and Uemura san quotes Hara san because he relates a KEY stage in Nissan's Go/No Go stage of the Maru Z project. Without passing this stage, Nissan's senior management simply would not have given clearance for the engineering and styling work to proceed. What was the deciding factor? The deciding factor was the inclusion of the road-going version of the Prince GR8 twin cam engine (the Nissan S20 two litre 24v twin cam six) as an option in the engineering and styling of the Maru Z project. Hara san described this as "A complete victory". Without it, they would not have got the go-ahead for the whole family of variants. It is a very revealing anecdote, the kind that automotive journalists and marque/model scholars set great store by. Will we ever read about this on zhome.com? I'm not holding my breath...

-

Z's on BAT and other places collection

I agree. I think thread-drift is almost inevitable and when a digression becomes big enough it can be worth splitting it off into its own thread. How about it @Mike?

-

Z's on BAT and other places collection

Unfortunately the decision was taken - I don't know by whom - to alter the text in order to make it more palatable to a (presumably?) American audience in the English language version. There are some inexplicable omissions too. Changing 'Fairlady Z' to 'Datsun 240Z' in the title and the text is not a translation. The sense in which Uemura san uses the term 'Fairlady Z' encompasses the whole family of variants in the 'Maru Z' project on which he and his colleagues were working from 1966 through 1969 and beyond. Substituting 'Datsun 240Z' does not. Indeed, it renders some parts of the text illogical and subverts the original intention. It turns an inclusive into a divisive. It also serves to reinforce the mistruth of statements such as "The real story of the Z Car - is carried by the Datsun 240-Z - as specified, as designed, as built for the American market" when Uemura san's original text made it clear that this was not the case. Ironic isn't it?

-

Z's on BAT and other places collection

I'm always curious as to whether you had any Road To Damascus type conversion of beliefs when you saw Uemura san's texts for the first time? I'm thinking of the great contrast between the story of how he and his colleagues set out to create a 'family' of variants for the S30-series which would be revealed to the world in late 1969 (S30, S30-S, PS30, PS30-SB, HLS30, HLS30-U and HS30) and your own take on the subject, as illustrated in the past on this very forum, in posts like these: Kind of ironic to see your name credited as 'Editor' on the translated version of Uemura san's book, but I guess that old "you are Daddy's one and only child" story which started at the Pierre Hotel on 22nd October 1969 is difficult to row back on. You do have a copy of the original Japanese language 'Fairlady Z Kaihatsu no Kiroku' book, I hope?

-

Z's on BAT and other places collection

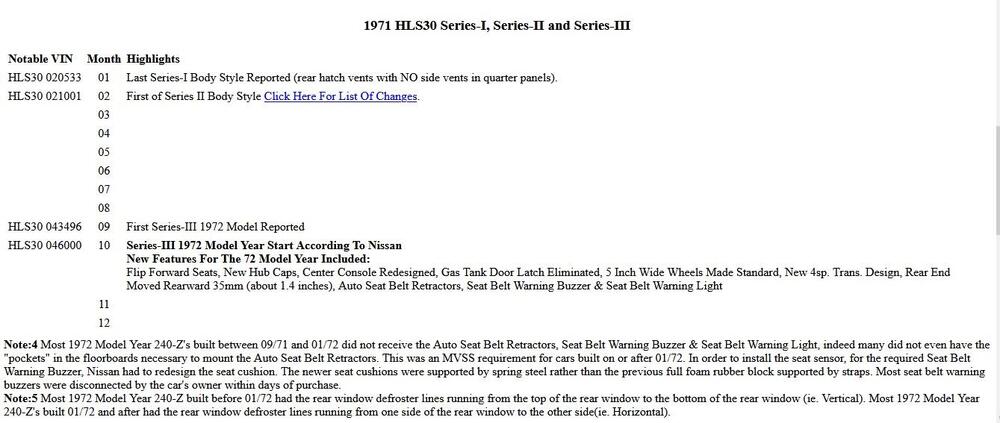

You're still making it sound as though these 'Series 1' etc terms are somehow official. Who has agreed to their definitions? Who is saying that they are a "starting point"? Here's a screenshot of a section from a page on your zhome.com site where no less than three of these 'Series' definitions pop up within the same production year of 1971. We have chassis numbers ('VIN') given as end and start dates for lists of new equipment and spec changes, as well as 'Model Year' added into the mix. Clearly, 'Series' numbers are being linked to content: A point I have made many times. For many years the USA spec 'Datsun 240Z' was presented to us as though it were a single child and that the other contemporary variants in the S30-series were insignificant afterthoughts. Sound familiar? So 'Series 1' and 'Series 2' etc are shown - QED - to be inaccurate, ill-defined and - finally - superfluous terms, right? What's really important are the full chassis number, the exact market variant/sub-variant (a suffix becomes handy here) and the production date. Then we consult the factory literature. He does indeed. Aha. I see why you've chosen to post that. You might like to note that in Uemura san's original Japanese language book - not the 'translated' version via Motomura san - he made it clear that the North American market 'HLS30-U' was the priority among the Export Specification S30-series variants (quite obviously, as it was the market with the greatest potential for volume sales) and that the priority was largely about putting together a variant which met the target selling price whilst also satisfying MVSS regulations. You might also like to note that - at that point - the North American market variant was intended to use the L16 four cylinder engine whilst the L20 six was intended for the Japanese market, to be joined by the GR8B 'S20'. No L24 at that point. It would be wise - not to mention scholarly - for us to tread carefully around the word 'priority' when discussing a family of variants in a 'Series', lest we find ourselves taking it to mean something more than was intended...

-

Z's on BAT and other places collection

Yes, it does indeed. And I think it has been kidnapped, along with 'Series'.

-

Z's on BAT and other places collection

I don't see what any of this has to do with the 'Series' discussion. The conversation was about the term 'Series' being used to define content and specs when - clearly - it isn't suitable for that purpose. Now we have the term 'Model' being thrown into the mix. The crux of the posts over the last few days was that terms such as 'Series 1' and 'Series 2' etc are being used as though they can define details on cars which were undergoing rolling changes. Yes, Nissan gave ranges of body serial numbers for specific prefixes as cut-offs for major changes, but applying 'Series 1' etc to them can be misleading. Your own writings on zhome.com link 'Series' numbers and ranges of chassis numbers to spec and equipment changes for 'HLS30' prefixed body serial numbers when that prefix was not unique to the variant you are applying them to. You are also calling the 'HLS30' a 'Model'. How can it be a 'Model'?

-

Z's on BAT and other places collection

No takers so far, then?

-

Z's on BAT and other places collection

How about '...the people that are trying to define the parts on a vehicle by "Series" are out of line'..? That makes more sense, doesn't it? I'd say that - more to the point - the term 'Series' is rendered just about irrelevant if you know the 'VIN' (chassis number). Furthermore, if I give an example of a 'VIN' (a full chassis number consisting of a prefix and a body serial number for that prefix) would anyone be able to tell me what some of the major parts attached to that particular car will be? What transmission will it have? What diff ratio will it have? What steering rack ratio will it have? What carburettors will it have? Let's start with 'HLS30-159035'.

-

Z's on BAT and other places collection

Whether you realise it or not, you are confirming the point being made against your narrative. Nissan was talking about ranges of serial numbers, not 'Series'. Yes, we can easily see why people came up - organically - with the 'Series 1', 'Series 2' etc definitions in trying to make sense of what had happened, but it still tries to fit a square peg into a round hole. It only takes a couple of innocently asked questions - as illustrated above - to show just how blurred around the edges these definitions turn out to be. Pretty soon we get a suggestion of 'Series 1.5' and the hare is running... Most of this is down to people looking at the Japanese auto industry - which had its own systems and habits - through the lens of the USA. Sometimes it works, sometimes it doesn't. As ever, looking at just one variant in a family (hey, a 'Series'!) of cars is not going to tell you the whole story.